Westermo Lynx SERIES User Manual

Industrial ethernet 8-port switch

Hide thumbs

Also See for Lynx SERIES:

- Management manual (1123 pages) ,

- User manual (32 pages) ,

- User manual (28 pages)

Summary of Contents for Westermo Lynx SERIES

- Page 1 User Guide 6640-2001 Lynx S E R I E S Industrial Ethernet 8-port Switch www.westermo.com...

-

Page 2: Legal Information

Legal information The contents of this document are provided “as is”. Except as required by applicable law, no warranties of any kind, either express or implied, including, but not limited to, the implied warranties of merchantability and fitness for a particular purpose, are made in relation to the accuracy and reliability or contents of this document. Westermo reserves the right to revise this document or withdraw it at any time without prior notice. Under no circumstances shall Westermo be responsible for any loss of data or income or any special, incidental, and consequential or indirect damages howsoever caused. More information about Westermo can be found at the following Internet address: http://www.westermo.com 6640-2001... -

Page 3: Before Installation

Safety Before installation: Read this manual completely and gather all information on the unit. Make sure that you understand it fully. Check that your application does not exceed the safe operating specifications for this unit. This unit should only be installed by qualified personnel. This unit should be built-in to an apparatus cabinet, or similar, where access is restricted to service personnel only. The power supply wiring must be sufficiently fused, and if necessary it must be possible to disconnect manually from the power supply. Ensure compliance to national installation regulations. This unit uses convection cooling. To avoid obstructing the airflow around the unit, follow the spacing recommendations (see Cooling section). Before mounting, using or removing this unit: Prevent access to hazardous voltage by disconnecting the unit from power supply. Warning! Do not open connected unit. Hazardous voltage may occur within this unit when connected to power supply. Class 1 Laser Product Do not look directly into fibre optical fibre port or any connected fibre although this unit is designed to meet the Class 1 Laser regulations. Care recommendations Follow the care recommendations below to maintain full operation of unit and to fulfil the warranty obligations. This unit must not be operating with removed covers or lids. Do not attempt to disassemble the unit. There are no user serviceable parts inside. Do not drop, knock or shake the unit, rough handling above the specification may cause damage to internal circuit boards. Do not use harsh chemicals, cleaning solvents or strong detergents to clean the unit. Do not paint the unit. Paint can clog the unit and prevent proper operation. Do not expose the unit to any kind of liquids (rain, beverages, etc). The unit is not water- proof. Keep the unit within the specified humidity levels. Do not use or store the unit in dusty, dirty areas, connectors as well as other mechanical part may be damaged. If the unit is not working properly, contact the place of purchase, nearest Westermo dis- tributor office or Westermo Tech support. Fibre connectors are supplied with plugs to avoid contamination inside the optical port. As long as no optical fibre is mounted on the connector, e.g. for storage, service or transportation, should the plug be applied. 6640-2001... -

Page 4: Agency Approvals And Standards Compliance

Note. Fibre Optic Handling Fibre optic equipment needs special treatment. It is very sensitive to dust and dirt. If the fibre will be disconnected from the modem the protective hood on the transmitter/ receiver must be connected. The protective hood must be kept on during transportation. The fibre optic cable must also be handle the same way. If this recommendation not will be followed it can jeopardise the warranty. Cleaning of the optical connectors In the event of contamination, the optical connectors should be cleaned by the use of forced nitrogen and some kind of cleaning stick. Recommended cleaning fluids: • Methyl-, ethyl-, isopropyl- or isobutyl-alcohol • Hexane • Naphtha Maintenance No maintenance is required, as long as the unit is used as intended within the specified conditions. Agency approvals and standards compliance Type Approval / Compliance EN 61000-6-2, Immunity industrial environments EN 55024, Immunity IT equipment EN 61000-6-3, Emission residential environments FCC part 15 Class B EN 50121-4, Railway signalling and telecommunications apparatus IEC 62236-4, Railway signalling and telecommunications apparatus Safety EN 60950-1, IT equipment FCC Part 15.105 Notice: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a residential installation. This equipment generates, uses and can radiate radio frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference will not occur in a partic- ular installation. If this equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment off and on, the user is encouraged to try to correct the interference by one or more of the following measures: … Reorient or relocate the receiving antenna … Increase the separation between the equipment and receiver … Connect the equipment into an outlet on a circuit different from that to ... -

Page 5: Declaration Of Conformity

Declaration of Conformity CE Certificate of Conformity Westermo OnTime AS declares that the listed products conform to the Council Directives and standards: 73/23/EEG Low Voltage Directive (LVD) 89/336/EEG Electromagnetic Compatibility (EMC –directive) EN 61000-2 EN 61000-6-2 EN 61000-6-4 EN 50121-4 EN 50121-3-2 (except conducted measurement values) -

Page 6: Type Tests And Environmental Conditions

Type tests and environmental conditions Environmental phenomena Basic standard Description Test levels EN 61000-4-2 Enclosure contact ± 6 kV Enclosure air ± 8 kV RF field AM modulated IEC 61000-4-3 Enclosure 20 V/m 80% AM (1 kHz), 80 – 2 000 MHz RF field 900 MHz ENV 50204 Enclosure 20 V/m pulse modulated 200 Hz, 900 ± 5 MHz Fast transient EN 61000-4-4 Signal ports ± 2 kV Power ports ± 2 kV Surge EN 61000-4-5 Signal ports ± 2 kV line to earth, ± 2 kV potential difference Power ports ± 2 kV line to earth, ± 2 kV line to line RF conducted EN 61000-4-6 Signal ports 10 V 80% AM (1 kHz), 0.15 – 80 MHz Power ports 10 V 80% AM (1 kHz), 0.15 – 80 MHz Power frequency magnetic field EN 61000-4-8 Enclosure 1000 A/m, 50 Hz Pulse magnetic field EN 61000-4-9 Enclosure... - Page 7 Description Lynx is a range of switches consisting of three different function levels and four different type approvals, giving you the ability to select the perfect switch for your application providing optimum functionality at the best value. Our unique FRNT (Fast Recovery of Network Topology) technology is the fastest proto- col on the market to re-configure a network in the event of any failure of a link or hard- ware. That is why the Lynx-series is used in safety critical applications such as tunnels, traffic signal control and railway systems. Installations in harsh environments and places with heavy electrical interference demand the use of a reliable media. The Lynx-series provides a number of solutions using fibre optic transceivers. Multi- or singlemode transceivers can be used to build point-to-point or redundant ring networks with ranges up to 120 km between each switch. Our BIDI transceiver, which transmits and receives data on a single fibre can be used in applications where the number of fibre cores is limited. Real-time properties are implemented in the Lynx-series in order to achieve determinism for real time critical applications. The Lynx-switches supports QoS (Quality of Service) with four priority queues and strict priority scheduling as well as HoL (Head of Line Blocking Prevention). All to assure that the data network is deterministic. 6640-2001...

-

Page 8: Interface Specifications

Interface specifications Power Operating voltage 19 to 60 VDC Rated current 146 mA @ 24 VDC 80 mA @ 48 VDC Rated frequency Inrush current, I 49·10 A s @ 48 VDC Startup current* 250 mA @ 24 VDC Polarity Reverse polarity protected Redundant power input Isolation to All other Connection Detachable screw terminal Connector size 0.2 – 2.5 mm (AWG 24 – 12) Shielded cable Not required * External supply current capability for proper startup Ethernet TX Electrical specification IEEE std 802.3. 2000 Edition Data rate 10 Mbit/s, 100 Mbit/s, manual or auto Duplex Full or half, manual or auto Circuit type SELV Transmission range 150 m, according to long cable specification Isolation to Power ... - Page 9 Ethernet SFP pluggable connections (FX or TX) Electrical specification IEEE std 802.3. 2000 Edition Data rate 100 Mbit/s, 1000 Mbit/s manual or auto Duplex Full or half, manual or auto Circuit type SELV Transmission range Depending on tranceiver Isolation to Power Connection TX connectors: RJ-45 shielded, auto MDI/MDI-X FX connectors: LC Shielded cable Not required Conductive housing Isolated to all other circuits Number of ports 1 or 2 Status relay Contact resistance 25 Ω Isolation to 1500 VDC Connection Detachable screw terminal Connector size 0.2 – 2.5 mm (AWG 24 – 12) 6640-2001...

- Page 10 Optical Power Budget The allowed link length is calculated from the optical power budget (OPB), the available optical power for a fibre-optic link, and the attenuation of the fibre, comprising losses due to in-line connectors, splices, optical switches and a margin for link ageing (typical 1.5 dB for 1300 nm). The worst-case optical power budget (OPB) in dB for a fibre-optic link is determined by the differ- ence between the transmitter’s output optical power (min) and the receiver input sensitivity (max). FX (Fibre) SM-LC80 SM-LC40 SM-LC15 MM-LC2 Fibre connector LC duplex LC duplex LC duplex LC duplex Fibre type Singlemode Singlemode Singlemode Multimode, 9/125 mm 9/125 mm 9/125 mm 62.5/125 and 50/125 mm Wavelength 1550 nm 1310 nm 1310 nm 1310 nm Transmitter –5/0 dBm** –5/0 dBm** –15/–8 dBm** –20/–14 dBm* Output optical power min/max Receiver –34 dBm –34 dBm –31 dBm –31 dBm Input sensitivity, max...

-

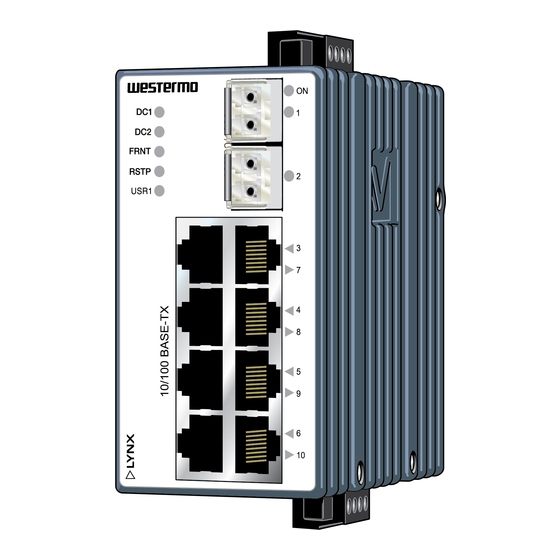

Page 11: Location Of Interface Ports And Led's

Location of interface ports and LED’s LED Indicators (for details see page 12) Power, screw terminal (for details see below) FX(Fibre) (for details see page 10) Ethernet connection TX (6 ports) Contact Signale Direction Description No.1 In/Out Transmitted/Received data No. 2 TD– In/Out Transmitted/Received data No. 3 In/Out Transmitted/Received data No. 4 – Not Connected No. 5 – Not Connected No. 6 RD– In/Out Transmitted/Received data No. 7 – Not Connected No. 8 – Not Connected Shield HF-connected Fault contact (for details see below) NOTE! Railway installation close to the rails. For a cable located inside 3 m boundary and connected to this ... -

Page 12: Led Indicators

LED indicators Status Description Unit has no power DC 1 GREEN Internal power ok DC 2 RED Initialisation progressing FRNT ST 1 FLASH Connected to IP Configuration tool ST 2 Unit has no power on +DC1 GREEN Internal DC1 power is ok Unit is unconnected Unit has no power on +DC2 GREEN Internal DC2 power is ok Unit is unconnected FRNT FRNT is not enabled or not supported GREEN FRNT is running and the switch is con- figured as member switch in the ring. GREEN FLASH FRNT is running and the switch is con- figured as Focal Point FRNT Error ST 1 GREEN Indicates STP root ST 2 1 to 8 No Link GREEN... - Page 13 Configuration The units can easily be configured via the onboard Web based configuration tool. Local IP addresses can also be configured by using the Westernmo IP Configuration tool, from the IP Configuration tool it is then possible to browse into the unit for further configuration. IP Address When delivered, the default IP address of the Lynx is 192.168.2.85. Default gateway 192.168.2.85 If the default address of the unit is valid in the connected network it is possible to access the unit directly from a web browser. Change local IP address The local address of Lynx can be configured using the IP Configuration tool, then it is possible to browse into the unit for further configuration. The IP Configuration program is available on the CD or for download from the WESTERMO web page: http://www.westermo.com, (choose Downloads/Software/Ethernet/ Name: setup.exe Install the software and start the application from a PC on the network connected to the same network as the Lynx. Make sure that the Default IP of the configuration soft- ware (see figure below) is in the same subnet as your PC. Note! If you are not sure about the subnet – consult your network administrator. Note! IP Config version must be 9.8.4 or higher. IP configuration 192. 168. 2. 85 Mask: 255. 255. 255. Default IP: Help About Device list: IP Adress Subnet Mask MAC Adress...

- Page 14 By clicking the “Scan for switches” button the IP Configuration tool will detect the switches/routers in the network. The software will list all Westermo managed switches or routers connected to the network. Information as in the figure 1 will appear for each detected unit connected to the same network as your PC. IP configuration If you only want to change the IP address and the subnet mask, this Access switch via web? can be done within the IP config tool. Cancel By clicking the listed Lynx that you wish be re-configured you will be Figure 2 asked if you would like to access via web figure 2. Click the abort button, enter the preferred IP address, Subnet mask and IP gateway address and click the Set button to confirm the settings in the unit (see figure 3). Note! If you are not sure about the settings – consult your network administrator. Click the Close button to get back to main view. Selected Device You will then be asked if you would like to quit. Lynx configuration Click the OK button, figure 4, and you will be back to the main view of the IP Configuration 2 200 IP adress: program(see figure 1). 255 255 Subnet mask: 00 07 7C 80 4A 6C...

- Page 15 Log in via Web Westermo - location - Provided by Westermo UK http://192.168.2.200/conf/p.cgi Google You will be prompted with a Login screen where File Edit View Favorites Tools Help the default settings for Username and Password are: Home Feeds (J) Print Page Tools Feeds (J) Westermo - location Username: admin Password: westermo L o g i n Username: Password: Figure 5...

- Page 16 Mounting This unit should be mounted on 35 mm DIN-rail, which is horizontally mounted inside an apparatus cabinet, or similar. Snap on mounting, see figure. Cooling This unit uses convection cooling. To avoid obstructing the airflow around the unit, use the following spacing rules. Minimum spacing 25 mm (1.0 inch) above /below and 10 mm (0.4 inches) left /right the unit. Spacing is recommended for the use of unit in full operat- ing temperature range and service life. Removal Press the device upwards to compress locking spring, tilt forward to unhook device from DIN-rail. 6640-2001...

- Page 20 Westermo Data Communications GmbH Svalgången 1 Goethestraße 67, 68753 Waghäusel SE-724 81 Västerås Tel.: +49(0)7254-95400-0 • Fax.:+49(0)7254-95400-9 Phone: +46 (0)16 42 80 00 • Fax: +46 (0)21 35 18 50 E-Mail: info@westermo.de info.sverige@westermo.se Westermo Data Communications S.A.R.L. Westermo OnTime AS 9 Chemin de Chilly 91160 CHAMPLAN Gladsvei 20 0489 Oslo, Norway Tél : +33 1 69 10 21 00 • Fax : +33 1 69 10 21 01 Phone +47 22 09 03 03 • Fax +47 22 09 03 10 E-mail : infos@westermo.fr E-mail: contact@ontimenet.com Westermo Data Communications Pte Ltd Westermo Data Communications Ltd 2 Soon Wing Road #08-05 Talisman Business Centre • Duncan Road Soon Wing Industrial Building Park Gate, Southampton • SO31 7GA Singapore 347893 Phone: +44(0)1489 580-585 • Fax.:+44(0)1489 580586 Phone +65 6743 9801 • Fax +65 6745 0670 E-Mail: sales@westermo.co.uk E-mail: earnestphua@westermo.com.sg Westermo Teleindustri AB have distributors in several countries, contact us for further information.

Need help?

Do you have a question about the Lynx SERIES and is the answer not in the manual?

Questions and answers