Table of Contents

Advertisement

Quick Links

Instructions – Parts List

120 VAC, 15A

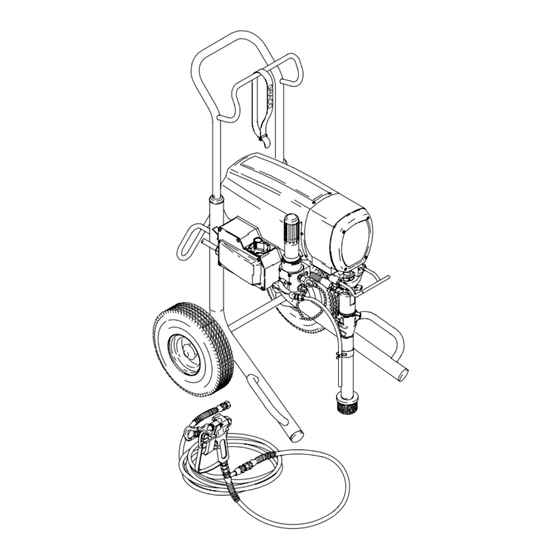

ULTRARMAX 795

Airless Paint Sprayer

3000 psi (21 MPa, 210 bar) Maximum Working Pressure

Model 232140, Series A

Basic sprayer on upright cart without

hose or gun

Model 232141, Series A

Complete sprayer on upright cart with hose,

gun, RAC IVt DripLesst Tip Guard

and SwitchTipt

U.S. PATENT No. 4,323,741; 4,397,610

PATENTED 1983, CANADA

AND OTHER PATENTS PENDING

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

Related Manuals

Displacement Pump

. . . . . . . . . . . . . . . . .

Spray Gun

. . . . . . . . . . . . . . . . . . . . . . . . .

Spray Tip

. . . . . . . . . . . . . . . . . . . . . . . . . . .

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440–1441

Copyright 2002, Graco Inc. is registered to I.S. EN ISO 9001

308798

307614

308644

308800F

7706A

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Graco 232140

-

Page 1: Related Manuals

......308644 7706A GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440–1441 Copyright 2002, Graco Inc. is registered to I.S. EN ISO 9001... -

Page 2: Table Of Contents

D Read all instruction manuals, tags, and labels before operating the equipment. D Use the equipment only for its intended purpose. If you are not sure, call your Graco distributor. D Do not alter or modify this equipment. Use only genuine Graco parts. -

Page 3: Warnings

WARNING INJECTION HAZARD Spray from the gun, leaks or ruptured components can inject fluid into your body and cause extremely serious injury, including the need for amputation. Fluid splashed in the eyes or on the skin can also cause serious injury. D Fluid injected into the skin is a serious injury. -

Page 4: Fire And Explosion Hazard

WARNING FIRE AND EXPLOSION HAZARD Improper grounding, poor ventilation, open flames or sparks can cause a hazardous condition and result in a fire or explosion and serious injury. D If there is any static sparking or you feel an electric shock while using this equipment, stop spray- ing immediately. -

Page 5: Component Identification And Function

Component Identification and Function 03008 Fig. 1 7706A Motor DC motor, permanent magnet, totally enclosed, fan cooled Drive Assembly Transfers power from DC motor to the displacement pump Pail Hanger Container for fluid to be sprayed may be hung here Displacement Pump Transfers fluid to be sprayed from source through spray gun Primary Fluid Outlet... -

Page 6: Setup

See Fig. 1. fluid outlet. NOTE: See Fig. 1, except where noted. WARNING 1. Fill packing nut full with Graco Throat Seal Liquid FIRE AND EXPLOSION HAZARD (TSL), supplied. Fig. 2. Proper electrical grounding is essential to reduce the risk of fire or explosion which can result in serious injury and property damage. -

Page 7: Startup

Setup Grounding Grounded Outlets WARNING Improper installation or alteration of the grounding Grounding Prong plug will result in a risk of electric shock, fire or Fig. 3 explosion that could cause serious injury or death. 2. Do not alter ground prong or use adapter. 3. - Page 8 Startup 10. Adjust spray pattern. RAC IV RETAINING HANDLE GUN SAFETY LATCH ENGAGED a. Increase pressure just until spray from gun is completely atomized. Use lowest pressure necessary to get desired results. This reduces overspray and fogging, decreases tip wear and extends the life of the sprayer.

-

Page 9: Shutdown And Care

Shutdown and Care 6. Coil hose and hang it on hose rack when storing it, WARNING even for overnight, to help protect hose from kink- ing, abrasion, coupling damage, etc. INJECTION HAZARD To reduce the risk of serious injury, whenever you are instructed to relieve pressure, follow the Pressure Relief Procedure on page 7. -

Page 10: Flushing

Flushing When to flush CAUTION Determine material to spray from column 1. Flush with material in column 2. Then follow recommendations in Do not leave water or water-based fluids in sprayer if one of next three columns. it could freeze. Push water out with mineral spirits. Frozen fluid in sprayer prevents starting and may cause serious damage. -

Page 11: Troubleshooting

Troubleshooting WARNING INJECTION HAZARD To reduce the risk of serious injury, whenever you are instructed to relieve pressure, follow the Pres- sure Relief Procedure on page 7. MOTOR WON’T OPERATE TYPE OF PROBLEM WHAT TO CHECK WHAT TO DO If check is OK, go to next check When check is not OK refer to this column Basic Fluid Pressure Problems 1. - Page 12 Troubleshooting MOTOR WON’T OPERATE (Continued) WHAT TO CHECK WHAT TO DO TYPE OF PROBLEM If check is OK, go to next check When check is not OK refer to this column Basic Electrical Problems 1. Check leads from motor to be sure they are 1.

-

Page 13: Low Output

Troubleshooting LOW OUTPUT WHAT TO CHECK WHAT TO DO TYPE OF PROBLEM If check is OK, go to next check When check is not OK refer to this column Low Output 1. Check for worn spray tip. 1. Follow Pressure Relief Procedure Warn- ing, then replace tip. - Page 14 Troubleshooting NO OUTPUT WHAT TO CHECK WHAT TO DO TYPE OF PROBLEM If check is OK, go to next check When check is not OK refer to this column Motor runs and pump strokes 1. Check paint supply. 1. Refill and reprime pump. 2.

- Page 15 Troubleshooting MOTOR IS HOT AND RUNS INTERMITTENTLY WHAT TO CHECK WHAT TO DO TYPE OF PROBLEM If check is OK, go to next check When check is not OK refer to this column Motor is hot and runs intermit- 1. Determine if sprayer was operated at high 1.

- Page 16 General Repair Information CAUTION WARNING To reduce the risk of a pressure control malfunction: ELECTRIC SHOCK HAZARD To reduce the risk of serious injury, Always use needle nose pliers to disconnect a including electric shock, DO NOT touch wire. Never pull on the wire, pull on the connector. any moving parts or electrical parts with Mate wire connectors properly.

-

Page 17: Spin Test

Spin Test Armature, Brushes, and Motor Wiring Open WARNING Circuit Test (Continuity) 1. Relieve pressure. Connect red and black motor ELECTRIC SHOCK HAZARD leads together with a test lead. Turn motor fan by Do not touch brushes, leads, springs or hand at about two revolutions per second. -

Page 18: Motor Brush Replacement

Motor Brush Replacement NOTE: Replace brushes worn to less than 1/2 in. Note 5. Inspect commutator for excessive pitting, burning that brushes wear differently on each side of mo- or gouging. A black color on commutator is normal. tor, so check both. Brush Repair Kit 220853 is Have commutator resurfaced by a qualified motor available. -

Page 19: Power Supply Cord Replacement

Motor Brush Replacement 11. Test brushes. CAUTION a. Remove pump connecting rod pin. Do not run the sprayer dry for more than 30 seconds b. With sprayer OFF, turn pressure control knob while checking the brushes to avoid damaging the fully counterclockwise to minimum pressure. - Page 20 Power Supply Cord and On/Off Switch Replacement 79 G 107 E 7696B Fig. 15 308800...

-

Page 21: Pressure Control Repair

Pressure Control Repair Motor Control Board Installation WARNING 1. Relieve pressure. INJECTION HAZARD To reduce the risk of serious injury, whenever you are instructed to relieve 2. Fig. 16. Install motor control board (104) with four pressure, follow the Pressure Relief screws (102) and washers (103). - Page 22 Pressure Control Repair Pressure Control Transducer Removal Pressure Adjust Potentiometer Removal 1. Relieve pressure. 1. Relieve pressure. 2. Fig. 16. Remove five screws (28) and cover (82). 2. Fig. 16. Remove five screws (28) and cover (82). 3. Disconnect lead (E) from motor control board (104).

- Page 23 Pressure Control Repair 107 A 7697C Fig. 16 308800...

-

Page 24: Bearing Housing & Connecting Rod Replacement

Bearing Housing and Connecting Rod Replacement 11. Align connecting rod (63) with crank (E) and drive WARNING housing locating pins (G) with bearing housing (22) holes. Push bearing housing onto drive housing or INJECTION HAZARD tap it into place with a plastic mallet. To reduce the risk of serious injury, whenever you are instructed to relieve CAUTION... -

Page 25: Drive Housing Replacement

Drive Housing Replacement 4. Lightly tap lower rear of bearing housing (22) with WARNING a plastic mallet to loosen it from drive housing (67). Pull assembled bearing housing and connecting INJECTION HAZARD rod straight off drive housing. To reduce the risk of serious injury, whenever you are instructed to relieve 5. - Page 26 Drive Housing Replacement 25,23 Torque to 175 in-lb (19 N.m) Torque to 90–100 in-lb (10.2–11.3 N.m) Liberally apply grease 7699A Fig. 18 308800...

-

Page 27: Motor Replacement

Motor Replacement WARNING CAUTION DO NOT drop gear cluster (51) when removing drive INJECTION HAZARD housing (67). The gear cluster may stay engaged in To reduce the risk of serious injury, the motor front end bell or the drive housing. whenever you are instructed to relieve pressure, follow the Pressure Relief DO NOT lose thrust balls (90) located at each end of... - Page 28 Motor Replacement Torque to 90–100 in-lb (10.2–11.3 N.m) Liberally apply grease 7700B Fig. 19 308800...

-

Page 29: Displacement Pump Repair

Displacement Pump Repair Removing pump 1. Flush pump. Relieve pressure. Fig. 20. Cycle 4. Fig. 22. Push out pin. pump with piston rod (222) in its lowest position. 2. Fig. 20. Unscrew suction tube and hose from pump. 7675A Fig. 22 5. - Page 30 7676A Fig. 24 2. Fig. 25. Push pin (21) into holes. 7673A Fig. 27 Fig. 28. Fill packing nut with Graco TSL, through one of the slits, until fluid flows onto the top of seal. 7675A Fig. 25 7677A Fig. 28...

-

Page 31: Accessories

....14 AWG, 3 wire, 15 ft (4.5 m) Order the labels directly from Graco, free of Inlet Paint Strainer .... -

Page 32: Parts Drawing - Sprayer

Parts Drawing – Sprayer Ultra MAX 795 Sprayers Model 232–140, Series A Includes items 1 – 112, 123, 126 Basic Sprayer Model 232–141, Series A Includes items 1 – 126 Complete Sprayer 73a* Ref 85 Ref 70 Ref 120 SEE PARTS ON PAGE 34 7705B Ref 85 7705B... -

Page 33: Parts List - Sprayer

Parts List – Sprayer Ultra MAX 795 Sprayers Model 232–140 Series A Model 232–141, Series A Includes items 1 – 112, 123, 126 Includes items 1 – 126 Basic Sprayer Complete Sprayer NO. PART NO. DESCRIPTION NO. PART NO. DESCRIPTION 110996 NUT, 5/16–18 unc–2a 239923... - Page 34 Parts Drawing – Sprayer 7701B 308800...

-

Page 35: Wiring Diagram

Parts List – Sprayer Ultra MAX 795 Sprayers Model 232–140, Series A Model 232–141, Series A Includes items 1 – 112, 123, 126 Includes items 1 – 126 Basic Sprayer Complete Sprayer NO. PART NO. DESCRIPTION NO. PART NO. DESCRIPTION 224807 ASSEMBLY, cam, drain valve 240316... -

Page 36: Graco Standard Warranty

Graco’s written recommendations. This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or sub- stitution of non–Graco component parts.

Need help?

Do you have a question about the 232140 and is the answer not in the manual?

Questions and answers