Table of Contents

Advertisement

Quick Links

Download this manual

See also:

Operator's Manual

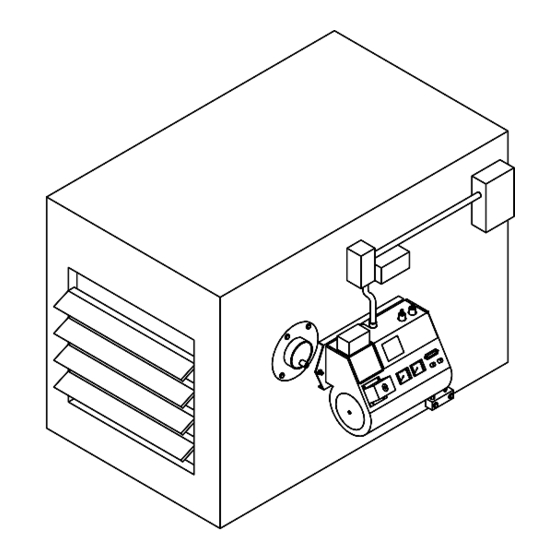

CLEAN BURN MODELS: CB-1400, CB-1800, and CB-2800

U.L. Listed Used Oil

Burning Appliance

#MH15393 (N)

U.L.-C Listed

#CMP217

PUBLICATION DATE: 12/15/01, Rev. 7

WARNING: DO NOT assemble, install, operate, or maintain this equipment without first

reading and understanding the information provided in this manual. Installation and

service must be accomplished by qualified personnel. Failure to follow all safety precautions

and procedures as stated in this manual may result in property damage, serious personal injury

or death.

IMPORTANT FOR U.S. INSTALLATIONS: All installations must be made in accordance with state and local codes

which may differ from the information provided in this manual. Save these instructions for reference.

IMPORTANT FOR CANADIAN INSTALLATIONS: These instructions have been reviewed and accepted by

Underwriters' Laboratories of Canada as being appropriate for the installation of the ULC labelled products

identified herein. The use of these instructions for the installation of products NOT bearing the ULC label and

NOT identified herein may result in an unacceptable or hazardous installation.

IMPORTANT FOR CANADIAN INSTALLATIONS: The installation of this equipment is to be accomplished by

qualified personnel and in accordance with the regulation of authorities having jurisdiction and CSA Standard B 139,

Installation Code for Oil Burning Equipment.

OPERATOR'S MANUAL

MULTI-OIL FURNACES

with CB-525-S2 BURNER

CLEAN BURN PART # 43081

Advertisement

Table of Contents

Need help?

Do you have a question about the CB-1400 and is the answer not in the manual?

Questions and answers