Table of Contents

Advertisement

Quick Links

User Manual

Scales of WPY/KB series

Manual number:

ITKU-47-12-05-12-A

Mass Comparator

M A N U F A C T U R E R O F E L E C T R O N I C

W E I G H I N G I N S T R U M E N T S

RADWAG Wagi Elektroniczne, 26–600 Radom Bracka 28 Street - POLAND

Phone +48 48 38 48 800, phone/fax. +48 48 385 00 10

Selling department +48 48 366 80 06

www.radwag.com

Advertisement

Table of Contents

Summary of Contents for RADWAG WPY/KB series

-

Page 1: User Manual

W E I G H I N G I N S T R U M E N T S RADWAG Wagi Elektroniczne, 26–600 Radom Bracka 28 Street - POLAND Phone +48 48 38 48 800, phone/fax. +48 48 385 00 10 Selling department +48 48 366 80 06 www.radwag.com... - Page 2 MAY 2012...

-

Page 3: Table Of Contents

Table OF CONTENTS INTENDED USE ..........................7 2. PRECAUTIONARY MEASURES ....................7 3. WARRANTY CONDITIONS ......................7 4. UNPACKING AND MOUNTING....................8 4.1. Comparator WPY/KB – preparation for work ...............9 5. CONSTRUCTION ........................10 5.1. Main dimensions ........................10 5.2. Description of connectors....................11 5.2.1. Connectors’ description in PUE 7 ................11 5.2.2. - Page 4 15. COMMUNICATION........................35 15.1. RS 232 settings .........................36 15.2. ETHERNE T setting ......................36 1 .3. TCP protocol setting ......................37 16. DEVICES ..........................37 16.1. Computer ..........................37 16.1.1. Computer port ......................37 16.1.2. Computer addre ss ....................38 16.1.3. Continuous trans mission ..................38 16.1.4. Weighing printou t pattern..................39 16.1.5.

- Page 5 22. SPECIAL FUNCTIONS OF WORKING MODES..............63 22.1. Recording mode ........................64 22.2. wn-weighing .........................64 22.3. Checkw eighing........................65 22.4. Tare mo de.........................65 22.5. Labelling mode........................66 22.5.1. Setting of the nu mber of labels to print ..............66 22.5.2. Setting of the nu mber of cumulative labels to print..........67 22.5.3.

- Page 6 28. COMMUNICATION PROTOCOL ....................95 28.1. Gene ral information ......................95 28.2. Inventory of RS commands....................96 28.3. Respond message format ....................97 28.4. Command’s description ....................97 28.4.1. Zeroing ........................97 28.4.2. Tarring ........................97 28.4.3. Get ta re value ......................98 28.4.4. Set tare value ......................98 28.4.5.

-

Page 7: Intended Use

G. Devices that are to be withdrawn from usage should be utilized according to the law. 3. WARRANTY CONDITIONS A. RADWAG is obliged to repair or change those elements that appears to be faulty because of production and construction reason, B. Defining defects of unclear origin and outlining methods of elimination... -

Page 8: Unpacking And Mounting

• Inappropriate cleaning. E. Forfeiture of warranty appears after: • Access by an unauthorized service, • Intrusion into mechanical or electronic construction of unauthorized people, • Installing another operating system, • Removing or destroying protection stickers. F. The detailed warranty conditions one can find in warranty certificate. G. -

Page 9: Comparator Wpy/Kb - Preparation For Work

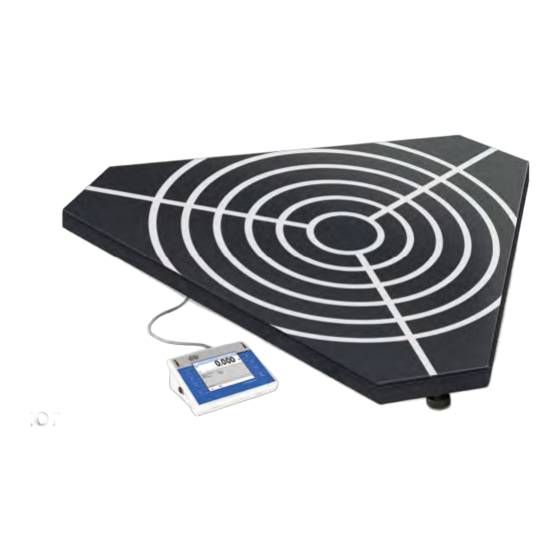

4.1. Comparator WPY/KB – preparation for work Comparators of WPY/KB series, because of its construction (sensitive strain gauges), require appropriate conditions to work properly, including stable temperature. Temperature drifts in rooms with comparators should not exceed 1°C per hour. Proceeding in case of preparing the comparator to work: 1. -

Page 10: Construction

5. CONSTRUCTION 5.1. Main dimensions Dimensions of PUE 7 in plastic casing Dimensions of PUE 7P with stainless housing Dimensions of platform... -

Page 11: Description Of Connectors

5.2. Description of connectors 5.2.1. Connectors’ description in PUE 7 1 – Ethernet RJ45 1 – power supply socket 2 – RS232 (COM1) 2 – I/O, RS232 (COM2) 3 – USB 5.2.2. Connectors’ description in PUE 7P 1 – Ethernet RJ45 1 –... -

Page 12: Connector With Rs232 And I/O

• Press to start the operating system loading procedure. Windows CE together with RADWAG software loading is signalled by blinking the red diode ON/LOAD. • When the loading procedure is completed the main software window appears. -

Page 13: Keypad Overlay

7. KEYPAD OVERLAY 8. FUNCTIONS OF KEYS Description Turning on/off the scale Zeroing Tarring Printing out the result or confirming some entered data Function key (entering the menu) Selecting products Selecting contractors Inscribing a tare value... -

Page 14: Program Structure

9. PROGRAM STRUCTURE The main menu has been divided into three functional groups. In every group there are parameters of similar use. 9.1. Main menu items The main menu comprises three functional groups: Parameters Databases Info 9.1.1. Parameters Icon Description Scale Working Modes Communication... -

Page 15: Databases

9.1.2. Databases Icon Description Products Operators Weighings / Alibi Contractors Recipes Recipes reports Comparisons Packages Warehouses Labels Universal variables Delete older data Export database weighings to a file 9.1.3. Scale Info Submenu < Info> is for viewing information: • Scale factory number, •... -

Page 16: Inventory Of Parameters

9.2. Inventory of parameters 9.2.1. Scale parameters - weighing Icon Description Value Platform 1 Median Filter None Filter Slow Autozero LO threshold 9.2.2. Working modes Icon Description Value Weighing Manual, each Save Mode stable Down-weighing Checkweighing Tare mode Labelling mode Number of labels No. - Page 17 Threshold CC label automatic triggering Mode None Threshold Statistics Global Counting pieces Manual, each Save Mode stable Down-weighing Checkweighing Tare mode Labelling mode Number of labels No. of cumulative labels No. of CC labels C label automatic triggering Mode None Threshold CC label automatic triggering Mode...

- Page 18 Manual, each Save Mode stable Down-weighing Checkweighing Tare mode Labelling mode Number of labels No. of cumulative labels No. of CC labels C label automatic triggering Mode None Threshold CC label automatic triggering Mode None Threshold Statistics Global Comparator Automatic Save Mode first stable Checkweighing...

-

Page 19: Communication

9.2.3. Communication Icon Description Value COM1 Baud Rate 9600 Data bits Stop bits Parity None COM2 Baud Rate 9600 Data bits Stop bits Parity None Ethernet DHCP IP Address 192.168.0.2 Subnet mask 255.255.255.0 Gateway 192.168.0.1 Port 4001 9.2.4. Devices Icon Description Value Computer... - Page 20 Port None Address Continuous transmission Weighing Printout Pattern E2R System System is active Lock selecting products Printer Port COM1 Code page 1250 Printouts Weighing printout pattern See ch. 16.2.3 Product printout pattern See ch. 16.2.3 Cumulative printout pattern See ch. 16.2.3 Cumulative printout pattern See ch.

-

Page 21: Display

Offset Code length Transponder card reader Port None Additional display Port None Pattern See ch. 16.2.3 *) Not related to „Comparator”. 9.2.5. Display Icon Description Value Text information Displaying pattern See ch. 17.1.1 Font Arial Font size Small Bold Actions F1 Button Choose product F2 Button... -

Page 22: Inputs / Outputs

Screen button 3 Statistics C: Print Screen button 4 CCStatistics : Print Screen button 5 C Statistics : Zero Screen button 6 Choose package Screen button 7 Edit batch number Screen button 8 None Screen button 9 None Left proximity sensor None Right proximity sensor None... -

Page 23: Authorizations

Output 2 None Output 3 None Output 4 None 9.2.7. Authorizations Icon Description Value Anonymous operator Operator Date & Time Administrator Printouts Administrator Databases Products Administrator Contractors Administrator Packages Administrator Warehouses Administrator Labels Administrator Delete older data Advanced Operator 9.2.8. Other Icon Description Value... -

Page 24: User Calibration

Beep Buttons Touch screen calibration 9.2.9. User Calibration An option only for non-verified scale Icon Description Value Platform 1 Setting of start mass Calibration 10. INDICATING WINDOW Main view:... - Page 25 In the main application window one can see four separate parts: • In the top part of the window there is a status bar where a work mode, logged-in user and time&date are displayed and active connection with a computer are displayed. •...

-

Page 26: Logging On

• In operating mode <Weighing> 9buttons are at ones disposal displayed subsequently from 1 to 9 starting from the left side, • In operating modes: <Counting pieces> or <Deviations> one can define up to 7 screen buttons displayed subsequently from 1 to 7 starting from the left side. -

Page 27: Authorization Access Levels

11.3. Authorization access levels Weighing software uses four access levels: administrator, advanced operator, operator, none. Every user with any attributed access level can perform weighings and select data from in databases to be used during weighing. Access to user parameters, databases and working modes depending on the authorization access level attributed: Operator type Access level description... -

Page 28: Navigating Within The Menu

It can be declared in submenu < Authorizations>, which is accessable only for users with the <Administrator> authorization level (see ch. 19 of this manual). 2. A user logged in as <Administrator> in submenu < Authorizations> (see ch. 19 of this manual) can change authorization levels for accessing different databases and functions <... -

Page 29: Return To Weighing

Searching a database according to a name Searching a database according to a code Printing on item from a database Clearing an editing field Screen keyboard on / off Reading a printout pattern from a *.lb file (active after connecting a pendrive) Variables for a printout pattern One level up 12.2. -

Page 30: Weighing

13. WEIGHING Put a load on the weight pan. When pictogram is displayed the indication is ready to read. Notice: A weighing can be saved after stabilising a measurement over zero (pictogram 13.1. Conditions of operational use In order to assure a long term operating period with appropriate measurements following principles should be adhered to: •... -

Page 31: Zeroing

• Avoid side loads, particularly side strokes: 13.2. Zeroing In order to zero the indication choose a platform on the touch panel and press . After zeroing is performed the indication is equal zero and following symbols usually appear: Zeroing is possible only when the indication is stable. Notice: Zeroing is possible only within ±2% of full range around zero. -

Page 32: Inscribing Tare

13.4. Inscribing tare It is possible to inscribe a tare value. Procedure: • While in any work mode press then the screen keyboard is displayed, • Inscribe tare and press • The program returns to weighing and the and the display shows the entered value with the „–”... -

Page 33: Scale Parameters

Notice: The procedure of attributing functions to buttons and proximity sensors is described in ch. 17.2 of this manual. Possible selection: • gram [g] • kilogram [kg] • carat [ct] • pound [lb] • ounce [oz] • Newton [N] 14. SCALE PARAMETERS Users can set the scale according to the ambient conditions (filtering level) or own needs (autozero) and set the LO threshold for minimum load that enables operation of some functions. -

Page 34: Median Filter

14.1. Median filter The median filter is intended for eliminating short-lasting mechanical shocks. Procedure: • Enter < Weighing> according to ch. 14 of the manual, select < Median Filter> and then set an appropriate value. Accessible settings: None - median filter is off 0.5, 1, 1.5, 2, 2.5 - filtering level to choose 14.2. -

Page 35: Minimum Weight For Different Functions (Lo)

If AUTOZERO is disabled zero is not corrected automatically. However, in particular cases, this function can disrupt the measurement process e.g. slow pouring of liquid or powder on the weighing pan. In this case, it is advisable to disable the autozero function. Procedure: •... -

Page 36: Rs 232 Settings

In order to enter < Communication>, press and then „ Parameters / Communication”. 15.1. RS 232 settings Procedure: • Enter < Communication> according to ch.15 of the manual, select < COM1> or < COM2>, and then set an appropriate value. For RS 232 following parameters are accessible: •... -

Page 37: Tcp Protocol Setting

• Go back to weighing saving parameters and restart the device. 15.3. TCP protocol setting TCP (Transmission Control Protocol) is a protocol for communication between two computers. It operates in mode client-server. Server awaits on connection iniciation on a specified port while client initiates connection to the server. -

Page 38: Computer Address

The scale can communicate with a computer via following ports: • RS 232 (COM1), • RS 232 (COM2), • Tcp. 16.1.2. Computer address Procedure: • Enter < Devices> parameter group as described in chapter 16 of the manual, • Choose „ Computer / Address”... -

Page 39: Weighing Printout Pattern

16.1.4. Weighing printout pattern Users in parameter < Weighing Printout Pattern> can define variables included in the printout from the scale to a computer. Procedure: • Enter < Devices> parameter group as described in chapter 16 of the manual, • Choose „ Computer / Weighing Printout Pattern”... -

Page 40: Printer

Procedure: • Enter < Devices> parameter group as described in chapter 16 of the manual, • Choose „ Computer / E2R System / System is active” and then set an appropriate value. Accessible settings: System is not active System is active •... -

Page 41: Printer Code Page

Printers can be attached to: • RS 232 (COM1), • RS 232 (COM2), • USB, • Tcp. 16.2.2. Printer code page Procedure: • Enter parameters < Devices> as described in chapter 16 of the manual, • Choose „ Printer / Code Page”... - Page 42 Screen keyboard on/off Reading a printout pattern from a *.lb file (button active while connecting a USB pendrive) List of variables for printout patterns (see the list in APPENDIX A of this manual) Clear the editing field Default printouts’ settings: Weighing Printout Pattern Product Printout Pattern {50}...

-

Page 43: Barcode Scanner

16.3. Barcode scanner Cooperating with a barcode scanner allows immediate finding of the product in the assortment database the wanted product immediately. Configuration of communication can be configured in < Barcode reader>. Users can set the following things: • Communication port for a barcode scanner, •... -

Page 44: Code Length

• Write a new offset and confirm it by pressing 16.3.3. Code length Number of characters that is considered while searching the assortment database. Procedure: • Enter < Devices> according to ch.16 of the manual, • Choose „ Barcode Scanner / Code Length”... -

Page 45: Procedure Of Attributing The Card Number To An Operator

The scale can communicate with the reader via following ports: • RS 232 (COM1), • RS 232 (COM2). 16.4.2. Procedure of attributing the card number to an operator To use a transponder card to log on an operator the card needs to be ascribed to the operator in the database of operators. -

Page 46: Communication Protocol Frame

Communication with additional displays can be performed via following ports: • RS 232 (COM1), • RS 232 (COM2), • Tcp. 16.5.2. Communication protocol frame PUE 7 weighing indicator with following displays: • WD display, • WWG display. To start cooperation of PUE 7 with displays go to parameter < Sample>... -

Page 47: Display

17. DISPLAY Users can adapt the main display and visible information to their needs. All parameters of the display can be found in the parameters’ group < Display>. Entering < Display> can be made in two ways: • Direct pressing in the work area of the main display, •... -

Page 48: Display Patterns

17.1.1. Display patterns The main application window comprises a work area including information that can be freely configured by a user. Procedure: • Enter < Display> according to ch. 17 of this manual, • Choose: „ Text information / Displaying pattern”, then an editing field with prompted value is displayed together with the screen keyboard, •... -

Page 49: Screen Font

17.1.2. Screen font The font type can be changed in the display workspace. Procedure: • Enter < Display> according to ch. 17 of this manual, • Choose: „ Text information / Font” and set the required font type. Accessible fonts: •... -

Page 50: Function Keys

• Choose: „ Text information / Bold” and choose a setting. Accessible settings: Bold is off Bold is on 17.2. Function keys In submenu < Actions> users can set actions following keys: function keys, screen keys, proximity sensors. If a button has been attributed a function it has been activated at the same time. -

Page 51: Bargraph Type

• By pressing a formerly defined button or proximity sensor < Change platform>. • By activating in parameters all platforms that will be separately placed in the main window of the program. In that case platforms can be activated by pressing the area of this platform. Notice: The procedure of attributing functions to buttons and proximity sensors is described in ch. -

Page 52: Bargraf "Quick Weighing

17.4.1. Bargraf “Quick weighing” • The bargraph consists of 8 red fields and three green fields. • The green fields signal weighings between MIN and MAX threshold, where: MIN = the minimum threshold of acceptable weighing - LO MAX = the maximum threshold of acceptable weighing - HI •... -

Page 53: Inputs / Outputs

• The central green field – signals that the load on the pan is within the set required interval for the weighed product (OK value between Min and Max thresholds); • The right red field – signals that the load on the pan is greater than the maximum weighing threshold (Max threshold). -

Page 54: Configuration Of Outputs

18.2. Configuration of outputs Ascribing a function to the output enables the output at the same time. If an output has no ascribed function it is disabled. Procedure: • Enter < Inputs / Outputs> according to ch. 18 of this manual, •... -

Page 55: Authorization

19. AUTHORIZATION The submenu < Authorization> is accessible only while being logged in as the Administrator. In this group of parameters access levels can be outlined. To enter submenu < Authorization>, press and then „ Parameters / Authorization”. 19.1. Anonymous Operator The program allows to attribute the authorization access level to an operator who does not perform the log-in procedure (anonymous operator). -

Page 56: Printouts

Accessible authorization levels: None, Operator, Advanced Operator, Administrator. Notice: Setting <None> allows free access to settings of date and time (without the need of logging in). 19.3. Printouts Default settings of the scale allows a logged on Administrator to edit printout patterns. -

Page 57: Delete Older Data

Procedure: • Enter parameters’ group < Authorization> according to ch. 19 of the manual, choose < Databases>, and then set the parameter. Accessible authorization levels: None, Operator, Advanced Operator, Administrator. Notice: Setting <None> allows free access to settings of date and time (without the need of logging in). -

Page 58: Languages

20.1. Languages Procedure: • Enter submenu < Others> according to ch. 20 of this manual, choose < Language> and set the parameter. Accessible languages: • Polish, • English, • German, • French, • Russian, • Spanish, • Czech, • Hungarian. 20.2. -

Page 59: Sound Signal

20.3. Sound signal Procedure: • Enter < Others> according to ch. 20 of this manual, < Beep> and set accordingly. Settings: - Sound for buttons and proximity sensors disabled None Buttons - Sound for buttons enabled Sensors - Sound for proximity sensors enabled - Sound for buttons and proximity sensors enabled 20.4. -

Page 60: Calibration Procedure

To enter < Customer Calibration>, press and then „ Parameters / Customer Calibration”. 21.1. Calibration procedure • Enter submenu < Customer Calibration> according to ch. 21 and select: “ Platform 1 / Calibration”, • After entering the parameter the following message box appears: •... - Page 61 • After the procedure of calibration factor determination following command appears: • Return to weighing, saving parameters. < Setting of start mass> parameter allows to adjust start mass of platform 1. Notice: The factory calibration process for platforms 2, 3, 4 is analogical to the one described above.

-

Page 62: Start Mass Adjustment

21.2. Start mass adjustment It is possible to adjust only a start mass, it helps to correct the start zero when the span does not change. Procedure: • Enter submenu < Customer Calibration> according to ch. 21 and select: “ Platform 1 / Setting of start mass”, •... -

Page 63: Special Functions Of Working Modes

22. SPECIAL FUNCTIONS OF WORKING MODES WPY/KB scales can operate in following work modes: Weighing Counting pieces Deviations Comparator In settings of different working modes special functions that allows adopting the operation to the customers’ needs: Counting Special functions: Weighing Deviations Comparator pieces... -

Page 64: Recording Mode

2. The change in on mode results in the same change for other working modes working modes. 22.1. Recording mode Depending on setting parameter < Save Mode> users can send data from the scale to an external device. Procedure: • Enter parameters group < Working modes>... -

Page 65: Checkweighing

22.3. Checkweighing In case of enabling the checkweighing mode, printouts are performed only when a weighing is between MIN and MAX thresholds that have been defined before. Procedure: • Enter parameters group < Working Modes> according to ch. 22 of this manual, •... -

Page 66: Labelling Mode

Total sum Summing up all subsequently entered tare values Autotare Automatic tare mode together with mode <Sum of all> 22.5. Labelling mode The labelling system is intended to print labels for marking weighed goods e.g. a packing process. The program can print standard labels for single products, cumulative labels for sticking to bulk containers and cumulative labels for cumulative labels for sticking to the large transport containers holding bulk containers. -

Page 67: Setting Of The Number Of Cumulative Labels To Print

• Enter the required working mode and choose: „ Labelling mode / Number of labels” then the editing field <Number of labels> with the screen keyboard is opened, • Choose the required number of labels and confirm by pressing 22.5.2. Setting of the number of cumulative labels to print In the parameter <... -

Page 68: Automatic Triggering Of Cumulative Labels

• Enter the required number od cumularive labels and confirm by pressing 22.5.4. Automatic triggering of cumulative labels Users have access to the function of automatic triggering of printing cumulative labels after setting parameters < Mode> and < Threshold>. Procedure: •... -

Page 69: Automatic Triggering Cumulative Labels Of Cumulative Labels

By default setting button is accessible in the bottom part of the display but activating the button can be done in subm enu: „ Parameters / Display / Actions” (see ch. 17.2 of the manual). For automatic printout of cumulative labels counters and total mass variables are always zeroed. - Page 70 None Cumulative label of cumulative labels printout is initiated by pressing Cumulative label of cumulative labels printout is initiated by Mass exceeding the value set in parameter < Threshold>. The value is treated as the total from single weighings, Number Cumulative label of cumulative labels printout is initiated by exceeding the value set in parameter <...

-

Page 71: Statistics

• Confirm the changes introduced by pressing 22.6. Statistics All statistics are continuously updated after each measurement is saved in the scale memory. Statistics can be calculated globally (does not depend on the selected product) or separately for every product from the assortment database. -

Page 72: Minimum Reference Mass

Options: Automatic correction of reference mass disabled Automatic correction of reference mass enabled Function < Automatic correction of reference mass> in mode < Counting Pieces> is enabled at the moment of estimating the sample quantity and signalled by displaying <PCS> and <SMP> (single piece mass) on the top part of the display. -

Page 73: Selecting The Series Type

• Choose „ Counting pieces / Minimum reference mass” and then set an appropriate value. Accessible settings: 1 d, 2 d, 5 d, 10 d. Notice: While the procedure of evaluation the mass of single piece the the mass of all pieces put on the pan is lower than the value declared in parameter „... -

Page 74: Work Mode - Weighing

23. WORK MODE - WEIGHING The < Weighing> mode is the standard working mode allowing to perform weighings and saving them in the database < Weighings / Alibi>. 23.1. Starting the working mode The < Weighing> mode is the standard working mode. If a user has changed the operating mode to another follow the actions below: •... -

Page 75: Setting A Reference Unit By Entering Known Piece Mass

• The weight unit is automatically changed to „pcs” and two screen buttons on the right side appear: Enter piece mass Estimate piece mass 24.2. Setting a reference unit by entering known piece mass Procedure: • Enter mode < Counting Pieces> according to ch. 24.1 of this manual, •... -

Page 76: Setting The Reference Mass By Entering Single Piece Mass Directly To The Database

• Enter a value and confirm it by pressing , then the following message is displayed: <Put pieces: xx> (where xx – the value entered before), • Put the declared quantity of pieces on the pan and when the result is stable (symbol ) confirm it by pressing •... -

Page 77: Working Modes - Deviations

a) Estimate the unit mass (see 24.2 and 24.3), b) Enter the products database c) Keep the finger pressed on the required position then a context menu is displayed, d) Choose option <Ascribe standard>, then the standard unit mass is attributed to the product in the field <Mass>. Notice: Attributing a standard to a selected product is also possible by programmable button. -

Page 78: Reference Unit Mass Estimated By Weighing

25.2. Reference unit mass estimated by weighing Procedure: • Enter < Deviations> according to ch. 25.1 of this manual, • If the standard is to be weighed in a container, the container needs to be put on the pan and tarred, •... - Page 79 The results are calculated according the tables below: For an ABBA series D = B – A ….. … For an ABA series D = B – A ….. … The standard deviation is calculated as follows: • Differences ABBA or ABA series is calculated: −...

-

Page 80: Starting The Working Mode

26.1. Starting the working mode Procedure: • While in the main window press in the top bar, then you will see a submenu <Working modes> comprising a list of modes, • Choose mode < Comparator>, program automatically returns to the main window displaying in the top bar the name of selected working mode, •... - Page 81 Scale parameters - Weighing Icon Description Value Platform 1 Median Filter None Filter Slow Autozero LO threshold Working modes - Comparator – Komparator Icon Description Value Comparator Save Mode Automatic first stable Checkweighing Tare mode Single Statistics Global Method ABBA Number of measurements Ask for numbers of standards 3.

- Page 82 5. After about 2 minuts a weighing result appears on the display additionally accompanied by a beep sound lasting for about 2 secunds. 6. After the stabilization process the comparator performs a measurement in mode „Automatic first stable”. 7. After getting the first measurement unload the pan taking off the weight “A”.

- Page 83 • After about 2 minuts a weighing result appears on the display additionally accompanied by a beep sound lasting for about 2 secunds. • After the stabilization process the comparator performs a measurement in mode „Automatic first stable”. (pictogram appears). •...

- Page 84 • Load againg standard weight “A” and the device enters the stabilization process showing “-----“, • After about 2 minuts a weighing result appears on the display additionally accompanied by a beep sound lasting for about 2 sekunds, • After the stabilization process the comparator performs a measurement in mode „Automatic first stable”.

-

Page 85: Databases

27. DATABASES PUE 7 databases hold different data: Products Operators Weighings / Alibi Contractors Comparisons Packages Warehouses Labels Universal variables In order to enter < Databases>, press and choose < Databases>. 27.1. Searching databases Users can quickly search databases according to the following criteria: •... -

Page 86: Quick Name Search

27.1.1. Quick name search Procedure: • Enter < Databases> according to ch. 27 of the manual, • Enter < Products>, • Press , then an editing field appears <Search by name> with the screen keyboard, • Inscribe the name of a product or its part and press •... -

Page 87: Adding New Items In Databases

27.2. Adding new items in databases Procedure: • Enter < Databases> according to ch. 27 of this manual, • Enter database < Products>, • Press , then the message is displayed: <Create new record?>, • Confirm it by pressing , the program automatically enters edition of new record. -

Page 88: Printing Items From Databases

Procedure: • Enter the submenu < Databases> according to ch. 27 of the manual, • Enter < Delete older data>, then an editing field is displayed <Give year> with the screen keyboard, • Give a date before which data need to be removed and confirm it by pressing Caution: If a user enters a date from the protected period the program displays... - Page 89 Procedure: • Connect a pendrive to USB, • Enter submenu < Databases> according to ch. 27 of this manual, • Enter option < Export database of weighings to a file>, the program automatically starts saving the database on the pendrive, Notice: In case a pendrive is not recognized after entering <...

-

Page 90: Database Edition

27.7. Database edition The database edition can be performed by an administrator. 27.7.1. Operators’ database Procedure: • Enter < Databases> according to ch. 27 of this manual, • Enter < Operators> and press the required position. Record of operator: Name Operator name Code Operator code... -

Page 91: Database Of Weighings / Alibi

Mass Nominal product mass Minimum mass for checkweighing Maximum mass for checkweighing Tare value (it is preset automatically after Tare selecting a product) Price Unit price Number of validity Number of days to calculate expiery date dates Date Constant product date Value Added Tax in [%] Ingredients Dialogue box for entering ingredients... -

Page 92: Database Of Contractors

Weighing record: Date Weighing date Mass Weighing result Tare Tare value Product Product name Operator Operator name Contractor Contractors name Batch number Number of produced batch Source warehouse Source warehouse name Target warehouse Target warehouse name Package Package name Checkweighing A weighing threshold (MIN, OK or MAX) Platform number Platform number to perform weighings... -

Page 93: Database Of Packages

Contractor record: Name Contractor’s name Code Contractor’s code Tax ID Contractor’s tax ID Address Contractor’s address Postal code Contractor’s postal code City Town/City of contractor Discount Contractor’s discount Label Contractor’s label pattern 27.7.5. Database of packages Procedure: • Enter < Databases>... -

Page 94: Database Of Warehouses

27.7.6. Database of warehouses Procedure: • Enter < Databases> according to ch. 27 of this manual, • Enter < Warehouses> and press the required position. Warehouse record: Name Warehouse name Code Warehouse code Description Additional warehouse description 27.7.7. Database of labels The database comprises patterns of labels which users can attribute to products or contractors to operate in labelling mode. -

Page 95: Database Of Universal Variables

28. COMMUNICATION PROTOCOL 28.1. General information A. A character protocol scale-terminal has been designed for communication between RADWAG scales and external devices via RS-232 interface. B. It consists of commands sent from an external device to the scale and a responses from a scale. -

Page 96: Inventory Of Rs Commands

28.2. Inventory of RS commands Commands Description of commands Zeroing Tarring Get tare value Set tare value Send the stable result in basic unit Send the result immediately in basic unit Send immediate results from all platforms in basic units Send the stable result in current unit Send the result immediately in current unit Switch on continuous transmission in basic unit... -

Page 97: Respond Message Format

28.3. Respond message format After sending a request message you can receive: XX_A CR LF command accepted and in progress XX_D CR LF command completed (appears only after XX_A) XX_I CR LF command comprehended but cannot be executed XX _ ^ CR LF command comprehended but time overflow error appeared XX _ v CR LF command comprehended but the indication below the... -

Page 98: Get Tare Value

T_A CR LF - command accepted and in progress T_D CR LF - command completed T_A CR LF - command accepted and in progress T_v CR LF - command comprehended but tare range overflow appeared T_A CR LF - command accepted and in progress T_E CR LF - time limit for stable result exceeded T_I CR LF... -

Page 99: Send The Stable Result In Basic Unit

28.4.5. Send the stable result in basic unit Syntax: S CR LF Possible answers: S_A CR LF - command accepted and in progress S_E CR LF - time limit for stable result exceeded S_I CR LF - command comprehended but cannot be executed S_A CR LF - command accepted and in progress MASS FRAME... -

Page 100: Send Immediate Results From All Platforms In Basic Units

Example: S I CR LF – computer command S I _ ? _ _ _ _ _ _ _ 1 8 . 5 _ k g _ CR LF - command done, mass value in basic unit is returned immediately. 28.4.7. -

Page 101: Send The Result Immediately In Current Unit

Possible answers: SU_A CR LF - command accepted and in progress SU_E CR LF - timeout while waiting for stable results SU_I CR LF - command comprehended but cannot be executed SU_A CR LF - command accepted and in progress MASS FRAME - mass value in current unit is returned Frame format:... -

Page 102: Switch On Continuous Transmission In Basic Unit

28.4.10. Switch on continuous transmission in basic unit Syntax: C1 CR LF Possible answers: C1_I CR LF - command comprehended but cannot be executed C1_A CR LF - command comprehended and in progress MASS FRAME - mass value in basic unit is returned Frame format: 7-15 space... -

Page 103: Switch Off Continuous Transmission In Current Unit

28.4.13. Switch off continuous transmission in current unit Syntax: CU0 CR LF Possible answers: CU0_I CR LF - command comprehended but cannot be executed CU0_A CR LF - command comprehended and executed 28.4.14. Set lower threshold Syntax: DH_XXXXX CR LF, where: XXXXX – mass format Possible answers: DH_OK CR LF - command executed... -

Page 104: Read Upper Threshold

Mass - 9 characters justified to the right Unit - 3 characters justified to the left 28.4.17. Read upper threshold Syntax: OUH CR LF Possible answers: UH_MASA CR LF - command executed Frame format: 4-12 space mass space unit space Mass - 9 characters justified to the right Unit... -

Page 105: Connecting External Devices

Format frame: 4 -12 stability space sign mass space unit Stability character [space] if stable [?] if not stable [^] if an indication over the range [v] if fan indication below the range sign [space] for positive values or [-] for negative values mass 9 characters justified to the right 3 characters justified to the left... - Page 106 Scale – computer cable Scale – Kafka printer cable Scale – printer (CITIZEN, EPSON) cable...

-

Page 107: Technical Parameters

Scale – I/O cable 31. TECHNICAL PARAMETERS Technical data: WPY 200/KB Max capacity 210kg 1g (for mass standards 100kg) Readability 2g (for mass standards 200kg) 1g (for mass standards 100kg) Repeatability * 2g (for mass standards 200kg) Electric compensation range 0 ÷... - Page 108 Technical data: WPY 500/KB Max capacity 510kg 2g (for mass standards 200kg) Readability 5g (for mass standards 500kg) 2g (for mass standards 200kg) Repeatability * 4g (for mass standards 500kg) Electric compensation range 0 ÷ 510 kg Supplementary weights none Stabilization time 120 s Adjustment / calibration...

-

Page 109: Error Messages

32. ERROR MESSAGES Value beyond the zero range, Err2 Err3 Value beyond the tare range, Err8 Tarring / zeroing operation time exceeded, NULL Zero value from the AD converter, FULL Measurement range overflow, Display range overflow, Start mass error, the mass on the weighing platform is beyond the acceptable range (-5% to +15% of start mass) 33. -

Page 110: Appendix A - Variables For Printouts

34. APPENDIX A – Variables for printouts 34.1. Inventory of variables Notice: Every variable needs to be included in brace brackets e.g. {x}, where x – variable number. A list of variables accessible in the system for defining printout patterns and data displayed in the workspace of scale’s screen: Description Symbol Standard printout in calibration unit... - Page 111 {22} Cumulative of Cumulative Statistics: Average {23} Cumulative of Cumulative Statistics: Minimum {24} Cumulative of Cumulative Statistics: Maximum {25} Mass: lb {26} Checkweighing {27} Value to pay {28} C Value (cumulative amount to pay) {29} CC value (cumulative of cumulatives amount to pay) {30} Gross (amount to pay + VAT) {31}...

- Page 112 {63} Product: Density {64} Product: Ingredients {65} Product: Description {75} Operator: Name {76} Operator: Code {77} Operator: Access level {80} Package: Name {81} Package: Code {82} Package: Mass {85} Contractor: Name {86} Contractor: Code {87} Contractor: Tax ID {88} Contractor: Address {89} Contractor: Postal code {90}...

- Page 113 {115} CPG Report: Limit of the average {116} CPG Report: Standard deviation {117} CPG Report: Measurements {118} CPG Report: Unit {119} CPG Report: Report Number {120} Average Tare Report: Date {121} Average Tare Report: Result {122} Average Tare Report: Standard deviation {123} Average Tare Report: 0.25T1 {124}...

-

Page 114: Formatting Variables

34.2. Formatting variables Users can format numeric, text and date variables intended for displaying or printing out. Different format commands: • Justification to the left, • Justification to the right, • Setting the number of characters for printout / display, •... - Page 115 Date separator between days, {2:yy/MM/dd} – Present date formatted as: months and years year - month - day, where yy represents two less significant digits of year. „Escape” character removing {2:yy\/MM\/dd} – Present date formatted as formatting function form next yesr / month / day;...

-

Page 116: Appendix B - Functions Of Programmable Buttons

35. APPENDIX B – Functions of programmable buttons Icon Function name Print Zero Tare Enter tare Parameters Local Parameters Set MIN and MAX Statistics (cumulative) : Print and zero Statistics (cumulative) : Print Statistics (cumulative) : zero Statistics (cumulative of cumulative) : Print and zero Statistics (cumulative of cumulative) : Print... - Page 117 Statistics (cumulative of cumulative) : zero Edit batch number Start Stop Choose an operator Choose an operator by name Choose an operator by code Choose a product Choose a product by name Choose a product by code Choose a package Choose a package by name Choose a package by code...

- Page 118 Choose a contractor Choose a contractor by name Choose a contractor by code Choose a source warehouse Choose a source warehouse by name Choose a source warehouse by code Choose a target warehouse Choose a target warehouse by name Choose a target warehouse by code Change working mode Counting pieces: Specify piece mass Counting pieces: Estimate piece mass...

- Page 119 Deviations: Specify sample mass Deviations: Estimate sample mass Emergency stop Chute permission Disable tare Restore tare Change unit Change platform Edit universal variable 1 Edit universal variable 2 Edit universal variable 3 Edit universal variable 4 Edit universal variable 5...

-

Page 120: Appendix C - Label Pattern

36. APPENDIX C – Label pattern A label pattern can be created in 2 ways: • From the terminal level using variables, • Using PC software EDYTOR ETYKIET R01. A created project needs to be saved as an „lb” file then copied on a pendrive that can be connected to the terminal. -

Page 121: Designing A Label On A Computer

Let us create a label pattern for the label below: Notice: The installer of EDYTOR ETYKIET R01 is accessible to download on website: www.radwag.com. on the overlap: Products / Measuring indicators / PUE7. Procedure: 1. Run software EDYTOR ETYKIET R01, 2. - Page 122 Notice: Before starting the design process the label and printer parameters need to be set. The settings are described in the file: Help / Help / Program options / Settings. . Then following window appears: 4. To add a text in the label click on 5.

- Page 123 6. Click on the key and in the field <Text> inscribe: {4} (date & time), confirm by pressing and place it in the right place, 7. Place other texts and variables on the label in the same way as the one shown above. 8.

-

Page 124: Saving Label Patterns In The Scale

11. In place <Codebar value> write variable: {7:V6.3} (net mass for EAN13, 6-character code with three decimal characters), confirm it by pressing then place the code in the right place in the label. 12. Record the design of the label by selecting <File> in software menu and then <Save as lb –... -

Page 125: Attributing A Label To A Product

36.4. Attributing a label to a product Procedure: • Enter < Databases> according to ch. 27 of this manual, • Enter < Products> and press the required item. • Enter < Label>, then the database of labels is open with the list of all labels, •... -

Page 126: Appendix D - Citizen Printer Setting

2. Users can perform the test label printout – see ch. 27.5 of this manual. 37. APPENDIX D - CITIZEN printer setting Baud rate : 9600b/sec Parity control : No Number of data bits : 8bit Number of stop bits : 1 bit Flow control : No... -

Page 127: Appendix F - Communication With Barcode Scanners

39. APPENDIX F - Communication with barcode scanners 1. For communication with barcode scanners RADWAG scales use RS232 interfaces and simplex transmission (one direction) without handshaking. Only two wires are required for assuring such a transmission. Used scanners should be equipped in such interface with disabled both hardware and software handshaking. - Page 128 O F E L E C T R O N I C W E I G H I N G I N S T R U M E N T S RADWAG WAGI ELEKTRONICZNE 26 – 600 Radom, Bracka 28 Street POLAND Phone +48 48 38 48 800, phone/fax.

Need help?

Do you have a question about the WPY/KB series and is the answer not in the manual?

Questions and answers