Summary of Contents for Spring Air Systems DN REV-LOW

- Page 1 DN REV-LOW Maintenance and Operating Manual ___________________________ Spring Air Systems Inc., Oakville, Ontario Phone (905) 338-2999, Fax (905) 338-0179, info@springairsystems.com www.springairsystems.com...

-

Page 2: Table Of Contents

DN REV-LOW Maintenance and Operating Manual Table of Contents Introduction Spring Air Systems Hood Model Number Designations Principle of Operation VARIFLOW Baffles Baffle Settings REV-LOW Maintenance Instructions Cleaning the Exterior REV-LOW Maintenance Schedule Trouble Shooting Measuring the Exhaust Airflow Installing the Terminator Baffle... -

Page 3: Introduction

Your system consists of a dry extractor, exhaust fan and on/off switch. Others may have supplied the exhaust fan and on/off operator. Your SPRING AIR SYSTEMS INC. Dry extractor model was selected to best meet the design requirements of your commercial kitchen application. -

Page 4: Spring Air Systems Hood Model Number Designations

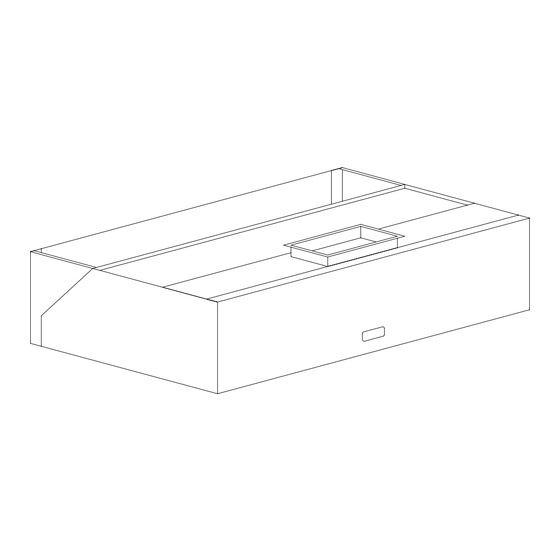

SPRING AIR SYSTEMS HOOD MODEL NUMBER DESIGNATIONS There are numerous types and styles of SPRING AIR SYSTEM Rev-Low ventilator available. Refer to the UL/ULC label for the complete model number and exhaust flow requirement for your dry ventilator. The UL/ULC label is located on the underside of the grease through on the right hand side of the dry ventilator. -

Page 5: Variflow Baffles

VARIFLOW Baffles Exhaust duct collar Top of core extractor End mullion Front of core extractor Variflow Baffle Core extractor slot Shown in full open position Removable Inserts Grease trough Core extractor slot Section View of Core Extractor for DN-B-F REV LOW Hood Figure 3 The REV LOW accomplishes this complicated process with a unique core extractor profile that contains a series of specially designed VARI-FLOW baffles located along length of the core... -

Page 6: Baffle Settings

Each baffle is factory set base on the type of appliance under the hood. REV-LOW MAINTENANCE INSTRUTIONS Hood with Spring Air Systems RPD Controller At the start of the day 1. Rotate the occupied/Unoccupied switch to the occupied position to start the exhaust system. - Page 7 At the end of the day 1. After the cooking equipment has been turned off rotate the occupied/Unoccupied switch to the unoccupied position to shut off the exhaust system. The exhaust and supply fan(s) will shut down. 2. The REV-LOW hood will deposit particulate on both the hood backwall and roof. Wipe down the stainless steel backwall above the appliances and the interior of the hood, including the back and roof.

-

Page 8: Cleaning The Exterior

CLEANING THE EXTERIOR Normal soil can be removed with a mild detergent and water mixture applied to a cloth. To remove baked on grease, apply a cleanser to a damp cloth or sponge and rub on the metal in the direction of the polishing lines. -

Page 9: Measuring The Exhaust Airflow

REMOVEABLE INSERT INSTALLATION HANDLE IS UP AND OUT CORRECT UP SIDE DOWN MEASURING THE EXHAUST AIRFLOW The exhaust air is measured along the inlet slot of the ventilator. To ensure accurate results take a reading every foot along the length of the ventilator is recommended. VANAXIAL VELOMETER PITOT TUBE OR ANEMOMETER Hold the instrument... -

Page 10: Installing The Terminator Baffle

INSTALLING THE TERMINATOR BAFFLE The TBDD Terminator baffle is available in various lengths to suit adverse site LEAVE GAP LOOSE ENOUGH TO SLIP BAFFLE ONTO THE ADJUSTABLE BAFFLE INSTALLER CAN FLATTEN WITH HAMMER TO TIGHEN FIT ON SITE. 0.625" ADJUSTABLE BAFFLE "B" REMOVEABLE ACCESS "A"... -

Page 11: Rev-Low-Startup Report

REV-LOW- STARTUP REPORT General Information Job Name Date Customer Location Spring Air Service Exhaust Fan Model No. Manufacturer Up blast Discharge Exhaust Fan HP Exhaust Air Design (CFM) Supply Air Design (CFM) Ventilator mounting Height from finished floor to front of hood Make Up Air Systems Good Fair... - Page 12 Hood Item Model Length Width No. of Baffles Baffle Size * Design CFM Baffle No. Baffle Setting Velocity Reading Calculated Exhaust Volume Left to Right (fpm) per Baffle (CFM) ** Total Exhaust Measured CFM Design Exhaust CFM Hood Item Model Length Width No.

- Page 13 Other Fine Products From SPRING AIR SYSTEMS... • Water Wash Ventilators ♦ Hot Water Wash ♦ Cold Water Spray/Hot Water Wash ♦ Water Wash Control Panels • Dry Extractor Hoods • REV-LOW Hoods • Cartridge Hoods • Filter Hoods • Surface Fire Suppression •...

Need help?

Do you have a question about the DN REV-LOW and is the answer not in the manual?

Questions and answers