Table of Contents

Advertisement

Original Instruction Manual

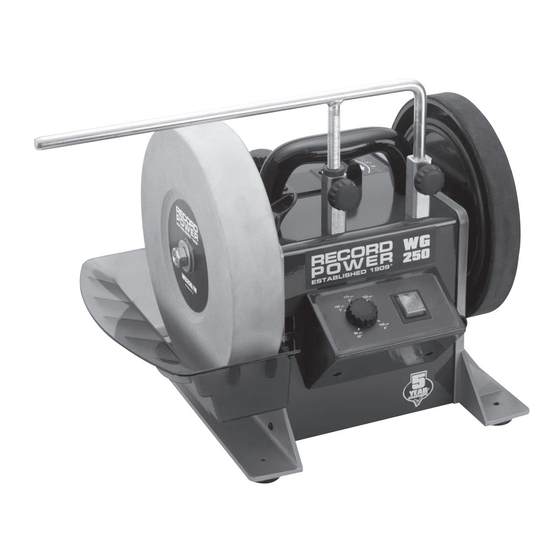

WG250 Wet Stone Sharpening System

Version 3.0

November 2012

It is important to register your product as soon as possible in order to receive efficient after sales

support and be entitled to the full 5 year guarantee. Your statutory rights are not affected.

Kg

Always wear safety glasses when

using woodworking equipment.

To register this product please visit

www.recordpower.info

Please see back cover for contact details.

Important

i

For your safety read instructions carefully before

assembling or using this product.

Always read the instructions

provided before using

Save this manual for future reference.

woodworking equipment.

1

Advertisement

Table of Contents

Summary of Contents for Record Power WG250

- Page 1 Original Instruction Manual WG250 Wet Stone Sharpening System Version 3.0 November 2012 To register this product please visit www.recordpower.info It is important to register your product as soon as possible in order to receive efficient after sales support and be entitled to the full 5 year guarantee. Your statutory rights are not affected.

-

Page 2: Table Of Contents

14. Parts Lists & Diagrams EU Certificate of Conformity WARNING: This product is heavy and as a precaution it is advised that two people assemble the machine. Original Instruction Manual | WG250 Wet Stone Sharpening System | Version 3.0 | November 2012... -

Page 3: Explanation Of Symbols

1. Explanation of Symbols The symbols and their meanings shown below may be used throughout this manual. Please ensure that you take the appropriate action wherever the warnings are used. Mandatory Instructions Read and fully understand the instruction manual before attempting to use the machine. -

Page 4: General Health & Safety Guidance

• Find and read any warning labels on the machine feet and the floor surface to ensure the machine is stable. • It is important that any labels bearing health and Original Instruction Manual | WG250 Wet Stone Sharpening System | Version 3.0 | November 2012... - Page 5 2. General Health & Safety Guidance - cont. 7. Remove adjusting keys and wrenches the presence of flammable liquids, gases or dust. • Ensure that all adjusting wrenches and keys are removed • The presence of high levels of dust created by machining before switching the machine ‘ON’.

- Page 6 • Do not use another person as a substitute for a table routine and preventative maintenance that should be Original Instruction Manual | WG250 Wet Stone Sharpening System | Version 3.0 | November 2012...

- Page 7 2. General Health & Safety Guidance - cont. performed periodically by the user. • Check for alignment of moving parts, binding of moving parts, breakage of parts and any other conditions that • Remember always to switch off and unplug the machine may affect the operation of the machine.

-

Page 8: Additional Health & Safety For Wet Stone Sharpeners

& Safety Executive and available from their website www. hse.gov.uk. • Rotate the stone by hand to ensure that it can move freely without interference from other components. Original Instruction Manual | WG250 Wet Stone Sharpening System | Version 3.0 | November 2012... -

Page 9: Record Power Guarantee

Product manual or check www. recordpower.info for details). The claim itself should 1.2.3 if asked to do so by Record Power, its Authorised be made in a letter setting out the date and place Distributor or Authorised Dealer, you return the of purchase, and giving a brief explanation of the Product, at your own cost, to Record Power’s... - Page 10 – please check with the Authorised Distributor in your country (details of the Authorised Distributor for your country can be found in the manual or at www.recordpower.info). Original Instruction Manual | WG250 Wet Stone Sharpening System | Version 3.0 | November 2012...

-

Page 11: Specifications

5. Specifications Motor: 230V / 50Hz / 160W Full load current: 0.7 A No load speed: 90 - 150 min¯¹ Grinding wheel size: 250 x 50mm Honing wheel diameter: 230 x 30 mm Grinding wheel bore: 12mm Acoustic power level LWA: 74 dB (A) Acoustic pressure level LPA: 68,7 dB (A) -

Page 12: Getting To Know Your Machine

Friction drive wheel Water tank Straight edge Jig Support arm Stone grader Speed adjust knob Honing compound ON/OFF switch Angle setting gauge Rubber feet Angle finder Original Instruction Manual | WG250 Wet Stone Sharpening System | Version 3.0 | November 2012... -

Page 13: Assembly

8. Assembly • If you notice any transport damage while unpacking, notify the supplier immediately. • Dispose of the packing in an environmentally friendly manner. • Clean all rust protected surfaces with a mild solvent. Remove the Transport Lock There is a foam block inside the machine that is used during shipment to keep the motor shaft from resting on the drive wheel. - Page 14 Before the first use of the leather honing wheel (A) condition with mineral oil (available as part of the WG250/X Maintenance Kit) and honing compound (R). Original Instruction Manual | WG250 Wet Stone Sharpening System | Version 3.0 | November 2012...

- Page 15 The WG250/N Profiled Leather Honing Wheel is an optional accessory. 1. Install the WG250/N Profiled Leather Honing Wheel on the shaft next to the leather honing wheel (A). 2. Place a washer on the shaft and tighten the lock knob (N).

-

Page 16: Set Up And Adjustment

Once the power is restored, re-start the machine by pressing the button marked ‘I’ on the switch. Original Instruction Manual | WG250 Wet Stone Sharpening System | Version 3.0 | November 2012... - Page 17 9. Set up and Adjustment - Cont. Using the Diamond Trueing Tool The WG250/K Diamond Trueing Tool is used to maintain the surface of the sharpening stone. In addition, it ensures that the sharpening surface remains both concentric to the shaft to which it is mounted and parallel to the support arm.

- Page 18 (Q). As relatively high pressure is needed for the stone grader to work effectively, it is recommended that it is applied to the sharpening Original Instruction Manual | WG250 Wet Stone Sharpening System | Version 3.0 | November 2012...

- Page 19 If no jig is available to suit the particular application, either use the tool rest jig (WG250/I) or use the support arm as a tool guide. • In most cases you will achieve the best result if you grind towards the edge of the tool (as pictured).

-

Page 20: Set Up And Adjustment

• When no added torque is required or when the machine is not in use, release the pressure to avoid permanent deformation of the friction drive rubber (O). Original Instruction Manual | WG250 Wet Stone Sharpening System | Version 3.0 | November 2012... -

Page 21: Optional Jigs For The Wg250 Wet Stone Sharpener

10. Optional Jigs for the WG250 Wet Stone Sharpener 45mm To complement the WG250 Wet stone Sharpener Record Power offers an extensive range of jigs to allow the sharpening of a 45mm wide range of tools. WG250/B Short Tool Jig... -

Page 22: Wg250/G Short Knife Jig

8. An inclusive angle of 25-30º range gives a uniform grind across the blade. 9. Ensure slow consistent movements over the grind stone. 10. Turn the jig holding the knife over to repeat process. Original Instruction Manual | WG250 Wet Stone Sharpening System | Version 3.0 | November 2012... -

Page 23: Wg250/H Long Knife Jig

45mm 10.2. WG250/H Long Knife Jig Use to sharpen: • Knives over 4” in length • Large knives • Large cutlery knives • Draw knives Getting to Know the Long Knife Jig The adjustable clamp allows the jig to hold knives of any thickness. -

Page 24: Wg250/A Gouge Jig

Fig 5, ensuring contact is kept whilst pivoting the shaft to sharpen all the way round the edge. See Fig 6. Fig 5 Fig 6 Original Instruction Manual | WG250 Wet Stone Sharpening System | Version 3.0 | November 2012... -

Page 25: Wg250/B Short Tool Jig

10.4. WG250/B Short Tool Jig Use to sharpen: • Small carving tools • Small gouges • V-tools Getting to Know the Short Tool Jig The Short Tool Jig rests on to the support arm of your wet stone sharpener. A. Knob screw B. -

Page 26: Wg250/E Scissor Jig

5. Reverse the scissors in the holder (B) and repeat. Note: Usually you use only the right clamp. For large scissors and garden shears you use both clamps. Original Instruction Manual | WG250 Wet Stone Sharpening System | Version 3.0 | November 2012... -

Page 27: Wg250/D Plane Camber Jig

10.6. WG250/D Plane Camber Jig Use to sharpen: • Camber planer blades up to 3” wide Getting to Know the Plane Camber Jig The plane camber jig slides on the support arm of your wet stone sharpener. A. Lock nut B. -

Page 28: Wg250/J Axe Jig

3. Cup the head of the axe in the jig and move the axe blade slowly back and forth across the Sharpening Stone when in motion. 4. Reverse the axe in the jig and repeat. Original Instruction Manual | WG250 Wet Stone Sharpening System | Version 3.0 | November 2012... -

Page 29: Wg250/C Straight Edge Jig

10.8. WG250/C Straight Edge Jig Use to sharpen: • Plane irons • Bevel edge chisels Getting to Know the Straight Edge Jig The straight edge jig slides on to the support arm of your wet stone sharpener. The straight edge jig aligns the tool automatically to its upper and flat side. -

Page 30: Wg250/I Tool Rest Jig

6. The tool rest jig can be mounted on the support arm with either the short or long edge facing the stone to achieve different angles. Original Instruction Manual | WG250 Wet Stone Sharpening System | Version 3.0 | November 2012... -

Page 31: Wg250/F Side Wheel Sharpening Jig

10.10. WG250/F Side Wheel Sharpening Jig Use to sharpen: • Scrapers Getting to Know the Side Jig The side jig mounts on to the support arm of your wet stone sharpener and allows you to grind against the side of the Sharpening Stone. -

Page 32: Wg250/O Support Arm Extension Kit

Attention: Never attempt to hone towards the edge of the tool. The tool will be thrown away and the honing wheel damaged. Original Instruction Manual | WG250 Wet Stone Sharpening System | Version 3.0 | November 2012... -

Page 33: Maintenance

• These solvents may damage the plastic parts. • To protect your sharpener from dust and damage when not in use, an optional heavy duty cloth cover, WG250/Q is available. Please contact your local retailer or visit the Record Power website for further details. - Page 34 (O). 5. If the leather strop wheel seems to wobble, please try rotating it to the next pin location. 6. Tighten the lock knob (N) Original Instruction Manual | WG250 Wet Stone Sharpening System | Version 3.0 | November 2012...

-

Page 35: Troubleshooting

12. Troubleshooting Problem Possible cause Suggested corrective action Motor does not start 1. Power cable defect 1. Change proper power cable 2. Connections on the motor or 2. Have to be checked by an switch defect electrician 3. Carbon brushes worn 3. -

Page 36: Electrical Connection & Wiring Diagram

BS4343 (CEE17 / IEC60309) will be used. 230 V machines will be fitted with a blue 3 pin connector. Original Instruction Manual | WG250 Wet Stone Sharpening System | Version 3.0 | November 2012... -

Page 37: Parts Lists & Diagrams

14. Parts Lists & Diagrams... - Page 38 Slide Bearing Cover Drawer Slide bearing Socket head cap screw M8x25 shown: (For handle) Nylon Insert Lock nut M8 (For handle) Flat Washer M8 (For handle) Original Instruction Manual | WG250 Wet Stone Sharpening System | Version 3.0 | November 2012...

- Page 39 EU Declaration of Conformity Cert No: EU / WG250 / 1 RECORD POWER LIMITED, Unit B, Ireland Industrial Est. Adelphi Way, Staveley, Chesterfield S43 3LS declares that the machinery described:- Type: Wet Stone Sharpener Model No: WG250 Serial No .................

- Page 40 Woodworking Machinery & Accessories United Kingdom Eire Australia New Zealand Record Power Ltd Record Power Ltd Tools 4 Industry Tools 4 Industry Unit B Adelphi Way, Ireland Unit B Adelphi Way, Ireland Po Box 3844 Po Box 276079 Industrial Estate, Staveley,...

Need help?

Do you have a question about the WG250 and is the answer not in the manual?

Questions and answers

How does the wg250 scissors work