Table of Contents

Advertisement

Quick Links

No. 28200-2-03-8

INSTRUCTION MANUAL

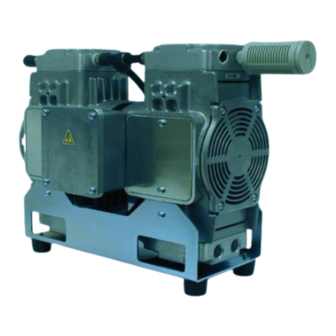

Oscillating Piston Dry Vacuum Pump

DOP-200S,100T,50F,100ST,50DT,50S4,50S4Ⅱ

DOP-200SV,100TV,50FV,100STV,50DTV,50S4V,50S4VⅡ

DOP-300S,150T,300SV,150TV

DOP-300S

DOP-300SV

Request to Users

Please read this manual thoroughly to ensure safe and

effective use of the equipment.

Keep this manual in a safe place.

Due to periodic improvements in performance, the

equipment described in this manual is subject to changes

in dimensions and specifications without prior notice.

ULVAC KIKO, Inc.

Advertisement

Table of Contents

Summary of Contents for Ulvac DOP-300S

- Page 1 Please read this manual thoroughly to ensure safe and effective use of the equipment. Keep this manual in a safe place. Due to periodic improvements in performance, the equipment described in this manual is subject to changes in dimensions and specifications without prior notice. ULVAC KIKO, Inc.

-

Page 2: Table Of Contents

Contents Pages with a shaded background are those which contain items related to safety. Before Using the Equipment ....................... 01 Checks When Opening Packaging ..................... 02 Using the Pump Safely ........................03 ・ Safety icons ..........................03 ・ Cautions for Safety in Use ....................... 04 1. - Page 3 Usage Status Check Sheet (used with requests for disassembly and repair) ・ Product information, service bases, and contact information Figures and Tables Fig. 2.1 DOP-200S .......................... 2 Fig. 2.2 DOP-200SV ........................2 Fig. 2.3 DOP-300S .......................... 2 Fig. 2.4 DOP-300SV ........................2 Fig.

-

Page 4: Before Using The Equipment

Before Using the Equipment Thank you for purchasing this product. Your custom is very much appreciated. This pump is only for vacuum pumping, and may malfunction or cause accidents if not handled appropriately. Read the manual thoroughly, and pay due attention to inspections, maintenance, and safety. -

Page 5: Checks When Opening Packaging

Checks When Opening Packaging Check the following after opening the packaging. (1) Is the product as you requested? (2) Are the accessories and necessary parts included? Standard accessories ・ Instruction manual -------------------- x 1 ・ Inlet pipe protective cap and vent plug -------------------- x 1 each ・... -

Page 6: Using The Pump Safely

Using the Pump Safely To ensure that the pump is handled correctly, read this section thoroughly before use. This manual and the warning labels on the pump include safety icons as an aid to understanding safety requirements. These safety icons warn the operator and others of possible dangers and damage and should always be followed. -

Page 7: Cautions For Safety In Use

・ Cautions for Safety in Use Danger Applications (1) This pump is not designed to be explosion-proof, and should therefore not be used to evacuate explosive gases. (2) In addition to discharge of gas via the pump outlet, gas may leak from the pump itself. Do not use the pump to evacuate toxic gases. - Page 8 Warning Power Supply (10) Ensure that the power cord used for the pump is appropriate for the rated voltage and current. Use a 4-core cable, with each core wire having a cross-section area of 1.0mm or more. Ensure that one of the core wires is used as an earth wire. Firmly attach the 6 - 12mm diameter SKINTOP compatible cable fitted with the appropriate terminals (M4 terminal block screws) to a terminal block.

- Page 9 Caution Installation (3) The fine clearances used in this pump require that the following conditions be satisfied during storage, installation, and operation. 1. Ambient temperature of 0-40°C and relative humidity of 85% or less during operation. 2. Other conditions for storage and operation a) Level floor of sufficient strength b) No condensation Dust-free environment...

- Page 10 Note Installation (1) Application of shock to the pump, or allowing it to fall over, may result in a malfunction. (2) Do not grip or bend the tube on the side of the pump. Any damage to this tube may reduce the performance of the pump.

-

Page 11: Product Outline

(4) Do not attempt to evacuate gases containing particles, dust, water, or corrosive gases. (5) Do not operate the pump for long periods at near-atmospheric pressure. 1.2 Specifications Table 1.1 Product Specifications (50Hz/60Hz) Model DOP-200S DOP-200SV DOP-300S DOP-300SV Evacuate rate (L/min) -

Page 12: Thermal Protection Relay

2) Always fit other protective devices (eg earth leakage breaker, motor breaker) in addition to the overload protection relay. Warning See "Warning" (8) on p.04. Caution See "Caution" (5) on p.06. 2. Dimensions (Product specification of each model is put on P.18-21.) Fig.2.1 DOP-200S Fig.2.2 DOP-200SV Fig.2.3 DOP-300S Fig.2.4 DOP-300SV... -

Page 13: Installation And Storage

3. Installation and Storage 3.1 Cautions for Installation and Storage See "Warning" (1), (2), (3), (5), (6), (7), Warning (8), (9), (10), (11), (12) and (13) on p.04 and p.05. See "Caution" (1), (2) and (3) on p.05 Caution and p.06. Note See "Note"... -

Page 14: Fluctuations In The Power Voltage And Frequency

3) Switch power ON, check the direction of rotation, and check for suction. 4) When checks are complete, switch off the main power supply and stop the pump. Check that the pump has stopped. 3.5 Fluctuations in the power voltage and frequency Standard: Rotating electric machine general rules IEC 60034-1:2004. -

Page 15: Cautions For Operation

4. Cautions for Operation 4.1 Cautions for Operation Danger See "Danger" (1) and (2) on p.04. See "Warning"(8), (14), (15) and (16) Warning on p.04 and p.05. Caution See "Caution" (4), (6) and (7) on p.06. See "Note" (3), (4), (5), (6), (7), (8), (9), Note (10), and (11) on p.07. -

Page 16: Pump Performance

5. Pump Performance 5.1 Pressure Achieved The term “pressure achieved” as employed in the catalogue and in this manual is defined as “the minimum pressure obtained by the pump without introduction of gas from the pump inlet (i.e. the no-load condition)”. Note that the indicator values for pressure may differ between types of vacuum gauges. -

Page 17: Maintenance, Inspection, And Repair

6. Maintenance, Inspection, and Repair 6.1 Cautions for Maintenance, Inspection, and Repair Danger See "Danger" (3) on p.04. See "Warning" (4), (17) and (18) on Warning p.04 and p.05. Caution See "Caution" (8) and (9) on p.06. Note See "Note" (13) on p.07. Customer repair technicians are able to perform the following maintenance and repairs. - Page 18 Bearings 1 set 1 set 15000 h ※1 DOP-200S,200SV,100T,100TV,50F,50FV,100ST,100STV,50DT,50DTV,50S4,50S4V,50S4Ⅱ,50S4VⅡ ※2 DOP-300S,300SV,150T,150TV ※3 DOP-50S4,50S4V,50S4Ⅱ,50S4VⅡ:Quantity 4 Life of these components tends to be extended when the requirements in "4.1 Cautions for Operation" are followed, and the pump is operated under a light load. The term 'light load' refers to operation at achieved pressure (inlet closed).

-

Page 19: Replacing Consumables And Cleaning

It is recommended that the consumables for the remaining three heads are also replaced using this procedure. The replacement procedure is described using the DOP-200S. Remove the angle when replacing consumables in the vertical type of pump. -

Page 20: Preparations For Replacing The Pump

1) Preparations for Replacing the Pump (1) Switch off the pump primary power supply, and remove the piping connected to the inlet pipe. (2) Remove the pump from the equipment. (3) Open the terminal box, and remove the wiring connected to the terminal block. (1),(2) Remove from the equipment. -

Page 21: Removing The Cylinder

(1) Loosen the screws. (2) Pull the joint forward. (3) Remove the head cover. 3) Removing the Cylinder (1) Mark the casing and cylinder with a permanent marker before removing the cylinder. (2) While wearing the gloves, turn the fan slowly upwards. Always ensure that gloves are worn. -

Page 22: Removing The Holder Plate, Cup Packing, And Inlet Valve Rubber Separator

4) Removing the Holder Plate, Cup Packing, and Inlet Valve Rubber Separator (1) Mark the holder plate at the mark on the casing. (2) Loosen the four countersunk M5xL12 screws in the holder plate. While wearing gloves, hold the loosened connecting rod and loosen the four countersunk screws. (3) Remove the holder plate. -

Page 23: Removing Small Cylinder Components

5) Removing Small Cylinder Components (1) Loosen the outlet valve holder plate M3xL5 roundhead screw. (2) Remove the outlet valve holder plate, backup outlet valve, and outlet valve. (3) Loosen the inlet valve holder plate M3xL5 roundhead screw. (4) Remove the inlet valve holder plate and inlet valve. -

Page 24: Detailed Holder Plate Components

6) Detailed Holder Plate Components (1) Holder plate and cup packing components list e: Inlet valve rubber separator f: Cup packing f e 7) Replacing and Assembling Consumables (1) Replace the cup packing. Place the cup packing on the connecting rod to ensure that the canopy is downwards. - Page 25 (4) Place two inlet valves on the washed cylinder and place the backup inlet valve, inlet valve holder plate on top. Ensure that the inlet valve holder plate is mounted in the correct orientation. The top of the inlet valve holder plate is set facing up so that the shorter direction (distance from the center of the hole to the edge face) is pointing towards the right-hand side of the inlet valve.

- Page 26 (7) Align the cylinder with the mark, and insert in the cup packing. (8) Remove the head cover gasket and wash the head cover. After washing, blow with compressed air, and fit the new gasket. (9) Insert the head cover joint in the connecting tube and align the screw holes in the casing and head cover.

-

Page 27: Troubleshooting List

6.5 Troubleshooting List Table 6.3 Troubleshooting List Problem Causes Solutions Reference (1) Not connected to power supply. (1) Connect power supply. (2) The main power supply switch is not (2) Set switch to I. (3) Problem with power supply voltage. (3) Ensure that voltage variation is within +/-10%. -

Page 28: Product Specification Of Each Model

7. Product specification of each model (50/60Hz) Model DOP-100T DOP-100TV DOP-50F DOP-50FV Evacuate rate (L/min) 100/110 50/55 Pressure achieved 0.27 (kPa) 3φ200V280W4P 50/60Hz 3φ200V280W4P 50/60Hz 3φ220V280W4P 60Hz 3φ220V280W4P 60Hz Motor Fitted with thermal protection relay Fitted with thermal protection relay (automatic reset type) (automatic reset type) Voltage, frequency 200V・50Hz 200V・60Hz 220V・60Hz 200V・50Hz 200V・60Hz 220V・60Hz... - Page 29 Product specification of each model (50/60Hz) Model DOP-100ST DOP-100STV DOP-50DT DOP-50DTV Evacuate rate (L/min) 100/110 50/55 Pressure achieved (kPa) 3φ200V280W4P 50/60Hz 3φ200V280W4P 50/60Hz 3φ220V280W4P 60Hz 3φ220V280W4P 60Hz Motor Fitted with thermal protection relay Fitted with thermal protection relay (automatic reset type) (automatic reset type) Voltage, frequency 200V・50Hz 200V・60Hz 220V・60Hz 200V・50Hz 200V・60Hz 220V・60Hz Rated current (A)

- Page 30 Product specification of each model (50/60Hz) Model DOP-50S4 DOP-50S4V DOP-50S4Ⅱ DOP-50S4VⅡ Evacuate rate (L/min) 50/55 Pressure achieved 12(Single head) 12(Sigle head) (kPa) 3φ200V280W4P 50/60Hz 3φ200V400W4P 60Hz Motor Fitted with thermal protection relay Fitted with thermal protection relay (automatic reset type) (automatic reset type) —...

- Page 31 Product specification of each model (50/60Hz) Model DOP-150T DOP-150TV Evacuate rate (L/min) 140/160 Pressure achieved (kPa) 3φ200V400W4P 50/60Hz 3φ220V400W4P 60Hz Motor Fitted with thermal protection relay (automatic reset type) Voltage, frequency 200V・50Hz 200V・60Hz 220V・60Hz Rated current (A) Speed (r.p.m) 1401 1672 1701 O.D.φ16×I.D.φ12 (R1/2)

-

Page 32: In Conclusion

8. In Conclusion Please contact the manufacturer’s sales division if you have any questions. Warranty (1) The warranty for this pump (this equipment) extends for a period of one year from the date of shipment. (2) Any malfunctions or defects which occur under normal usage conditions during the warranty period will be repaired free of charge. -

Page 33: Usage Status Check Sheet

Usage Status Check Sheet (for use in Instruction Manual) * For the purpose of safety control of repair personnel, fill in within the heavy line frame and attach the sheet to the item of which repair is requested. * In case this sheet were not attached or filled in, your request of repair and service may not be accepted. - Page 34 株式会社アルバック 規格品事業部 東日本営業部 〒253-8543 神奈川県茅ヶ崎市萩園2500 TEL:0467-89-2416 株式会社アルバック 規格品事業部 西日本営業部 〒532-0003 大阪府大阪市淀川区宮原3-3-31 上村ニッセイビル5F TEL:06-6397-2286 ULVAC KIKO,Inc. https://ulvac-kiko.com/en Please contact us for products, Service Base or other Inquiries from here. https://showcase.ulvac.co.jp/en/ ULVAC,Inc. Components Division 2500 Hagisono, Chigasaki, Kanagawa, 253-8543, Japan TEL:+81-467-89-2261...

Need help?

Do you have a question about the DOP-300S and is the answer not in the manual?

Questions and answers