Bunn TITAN DUAL Installation & Operating Manual

Hide thumbs

Also See for TITAN DUAL:

- Installation and operating manual (57 pages) ,

- Programming manual (36 pages) ,

- Service & repair manual (30 pages)

Table of Contents

Advertisement

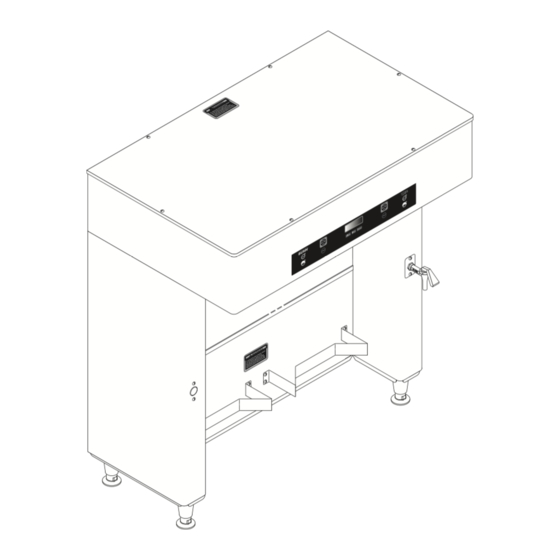

TITAN DUAL™

INSTALLATION & OPERATING MANUAL

BUNN-O-MATIC CORPORATION

POST OFFICE BOX 3227

SPRINGFIELD, ILLINOIS 62708-3227

PHONE: (217) 529-6601 FAX: (217) 529-6644

To ensure you have the latest revision of the manual or to obtain the illustrated parts catalog, please visit the Bunn-O-Matic website, at

www.bunn.com. This is absolutely FREE, and the quickest way to obtain the latest catalog and manual updates. Contact Bunn-O-Matic

Corporation at 1-800-286-6070 to obtain a paper copy of the required Illustrated Parts Catalog mailed via U.S. Postal Service.

www.bunn.com

40119.0000C 03/08 ©2007 Bunn-O-Matic Corporation

Advertisement

Chapters

Table of Contents

Summary of Contents for Bunn TITAN DUAL

- Page 1 PHONE: (217) 529-6601 FAX: (217) 529-6644 To ensure you have the latest revision of the manual or to obtain the illustrated parts catalog, please visit the Bunn-O-Matic website, at www.bunn.com. This is absolutely FREE, and the quickest way to obtain the latest catalog and manual updates. Contact Bunn-O-Matic Corporation at 1-800-286-6070 to obtain a paper copy of the required Illustrated Parts Catalog mailed via U.S.

-

Page 2: Warranty

SOLE OPTION AS SPECIFIED HEREIN, TO REPAIR, REPLACEMENT OR REFUND. In no event shall BUNN be liable for any other damage or loss, including, but not limited to, lost profits, lost sales, loss of use of equipment, claims of Buyer’s customers, cost of capital, cost of down time, cost of substitute equipment, facilities or services, or any other special, incidental or consequential damages. -

Page 3: Table Of Contents

INTRODUCTION This equipment will brew coffee into an awaiting server or airpot. The brewer may have an auxillary hot water faucet. It is only for indoor use on a sturdy and level counter or shelf. Please install in an area where there are no water jet devices. -

Page 4: User Notices

USER NOTICES Carefully read and follow all notices in this manual and on the equipment. All labels on the equipment should be kept in good condition. Replace any unreadable or damaged labels. WARNING HAZARDOUS VOLTAGE DISCONNECT FROM POWER SOURCE BEFORE REMOVING! 12559.0003 #00986.0000 #00658.0000... -

Page 5: Electrical Requirements

ELECTRICAL REQUIREMENTS WARNING - If the power cord is ever damaged, it must be replaced by the manufacturer or its service agent with a special cord available from the manufacturer or its service agent in order to avoid a hazard. Refer to Data Plate on the Brewer, and local/national electrical codes to determine circuit requirements. -

Page 6: Plumbing Requirements

NOTE - Bunn-O-Matic recommends 3⁄8" copper tubing for all installations from the 1⁄2" water supply line. A tight coil of copper tubing in the water line will facilitate moving the brewer to clean the counter top. Bunn-O-Matic does not recommend the use of a saddle valve to install the brewer. The size and shape of the hole made in the supply line by this type of device may restrict water flow. -

Page 7: Operating Controls

OPERATING CONTROLS READY TO BREW ENABLE ENABLE ON / OFF ON / OFF WATER TEMP: 200° BREW BREW LARGE LARGE BREW BREW SMALL SMALL A. MAIN ON/OFF SWITCH This switch, located under the brewer in front of the right rear leg, turns power on and off to all components in the brewer. -

Page 8: Initial Set-Up

INITIAL SET-UP Insert an empty funnel into the funnel rails of one of the 205° F (96.1° C) brew stations. Place an empty server under the funnel. Connect the brewer to the power source. Make sure the corresponding ON/OFF switch is ON (LED will be lit). Water will flow into the tank and stop when the tank is filled to its capacity. -

Page 9: Coffee Brewing

1. Begin each brew cycle with a clean empty brew funnel. edge of filter 2. Insert a BUNN filter into the funnel. NOTE: The funnels are equipped with 4 wire loops that can be folded over top edge of filter if desired, to prevent filter from folding in during the brew cycle. -

Page 10: Cleaning

1. The use of a damp cloth rinsed in any mild, nonabrasive, liquid detergent is recommended for cleaning all surfaces on Bunn-O-Matic equipment. Do NOT clean this equipment with a water jet device. 2. Check and clean each sprayhead. The sprayhead holes must always remain open. -

Page 11: Glossary

GLOSSARY BREW LOCKOUT: The inability to initiate a brew if the water temperature is less than the ready temperature programmed into the brewer. BREW METER: The setting of a pulse brew routine by entering in the total desired water delivery time. The brewer will then calculate and perform a pulse brew routine using a predetermined formula. -

Page 12: Programming

PROGRAMMING Using the menu-driven display on the front of the brewer, the operator has the ability to alter or modify various brewing parameters such as brew temperatures, brew volumes, bypass percentages, pulse brew, etc. This allows for the precise brewing of various flavors of coffee. Programming of the brewer is achieved by entering a certain function. -

Page 13: Programming The Brewer

PROGRAMMING THE BREWER The programming of the brewer is divided into two levels. There is one function in Level 1. All other functions are accessed in Level 2. The following function screens are in order of appearance. Each screen will have instructions on how to access and the procedures for programming the various functions of the brewer. -

Page 14: Function Flow Chart

PROGRAMMING THE BREWER (cont.) PROGRAMMING FUNCTIONS - FLOW CHART BREW LOCKOUT? PROGRAMMING FUNCTIONS - LEVEL I DONE PROGRAMMING FUNCTIONS - LEVEL 2 SET TEMP 200° SET LANGUAGE? UNITS READY TEMP 195° DONE METRIC DONE ENG DONE REFILL L SPRY OZ/M: XX.X R SPRY OZ/M: XX.X BREW SETTINGS ? DONE... -

Page 15: Brew Lockout

PROGRAMMING THE BREWER (cont.) PROGRAMMING FUNCTIONS - LEVEL I BREW LOCKOUT This function allows the operator to prevent or allow brewing if the water temperature is less than the set READY temperature. Procedure for setting Brew Lockout: 1. To access this function screen press and hold the right hidden button. Release when the display reads: BREW LOCKOUT? DONE Press here... -

Page 16: Set Language

PROGRAMMING THE BREWER (cont.) PROGRAMMING FUNCTIONS - LEVEL 2 (cont.) The functions in the second level of programming allow the operator to adjust brew settings and other feature options. To access the level 2 function screens press and hold the right hidden button for approximately 5 seconds. Release when the display reads: SET LANGUAGE This function allows the operator to select the language used for the display. -

Page 17: Units

PROGRAMMING THE BREWER (cont.) PROGRAMMING FUNCTIONS - LEVEL 2 (cont.) UNITS This function allows the operator to select if numeric settings are displayed in English or Metric units. Procedure for setting the Units: 1. Press and hold the right hidden button until the display reads SET LANGUAGE? Press and release the right hidden button until the display reads UNITS. -

Page 18: Set Temp: Xxx

PROGRAMMING THE BREWER (cont.) PROGRAMMING FUNCTIONS - LEVEL 2 (cont.) SET TEMP: XXX° DONE SET TEMP This function allows the operator to adjust the brew water temperature in the tank. This also sets the hot water faucet dispense temperature. READY TEMP: XXX° Procedure for setting the Set Temp DONE Range: 185°... -

Page 19: Ready Temp

PROGRAMMING THE BREWER (cont.) PROGRAMMING FUNCTIONS - LEVEL 2 (cont.) READY TEMP READY TEMP: XXX° This function allows the operator to set the minimum DONE temperature allowable to start a brew cycle. The range can be from 2° to 20° F within the set temperature. The water must be at the READY temperature or higher for the display to indicate READY TO BREW. -

Page 20: Brew Settings

PROGRAMMING THE BREWER (cont.) PROGRAMMING FUNCTIONS - LEVEL 2 (cont.) BREW SETTINGS ? BREW SETTINGS This function allows the operator to modify the BREW VOLUMES, BYPASS PERCENTAGES and BREW METER for each batch size of both brew stations. PRESSING NO WILL LEFT SIDE Procedure to set or modify brew volumes. -

Page 21: Bypass

PROGRAMMING THE BREWER (cont.) PROGRAMMING FUNCTIONS - LEVEL 2 (cont.) BREW SETTINGS ? BREW SETTINGS (cont.) Procedure to set or modify % Bypass settings. Range: 0 to 90% for both batch sizes PRESSING NO WILL LEFT SIDE ADVANCE TO NEXT FUNCTION SCREEN MODIFY SHOW NEXT 1. -

Page 22: Brew Meter

PROGRAMMING THE BREWER (cont.) PROGRAMMING FUNCTIONS - LEVEL 2 (cont.) BREW SETTINGS ? BREW SETTINGS (cont.) Procedure to set or modify BREW METER. Range: 1 to 14 for both batch sizes PRESSING NO WILL LEFT SIDE ADVANCE TO NEXT FUNCTION SCREEN MODIFY SHOW NEXT NOTE: Using BREW METER will overwrite PULSE BREW settings. -

Page 23: Pulse Brew

PROGRAMMING THE BREWER (cont.) PROGRAMMING FUNCTIONS - LEVEL 2 (cont.) BREW SETTINGS (cont.) SET PULSE BREW/PREINFUSION This function allows the operator to program the brewer 3. Press and release YES. The display should now to “pulse” the sprayhead flow on and off during a brew read 1ST ON TIME X:XX. -

Page 24: Set Pulse Brew

PROGRAMMING THE BREWER (cont.) PROGRAMMING FUNCTIONS - LEVEL 2 (cont.) BREW SETTINGS (cont.) BREW SETTINGS ? 1st ON TIME X:XX DONE PRESSING NO WILL LEFT SIDE ADVANCE TO NEXT FUNCTION SCREEN MODIFY SHOW NEXT OFF TIME: X:XX DONE PRESS AND RELEASE RIGHT HIDDEN SWITCH UNTIL DISPLAY READS: SET PULSE BREW... -

Page 25: Drip Time

PROGRAMMING THE BREWER (cont.) PROGRAMMING FUNCTIONS - LEVEL 2 (cont.) BREW SETTINGS (cont.) 11. If NO is pressed, display will advance to RIGHT SIDE, along with MODIFY SHOW NEXT; proceed DRIP TIME to step 13. If YES is pressed, display should read This function allows the operator to adjust the DRIP ARE YOU SURE ?. - Page 26 PROGRAMMING THE BREWER (cont.) PROGRAMMING FUNCTIONS - LEVEL 2 (cont.) BREW SETTINGS (cont.) BREW SETTINGS ? COPY SETTINGS ? PRESSING NO WILL LEFT SIDE ADVANCE TO NEXT FUNCTION SCREEN MODIFY SHOW NEXT LEFT ->->->-> RIGHT PRESS AND RELEASE RIGHT HIDDEN SWITCH UNTIL DISPLAY READS: DRIP TIME X:XX ARE YOU SURE ?

-

Page 27: Refill

PROGRAMMING THE BREWER (cont.) PROGRAMMING FUNCTIONS - LEVEL 2 (cont.) REFILL XXX REFILL 155 Range: 0 to 155 DONE This function allows the operator to adjust the sensitiv- ity of the refill circuit. This is mainly a troubleshooting feature. Water in different geographical locations can LSPRY OZ/M: XX.X have different conductivities. -

Page 28: Flow Rates

PROGRAMMING THE BREWER (cont.) PROGRAMMING FUNCTIONS - LEVEL 2 (cont.) L/R SPRAY OZ/M L SPRY OZ/M: XX.X This function allows the operator to view or to enter DONE the actual flow rate coming out of the sprayhead for each side of the brewer. This is NOT used to control the actual flow rate, but to tell the internal controller how fast the water is flowing. - Page 29 PROGRAMMING THE BREWER (cont.) PROGRAMMING FUNCTIONS - LEVEL 2 (cont.) L BYPS OZ/M: XX.X L/R BYPASS OZ/M DONE This function allows the operator to view or to enter the actual flow rate coming out of the bypass nozzle for each side of the brewer. This is NOT used to control the actual flow rate, but to tell the internal controller R BYPS OZ/M: XX.X how fast the water is flowing.

-

Page 30: Calibrate Flow

PROGRAMMING THE BREWER (cont.) PROGRAMMING FUNCTIONS - LEVEL 2 (cont.) CALIBRATE FLOW CALIBRATE FLOW? This function allows the operator to enter the actual flow rate of the sprayhead and the bypass for each side of the PRESSING NO WILL ADVANCE TO brewer by dispensing both separately for one minute. - Page 31 PROGRAMMING THE BREWER (cont.) PROGRAMMING FUNCTIONS - LEVEL 2 (cont.) CALIBRATE FLOW (Continued) CALIBRATE FLOW? Procedure to calibrate the bypass flow rate: PRESSING NO WILL ADVANCE TO 1. Place a container, accurately graduated and with a BREW COUNTERS minimum capacity of 60 ounces, beneath the fun- nel.

-

Page 32: Brew Counters

PROGRAMMING THE BREWER (cont.) PROGRAMMING FUNCTIONS - LEVEL 2 (cont.) BREW COUNTERS BREW COUNTERS? This function allows the operator to track the total num- ber of brew cycles completed, as well as the number of PRESSING NO WILL ADVANCE TO batches brewed using each of the brew buttons. -

Page 33: Enable Ads

PROGRAMMING THE BREWER (cont.) PROGRAMMING FUNCTIONS - LEVEL 2 (cont.) ENABLE ADS 11. To write the bottom line of the new ad, press and This function allows the operator to choose whether release YES. or not to display an advertising message. An ad can be 12. - Page 34 PROGRAMMING THE BREWER (cont.) PROGRAMMING FUNCTIONS - LEVEL 2 (cont.) ENABLE ADS (Continued) ENABLE ADS DONE WITH YES FLASHING PRESS DONE WRITE BTM LINE? PRESSING DONE WHEN 2 LINES 16 CHARS NO IS FLASHING WILL PRESSING NO WILL DISABLE THIS FUNC- RETURN TO AVAILABLE TION AND ADVANCE TO...

-

Page 35: Enable Clean

PROGRAMMING THE BREWER (cont.) ENABL CLEAN ? PROGRAMMING FUNCTIONS - LEVEL 2 (cont.) DONE ENABL CLEAN WITH YES FLASHING WITH NO FLASHING This function allows the operator to enable the sanita- PRESS DONE PRESS DONE tion function and set the time before a cleaning alert will be displayed. -

Page 36: Enable Energy Saver

PROGRAMMING THE BREWER (cont.) PROGRAMMING FUNCTIONS - LEVEL 2 (cont.) ENABLE ENERGYSAVR This function allows the operator to enable the ENERGY 10. Once the idle time has expired, the display will SAVINGS mode function and set the idle time. Once read either ENERGY SAVER...NO TEMPERATURE the set idle time has expired, the operator can choose or ENERGY SAVER...REDUCED TEMPERATURE,... -

Page 37: Enable Freshness Timer

PROGRAMMING THE BREWER (cont.) PROGRAMMING FUNCTIONS - LEVEL 2 (cont.) ENABLE FRESH TIMER This function allows the operator to enable the Freshness Alert and set the expiration time. The expiration time is the amount of time the product is allowed to sit in the server/dispenser before a fresh batch is brewed. -

Page 38: Asset Number

PROGRAMMING THE BREWER (cont.) PROGRAMMING FUNCTIONS - LEVEL 2 (cont.) ASSET NUMBER ENTER ASSET #? This function allows the operator to enter the machine's asset number. This can be useful for tracking the usage or service of an individual machine within a group. Procedure to enter the asset number: AN XXXXXX 1. -

Page 39: Service Number

PROGRAMMING THE BREWER (cont.) PROGRAMMING FUNCTIONS - LEVEL 2 (cont.) SERVICE NUMBER ENTER SERVICE #? This function allows the operator to enter in the tele- phone number to call if service is needed. The service number will be displayed anytime there is a fault mes- sage displayed (see Troubleshooting on page 46). -

Page 40: Service Tools

PROGRAMMING THE BREWER (cont.) PROGRAMMING FUNCTIONS - LEVEL 2 (cont.) SERVICE TOOLS 9. Press OFF to end the flow of water. This function allows the testing of individual components 10. Press NEXT to advance to the next component to and the ability to check switches for proper function. This be tested, <- <- FUNNEL LOCK. - Page 41 PROGRAMMING THE BREWER (cont.) PROGRAMMING FUNCTIONS - LEVEL 2 (cont.) SERVICE TOOLS? PRESSING NO WILL ADVANCE TO FACTORY DEFAULTS TEST OUTPUTS? REFILL VALVE NEXT PRESSING NO WILL ADVANCE TO TEST SWITCHES <- <- BREW VALVE TANK HEATR RELAY NEXT NEXT <- <- BYPASS VALVE TANK HEATR TRIAC NEXT...

- Page 42 PROGRAMMING THE BREWER (cont.) PROGRAMMING FUNCTIONS - LEVEL 2 (cont.) Procedure to test switches: SERVICE TOOLS? The following switches can be individually tested: <- <- Full Batch Full Batch -> -> PRESSING NO WILL ADVANCE TO <- <- Half Batch Half Batch ->...

- Page 43 PROGRAMMING THE BREWER (cont.) PROGRAMMING FUNCTIONS - LEVEL 2 (cont.) Procedure to test coil frequency: SERVICE TOOLS? 1. Press and hold the right hidden button until the dis- play reads SET LANGUAGE. Press the right hidden PRESSING NO WILL ADVANCE TO button until the display reads SERVICE TOOLS.

-

Page 44: Factory Defaults

PROGRAMMING THE BREWER (cont.) PROGRAMMING FUNCTIONS - LEVEL 2 (cont.) FACTORY DEFAULTS This function allows the operator to erase ALL of the FACTORY DEFAULTS previously entered recipes and ad messages. Factory-set default values will replace ALL previous settings. PRESSING NO WILL RETURN TO MAIN SCREEN Procedure to set factory defaults:... -

Page 45: Default Settings

PROGRAMMING THE BREWER (cont.) PROGRAMMING FUNCTIONS - LEVEL 2 (cont.) FACTORY DEFAULT VALUES Brew Lockout - Enabled Set Temp – 205° Language - English Ready Temp 200° Units - English Enable Ads – Disabled BREW VOLUMES Enable Clean – Disabled Half Batch –... -

Page 46: Troubleshooting

TROUBLESHOOTING A troubleshooting guide is provided to suggest probable causes and remedies for the most likely problems encountered. If the problem remains after exhausting the troubleshooting steps, contact the Bunn-O-Matic Technical Service Department. • Inspection, testing, and repair of electrical equipment should be performed only by qualified service person- nel. - Page 47 TROUBLESHOOTING (cont.) PROBLEM PROBABLE CAUSE REMEDY Temperature Too Low 1. Water temperature in the tank A) Wait for the brewer to heat to the does not meet the ready tempera- proper temperature. ture. B) Disable the BREW LOCKOUT function. See page 13 for proce- dure.

- Page 48 TROUBLESHOOTING (cont.) PROBLEM PROBABLE CAUSE REMEDY Brew cycle will not start 1. No water Check plumbing and shut-off valves 2. No power or incorrect voltage to Check for voltage across the termi- the brewer nals at the terminal block. 3. ON/OFF switch Test the ON/OFF switch.

- Page 49 TROUBLESHOOTING (cont.) PROBLEM PROBABLE CAUSE REMEDY Automatic refill will not operate 1. No water Check plumbing and shut-off or display shows FILL TIME TOO valves LONG 2. Refill probe or Sensitivity set- Remove the strainer and check for ting obstructions. Clear or replace. 3.

- Page 50 TROUBLESHOOTING (cont.) PROBLEM PROBABLE CAUSE REMEDY Automatic refill will not operate or Refill valve – Disconnect the brewer display shows FILL TIME TOO LONG from the power source and remove (Continued) wires from refill valve coil. Check for continuity across the terminals of the solenoid coil.

- Page 51 TROUBLESHOOTING (cont.) PROBLEM PROBABLE CAUSE REMEDY Water flows into tank continuously 1. Refill valve Foreign material lodged in valve, with power removed from brewer. holding it in open state. 2. Refill probe or sensitivity set- Check the sensitivity setting. Refer ting to the REFILL function on page 27.

- Page 52 TROUBLESHOOTING (cont.) PROBLEM PROBABLE CAUSE REMEDY Water will not heat or display shows 1. Limit Thermostat Remove power from the brewer. HEATING TIME TOO LONG. Check for continuity through the limit thermostat. CAUTION: Do not eliminate or bypass limit thermo- stat.

- Page 53 TROUBLESHOOTING (cont.) PROBLEM PROBABLE CAUSE REMEDY No bypass water 1. Bypass valve Test the bypass valve. Refer to the test outputs procedures on page Spitting or unusual steaming from 1. Lime buildup Inspect the probe and tank assembly sprayhead or air vent. for excessive lime deposits.

- Page 54 TROUBLESHOOTING (cont.) PROBLEM PROBABLE CAUSE REMEDY Inconsistent beverage level in 1. Improper water pressure Check operating water pressure to server/dispenser the brewer. It must be between 20 and 90 psi (138 and 620 kPa). 2. Brew valve Test the brew valve. Refer to test outputs on page 40.

- Page 55 Dripping from sprayhead. 1. Brew valve Repair or replace leaky valve Water overflows filter. 1. Type of paper filter BUNN paper filters should be used for proper extraction 2. No sprayhead Check sprayhead Beverage overflows server. 1. Beverage left in server from...

- Page 56 TROUBLESHOOTING (cont.) PROBLEM PROBABLE CAUSE REMEDY Weak beverage. 1. Type of paper filter BUNN paper filters should be used for proper extraction 2. Coffee A sufficient quantity of fresh drip or regular grind should be used for proper extraction. 3. Sprayhead...

-

Page 57: Wiring Diagram

J2-22 BREW RIGHT ON/OFF ON/OFF J16-1 LEFT RIGHT LEFT BREW FULL FULL J16-5 RIGHT HALF LEFT HALF 120/208 OR 120/240 STATIC VOLTS AC SHIELD 50-60 Hz 3 PHASE - 1 PHASE 39972.0000B 07/07 ©2007 BUNN-O-MATIC CORPORATION Page 57 40119 071107... -

Page 58: Schematic Wiring Diagram

J2-22 BREW RIGHT ON/OFF ON/OFF J16-1 LEFT RIGHT LEFT BREW FULL FULL J16-5 RIGHT HALF LEFT HALF STATIC 230/400 VOLTS AC + GND SHIELD 50-60 Hz 3 PHASE - 1 PHASE 39972.0001A 03/08 ©2008 BUNN-O-MATIC CORPORATION Page 58 40119 030608...

Need help?

Do you have a question about the TITAN DUAL and is the answer not in the manual?

Questions and answers