Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Tektronix DG2020A

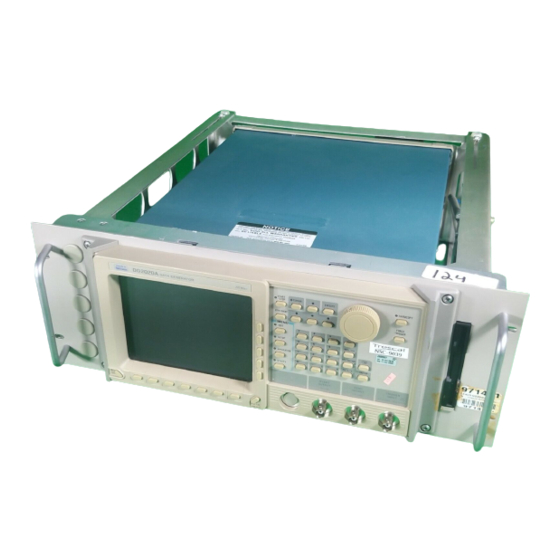

- Page 1 Service Manual DG2020A Data Generator 071-0055-52 Warning The servicing instructions are for use by qualified personnel only. To avoid personal injury, do not perform any servicing unless you are qualified to do so. Refer to all safety summaries prior to performing service.

- Page 2 Copyright © Tektronix, Inc. All rights reserved. Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes that in all previously published material. Specifications and price change privileges reserved. Tektronix, Inc., P.O. Box 500, Beaverton, OR 97077 TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

- Page 3 Tektronix, with shipping charges prepaid. Tektronix shall pay for the return of the product to Customer if the shipment is to a location within the country in which the Tektronix service center is located.

-

Page 5: Table Of Contents

........... . DG2020A Service Manual... - Page 6 ............Performance Tests for the DG2020A/Pod Combination .

- Page 7 ....4-15 Figure 4-11: DG2020A event output connections ....

- Page 8 Figure 4-26: Inhibit input operation confirmation connections ..4-32 Figure 6-1: DG2020A orientation ......6-11 Figure 6-2: Guide to removal procedures .

- Page 9 Table of Contents Figure 9-1: Block diagram of DG2020A with options 01 and 02 . . . 9- -3 Figure 9-2: Interconnect diagram of DG2020A with options 01 and 02 ........

- Page 10 ......Table 7-5: Maintenance kit contents ......DG2020A Service Manual...

-

Page 11: General Safety Summary

Do Not Operate in Wet/Damp Conditions. Do Not Operate in an Explosive Atmosphere. Keep Product Surfaces Clean and Dry. Provide Proper Ventilation. Refer to the manual’s installation instructions for details on installing the product so it has proper ventilation. DG2020A Service Manual... - Page 12 WARNING indicates an injury hazard not immediately accessible as you read the marking. CAUTION indicates a hazard to property including the product. Symbols on the Product. The following symbols may appear on the product: WARNING Protective Ground CAUTION Double High Voltage (Earth) Terminal Refer to Manual Insulated viii DG2020A Service Manual...

- Page 13 To avoid electric shock, do not touch exposed connections. X-Radiation. To avoid x-radiation exposure, do not modify or otherwise alter the high-voltage circuitry or the CRT enclosure. X-ray emissions generated within this product have been sufficiently shielded. DG2020A Service Manual...

- Page 14 Service Safety Summary DG2020A Service Manual...

-

Page 15: Adjustment Procedures

H Operating Information includes general information and operating instruc- tions at the level needed to safely power on and service the DG2020A. H Theory of Operation contains circuit descriptions that support general service to the module level. -

Page 16: Manual Conventions

H Names of front panel controls and menus appear in the same case (initial capitals, all uppercase, etc.) in the manual as is used on the DG2020A front panel and menus. Front panel names are all upper-case letters; for example, SETUP MENU, HARDCOPY, etc. - Page 17 This manual contains information needed to properly service the DG2020A Data Generator, as well as general information critical to safe and effective servicing. To prevent personal injury or damage to the DG2020A, consider the following before attempting service: H The procedures in this manual should be performed only by a qualified...

- Page 18 Tektronix service technicians are well equipped to service the DG2020A. Tektronix technicians train on Tektronix products; they have access to the latest information on improvements to the DG2020A as well as the latest new options. Warranty Repair Service Tektronix warrants this product for one year from date of purchase. (The warranty appears on the back of the title page in this manual.) Tektronix...

-

Page 19: Product Description

Product Description The DG2020A is a digital data generator designed for high performance and ease of use. The DG2020A is easy to use for testing and evaluating semiconductors and logic circuits, which are continually becoming faster and more complex. The DG2020A provides, in a compact package, high performance and a wide range of functions. - Page 20 Product Description DG2020A Service Manual...

-

Page 21: Performance Characteristics

DG2020A. The characteristics described herein are not absolutely guaranteed. Items marked with * are tested in the Performance Verification (Section 4). The certification and compliances for the DG2020A are also found at the end of this appendix. DG2020A Service Manual... -

Page 22: Warranted Characteristics

Performance Characteristics Warranted Characteristics This section will describe the warranted characteristics of the DG2020A. These can be divided into two main categories: electrical characteristics and environ- mental characteristics. Performance Conditions The electrical characteristics are valid under the following conditions: 1. The instrument must be in an environment whose limits are described in Environmental Characteristics. - Page 23 Internal Clock, PLL OFF, >6.25 MHz 25 ns to 60 ns Internal Clock, PLL OFF, ≦6.25 MHz (7 ns + 0.5 clock) to (20 ns + 1.5 clock) External Clock Delay from external 8 ns to 15 ns clock input DG2020A Service Manual...

- Page 24 > 0.7 V, V < 0.3 V Maximum input ¦ 2 V voltage Frequency DC to 200 MHz Delay to P3410 data 25 ns to 45 ns output Delay to P3420 data 20 ns to 40 ns output DG2020A Service Manual...

-

Page 25: Figure 1-1: Trigger Delay

Voltage range 90 μ 250 V AC 48.0 to 63.0 Hz 90 μ 127 V AC 48.0 to 440 Hz Maximum power 300 W Maximum current External Trigger Sync Out Clock Out Data Out Figure 1-1: Trigger delay DG2020A Service Manual... -

Page 26: Table 1-2: Warranted Environmental Characteristics

300 watts max. Maximum line current is 4 A rms at 50 Hz, 90 V line. (Fully loaded) Surge current 30 A peak for < 5 line cycles, after product has been off for at least 30 s. Cooling clearance Top clearance 1 inch Side clearance 6 inches Rear clearance 3 inches DG2020A Service Manual... -

Page 27: Typical Characteristics

Performance Characteristics Typical Characteristics This section will describe the typical characteristics for the DG2020A. These values represent typical or average performance and are not absolutely guaran- teed. Table 1-3: Electrical characteristics (typical) Characteristics Description Clock generator Internal clock Period jitter Measured by TDS694C- - 1MHD with TDSJIT1 Refer to Table 1-4. - Page 28 100 MHz (When PLL to On.) Measurement StdDev Pk- - Pk StdDev Pk- - Pk Clock output 20.0 ps 115.0 ps 17.0 ps 110.0 ps Data output (CH0 output) 9.0 ps 52.0 ps 8.5 ps 50.0 ps 1-10 DG2020A Service Manual...

-

Page 29: Nominal Traits

Performance Characteristics Nominal Traits This section describes general characteristics of the DG2020A. These can be divided into two main categories: electrical characteristics and mechanical characteristics. Table 1-6: Nominal traits - electrical characteristics Characteristics Description Output pattern Pattern length 64 word to 64 K word ( non sequenced operation ) - Page 30 - - 5.0 V to +5.0 V Resolution 0.1 V Impedance 1 kΩ Setup time to next block 47 clock to 54 clock Inhibit input Threshold Level - - 5.0 V to +5.0 V Resolution 0.1 V Impedance 1 kΩ 1-12 DG2020A Service Manual...

- Page 31 Delay Uncertainty Internal Clock, PLL:ON 5 ns to 10 ns Internal Clock, PLL:OFF None External Clock 1 clock period External clock input Impedance 50 Ω, terminated to +0.5 V Connector SMB ( at rear panel ) 1-13 DG2020A Service Manual...

- Page 32 640 ( H ) ¢ 480 ( V ) pixels Power source AC line power Fuse Rating 6A FAST, 250 V, UL 198G ( 3AG ) 5A ( T ), 250 V, IEC 127 Battery Type Li3 V, 650 mAH 1-14 DG2020A Service Manual...

- Page 33 5.9 inches Length 4.0 inches P3420 ( Variable output pod ) Net weight 1.0 kg ( excluding cables ) Dimensions Height 2.0 inches including feet Width 10.0 inches Length 6.3 inches Pod cable Length 1.2 m 1-15 DG2020A Service Manual...

-

Page 34: Table 1-6: Certifications And Compliances

Performance Characteristics Certification and Compliances The certification and compliances for the DG2020A are listed in Table 1-8. Table 1-8: Certifications and compliances Category Standards or description EC Declaration of Conformity - - Meets intent of Directive 89/336/EEC for Electromagnetic Compatibility. Compliance was... - Page 35 Installation Category II (as defined in IEC 61010- - 1, Annex J) Pollution Degree 2 (as defined in IEC 61010- - 1) Safety Class I (as defined in IEC 61010- - 1, Annex H) CSA-C22.2 No.1010.1, UL3111-1, IEC61010-1 Safety Certification Compliance: Altitude (maximum operating): 2000 meters 1-17 DG2020A Service Manual...

- Page 36 Performance Characteristics 1-18 DG2020A Service Manual...

-

Page 37: Preparation For Use

Preparation for Use This section describes how to prepare the DG2020A Data Generator for use. The information describes these items: H Proper operating environment H Checking power cord and line voltage configurations H Checking the fuse H Power-on and power-off cycles... -

Page 38: Power Cord Information

Preparation for Use Power Cord Information The DG2020A ships with the required power cord as ordered by the customer. Table 2-1 gives the color-coding of the conductors in the power cord. Table 2-2 shows information on the available power cords. -

Page 39: Operating Environment

Left and right 15 cm (6 in.) The feet on the bottom of the DG2020A cabinet provide the required clearance when it is set on a flat surface. The top of the DG2020A does not require ventilation clearance. CAUTION. To prevent temporary shutdown of the DG2020A, do not restrict air flow through the chassis. -

Page 40: Figure 2-1: Rear Panel Controls

Figure 2-1: Rear panel controls Fuse Type and Rating The DG2020A uses the same fuse for all operating line voltage ranges. One of two fuse types is installed in the instrument, depending upon the power cord option. Table 2-3 provides the available types and ratings. -

Page 41: Applying And Interrupting Power

Partial or total loss of stored information at power-on may indicate that the battery needs to be replaced. W ARNING. To avoid risk of fire or explosion, replace the DG2020A battery with a lithium battery having the part number listed in section 10, Mechanical Parts List. -

Page 42: Repackaging Instructions

275 pounds and with an inside dimension at least six inches greater than the DG2020A dimensions. (If available, use the original shipping carton, which meets these requirements.) If the DG2020A is shipped to a Tektronix Service Center, enclose the following information: H The owner’s address... -

Page 43: Operating Instructions

(see Figure 2-3). To connect a cable between the DG2020A and a pod, align the yellow wire end of the cable connector with the triangular yellow index mark on the DG2020A or pod connector. -

Page 44: Figure 2-3: Yellow Index Mark And Yellow Wire For Cable Connection

When attaching the pod cable, ensure that the plug and socket are aligned correctly. Make sure that you have correctly inserted the cable plug in the DG2020A and the pod before turning on power. The yellow wire end of the connector must be aligned with the triangular yellow index mark on the DG2020A or pod. -

Page 45: Internal Diagnostics Routines

How to Power On To power-on the DG2020A, follow these steps: 1. Set the PRINCIPAL POWER SWITCH (on the back of the DG2020A) to the ON position. This switch is the main power switch; it routes power to the standby circuit in the DG2020A. - Page 46 When you select a menu, the display shows the items controlled by that menu and numeric values currently in effect. Buttons around the display select lower-level menus, change menu selections, modify numeric values and units, and execute functions. 2-10 DG2020A Service Manual...

-

Page 47: Figure 2-4: Crt Display

Operating Instructions Display Figure 2-4: CRT display 2-11 DG2020A Service Manual... -

Page 48: Table 2-4: Dg2030 Display Elements

The instrument sometimes displays a pop-up menu when a bottom menu or side menu item is selected. Enter a numeric value or select an item using either the general purpose knob or the front panel buttons. 2-12 DG2020A Service Manual... -

Page 49: Menus

The DG2020A generates patterns from file residing in internal nonvola- tile memory. The DG2020A also has a floppy-disk drive for loading files from floppy disk into internal nonvolatile memory, and for saving files from memory to floppy disk. The disk drive accepts 3.5-inch floppy disks in the MS-DOS format. -

Page 50: Loading Files

The following steps explain how to load files from a floppy disk into internal memory. 1. Turn the disk so the side with the arrow is on top; insert the disk into the DG2020A floppy disk drive. 2. Push the EDIT button in the MENU column. 3. Select File from the bottom menu. -

Page 51: Signal Output

Operation 6 (For example, set to xx with general purpose knob.) Operation 7 Popup Menu Side Menu General Purpose Knob Front Panel Button Menu Button Bottom Menu Bottom Button Side Button Figure 2-6: Operating buttons and menu layout 2-15 DG2020A Service Manual... - Page 52 Attach the name IC1 to the newly created group. Front panel Menu button Bottom button Popup menu Side button button Rename Clear String I, C, 1 2. Assign DATA04 to DATA07 to a group called IC2. a. Set the MSB and LSB. 2-16 DG2020A Service Manual...

- Page 53 Press the front panel up arrow button to select channel A-00 from the POD assign list. Release Clear the A-01 to A-03 allocations in the same manner. b. Allocate the IC1 group data to the pod channels A-04 to A-07 and turn off the output impedance control for each channel. 2-17 DG2020A Service Manual...

- Page 54 Allocate D06 to D04 to A-09 to A-11 using the same procedure and turn off the output impedance control for each channel. . Press the OK button when done to activate the allocations. Note that the NOTE allocations will not become valid unless the OK button is pressed. 2-18 DG2020A Service Manual...

-

Page 55: Figure 2-7: Pod Channel Data Bit Allocation

Setting the Sampling Clock Frequency 4. Set the sampling clock frequency to 50 MHz. Front panel button Menu button Bottom button Popup menu Side button Oscillator Source (Select Int.) Int Frequency 5, 0, MHz (Select On.) 2-19 DG2020A Service Manual... - Page 56 Run Mode Repeat Setting the Pod Output There are two pod models that can be used with the DG2020A. The P3410 pod Level ( P3420 Only) output level is always at the TTL level. However, the P3420 pod output level is variable.

-

Page 57: Figure 2-8: Output Voltage Level And Delay Time Display For The P3420 Pod

Output Voltage Level Setting Delay Time Setting Figure 2-8: Output voltage level and delay time display for the P3420 pod Signal Output This step actually outputs the signals. 8. Press the START/STOP button on the front panel. 2-21 DG2020A Service Manual... - Page 58 Operating Instructions 2-22 DG2020A Service Manual...

-

Page 59: Theory Of Operation

Theory of Operation This section describes the basic operation of the major circuit blocks or modules in the DG2020A. Section 9, Diagrams, includes a block diagram and a intercon- nect diagram. Figures 9-1 shows the modules and functional blocks of the DG2020A with Options 01 and 02 installed. - Page 60 CAUTION. To avoid losing pattern data files stored in NVRam, save the files to a floppy disk before removing the A6 CPU board or A17 Backplane board. Then restore the files from floppy disk to DG2020A nonvolatile memory after reinstalling the board(s).

-

Page 61: Options

(A4) is also part of this block; it generates the voltage required for the analog circuits. The fan prevents heat build-up inside the cabinet. It pulls air into the right (floppy-disk) side of the DG2020A and exhausts it out the left side. Options The following three options are available on the DG2020A:... - Page 62 Theory of Operation DG2020A Service Manual...

-

Page 63: Performance Verification

Performance Verification Introduction This section describes the operation tests for the DG2020A data generator and the P3410 and P3420 pods, and the procedures for those test. The operation tests can be divided into two categories. H Self Tests The DG2020A incorporates a diagnostic system that performs comprehen- sive instrument testing. -

Page 64: Before Running The Operation Tests

File Loading The performance check disk provided with the DG2020A includes the files listed in Table 4-1. The specified file must be loaded into the DG2020A for each operation test item. These files include pattern data and setup information. Table 4-1: Performance check disk’s file list... -

Page 65: Table 4-2: Required Equipment

Tektronix DM2510 P3410, P3420 DC voltage range: ¦10 V Precision: 0.01 V Performance check Tektronix part no. 063-1899-XX DG2020A disk (provided with the DG2020A) P3410, P3420 Oscilloscope Bandwidth: 500 MHz or higher Tektronix TDS520, TDS540, or equiva- DG2020A lent P3410, P3420 Function generator Amplitude: 4 V, offset: 2 V (50 Ω... -

Page 66: Test Procedure Notes

Operation 6 (e.g., insert a disk in the disk drive.) Operation 7 Popup Menu Side Menu General Purpose Knob Front Panel Button Menu Button Bottom Menu Bottom Button Side Button Figure 4-1: Operating buttons and menu layout DG2020A Service Manual... -

Page 67: Self Tests

Performance Verification Self Tests Execute the DG2020A self tests and confirm that no errors occurred. 1. Press the required buttons in the following order. If All is selected as the Type, all test items will be run. Front panel Menu button... -

Page 68: Performance Tests For The Dg2020A/Pod Combination

Performance Verification Performance Tests for the DG2020A/Pod Combination The items in this performance test are for the DG2020A in combination with a pod. Perform these test items in the following order. H Internal clock frequency .. - Page 69 H Characteristics Confirmation Procedure 1. Load the TP1CLK.PDA test pattern file from the performance check disk. When the file is loaded, the DG2020A clock frequency will be set to 200 MHz internally and the PLL circuit will be turned on.

-

Page 70: Figure 4-4: External Clock Input Connection

H Two SMB-to-BNC cables H Performance check disk H Connections Connect the clock output from the DG2020A rear panel to the oscilloscope CH1 input with an SMB-to-BNC cable. Connect the function generator output to the DG2020A rear panel clock input with the other SMB-to-BNC cable. - Page 71 H SMB-to-BNC cable (when a P3420 pod is used) H Performance check disk H Connections Connect the DG2020A rear panel pattern data output-connector (POD A) to the data input-connector on the rear panel of a P3410 or P3420 pod using a pod connection cable.

-

Page 72: Figure 4-5: Pod Connection

DG2020A power before connecting the cable. Connecting the cable with the power in the on state can damage the DG2020A and the P3410 pod. When attaching the pod cable, ensure that the plug and socket are aligned correctly. -

Page 73: Figure 4-6: P3410 Data Output Connectors

3. Confirm that the clock pulse waveform can be observed on the oscilloscope. This clock pulse is output by the EDIT screen DATA35 data pattern. 4. Switch the SMB-to-pin-header cable (P3410) or SMB-to-BNC cable (P3420) to the pod CH1 output. 4-11 DG2020A Service Manual... - Page 74 H Connections The pod is connected in the same way as shown in Figure 4-5. Additionally, use the T-connector and BNC cables to connect the function generator output to the DG2020A trigger input connector and to the oscillo- scope CH2 input as shown in Figure 4-8.

-

Page 75: Figure 4-8: External Trigger Operation Connections

2. Press the START/STOP button on the front panel so that the button’s LED indicator lights. 3. Confirm that the function generator output signal (the oscilloscope CH2 signal) and a square wave synchronized with this signal (the oscilloscope CH1 signal) are displayed on the oscilloscope. 4-13 DG2020A Service Manual... - Page 76 3. Confirm that a square wave with a 1 s period is displayed on the oscillo- scope. 4. Press the front panel STEP/EVENT button. 5. Confirm that a square wave with a 500 ns period is displayed on the oscilloscope. 4-14 DG2020A Service Manual...

-

Page 77: Figure 4-9: P3410 Event Input Connections

8. Confirm that a 1 s square wave and a 500 ns square wave are displayed on the oscilloscope alternately for 1 cycle and 2 cycles respectively. The following three steps confirm the event output signal operation. 9. Connect the DG2020A EVENT OUTPUT to the oscilloscope’s CH2 with a BNC cable. 4-15... -

Page 78: Figure 4-11: Dg2020A Event Output Connections

11. Confirm that the event output signal is displayed on the oscilloscope. The following two steps confirm the synchronization output signal operation. 12. Switch the BNC cable from the DG2020A EVENT OUTPUT connector to the SYNC OUTPUT connector. 13. Confirm that the synchronization signal appears on the oscilloscope. -

Page 79: P3410 Pod Performance Test

DG2020A power before connecting the cable. Connecting the cable with the power in the on state can damage the DG2020A and the P3410 pod. When attaching the pod cable, ensure that the plug and socket are aligned correctly. -

Page 80: Figure 4-13: P3410 Voltage Level Display

Performance Verification 2. Turn on the DG2020A power. 3. Press the DG2020A SETUP button. Confirm that TTL high (HI) and TTL low (LO) are displayed in the voltage level column on the DG2020A screen. (See Figure 4-13.) Voltage Level Display... -

Page 81: Figure 4-16: Output Voltage Test Connections

H Performance check disk H Connections Connect the CH0 data output pin for the pod connected to the DG2020A to the digital multimeter input through an SMB-to-pin-header cable, and SMB to BNC adapter, and a BNC to dual banana adapter. Connect the 1 MΩ... -

Page 82: Figure 4-17: Variable Delay Test Connections

H Connections Connect the P3410 CH0 and CH8 data output pins to the oscillo- scope CH1 and CH2 inputs, respectively, using the SMB-to-pin-header cables and the SMB to BNC adapters. Oscilloscope P3410 pod SMB-to-pin-header Cable Figure 4-17: Variable delay test connections 4-20 DG2020A Service Manual... -

Page 83: Table 4-5: Delay Precision

Table 4-5 fall within ranges in the table below. Table 4-5: Delay precision Settings Delay span range 0.0 ns - - 2.0 ns to 2.0 ns 2.0 ns 0.0 ns to 4.0 ns 5.0 ns 3.0 ns to 7.0 ns 4-21 DG2020A Service Manual... -

Page 84: Figure 4-18: Event Input Operation Confirmation Connections

SMB-to-pin-header cable and an SMB to BNC adapter. Also con- nect the P3410 CH1 output pin to the P3410 EVENT INPUT using the other SMB-to-pin-header cable. Oscilloscope P3410 pod Event Input SMB-to-pin-header Cable Figure 4-18: Event input operation confirmation connections 4-22 DG2020A Service Manual... -

Page 85: Figure 4-19: Inhibit Operation Confirmation Connections

5. Set the oscilloscope CH1 input impedance to 50 Ω. 6. Press the START/STOP button on the front panel twice. 7. Confirm that a square wave with a 1 s period is displayed on the oscillo- scope. 4-23 DG2020A Service Manual... -

Page 86: P3420 Pod Performance Test

DG2020A power before connecting the cable. Connecting the cable with the power in the on state can damage the DG2020A and the P3410 pod. When attaching the pod cable, ensure that the plug and socket are aligned correctly. -

Page 87: Figure 4-21: P3420 Voltage Level Display

Performance Verification 2. Turn on the DG2020A power. 3. Press the DG2020A SETUP button. Confirm that the high and low level voltage values are displayed in the voltage levels column on the DG2020A screen. (See Figure 4-21.) Voltage Level Display... -

Page 88: Figure 4-23: Output Voltage Level Measurement Connections

H Performance check disk H Connections Connect the CH0 data output pin for the pod connected to the DG2020A to the digital multimeter input through an SMB-to-BNC cable, and a BNC to dual banana adapter. Connect the 1 MΩ resistor across the BNC to dual banana adapter terminals. - Page 89 8. Load the TP9DCL.PDA test pattern file from the performance check disk. 9. Press the keys shown below in the indicated order to set the low level voltage to 6 V and the high level voltage to 7 V. 4-27 DG2020A Service Manual...

- Page 90 - - 3.19 V to - - 2.81 V 13. Move the SMB-to-BNC cable connected the P3420 CH0 output connector to CH1 through CH11 in turn, and confirm the low level output voltage ranges in the same way for each of these channels. 4-28 DG2020A Service Manual...

-

Page 91: Figure 4-24: Variable Delay Precision Check

CH1 ! CH2 DLY Record Length . . . 2500 points in 50 divs Trigger source ..Input coupling (CH1 and CH2) . . . Input impedance (CH1 and CH2) . . . 1 MΩ 4-29 DG2020A Service Manual... -

Page 92: Table 4-8: Delay Precision

8.90 ns to 11.10 ns 20.0 ns 18.60 ns to 21.40 ns 5. Move the pin header cable connected to the P3420 CH8 to channels CH9 through CH11 in turn, and repeat step 3 to confirm the delay values. 4-30 DG2020A Service Manual... -

Page 93: Figure 4-25: Event Input Operation Confirmation Connections

..Auto Trigger level ..1.5 V Input coupling ..Hold off ..Input impedance 1 MΩ 4-31 DG2020A Service Manual... -

Page 94: Figure 4-26: Inhibit Input Operation Confirmation Connections

5. Set the oscilloscope CH1 input impedance to 50Ω. 6. Press the START/STOP button on the front panel twice. 7. Confirm that a square wave with a 1 s period is displayed on the oscillo- scope. 4-32 DG2020A Service Manual... -

Page 95: Adjustment Procedures

Adjustment Procedures The DG2020A does not contain any adjustments. DG2020A Service Manual... - Page 96 Adjustment Procedures DG2020A Service Manual...

-

Page 97: Maintenance

See below. H Inspection and Cleaning. Information and procedures for inspecting the DG2020A and cleaning its external and internal modules. See page 6-4. H Repacking. Procedures for removing defective modules and replacing new or repaired modules. See page 6-9. - Page 98 Do service of static-sensitive modules only at a static-free work station. 4. Do not remove the DG2020A cabinet unless you have met precaution number 3, above. Consider all internal modules static-sensitive. 5. Do not allow anything capable of generating or holding a static charge on the work station surface.

-

Page 99: Table 6-1: Relative Susceptibility To Static-Discharge Damage

6 = 600 to 800 V 2 = 200 to 500 V 7 = 400 to 1000 V (est.) 3 = 250 V 8 = 900 V 4 = 500 V 9 = 1200 V 5 = 400 to 600 V DG2020A Service Manual... -

Page 100: Inspection And Cleaning

DG2020A operates. General Care The cabinet helps keep dust out of the DG2020A and is a major component of the instrument cooling system. The cabinet should normally be in place when operating the DG2020A. The DG2020A front cover (optional accessory) protects the front panel and display from dust and damage. -

Page 101: Table 6-2: External Inspection Check List

Inspection — Exterior. Inspect the outside of the DG2020A for damage, wear, and missing parts, using Table 6-2 as a guide. If the DG2020A appears to have been dropped or otherwise abused, check it thoroughly to verify correct operation and performance. -

Page 102: Table 6-3: Internal Inspection Check List

3. If steps 1 and 2 do not remove all the dust or dirt, the DG2020A may be spray washed using a solution of 75% isopropyl alcohol by doing step 4 through 8. - Page 103 7. Dry all parts with low-pressure, deionized air. 8. Dry all components and assemblies in an oven or drying compartment using low-temperature (51.7_ C to 65.6_ C/125_ F to 150_ F) circulating air. Lubrication. There is no periodic lubrication required for the DG2020A. DG2020A Service Manual...

- Page 104 Maintenance DG2020A Service Manual...

-

Page 105: Removal And Installation Procedures

H Module locator diagrams for finding each module in the DG2020A H Procedures for removing and installing electrical and mechanical modules W ARNING. To avoid possible personal injury or damage to DG2020A compo- nents, read the Preparation for Use subsection on page 2-1, and Preventing ESD on page 6-2. -

Page 106: Table 6-4: Equipment Required

DG2020A. Equipment Required The removal of most modules in the DG2020A requires only a screwdriver handle mounted with a size T-15, TorxR screwdriver tip. Use this tool whenever a procedure step instructs you to remove or install a screw, unless a different size screwdriver is specified in that step. -

Page 107: Figure 6-1: Dg2020A Orientation

Removal and Installation Procedures DG2020A Orientation In this manual, procedures refer to “front,” “back,” “top,” etc. of the DG2020A. Figure 6-1 shows how the sides are referenced. Figure 6-1: DG2020A orientation 6-11 DG2020A Service Manual... -

Page 108: Access Procedure

Monitor Module and CRT Frame 6-34 A6 CPU, A30 Clock, A50 PG Master board 6-37 A51 PG Slave (Option 01 or 02) 6-37 Floppy-disk Drive Module 6-40 A17 Backplane board 6-40 Lithium battery 6-43 Figure 6-2: Guide to removal procedures 6-12 DG2020A Service Manual... -

Page 109: Figure 6-3: External Modules

Removal and Installation Procedures Fuse Cap Line Fuse Rear Cover Line Cord Cabinet CRT Filter Front-panel Module Menu Buttons Floppy-disk Drive Bezel Front-panel Knob EMI Gasket Trim Ring Front Cover (Optional) Figure 6-3: External modules 6-13 DG2020A Service Manual... -

Page 110: Figure 6-4: Internal Modules

Monitor Module Aux Power AC Inlet Rear Shield Cover CRT Frame Floppy Disk Drive Cover Battery Front Panel A17 Backplane Board Board Support Floppy Disk Bracket Floppy Disk Drive Board Support Connector Module Figure 6-4: Internal modules 6-14 DG2020A Service Manual... -

Page 111: Procedures For External Modules

-inch hex wrench for this procedure. Find the front-panel knob on the front panel in the locator diagram, External Modules, Figure 6-3. 2. Orient instrument: Set the DG2020A with the bottom down on the work surface and the front facing you (see Figure 6-5). -

Page 112: Figure 6-5: Front-Panel Knob Removal

Locate the line fuse and line cord in the locator diagram, External Modules, Figure 6-3. 2. Orient instrument: Set the DG2020A with the bottom down on the work surface and the back facing you. If you are servicing the line fuse, do the next step;... -

Page 113: Figure 6-6: Line Fuse And Line Cord Removal

Locate the rear cover and cabinet in the locator diagram, External Modules, Figure 6-3. 2. Orient instrument: Set the DG2020A face down, with the front cover on the work surface and the instrument bottom facing you (see Figure 6-7). - Page 114 Lift off the rear cover. 5. Orient instrument: Set the DG2020A face down, with the front cover on the work surface and right side facing you. 6. Remove floppy disk drive bezel: Using a screwdriver with a size T-9 Torx tip, remove the four screws securing the floppy-disk drive bezel to the cabinet.

-

Page 115: Figure 6-7: Rear Cover And Cabinet Removal

Removal and Installation Procedures Rear Cover T-15 Screws (4) Cabinet T-15 Screw T-9 Screws (4) Figure 6-7: Rear cover and cabinet removal 6-19 DG2020A Service Manual... - Page 116 Locate the modules to be removed in the locator diagram, External Modules, in Figure 6-3. 2. Orient instrument: Set the DG2020A with the back down on the work surface and bottom facing you (see Figure 6-8). 3. Remove front cover: If the optional front cover is installed, grasp the front cover by the left and right edges and snap it off of the trim ring.

- Page 117 Figure 6-8: Front cover, trim ring, and menu button removal (front cover not shown) CAUTION. To prevent contaminating DG2020A parts, do not touch the carbon contact points on the menu buttons installed in the trim ring. Also, do not touch the contacts on the flex circuit exposed when you remove the trim ring.

- Page 118 Trim Ring, and Menu Buttons procedure on page 6-20 removing only the module(s) you want to service. 4. Orient instrument: Set the DG2020A with the bottom down on the work surface and the front facing you. 5. Remove front-panel module: a.

-

Page 119: Figure 6-9: Front-Panel Module Removal

Remove the setscrew completely from the extension using the 0.05-inch hex wrench, and then remove the extension from the shaft of the rotary switch. c. As shown in Figure 6-10, release the four hooks, and then remove the A12 Keyboard from the chassis. 6-23 DG2020A Service Manual... -

Page 120: Figure 6-10: A12 Keyboard Removal

Removal and Installation Procedures Hooks A12 Keyboard Hooks Figure 6-10: A12 keyboard removal d. Now hand disassemble the front-panel module components using Figure 6-11 as a guide. Reverse the procedure to reassemble. 6-24 DG2020A Service Manual... -

Page 121: Figure 6-11: Disassembly Of Front-Panel Module

Then do the substeps in step 3 in reverse order, reversing the order of the items in each substep. Last, reinstall the trim ring and, if desired, the front cover, referring to the procedure, Front Cover, Trim Ring, and Menu Buttons (page 6-20). 6-25 DG2020A Service Manual... -

Page 122: Procedures For Internal Modules

H A30 Clock Board H A50 PG Master Board H For Option 01: A51 PG Slave Board H For Option 02: A51 PG Slave Board H A17 Backplane Board H Lithium Battery H Floppy Disk Drive Module 6-26 DG2020A Service Manual... - Page 123 3. Remove front cover, trim ring, and menu buttons: Perform the Front Cover, Trim Ring, and Menu Buttons procedure on page 6-20. 4. Orient instrument: Set the DG2020A with the top down on the work surface and the right side facing you.

-

Page 124: Figure 6-12: Connector Module Removal

Locate the modules to be removed in the locator diagram, Internal Modules, in Figure 6-4. 2. Orient instrument: Set the DG2020A with the bottom down on the work surface and the left side facing you. 3. Remove fan and fan frame: a. -

Page 125: Figure 6-13: Fan And Fan Frame Removal

Connect the cable (J3) to power supply module. c. Align the four protrusions of the fan frame with the holes of the chassis, slide the fan and fan frame to the lower left, and then install them. 6-29 DG2020A Service Manual... -

Page 126: Figure 6-14: Rear Shield Cover Removal

Locate the modules to be removed in the locator diagram, Internal Modules, Figure 6-4. 2. Orient instrument: Set the DG2020A with the bottom down on the work surface and the back facing you (see Figure 6-14). 3. Remove rear shield cover: a. -

Page 127: Figure 6-15: Power Supply Module Removal

T-15 Torx tip for this procedure. Locate the modules to be removed in the locator diagram, Internal Modules, in Figure 6-4. 2. Orient instrument: Set the DG2020A with the bottom down on the work surface and the left side facing you. - Page 128 2. Remove fan and fan frame: Perform the Fan and Fan Frame procedure on page 6-28. 3. Orient instrument: Set the DG2020A with the bottom down on the work surface and the back facing you (see Figure 6-16). 4. Remove the power supply module: Perform the procedure, Power Supply Module, on page 6-31.

-

Page 129: Figure 6-16: Aux Power Board And Ac Inlet Removal

Figure 6-16: AUX power board and AC inlet removal 7. Reinstallation: a. Install the AUX Power board by doing substeps 6a- -6c in reverse order. b. Install the AC Inlet by doing substeps 5a- -5e in reverse order. 6-33 DG2020A Service Manual... - Page 130 2. Remove front cover, trim ring, and menu buttons: Perform the Front Cover, Trim Ring, and Menu Buttons procedure on page 6-20. 3. Orient instrument: Set the DG2020A with the bottom down on the work surface and the left side facing you.

-

Page 131: Figure 6-17: Monitor Module Removal

Removal and Installation Procedures T-15 Screws Monitor Module J901 T-15 Screw T-15 Screws Figure 6-17: Monitor module removal 5. Remove CRT frame: Grasp the upper part of the CRT frame and take it out as shown in Figure 6-18. 6-35 DG2020A Service Manual... -

Page 132: Figure 6-18: Crt Frame Removal

Grasp the upper part of the CRT frame, align the notch of the chassis with the protrusion of the CRT frame, and place the CRT frame in the chassis. b. Install the monitor module by doing substeps 4a- -4d in reverse order. 6-36 DG2020A Service Manual... - Page 133 2. Remove the rear shield cover: Perform the procedure, Rear Shield Cover, on page 6-30. 3. Orient instrument: Set the DG2020A with the left side down on the work surface and the top facing you. 4. Remove board support: Remove the board support upward while pushing its hook to the inside.

- Page 134 Disconnect the flat cable at J400 on the A51 PG Slave board (see Figure 6-19). Grasp the upper part of the A51 Slave board (the second slot from the top) and pull it upward to remove it. 6-38 DG2020A Service Manual...

-

Page 135: Figure 6-19: Circuit Boards Removal

A51 PG Slave Board J510 (Option 01 or 02) J511 A50 PG Master Board J510 J511 A30 Clock Board J510 J460 J160 J511 A6 CPU Board J521 J531 J510 J520 J530 Figure 6-19: Circuit boards removal 6-39 DG2020A Service Manual... - Page 136 Locate the modules to be removed in the locator diagram, Internal Modules, in Figure 6-4. 2. Orient instrument: Set the DG2020A with the left side down on the work surface and the top facing you. 3. Remove all boards: Perform the procedure, Circuit Boards, on page 6-37.

-

Page 137: Figure 6-20: A17 Backplane Board Removal

Install the other boards: Perform the procedure, Circuit Boards, on page 6-37, in reverse order, reversing the items in each step. T- - 15 Screws (5) A17 Backplane Board Figure 6-20: A17 backplane board removal 6-41 DG2020A Service Manual... - Page 138 Grasp the battery, and lift it away from the board. 5. Install new battery: a. Place the new battery on the board with the negative tab of the battery closest to the board edge connector. b. Solder the tabs to the board. 6-42 DG2020A Service Manual...

-

Page 139: Figure 6-21: Battery Location On The A17 Backplane Board

2. Remove rear shield cover: Perform the Rear Shield Cover procedure on page 6-30. 3. Orient instrument: Set the DG2020A with the left side down on the work surface and the bottom facing you. 4. Remove all circuit boards: Perform the procedure, Circuit Boards, on page 6-37. -

Page 140: Figure 6-22: Floppy-Disk Drive Module Removal

Install circuit boards: Perform the procedure, Circuit Boards, on page 6-37, in reverse order. Floppy-disk Drive Cover #1 Screws Floppy-disk Flat Cable Drive Bracket #1 Screws Floppy-disk Drive T-10 Screws #1 Screws Spacer #1 Screws T-10 Screws Figure 6-22: Floppy-disk drive module removal 6-44 DG2020A Service Manual... -

Page 141: Repackaging

DG2020A dimensions. (If available, use the original shipping carton, which meets these requirements.) If the DG2020A is shipped to a Tektronix Service Center, enclose the following information: H The owner’s address... - Page 142 Repacking 6-46 DG2020A Service Manual...

-

Page 143: Troubleshooting

Troubleshooting This subsection contains information and procedures designed to isolate faulty modules in the DG2020A Data Generator. If these procedures indicate a module needs to be replaced, follow the Removal and Installation Procedures in the preceding subsection. Troubleshooting Procedures The troubleshooting procedures in this subsection consist of these flowcharts. -

Page 144: Figure 6-23: A6 Cpu Board

If the tests pass but there is still a problem, go to the Primary Troubleshooting Procedure on page 6-49. Red LED Green LED Figure 6-23: A6 CPU board 6-48 DG2020A Service Manual... -

Page 145: Figure 6-24: Primary Troubleshooting Procedure- -(1)

Troubleshooting Press the PRINCIPAL POWER SWITCH on the rear panel of the DG2020A. Power off and remove the cover using the Rear Cover and Cabinet removal Disconnect the fan Push the procedure. Check all the Can you cable at J3 on the ON/STBY button. -

Page 146: Figure 6-25: Primary Troubleshooting Procedure- -(2)

If there is no fault in normal? Is the trigger the cable connections, replace the A30 operation Clock board (page 6-37). normal? Check the pod connector. See page 6-51. Done. Figure 6-25: Primary troubleshooting procedure- (2) 6-50 DG2020A Service Manual... -

Page 147: Figure 6-26: Pod Connector Troubleshooting Procedure

Troubleshooting Use this procedure to check the pod connector. Turn off the power to the DG2020A and connect a properly working pod to the DG2020A using a pod cable. When the power to the DG2020A is turned on, is there a message on the screen... -

Page 148: Figure 6-27: Troubleshooting Procedure 1 — Power Supply Module

(see Fig. 6-29)? Replace the AC Inlet (page 6-32). Replace the AUX Power board (page 6-32). Replace the power supply module (page 6-31). Figure 6-27: Troubleshooting procedure 1 — power supply module 6-52 DG2020A Service Manual... -

Page 149: Figure 6-28: Aux Power Board

Troubleshooting Fuse PRINCIPAL POWER Switch Figure 6-28: AUX power board Figure 6-29: Power supply module 6-53 DG2020A Service Manual... -

Page 150: Figure 6-30: Troubleshooting Procedure 2 A6 Cpu Board Or Front-Panel Module

The front panel module is ok. Replace the A6 CPU board (page 6-37). Figure 6-30: Troubleshooting procedure 2 — A6 CPU board or front-panel module 6-54 DG2020A Service Manual... -

Page 151: Figure 6-31: Key Board

Troubleshooting TP101 (GND) TP100 (5V) Figure 6-31: Key board 6-55 DG2020A Service Manual... -

Page 152: Figure 6-32: Troubleshooting Procedure 3 — Monitor Module

(page Figure 6-34? 6-34). Do the horizontal and /or vertical sync Power the DG2020A off and disconnect lock ok? the cable from J901 on the monitor module (see Figure 6-33) then power back on. Do pins Power the DG2020A off and disconnect... -

Page 153: Figure 6-33: Monitor Module

Troubleshooting Pin 1 J901 Figure 6-33: Monitor module J901 pin 4 (Horizontal Sync) 31.75 kHz Rate J901 pin 6 (Vertical Sync) 60 Hz Rate 2.00V 2.00V M 20.0us 1.60V Figure 6-34: Horizontal and vertical sync signals 6-57 DG2020A Service Manual... -

Page 154: Figure 6-35: A Video Signal With White And Black Levels

Troubleshooting White Level J901 pin 9 (Video) Black Level M 10.0us 316mV 200mV Figure 6-35: A video signal with white and black levels 6-58 DG2020A Service Manual... -

Page 155: Figure 6-36: Troubleshooting Procedure 4 — Module Isolation

Troubleshooting This procedure assumes that the DG2020A is running and you can read the display. Select the diagnostics menu in Does the UTILITY menu and run all the display any failures The DG2020A is ok. the tests (see the discussion of... - Page 156 Troubleshooting 6-60 DG2020A Service Manual...

-

Page 157: Options And Accessories

H Option 95 ships with test result report. Refer to page 7-3 for details. Options A1- A5 In place of the standard North American, 110 V, 60 Hz power cord, Tektronix ships any of five alternate power cord configurations with the data generator. See Table 7-1 for a list of the power cord configurations. -

Page 158: Option 01 Description

A test result report will be provided with the DG2020A when this option is specified. When the option 95 is specified, the test result report of only the DG2020A is provided. If the test result report of the P3410 or the P3420 is necessary, the P3410 Option 95 or the P3420 Option 95 must be specified. -

Page 159: P3410 Option 95 Description

A test result report will be provided with the P3410 when this option is specified. When the option 95 is specified, the test result report of only the P3410 is provided. If the test result report of the DG2020A is necessary, the DG2020A Option 95 must be specified. P3420 Option 95 Description A test result report will be provided with the P3420 when this option is specified. -

Page 160: Table 7-2: Standard Accessories

Table 7-3 lists the standard accessories for the P3410 and P3420 pods Table 7-3: Standard accessories for pods Standard accessories Part number P3410 Set of 12 cables 012-1502-XX P3420 Set of 12 cables 012-1504-XX P3410/P3420 Connector with 12-pin header sockets 131-5919-XX P3410/P3420 Certificate of Calibration P3410/P3420 Instructions Sheet DG2020A Service Manual... -

Page 161: Table 7-4: Optional Accessories

Options and Accessories Optional Accessories Table 7-4 lists the optional accessories that are recommended for use with the DG2020A, P3410, and P3420. Table 7-4: Optional accessories Optional accessory DG2020A P3410 P3420 Part number Service Manual 071-0055-XX Front Cover 200-3232-XX Oscilloscope Camera Adapter... -

Page 162: Table 7-5: Maintenance Kit Contents

Extender-A board (for slot 1, 2, 3, 4) 671-2331-XX Extender-B board (for slot 5) 671-2487-XX Cable kit 198-5855-XX Ejector 003-1315-XX Header 131-5537-XX 50 Ω SMB to BNC adapter 015-0671-XX 50 Ω SMB to SMB cable 40 inch (101.6 cm) 012-1458-XX DG2020A Service Manual... -

Page 163: Electrical Parts List

The modules that make up this instrument are often a combination of mechanical and electrical subparts. Therefore, all replaceable modules are listed in sec- tion 10, Mechanical Parts List. Refer to that section for part numbers when using this manual. DG2020A Service Manual... - Page 164 Replaceable Electrical Parts DG2020A Service Manual...

- Page 165 H Block Diagram of DG2020A with Options 01 and 02 H Interconnect Diagram of DG2020A with Options 01 and 02 Block diagrams show the modules and functional blocks in the DG2020A. Interconnect diagrams show how the modules in the DG2020A connect together.

- Page 166 Diagrams DG2020A Service Manual...

-

Page 169: Replaceable Mechanical Parts

Replaceable Mechanical Parts This section contains a list of the replaceable modules for the DG2020A. Use this list to identify and order replacement parts. Parts Ordering Information Replacement parts are available through your local Tektronix field office or representative. Changes to Tektronix products are sometimes made to accommodate improved components as they become available and to give you the benefit of the latest improvements. -

Page 170: Using The Replaceable Parts List

Module Servicing Modules can be serviced by selecting one of the following three options. Contact your local Tektronix service center or representative for repair assistance. Module Exchange. In some cases you may exchange your module for a reman- ufactured module. These modules cost significantly less than new modules and meet the same factory specifications. -

Page 171: Beaverton, Or

ST CHARLES ROAD ELGIN IL 60120 SHAKEPROOF DIV 80009 TEKTRONIX INC 14150 SW KARL BRAUN DR BEAVERTON OR 97077- - 0001 PO BOX 500 86928 SEASTROM MFG CO INC 701 SONORA AVE GLENDALE CA 91201- - 2431 10-3 DG2020A Service Manual... -

Page 172: Replaceable Parts List

FILTER,LT,CRT:BLUE SMOKE,112MM X 145MM 80009 3780404XX - - 17 348- - 1289- - XX SHLD GSKT,ELEK:MESH TYPE,3.2MM X 4.7MM 80009 3481289XX - - 18 211- - 0722- - XX SCREW,MACHINE:6- - 32 X 0.25,PNH,STL 0KB01 ORDER BY DESC 10-4 DG2020A Service Manual... - Page 173 Replaceable Mechanical Parts Figure 10-1: Cabinet 10-5 DG2020A Service Manual...

- Page 174 FRAME,CRT FLTR:POLYCARBONATE TK1163 ORDER BY DESC - - 27 348- - 1302- - XX GASKET,SHIELD:CONDUCTIVE URETHANE FORM 80009 3481302XX - - 28 640- - 0081- - XX DISPLAY MONITOR:7 INCH,480 X 640 PIXEL 80009 6400081XX (DS100) 10-6 DG2020A Service Manual...

- Page 175 Replaceable Mechanical Parts A900 See Figure 10-5 for Detailed View Figure 10-2: Main chassis and CRT 10-7 DG2020A Service Manual...

- Page 176 - - 22 348- - 0948- - XX GROMMET,PLASTIC:BLACK,RING,9.5MM ID 80009 3480948XX - - 23 252- - 0571- - XX PLASTIC SHEET:EXTR CHAN,5MM X 3.3MM 80009 2520571XX - - 24 348- - 1472- - XX GASKET,SHIELD,ELEC 80009 3481472XX 10-8 DG2020A Service Manual...

- Page 177 Replaceable Mechanical Parts 17 A17 Figure 10-3: Main chassis and circuit boards 10-9 DG2020A Service Manual...

- Page 178 CONN,RF JACK:SMB,50OHM,FEMALE 80009 1310450XX (A30J330, J340) - - 10 129- - 1051- - XX SPACER,POST:12.5 MM L,W/4- - 40 INT THD 80009 1291051XX - - 11 671- - 3782- - XX CIRCUIT BD ASSY:CLOCK 80009 6713782XX (A30) 10-10 DG2020A Service Manual...

- Page 179 Replaceable Mechanical Parts Figure 10-4: Circuit boards 10-11 DG2020A Service Manual...

- Page 180 - - 10 380- - 1060- - XX HOUSING,SWITCH:POLYCARBONATE,AFG2020 80009 3801060XX - - 11 260- - 2552- - XX SWITCH,PUSH:50 BUTTON,SP/ST 80009 2602552XX - - 12 366- - 0769- - XX PUSH BUTTON:IVORY GRAY,OVAL 80009 3660769XX 10-12 DG2020A Service Manual...

- Page 181 Replaceable Parts Figure 10-5: Front panel assembly 10-13 DG2020A Service Manual...

- Page 182 Mfr. Index Number Number Effective Discont’d Name & Description Code Mfr. Part Number OPTION 01 10- - 6- - 1 671- - 4242- - XX CIRCUIT BD ASSY:PG SLAVE (A51) 80009 6714242XX Figure 10-6: Option 01 10-14 DG2020A Service Manual...

-

Page 183: Figure 10-7: Option

Mfr. Index Number Number Effective Discont’d Name & Description Code Mfr. Part Number OPTION 02 10- - 7- - 1 671- - 4242- - XX CIRCUIT BD ASSY:PG SLAVE (A51) 80009 6714242XX Figure 10-7: Option 02 10-15 DG2020A Service Manual... - Page 184 CA ASSY,SP,ELEC:26,350MM L,FLAT FLEX 80009 1742775XX W900 174- - 2770- - XX CA ASSY,SP,ELEC:10,26 AWG,390MM L,RIBBON 80009 1742770XX DG2020A Option 01 Only W410 174- - 3218- - XX CA ASSY,SP:30,28 AWG,3CM L,FLAT 80009 1743218XX W520 174- - 3203- - XX...

- Page 185 (OPTION A4- - NORTH AMERICAN) 161- - 0167- - 00 CABLE ASSY,PWR,:3.0 X 0.75,6A,240V,2.5M L S3109 ORDER BY DESC (OPTION A5- - SWITZERLAND) OPTIONAL ACCESSORIES FOR DG2020A 071- - 0055- - XX MANUAL,TECH:SERVICE 80009 0710055XX 200- - 3232- - XX...

- Page 186 012- - 1508- - XX LEAD SET,ELEC:2,26 AWG,7.5 CM L,PKG OF 5 EA 80009 0121508XX 012- - 1509- - XX LEAD SET,ELEC:8,26 AWG,12 CM L,PKG OF 3 EA 80009 0121509XX 015- - 0671- - XX ADAPTER,CONN:SMB(FEMALE) TO BNC(MALE) 80009 0150671XX 10-18 DG2020A Service Manual...

Need help?

Do you have a question about the DG2020A and is the answer not in the manual?

Questions and answers