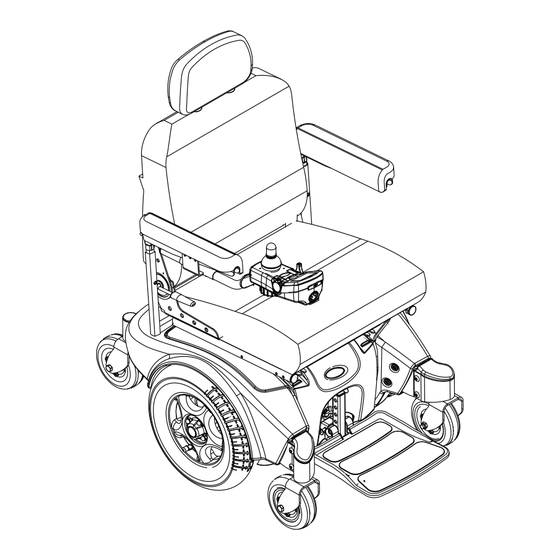

Invacare Pronto M94 Owner's Manual

With surestep

Hide thumbs

Also See for Pronto M94:

- Owner's manual (80 pages) ,

- Brochure & specs (4 pages) ,

- Service manual (132 pages)

Table of Contents

Advertisement

Quick Links

Download this manual

See also:

Service Manual

Owner's Operator and Maintenance Manual

Pronto

M94

®

™

®

with SureStep

DEALER: This manual MUST be given to

the user of the product.

USER: BEFORE using this product, read this

manual and save for future reference.

For more information regarding

Invacare products, parts, and services,

please visit www.invacare.com

Advertisement

Table of Contents

Troubleshooting

Subscribe to Our Youtube Channel

Summary of Contents for Invacare Pronto M94

-

Page 1: Pronto M94

® with SureStep DEALER: This manual MUST be given to the user of the product. USER: BEFORE using this product, read this manual and save for future reference. For more information regarding Invacare products, parts, and services, please visit www.invacare.com... -

Page 2: Reference Documents

ACCESSORIES WARNING Invacare products are specifically designed and manufactured for use in conjunction with Invacare accessories. Accessories designed by other manufacturers have not been tested by Invacare and are not recommended for use with Invacare products. REFERENCE DOCUMENTS MANUAL PART NUMBER MK6i™Electronics Field Service Guide... -

Page 3: Table Of Contents

TABLE OF CONTENTS TABLE OF CONTENTS REFERENCE DOCUMENTS ..............2 REGISTER YOUR PRODUCT ............... 6 SPECIAL NOTES ................7 LABEL LOCATIONS ................9 TYPICAL PRODUCT PARAMETERS ..........10 SECTION 1—GENERAL GUIDELINES ..........11 Controller Settings/Repair or Service ....................11 Accessories Information .........................11 Operation Information ..........................11 Batteries..............................13 Charging Batteries ..........................13... - Page 4 TABLE OF CONTENTS TABLE OF CONTENTS SECTION 5—WHEELCHAIR OPERATION ........... 30 Operating the Wheelchair........................30 Turning the Power On/Off ........................30 Using the Joystick to Drive the Wheelchair..................31 SPJ+, MK6i SPJ+ w/PSS and MK6i SPJ+ w/ACC Joystick Switches and Indicators ....32 On/Off Button ............................32 Speedometer............................32 Speed Control Buttons........................33 Joystick..............................33...

- Page 5 TABLE OF CONTENTS TABLE OF CONTENTS SECTION 7—SEAT ................48 Adjusting the Headrest ...........................48 Adjusting the Back Angle ........................48 Van Seat Model.............................48 Adjustable Seat Back Angle (ASBA) Model..................49 Removing/Installing the Seat Assembly....................50 Removing ...............................50 Installing..............................50 Adjusting the Seat Height ........................51 Adjusting Seat Position on Seat Frame....................52 ASBA Model ............................52 Van Seat Model.............................52...

-

Page 6: Register Your Product

Register ONLINE at warranty.invacare.com Please have your model number and purchase date available to complete your registration. Any registration information you submit will only be used by Invacare Corporation and protected as required by applicable laws and regulations. Pronto® M94™... -

Page 7: Special Notes

CHANGE WITHOUT NOTICE. WHEELCHAIR USER As a manufacturer of wheelchairs, Invacare endeavors to supply a wide variety of wheelchairs to meet many needs of the end user. However, final selection of the type of wheelchair to be used by an individual rests solely with the user and his/her healthcare professional capable of making such a selection. - Page 8 WARNING The drive behavior initially experienced by the user may be different from other chairs previously used. This Power Wheelchair has Invacare’s SureStep technology, a feature that provides the chair with optimum traction and stability when driving forward over transitions and thresholds of up to 2-inches. The following warnings apply specifically to the SureStep Feature.

-

Page 9: Label Locations

LABEL LOCATIONS LABEL LOCATIONS NOTE: The serial number label is located on the inside of the right rear frame. Part No 1122145 Pronto® M94™... -

Page 10: Typical Product Parameters

TYPICAL PRODUCT PARAMETERS TYPICAL PRODUCT PARAMETERS 18-INCH 20-INCH 22-INCH 24-INCH ASBA SEAT VAN SEAT VAN SEAT VAN SEAT VAN SEAT SEAT WIDTH RANGE: 18 inches 20 inches 22 inches 24 inches 18-24 inches SEAT DEPTH: 16 -18 inches 18-20 inches 20-22 inches 20-22 inches 16-22 inches... -

Page 11: Section 1-General Guidelines

SECTION 1—GENERAL GUIDELINES SECTION 1—GENERAL GUIDELINES WARNING SECTION 1 - GENERAL GUIDELINES contains important information for the safe operation and use of this product. Controller Settings/Repair or Service Set‐up of the Electronics Control Unit is to be performed only by a qualified technician. The final adjustments of the controller may affect other activities of the wheelchair. Damage to the equipment could occur if improperly set‐up or adjusted. Wheelchairs should be examined during maintenance for signs of corrosion (water exposure, incontinence, etc.). Electrical components damaged by corrosion should be replaced IMMEDIATELY. Wheelchairs that are used by incontinent users and/or are frequently exposed to water may require replacement of electrical components more frequently. Accessories Information EXTREME care should be exercised when using oxygen in close proximity to electric circuits and other combustible materials. Contact your oxygen supplier for instruction in the use of oxygen. - Page 12 DO NOT make sharp turns in the forward or reverse direction at excessive speed. Failure to observe this warning can cause the wheelchair to tip over and may result in injury to users, bystanders and/or damage to product. DO NOT store items under seat ‐ interference with seat latch may result. Avoid storing or using the wheelchair near open flame or combustible products. Serious injury or damage to property may result. DO NOT engage or disengage the motor release levers until the power is in the off position. DO NOT operate on roads, streets or highways. DO NOT climb, go up or down ramps or traverse slopes greater than 9°. DO NOT attempt to move up or down an incline with a water, ice or oil film. NEVER leave an unoccupied wheelchair on an incline. DO NOT attempt to stop a moving wheelchair with wheel locks. Wheel locks are not brakes. DO NOT attempt to drive over curbs or obstacles. Doing so may cause your wheelchair to turn over and cause bodily harm or damage to the chair. DO NOT attempt to lift the wheelchair by any removable (detachable) parts. Lifting by means of any removable (detachable) parts of the wheelchair may result in injury to the user or damage to the wheelchair. DO NOT use parts, accessories, or adapters other than those authorized by Invacare ‐ otherwise the warranty is void. DO NOT leave the power button in the on position when entering or exiting your wheelchair. DO NOT lean over the top of the back upholstery to reach objects behind you, as this may cause the wheelchair to tip over. DO NOT stand on the frame of the wheelchair. DO NOT stand on the flip‐up footboard, otherwise damage may occur. When getting in or out of the wheelchair, make sure that the flip‐up footboard is in the upward position. DO NOT stand on the front riggings, otherwise damage may occur. When getting in or out of the wheelchair, make sure that the footplates on the front riggings are in the upward position or moved out of the way. ALWAYS keep hands and fingers clear of moving parts to avoid injury. ALWAYS wear your seat positioning strap. The seat positioning strap is a positioning belt only. It is not designed for use as a safety device withstanding high stress loads such as auto or aircraft safety belts. If signs of wear appear, belt MUST be replaced immediately. Make sure the detent balls of the quick‐release pin are fully released beyond the outer edge of the tube before operating the wheelchair. Otherwise, injury and/or damage may result. Pronto® M94™...

-

Page 13: Batteries

SECTION 1—GENERAL GUIDELINES The detent balls MUST be protruding past the top of the seat plate assembly for a positive lock. Keep detent balls clean. Before performing any maintenance, adjustment or service verify that On/Off switch on the joystick is in the off position. Avoid storage or use near external flame or combustible products. Batteries The warranty and performance specifications contained in this manual are based on the use of deep cycle gel cell or sealed lead acid batteries. Invacare strongly recommends their use as the power source for this unit. Carefully read battery/battery charger information prior to installing, servicing or operating your wheelchair. The use of rubber gloves is recommended when working with batteries. Some battery manufacturers mold a carrying strap and/or hold down flanges directly into the battery case. Batteries that interfere with the battery box cannot be used for these applications. Attempting to “wedge” a battery into a battery box may damage the box, the battery and/or be a fire hazard, resulting in serious injury or further damage to property. Charging Batteries DANGER When using an extension cord, use only a three wire extension cord having at least 16 AWG (American Wire Gauge) wire and the same or higher electrical rating as the device being connected. -

Page 14: Grounding Instructions

SECTION 1—GENERAL GUIDELINES Ensure the pins of the extension cord plug are the same number, size, and shape as those on the charger. DO NOT under any circumstances cut or remove the round grounding plug from the charger AC cable plug or the extension cord plug. Grounding Instructions DO NOT, under any circumstances, cut or remove the round grounding prong from any plug used with or for Invacare products. Some devices are equipped with three‐prong (grounding) plugs for protection against possible shock hazards and fire. Where a two‐ prong wall receptacle is encountered, it is the personal responsibility and obligation of the customer to contact a qualified electrician and have the two‐prong receptacle replaced with a properly grounded three‐prong wall receptacle in accordance with the National Electrical Code. If you must use an extension cord, use ONLY a three‐wire extension cord having the same or higher electrical rating as the device being connected. In addition, Invacare has placed RED/ORANGE warning tags on some equipment. DO NOT remove these tags. Rain Test Invacare has tested its power wheelchairs in accordance with ISO 7176 “Rain Test.” This provides the end user or his/her assistant sufficient time to remove his/her power wheelchair from a rain storm and retain wheelchair operation. DO NOT leave power wheelchair in a rain storm of any kind. DO NOT use power wheelchair in a shower. DO NOT store power wheelchair in a damp area for an extended period of time. Direct exposure to excessive rain or dampness may cause the chair to malfunction electrically and mechanically, may cause the chair to prematurely rust or may damage the upholstery. Check to ensure that the RED and BLACK battery terminal caps are secured in place, joystick boot is not torn or cracked where water can enter and that all electrical connections are secure at all times. DO NOT use the wheelchair if the joystick boot is torn or cracked. If the joystick boot becomes torn or cracked, replace IMMEDIATELY. Weight Training Invacare does not recommend the use of its wheelchairs as a weight training apparatus. Invacare wheelchairs have not been designed or tested as a seat for any kind of weight training. If occupant uses said wheelchair as a weight training apparatus, Invacare shall not be liable for bodily injury and the warranty is void. -

Page 15: Section 2-Emi Information

SECTION 2—EMI INFORMATION SECTION 2—EMI INFORMATION WARNING CAUTION: IT IS VERY IMPORTANT THAT YOU READ THIS INFORMATION REGARDING THE POSSIBLE EFFECTS OF ELECTROMAGNETIC INTERFERENCE ON YOUR POWERED WHEELCHAIR. Electromagnetic Interference (EMI) From Radio Wave Sources Powered wheelchairs and motorized scooters (in this text, both will be referred to as powered wheelchairs) may be susceptible to electromagnetic interference (EMI), which is interfering electromagnetic energy (EM) emitted from sources such as radio stations, TV stations, amateur radio (HAM) transmitters, two way radios, and... - Page 16 2) This device has been tested to a radiated immunity level of 20 volts per meter. 3) The immunity level of the product is unknown. Modification of any kind to the electronics of this wheelchair as manufactured by Invacare may adversely affect the EMI immunity levels. Pronto® M94™ Part No 1122145...

-

Page 17: Section 3-Safety/Handling Of Wheelchairs

“Safety and Handling” of the wheelchair requires the close attention of the wheelchair user as well as the assistant. This manual points out the most common procedures and techniques involved in the safe operation and maintenance of the wheelchair. It is important to practice and master these safe techniques until you are comfortable in maneuvering around the frequently encountered architectural barriers. Use this information only as a “basic” guide. The techniques that are discussed on the following pages have been used successfully by many. Individual wheelchair users often develop skills to deal with daily living activities that may differ from those described in this manual. Invacare recognizes and encourages each individual to try what works best for him/her in overcoming architectural obstacles that they may encounter, however ALL WARNINGS and CAUTIONS given in this manual MUST be followed. Techniques in this manual are a starting point for the new wheelchair user and assistant with “safety” as the most important consideration for all. Stability and Balance WARNING Ensure that driving surfaces, ramps, lifts, elevators, etc. are capable of supporting combined weight of user and wheelchair (for a 500 lbs user, the combined weight could be up to 800 lbs). -

Page 18: Coping With Everyday Obstacles

SECTION 3—SAFETY/HANDLING OF WHEELCHAIRS Coping With Everyday Obstacles WARNING DO NOT attempt to reach objects if you have to move forward in the seat or pick them up from the floor by reaching down between your knees. Many activities require the wheelchair user to reach, bend and transfer in and out of the wheelchair. -

Page 19: A Note To Wheelchair Assistants

800 lbs). Extreme caution is advised when it is necessary to move an unoccupied power wheelchair up or down the stairs. Invacare recommends using two assistants and making thorough preparations. Use ONLY secure, nondetachable parts for hand-hold supports. - Page 20 SECTION 3—SAFETY/HANDLING OF WHEELCHAIRS 3. Remove any accessories on the wheelchair. 4. Bend your knees and keep your back straight. 5. Ensure that the casters are oriented as shown in FIGURE 3.2. 6. Using the rear and front forks as hand hold supports, transfer the wheelchair base to desired location. Refer to FIGURE 3.2. WARNING WARNING Pinch Point Pinch Point Rear Front Forks Forks Rear Caster Front Caster Orientation Orientation FIGURE 3.2 Lifting/Stairways - orientation of casters and Pinch Points 7.

-

Page 21: Transferring To And From Other Seats

SECTION 3—SAFETY/HANDLING OF WHEELCHAIRS Transferring to and From Other Seats WARNING ALWAYS turn the wheelchair power off and engage the Motor Release Levers to prevent the wheels from moving before attempting to transfer in or out of the wheelchair. Also, make sure every precaution is taken to reduce the gap distance by aligning both the front and rear casters parallel with the object you are transferring onto. -

Page 22: Reaching And Bending - Backward

SECTION 3—SAFETY/HANDLING OF WHEELCHAIRS FIGURE 3.4 Reaching, Leaning and Bending - Forward Reaching and Bending - Backward WARNING DO NOT lean over the top of the back upholstery. This will change your center of gravity and may cause you to tip over. NOTE: For this procedure, refer to FIGURE 3.5. -

Page 23: Section 4-Safety Inspection/Troubleshooting

SECTION 4—SAFETY INSPECTION/TROUBLESHOOTING SECTION 4—SAFETY INSPECTION/ TROUBLESHOOTING NOTE: Every six months or as necessary take your wheelchair to a qualified dealer for a thorough inspection and servicing. Regular cleaning will reveal loose or worn parts and enhance the smooth operation of your wheelchair. To operate properly and safely, your wheelchair must be cared for just like any other vehicle. Routine maintenance will extend the life and efficiency of your wheelchair. Safety Inspection Checklists Initial adjustments should be made to suit your personal body structure needs and preference. Thereafter follow these maintenance procedures: Inspect/Adjust Initially ❑ Ensure the wheelchair rolls straight (no excessive drag or pull to one side). ❑ Ensure the arms are secure but easy to release and adjustment levers engage properly (on ASBA only). ❑ Ensure the adjustable height arms operate and lock securely. ❑ Ensure the armrest pads sit flush against arm tubes. ❑ Ensure the seat is secured to wheelchair frame. ❑ Ensure the seat release latch is functional. Replace if necessary. ❑ Ensure the wheel mounting nuts are secure on drive wheels. ❑ Ensure the no excessive side movement or binding when drive wheels are lifted and spun when disengaged (freewheeling). ❑ Ensure the wheel/fork assembly has proper tension when caster is spun. Caster should come to a gradual stop. CAUTION As with any vehicle, wheels and tires should be checked periodically for cracks and wear and should be replaced as necessary. -

Page 24: Inspect/Adjust Weekly

SECTION 4—SAFETY INSPECTION/TROUBLESHOOTING Inspect/Adjust Weekly ❑ Ensure the seat is secured to wheelchair frame. ❑ Ensure the seat and/or back upholstery have no rips and DO NOT sag. Replace if necessary. ❑ Ensure the seat release latch is not worn and is functional. Replace if necessary. ❑ Ensure the inspect tires for flat spots and wear. ❑ Ensure the arm pivot points are not worn and/or loose. Replace if necessary. ❑ Ensure the inspect and clean the stability lock gears. Replace if worn. ❑ Ensure that casters are free of debris. Inspect/Adjust Monthly ❑ Ensure the wheel mounting nuts are secure on drive wheels. ❑ Ensure the no excessive side movement or binding when drive wheels are lifted and spun when disengaged (free‐wheeling). ❑ Ensure the wheel/fork assembly has proper tension when caster is spun. Caster should come to a gradual stop. CAUTION As with any vehicle, wheels and tires should be checked periodically for cracks and wear and should be replaced as necessary. -

Page 25: Troubleshooting - Mechanical

SECTION 4—SAFETY INSPECTION/TROUBLESHOOTING ❑ Ensure the seat release latch is not worn. Replace if necessary. ❑ Inspect and clean the stability lock gears. Replace if worn. ❑ Clean upholstery and armrests. ❑ Inspect the seat positioning strap for wear. Replace if worn or damaged. ❑ Inspect charger AC power cord for damage. Replace if necessary. ❑ Ensure that casters are free of debris. ❑ Check that all labels are present and legible. Replace if necessary. ❑ Inspect electrical components for signs of corrosion. Replace if corroded or damaged. Troubleshooting - Mechanical SOLUTIONS If pneumatic, check tires for correct and equal pressure. Check for loose stem nuts/bolts. Check that casters contact ground at the same time. If pneumatic, check tires for correct and equal pressure. -

Page 26: Information Gauge Display Diagnostics

Contact Invacare/Dealer for service. Controller Fault Contact Invacare/Dealer for service. Communications Fault Contact Invacare/Dealer for service. General Fault Contact Invacare/Dealer for service. Incompatible or incorrect Wrong type of remote connected. Contact Invacare/Dealer for Remote service. Pronto® M94™ Part No 1122145... -

Page 27: Mpj+, Psr+, Psf+ Joysticks Or Displays

ATTENDANT ACTIVE and can be used to drive the chair displays. (Error code W05). Batteries draw excessive current Battery failure. Have batteries checked for shorted cell. when charging. Replace if necessary. Electrical malfunction. Contact Dealer/Invacare for service. Part No 1122145 Pronto® M94™... - Page 28 Battery failure. Check batteries for shorted cell. level is low - immediately after Replace if necessary. recharge. Malfunctioning battery charger. Contact Dealer/Invacare for Service. Electrical malfunction. Contact Dealer/Invacare for Service. Battery indicator flashes the charge Batteries not charged. Have charger checked.

-

Page 29: Checking Battery Charge Level

SECTION 4—SAFETY INSPECTION/TROUBLESHOOTING Checking Battery Charge Level The following “Do’s” and “Don’ts” are provided for your convenience and safety. DON’T Don’t perform any installation or maintenance Read and understand this manual and any service informa- without first reading this manual. tion that accompanies a battery and charger before operat- ing the wheelchair. Don’t perform installation or maintenance of bat- Move the wheelchair to a work area before cleaning termi- teries in an area that could be damaged by bat-... -

Page 30: Section 5-Wheelchair Operation

SECTION 5—WHEELCHAIR OPERATION SECTION 5—WHEELCHAIR OPERATION WARNING After ANY adjustments, repair or service and before use, make sure that all attaching hardware is tightened securely - otherwise injury or damage may result. Set-up of the Electronic Control Unit is to be performed only by a qualified techni- cian. -

Page 31: Using The Joystick To Drive The Wheelchair

SECTION 5—WHEELCHAIR OPERATION Using the Joystick to Drive the Wheelchair NOTE: For this procedure, refer to FIGURE 5.2. The joystick is located on the joystick housing and provides smooth control of speed and direction. It is equipped with 360 degrees of mobility for ease of operation. The joystick is spring‐loaded, and automatically returns to the upright (neutral) position when released. Pushing the joystick in a given direction causes the wheelchair to move in that direction. The joystick has proportional drive control, meaning that the further it is pushed from the upright (neutral) position, the faster the wheelchair moves. The maximum speed, however, is limited by the setting of the speed‐control knob. To slow the wheelchair to a stop, simply release the joystick. The wheelchair has automatic speed and direction compensation to minimize corrections. When first learning to drive, select a slow speed and try to drive the wheelchair as slowly as possible by pushing the joystick slightly forward. This exercise will help you learn to utilize the full potential of the proportional control and allow you to start and stop smoothly. To drive the wheelchair, perform the following: 1. Adjust speed control knob to the appropriate setting. 2. Turn the power On. Refer to Turning the Power On/Off on page 30. 3. Maneuver the joystick in the following manner: MOVEMENT ACTION To Move To Move Left Forward FORWARD Push joystick forward, towards... -

Page 32: Spj+, Mk6I Spj+ W/Pss And Mk6I Spj+ W/Acc Joystick Switches And Indicators

SECTION 5—WHEELCHAIR OPERATION SPJ+, MK6i SPJ+ w/PSS and MK6i SPJ+ w/ACC Joystick Switches and Indicators NOTE: For the following information, refer to FIGURE 5.3. Joystick Information Gauge Display On/Off Mode Button* Button Decrease Speedometer Speed Button (Tortoise) Increase Speed Button Additional (Hare) Input for GREEN Powered Seating Switch DETAIL “A”... -

Page 33: Speed Control Buttons

SECTION 5—WHEELCHAIR OPERATION Speed Control Buttons The speed control buttons (tortoise button ( ) and hare button ( ) are used to set and adjust the maximum speed. 1. To adjust the speed, perform one of the following: • Adjust Speed in 20% Increments (5 Speed Mode) ‐ Press the tortoise button ( ) or hare button ( ) to decrease/increase the speed in 20% increments. The larger bars in the speedometer will light. • Adjust Speed in Smaller Increments (VSP Mode) ‐ Perform the following steps: i. Press and hold both the tortoise button ( ) and hare button ( ) until the joystick beeps. ii. Perform one of the following: • Press the tortoise button ( ) or hare button ( ) to decrease/increase the speed in 20% increments. The larger bars in the speedometer will light. • Press and hold the tortoise button ( ) or hare button ( ) to decrease/ increase the speed in smaller increments. The smaller bars in the speedometer will light. Joystick The joystick has proportional drive control, meaning that the further the joystick is pushed from the upright (neutral) position, the faster the wheelchair or seat moves. Your ... -

Page 34: Information Gauge Display

SECTION 5—WHEELCHAIR OPERATION Information Gauge Display The information gauge display is located on the front of the joystick housing and provides the following information to the user on the status of the wheelchair: 1. Power is On. 2. True state‐of‐battery‐charge, including notification of when the battery requires charging: A. GREEN LEDs are lit, indicating well charged batteries. B. AMBER LEDs are lit, indicating batteries are moderately charged. Recharge batteries before taking a long trip. C. RED LEDs are lit, indicating batteries are running out of charge. Recharge batteries as soon as possible. The Information Gauge display also serves as a system diagnostic device when a fault is detected by the control module. A specific number of flashes of the LEDs indicate the type of fault detected. Refer to Information Gauge Display Diagnostics on page 33 for the diagnostic indications of the wheelchair status. MPJ+ Joystick Switches and Indicators NOTE: For this procedure, refer to FIGURE 5.4 on page 35. Drive Select Toggle Switch The drive select toggle switch is located on the left side, below the LCD. The drive select position is momentary, meaning that it will return to the neutral position after a selection is made. This switch allows the operator to select the type of operation or performance which best ... -

Page 35: Speed Control

SECTION 5—WHEELCHAIR OPERATION Memory Card Slot Charger/Programming Input (Front of Joystick) LCD Display Mode Switch Speed Control Knob Drive Select Toggle Switch Programmable Joystick Mono Port 1/2 or Remote External Mode On/Off Switch Input To Controller FIGURE 5.4 MPJ+ Joystick Switches and Indicators Speed Control The speed control knob is located on the side of the joystick housing. ... - Page 36 SECTION 5—WHEELCHAIR OPERATION Splash Screen NOTE: For this procedure, refer to FIGURE 5.5. This screen is displayed at startup of the joystick for about 2 seconds. This screen displays the software version and date information. After this screen, the joystick displays the Main Screen. FIGURE 5.5 LCD Display Screens - Splash Screen Main Screen NOTE: For this information, refer to FIGURE 5.6 on page 37. During normal operation, the active drive is displayed in the upper half of the LCD display. Battery charge level is shown in the Battery Gauge Display (BGD) located on the right side of the LCD display. At full charge, solid blocks fill in all ten segments between E (Empty) and F (Full). As the battery becomes discharged, the top most segments will progressively disappear until no segments appear between E and F. At this level, the user should charge the batteries as soon as possible. The lower half of the LCD display is the Information Center. The Information Center displays current data on the wheelchair. Refer to LCD Display table on page 36 for descriptions of information shown. LCD DISPLAY ITEM DESCRIPTION DRIVE NAME This field shows the currently selected Drive’s Name.

- Page 37 SECTION 5—WHEELCHAIR OPERATION ITEM DESCRIPTION STATUS INDICATOR The status indicator will show a “Warning” (exclamation point inside a triangle) indicator when the chair has a condition that requires attention. The status indicator will show a “STOP” sign when a serious condition exists. The chair will not be allowed to operate.

-

Page 38: Programmable Mono Port 1/2 Or External Mode Switch

SECTION 5—WHEELCHAIR OPERATION Connected Devices Screen NOTE: For this procedure, refer to FIGURE 5.8. This screen is displayed if the Mode Select switch is held active for about 10 seconds. This screen shows an icon that represents any additional devices that are connected to the chair. ICON DESCRIPTION 4-Switch Attendant Control RIM Control ECU (1 to 4) Proportional Attendant Control Compact Joystick Sip and Puff Control ASL Digital Control ASL Analog Control Shark Power Module Actuator FIGURE 5.8 LCD Display Screens - Connected Devices Screen Programmable Mono Port 1/2 or External Mode Switch The programmable mono port or external mode switch input is located at the rear of the ... -

Page 39: Remote On/Off Switch

SECTION 5—WHEELCHAIR OPERATION Remote On/Off Switch The remote On/Off switch input is located at the rear of the joystick on the right side and allows the power switch to be operated by an ability switch (normally open momentary switch with mono plug). To use the remote On/Off feature, the Drive Select/On/Off switch must be in the On position. Each activation of the ability switch will alternately turn the joystick On or Off. Mode Switch NOTE: For this procedure, refer to FIGURE 5.4 on page 35. The mode switch is used to select the operating mode for the wheelchair. The mode switch is located on the joystick. A mode switch is needed whenever any of the following operating modes are programmed: • Environmental Controls (ECU 1, ECU 2, ECU 3, ECU 4)* • 3 Speed Mode in Digital 3 Speed (Slow, Medium, Full) • Latched Modes • Sleep Mode • RIM Mode* • Remote Drive Selection Mode* • Tilt/Recline Mode* • Information Center Display Selection (does not require Reset activation at power up) If any of the above modes are selected, the control will require activation of the switch immediately after the power switch is turned On in order to enter the drive mode. The second line of the LCD will display ‐ PRESS RESET. *NOTE: In these modes, Standby Select allows the reset switch to be bypassed for users unable to activate the switch. Memory Card Slot The memory card slot is used with the basic or professional memory card for saving or ... -

Page 40: Preparing The Joystick For Use

SECTION 5—WHEELCHAIR OPERATION Preparing the Joystick for Use NOTE: For this procedure, refer to FIGURE 5.9. NOTE: The joystick is factory installed on the right side of the wheelchair. To reposition the joystick onto the left side of the wheelchair, refer to Repositioning the Joystick on page 40. 1. Turn the adjustment lock lever to NOTE: Joystick release the adjustment lock from not shown. joystick mounting tube. 2. Slide joystick mounting tube to the desired position. Joystick Mounting 3. Turn the adjustment lock lever to Tube secure the adjustment lock to the Adjustment joystick mounting tube. Lock Lever FIGURE 5.9 Preparing the Joystick for Use Repositioning the Joystick ASBA Seat Model NOTE: For this procedure, refer to FIGURE 5.10 on page 41. -

Page 41: Van Seat Model

SECTION 5—WHEELCHAIR OPERATION Mounting Bracket Washers (Threaded Plate) Arm Tube Mounting Joystick Mounting Tube Screws Adjustment Mounting Lock Lever Bracket NOTE: Joystick not shown. FIGURE 5.10 Repositioning the Joystick - ASBA Seat Model Van Seat Model NOTE: For this procedure, refer to FIGURE 5.11 on page 42. NOTE: Take note of position and orientation of mounting hardware for reinstalling the joystick assembly. 1. Turn the adjustment lock lever to release the joystick mounting tube from the mounting bracket. 2. -

Page 42: Disconnecting/Connecting The Joysticks

SECTION 5—WHEELCHAIR OPERATION Locknuts Arm Frame Hex Mounting Screws Spacers Adjustment Joystick Mounting Tube Lock Lever Mounting Bracket FIGURE 5.11 Repositioning the Joystick - Van Seat Model Disconnecting/Connecting the Joysticks NOTE: For this procedure, refer to FIGURE 5.12. NOTE: The joystick connector is located at the rear of the seat frame. SPJ+ Joysticks 1. Hold the light GREY collar portion of the joystick connector with one hand and the controller connector on the wheelchair in the other and disconnect them by pulling them apart. Connecting WARNING The joystick connector and controller connector fit together in one way only. -

Page 43: Mpj+ Joysticks

SECTION 5—WHEELCHAIR OPERATION MPJ+ Joysticks NOTE: For this procedure, refer to FIGURE 5.13. Disconnecting 1. Pull the latch away from the joystick connector. 2. Disconnect the joystick connector from the remaining connectors. Connecting 1. Ensure the latch is pulled away from the joystick connector. 2. Connect the joystick connector to the other connectors. 3. Push the latch in to secure the joystick connector to the other connectors. Joystick Connector Latch Other Connectors FIGURE 5.13 Disconnecting/Connecting the Joysticks - MPJ+ Joysticks Part No 1122145 Pronto® M94™... -

Page 44: Section 6-Arms

SECTION 6—ARMS SECTION 6—ARMS WARNING After ANY adjustments, repair or service and before use, make sure that all attaching hardware is tightened securely - otherwise injury or damage may result. Before performing any maintenance, adjustment or service verify that On/Off switch on the joystick is in the Off position. -

Page 45: Adjusting Flip Back Armrests

SECTION 6—ARMS Flip Back Armrest Flip Back Armrest Locked Release Lever (Vertical) Rear Arm Socket Seat Frame Quick Release Pin Unlocked (Horizontal) Front Arm Socket FIGURE 6.1 Installing/Removing Flip Back Armrests Adjusting Flip Back Armrests NOTE: For this procedure, refer to FIGURE 6.2 on page 46. Positioning Flip Back Armrests for User Transfer 1. -

Page 46: Adjusting Van Seat Armrests

SECTION 6—ARMS 3. Lock top of flip back armrest by pushing height adjustment lever into the Down (vertical) position. 4. Lift up on flip back armrest to make sure the armrest is locked in place. 5. Repeat STEPS 1‐4 for opposite flip back armrest, if necessary. Height Adjustment Locked Flip Back Armrest (Down - Vertical) Lever Release Lever Flip Back Armrest Unlocked (Up - Horizontal) Front Arm Socket FIGURE 6.2 Adjusting Flip Back Armrests Adjusting Van Seat Armrests Angle WARNING Pinch point may occur when adjusting the arm angle position. - Page 47 SECTION 6—ARMS Detail “A” - Angle Detail “B” - Height Adjustment Height Armrest Screw Adjustment Holes Armrest Lock Knob Seat Frame Assembly Pinch Point FIGURE 6.3 Adjusting Van Seat Armrests Part No 1122145 Pronto® M94™...

-

Page 48: Section 7-Seat

SECTION 7—SEAT SECTION 7—SEAT WARNING After ANY adjustments, repair or service and before use, make sure that all attaching hardware is tightened securely - otherwise injury or damage may result. Before performing any maintenance, adjustment or service verify that On/Off switch on the joystick is in the Off position. -

Page 49: Adjustable Seat Back Angle (Asba) Model

SECTION 7—SEAT Adjustable Seat Back Angle (ASBA) Model NOTE: For this procedure, refer to FIGURE 7.3. 1. Remove armrests from the wheelchair. Refer to Installing/Removing Flip Back Armrests on page 44. 2. Remove the mounting screw and washer from the top mounting hole of back angle plate and back cane. NOTE: To avoid losing the insert in each back cane, thread the mounting screw through the cane from the inside of wheelchair to hold the insert in place. 3. Remove the mounting screw and washer from the bottom mounting hole of the back angle plate and back cane. 4. Reposition the back canes into the correct mounting holes of the back angle plate to obtain a back angle between 80° and 100° in 5° increments. 5. Torque mounting screws to 75 inch‐pounds. 6. Reinstall the armrests onto the wheelchair. Refer to Installing/Removing Flip Back Armrests on page 44. 85° 80° Top Rear Top Rear Bottom Bottom Bottom Bottom Front Front... -

Page 50: Removing/Installing The Seat Assembly

SECTION 7—SEAT Removing/Installing the Seat Assembly WARNING DO NOT store items under seat - interference with seat latch may result. NOTE: For this procedure, refer to FIGURE 7.4. Removing 1. Disconnect the joystick. Refer to Disconnecting/Connecting the Joysticks on page 42. 2. Push down on the latch bar underneath front of seat. 3. Tilt front edge of seat up. 4. Slide the seat assembly forward to disengage seat from the pivot brackets located in the rear. Installing 1. Position the seat in the rear pivot brackets as shown in FIGURE 7.4. 2. Tilt front edge of seat down. 3. When seat is lowered, engage seat brackets into seat clevis pins. WARNING When reinstalling the seat verify that the seat brackets are engaged with the seat clevis pins by pulling up on the latch bar. -

Page 51: Adjusting The Seat Height

SECTION 7—SEAT Adjusting the Seat Height NOTE: For this procedure, refer to FIGURE 7.5 on page 52. NOTE: The seat can be adjusted to five height positions in ½‐inch increments. 1. Remove the seat. Refer to Removing/Installing the Seat Assembly on page 50. 2. Remove the mounting screw and locknut that secures the adjustable height tube to the support tube. 3. Adjust tube to desired mounting position. Refer to the following table for available mounting positions. AVAILABLE MOUNTING HOLES FOR FRONT ADJUSTABLE HEIGHT TUBE CHAIR IS EQUIPPED WITH VAN SEAT WITH FOOTBOARD REAR ADJUSTABLE HEIGHT TUBE Mounted in hole A N/A** ... -

Page 52: Adjusting Seat Position On Seat Frame

SECTION 7—SEAT Front Rear Adjustable Adjustable Mounting Height Tube Mounting Height Tube Hole Hole Locknut Support Mounting Tube Screws FIGURE 7.5 Adjusting the Seat Height Adjusting Seat Position on Seat Frame ASBA Model WARNING DO NOT attempt to adjust the seat position of the ASBA seat on the seat frame. This procedure MUST be performed by a qualified technician. -

Page 53: Adjusting Seat Depth - Van Seat Only

SECTION 7—SEAT DETAIL “A” - SEAT ASSEMBLY Seat Assembly Seat Frame Seat Positioning Strap Washer Mounting Screws DETAIL “B” - SEAT POSITIONS Bottom View of Seat Assembly * DO NOT Use * DO NOT Use Front of Seat Use these Mounting Holes Use these Mounting Holes for 1-inch-back Seat Position for 1-inch-back Seat Position... -

Page 54: Replacing The Seat Positioning Strap

SECTION 7—SEAT 4. Adjust seat back assembly to desired position and reinstall the six mounting screws. Securely tighten. NOTE: Refer to Detail “A” of FIGURE 7.7 for proper seat depth positions. For example, to achieve maximum seat depth, the front mounting hole on the seat back bracket aligns with the third hole on the seat base. 5. Reinstall the seat base onto the seat assembly. Refer to Adjusting Seat Position on Seat Frame on page 52. 6. Reinstall the seat. Refer to Removing/Installing the Seat Assembly on page 50. DETAIL “A” - SEAT DEPTH POSITIONS NOTE: Seat depth maximum is at the third seat hole. Seat Back Minimum Seat Depth Seat Depth Seat Size Mounting 16 inch 16 X 18 inch Seat Holes Back 16 inch... -

Page 55: Van Seat Model

SECTION 7—SEAT 4. Remove the two halves of the seat positioning strap from the rear seat frame. 5. Reposition the two new seat positioning strap halves underneath seat rails. 6. Reinstall the two mounting screws, quick release pin tabs, spacers, and locknuts that secure the seat pan and seat positioning straps to the seat frame and torque to 75 inch‐ pounds. 7. Reinstall the seat cushion onto the seat pan. Mounting Screws Seat Pan Seat Seat Frame Positioning Strap Rear of Seat Frame Seat Rail Seat Positioning Strap Front of Seat Frame Seat Rail Seat Frame Spacer Locknut FIGURE 7.8 Replacing the Seat Positioning Strap - ASBA Model Van Seat Model NOTE: For this procedure, refer to ... -

Page 56: Section 8-Footboard Assembly

SECTION 8—FOOTBOARD ASSEMBLY SECTION 8—FOOTBOARD ASSEMBLY WARNING After ANY adjustments, repair or service and before use, make sure that all attaching hardware is tightened securely - otherwise injury or damage may result. Before performing any maintenance, adjustment or service verify that On/Off switch on the joystick is in the Off position. -

Page 57: Adjusting The Footboard Assembly

SECTION 8—FOOTBOARD ASSEMBLY 2. Install the quick release pin by depressing the button while sliding the pin in. Make sure the detent balls are fully released beyond the outer edge of the tube (Detail “A” of FIGURE 8.3). Wheelchair Frame Mounting Detail “A” - Bottom View of Footboard Hole Quick Release Pin Quick Detent Release Ball Outer Edge Footboard Detent Balls of Tube Assembly FIGURE 8.1 Removing/Installing the Footboard Assembly Adjusting the Footboard Assembly Angle NOTE: For this procedure, refer to FIGURE 8.2. -

Page 58: Depth

SECTION 8—FOOTBOARD ASSEMBLY Depth NOTE: For this procedure, refer to FIGURE 8.3. 1. Remove the quick release pin that secures the footboard assembly to the wheelchair frame. WARNING Make sure the detent balls of the quick-release pin are fully released beyond the outer edge of the tube before operating the wheelchair. Otherwise, injury and/or damage may result. Keep detent balls clean. 2. -

Page 59: Section 9-Front Riggings

SECTION 9—FRONT RIGGINGS SECTION 9—FRONT RIGGINGS WARNING After ANY adjustments, repair or service and before use, make sure that all attaching hardware is tightened securely - otherwise injury or damage may result. DO NOT stand on the front riggings, otherwise damage may occur. When getting in or out of the wheelchair, make sure that the footplates on the front riggings are in the upward position or moved out of the way. -

Page 60: Removing

SECTION 9—FRONT RIGGINGS Removing 1. Push the front rigging release lever inward and rotate the footrest out. 2. Lift up on front rigging and remove from the wheelchair. 3. Repeat STEPS 1‐2 for opposite side of wheelchair. Adjusting Footrest Height Model PHWH93 NOTE: For this procedure, refer to FIGURE 9.2. 1. Remove any accessories from the footrest(s). 2. Remove the footrest from the Footrest Support wheelchair. Refer to Installing/ Locknut Removing Front Riggings on page 59. Coved Washer NOTE: Lay footrest on a flat surface to simplify section. Hex Bolt 3. Remove the hex bolt, coved washers and locknut that secure the lower Coved footrest to the footrest support. Washer Lower 4. -

Page 61: Replacing Heel Loops

SECTION 9—FRONT RIGGINGS 3. Securely tighten the lug bolt and locknut that secure the lower footrest to the footrest support. 4. Repeat STEPS 1‐3 for the opposite side of the wheelchair footrest, if necessary. Replacing Heel Loops NOTE: For this procedure, refer to FIGURE 9.4. 1. Note the position of hex bolt, coved Locknut washers and locknut for reinstallation. Coved Washer 2. Remove the hex bolt, coved washers Coved Hex Bolt and locknut that secure the lower Washer footrest to the footrest support. Phillips Bolt 3. Remove the lower footrest. Footrest Support Spacer 4. Remove the phillips bolt, spacer and locknut that secure the existing heel Lower Heel Loop loop to the lower footrest. - Page 62 SECTION 9—FRONT RIGGINGS NOTE: Telescoping front rigging supports may be extended up to 2‐inches from the wheelchair frame in 1‐inch increments. This adjustment does not affect seat depth. NOTE: When installing the front riggings support tubes, ensure that the hinge pins are on the outside of the chair facing away from the seat frame. NOTE: For this procedure, refer to FIGURE 9.6 on page 63. 1. Remove the seat. Refer to Removing/Installing the Seat Assembly on page 50. 2. Remove the two socket bolts and locknuts that secure telescoping front rigging support to the seat frame. 3. Perform one of the following: • Adjusting i. Align the appropriate mounting hole of the telescoping front rigging support with the front mounting hole in the seat frame tubes to achieve the desired depth as shown in FIGURE 9.6. • Replacing i. Remove the existing telescoping front rigging support from the wheelchair frame. ii. Insert the new telescoping front rigging support into the seat frame. iii. Align the appropriate mounting hole of the telescoping front rigging support with the front mounting hole in the seat frame tubes to achieve the desired depth as shown in FIGURE 9.6. NOTE: The footplate will be on the inside of the wheelchair when locked in place. 4. Using the two socket bolts and locknuts, secure the telescoping front rigging support to the seat frame as shown in FIGURE 9.6. 5.

-

Page 63: Adjusting/Replacing Telescoping Front Rigging Supports - Asba

SECTION 9—FRONT RIGGINGS Not Used Mounting Bolts Inner Mounting Holes Telescoping Front Rigging Support Seat Frame Mounting Spacer Holes Locknuts Hinge Not Used Pins STANDARD POSITION 1-INCH OUT 2-INCHES OUT 18 & 20-Inch 22 & 24-Inch 18 & 20-Inch 22 & 24-Inch 18 &... - Page 64 SECTION 9—FRONT RIGGINGS Mounting Screws Spacer Telescoping Front Tube Locknut Spacer Locknut FIGURE 9.7 Adjusting/Replacing Telescoping Front Rigging Supports - ASBA Pronto® M94™ Part No 1122145...

-

Page 65: Section 10-Shroud/Wheels

SECTION 10—SHROUD/WHEELS SECTION 10—SHROUD/WHEELS WARNING After ANY adjustments, repair or service and before use, make sure that all attaching hardware is tightened securely - otherwise injury or damage may result. Before performing any maintenance, adjustment or service verify that On/Off switch on the joystick is in the Off position. -

Page 66: Engaging/Disengaging Motor Release Lever

SECTION 10—SHROUD/WHEELS DETAIL “B” - FRONT SHROUD DETAIL “A” - TOP SHROUD Base Frame Top Shroud Hooks Rear of Seat Supports Wheelchair Base Frame Front Shroud Release Knob Front of Hook and Wheelchair Loop Strips FIGURE 10.1 Removing/Installing the Shrouds Engaging/Disengaging Motor Release Lever WARNING DO NOT engage or disengage the motor release lever until the On/Off switch on... -

Page 67: Replacing Front/Rear Caster Assemblies

SECTION 10—SHROUD/WHEELS DETAIL “A” Towards Center of Wheelchair Motor Release Lever Towards Outside of Wheelchair Motor Locks Disengaged (Freewheel Mode) Motor Locks Engaged (Drive Mode) FIGURE 10.2 Engaging/Disengaging Motor Release Lever Replacing Front/Rear Caster Assemblies NOTE: For this procedure, refer to FIGURE 10.3. NOTE: Front and rear caster assemblies are replaced in the same manner. NOTE: When replacing the front/rear caster assemblies, it is necessary to brace the caster assemblies to prevent the wheel from spinning. 1. -

Page 68: Adjusting Forks

SECTION 10—SHROUD/WHEELS Adjusting Forks NOTE: For this procedure, refer to FIGURE 10.4. 1. Remove the dust cover. 2. To properly tighten caster journal system and guard against flutter, perform the following check: A. Tip back the wheelchair. B. Pivot both forks and casters to top of their arc simultaneously. C. Let casters drop to bottom of arc (wheels should swing once to one‐side, then immediately rest in a straight downward position). D. Adjust locknuts according to freedom of caster swing. 3. Test wheelchair for maneuverability. 4. Readjust locknuts if necessary, and repeat STEPS 1‐3 until correct. 5. Snap dust cover into the caster headtube ensuring that the tabs are under the plastic side shrouds. NOTE: Components exploded for clarity. There is no need to remove the fork from the base frame. Tabs Base Frame Dust Cover Locknut Washer Side Shroud Caster Headtube Fork FIGURE 10.4 Adjusting Forks Pronto®... -

Page 69: Section 11-Batteries

DO NOT tip the batteries. Keep the batteries in an upright position. Invacare strongly recommends that battery installation and battery replacement always be done by a qualified technician. After ANY adjustments, repair or service and before use, make sure all attaching hardware is tightened securely - otherwise injury or damage may result. -

Page 70: Installing/Removing The Batteries

SECTION 11—BATTERIES Installing/Removing the Batteries NOTE: For this procedure, refer to FIGURE 11.1 on page 71 and FIGURE 11.2 on page 71. NOTE: Have the following tools available: TOOL COMMENTS Battery Lifting Strap Supplied 1/2-inch (6 pt) Box Wrench Not Supplied 7/16-inch (6pt) Box Wrench Not Supplied 3/8-inch (6pt) Box Wrench Not Supplied Diagonal Cutters Not Supplied Installing 1. Place the wheelchair in a well ventilated area where work can be performed without risking damage to carpeting or floor covering. - Page 71 SECTION 11—BATTERIES DETAIL“A” - BATTERIES WITH BUILT-IN DETAIL“B” - BATTERIES WITHOUT LIFTING STRAPS BUILT-IN LIFTING STRAPS Built-in Lifting Battery Lifting Straps Straps Rear Battery Front Battery Battery Tray Battery Battery Terminals/Posts FIGURE 11.1 Installing/Removing the Batteries 9. Connect the front battery to the controller (RED connector). Refer to FIGURE 11.2. 10. Connect the rear battery to the front battery (RED and BLACK connectors). Refer to FIGURE 11.2.

-

Page 72: Removing

SECTION 11—BATTERIES Removing 1. Place the wheelchair in a well ventilated area where work can be performed without risking damage to carpeting or floor covering. 2. Verify the joystick On/Off switch is in the Off position and disconnect joystick. Refer to Disconnecting/Connecting the Joysticks on page 42. 3. Remove the seat. Refer to Removing/Installing the Seat Assembly on page 50. 4. Remove the top shroud. Refer to Removing/Installing the Shrouds on page 65. 5. Disconnect the front battery from controller (RED connector). Refer to FIGURE 11.2. 6. Move aside the motor leads and controller cable to allow unobstructed access to the front of the battery tray. 7. Disconnect the rear battery from the front battery (RED and BLACK connectors). Refer to FIGURE 11.2. 8. If necessary, disconnect the wiring harness from batteries. Refer to Connecting/ Disconnecting the Battery Wiring Harness on page 72. 9. Unfasten the retaining strap that secures the two batteries in the battery tray. NOTE: Perform this section on one battery at a time starting with the FRONT battery. Repeat STEP 10 to remove remaining battery from battery tray. 10. Perform one of the following to remove the battery from the battery tray: • Batteries with Built‐In Lifting Strap ‐ Use built in lifting strap to remove the battery from the battery tray (Detail “A” of FIGURE 11.1). •... -

Page 73: Connecting

SECTION 11—BATTERIES NOTE: For this procedure, refer to FIGURE 11.3 on page 74. Connecting 1. Peel back battery terminal covers to expose battery clamp on each battery cable as follows: A. RED battery clamp cover from RED battery cable. B. BLACK battery clamp cover from BLACK battery cable on front battery or GREY battery clamp cover from BLACK battery cable on rear battery. 2. Using the mounting screws and nuts, secure the battery cables to the battery terminals as shown in FIGURE 11.3 in the following order: A. NEGATIVE (‐) BLACK battery cable to NEGATIVE (‐) battery terminal/post. B. POSITIVE (+) RED battery cable to POSITIVE (+) battery terminal/post. 3. Verify wiring harness is correctly installed and securely tightened. 4. Verify proper battery orientation. 5. Reposition battery terminal covers over battery post(s). 6. Using new tie‐wraps, secure the terminal covers to the battery terminals as shown in FIGURE 11.3. 7. Repeat STEPS 1‐6 to install and connect the rear battery to the rear battery harness. Disconnecting 1. Remove the existing tie‐wraps that secure the battery terminal covers to the battery terminals. 2. Peel back battery terminal covers to expose battery clamp on each battery cable as follows: A. -

Page 74: Charging Batteries

SECTION 11—BATTERIES POSITIVE (+) Battery Cable, NEGATIVE (-) Mounting Screw with Battery Cable Fuse Hardware Tie-Wrap NEGATIVE (-) Battery Terminal Mounting Screw Locknut Tie-Wrap POSITIVE (+) Battery Battery Terminal FIGURE 11.3 Connecting/Disconnecting the Battery Wiring Harness Charging Batteries WARNING Never attempt to recharge the batteries by attaching cables directly to the battery terminals. -

Page 75: When To Charge Batteries

SECTION 11—BATTERIES CAUTION As a general rule, you should recharge your batteries as frequently as possible to assure the longest possible life and to minimize required charging time. Plan to recharge them when you DO NOT anticipate using the wheelchair. Some basic concepts which will help you understand this automatic process are: The amount of electrical current drawn within a given time to charge a battery is called ... -

Page 76: Mpj+ Joystick

SECTION 11—BATTERIES MPJ+ Joystick NOTE: For this procedure, refer to FIGURE 11.5. The far right side of the display screen is the Battery Gauge Display (BGD). It provides information on the remaining charge in the batteries. At full charge, solid blocks fill in all ten Display segments between E (Empty) and F (Full). Screen As the battery becomes discharged, the Battery Gage farthest segments will progressively Display disappear a bar at a time until no segments appear between E and F. At this level the FIGURE 11.5 MPJ+ Joystick user should charge the batteries as soon as possible. Battery Charger Operation WARNING READ and CAREFULLY follow the manufacturer’s instructions for each charger (supplied or purchased). If charging instructions are not supplied, consult a qualified technician for proper procedures prior to use. - Page 77 SECTION 11—BATTERIES 2. The On/Off LED indicator illuminates solid RED indicating that the charger is ON. 3. If the On/Off LED indicator is ʺBlinkingʺ RED, this is abnormal. Unplug AC power cord from the on‐board battery charger and wall outlet. Contact Invacare at the number listed on the back page of this manual. 4. When the On/Off LED indicator light is OFF, charger is OFF. 5. When the Charge LED indicator light is YELLOW, the batteries are charging. 6. When the Charge LED indicator light is solid GREEN, the batteries are fully charged (as their condition will allow). At this point, the charger automatically stops charging. 7. When charging is complete, unplug the male connector of the AC power cord from the wall outlet and then unplug the female connector of the AC power cord from the AC receptacle on the charger. WARNING DO NOT operate wheelchair with AC power cord attached to the wheelchair. To Wall Outlet Male Connector on AC Power Cord...

-

Page 78: Independent Charger

SECTION 11—BATTERIES Independent Charger NOTE: The charger port located on the Front of the joystick requires the use of an independent charger. The independent charger is not supplied with the wheelchair. NOTE: For this procedure, refer to FIGURE 11.7. WARNING READ and CAREFULLY follow the individual instructions for each charger (supplied or purchased). If charging instructions are not supplied, consult a qualified technician for proper procedures. CAUTION DO NOT use an independent charger with an output rating of over 8A (amps). Oth- erwise, damage may occur. -

Page 79: Global Limited Warranty (Excluding Canada)

Invacare warrants the seat frame to be free from defects in materials and workmanship for a period of three (3) years from the date of purchase from Invacare or a dealer, with a copy of the seller’s invoice required for coverage under this warranty. -

Page 80: Canada Limited Warranty

Invacare warrants the seat frame to be free from defects in materials and workmanship for a period of three (3) years from the date of purchase from Invacare or a dealer, with a copy of the seller’s invoice required for coverage under this warranty.

Need help?

Do you have a question about the Pronto M94 and is the answer not in the manual?

Questions and answers