Table of Contents

Advertisement

Advertisement

Table of Contents

Summarization of Contents

OUTLINE

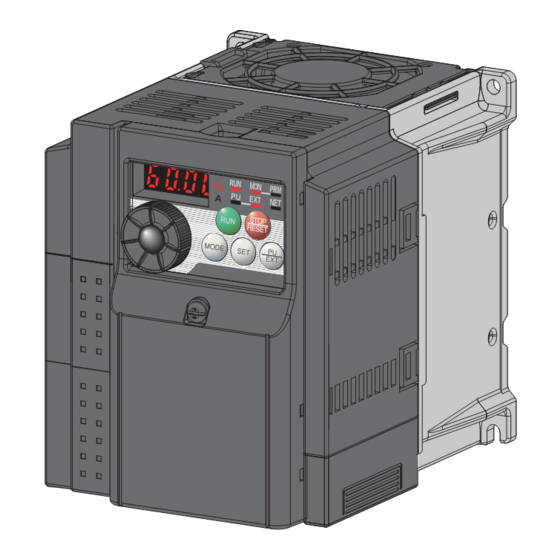

Product checking and parts identification

Instructions for unpacking and verifying the inverter model and components against the order and ensuring the product is intact.

Inverter and peripheral devices

Overview of the inverter unit and its associated peripheral devices, including power supplies, contactors, and filters.

Removal and reinstallation of the cover

Detailed procedures for safely removing and reinstalling the front and wiring covers of the inverter unit.

Installation of the inverter and enclosure design

Guidelines for designing and manufacturing enclosures, considering heat generation, environment, and equipment layout for optimal reliability.

WIRING

Terminal connection diagram

Diagram illustrating the connections for main circuit, control circuit, frequency setting, and safety stop signals.

Main circuit terminal specifications

Detailed specifications for main circuit terminals, including AC power input, inverter output, and connections for brake units and reactors.

Control circuit specifications

Details on control circuit terminals, including input signals, output signals, communication, and safety stop function.

Connection of stand-alone option unit

Instructions for connecting optional units like brake resistors, brake units, power factor converters, and DC reactors.

PRECAUTIONS FOR USE OF THE INVERTER

EMC and leakage currents

Measures to suppress electromagnetic interference and leakage currents, including selection of breakers and filters.

Installation of power factor improving reactor

Guidance on installing AC reactors to prevent excessive peak current flow in the power input circuit.

Power-OFF and magnetic contactor (MC)

Recommendations for using magnetic contactors on the inverter input side for safety and maintenance.

Inverter-driven 400V class motor

Measures to address surge voltage issues when driving 400V class motors, including motor insulation and carrier frequency.

Precautions for use of the inverter

General safety precautions for handling, wiring, and operating the inverter to prevent damage or injury.

Failsafe of the system which uses the inverter

Methods for implementing failsafe systems using inverter status signals and backup methods outside the inverter.

PARAMETERS

Operation panel

Detailed explanation of the names and functions of the operation panel keys, indicators, and displays.

Parameter list

Comprehensive list of all inverter parameters, their functions, setting ranges, initial values, and references.

Adjustment of the output torque (current) of the motor

Methods for adjusting motor torque, including manual torque boost, slip compensation, and stall prevention.

Limiting the output frequency

Settings for maximum, minimum, and high-speed output frequencies, and avoiding mechanical resonance points.

V/F pattern

Configuration of V/F patterns, including base frequency, voltage settings, and load pattern selection.

Frequency setting by external terminals

Methods for setting frequency using external terminals, including multi-speed operation, jog operation, and remote setting.

Setting of acceleration/deceleration time and acceleration/deceleration pattern

Adjusting acceleration and deceleration times, and selecting S-pattern or linear acceleration/deceleration.

Selection and protection of a motor

Guidelines for selecting motors and configuring motor protection features like overheat and stall prevention.

Motor brake and stop operation

Configuration of DC injection brake, regenerative braking, and various motor stop methods.

Function assignment of external terminal and control

Mapping input and output terminal functions for start signals, speed commands, and status monitoring.

Monitor display and monitor output signal

Configuration of operation panel display, PU monitor, and terminal FM output signals for various parameters.

Operation selection at power failure and instantaneous power failure

Settings for automatic restart and power failure deceleration stop functions to ensure continuous operation.

Operation setting at fault occurrence

Configuration of retry functions, phase loss protection, and earth fault detection to manage fault conditions.

Energy saving operation

Optimization settings for energy saving, including optimum excitation control and cooling fan operation.

Motor noise, EMI measures, mechanical resonance

Techniques to reduce motor noise, EMI, and mechanical resonance using PWM carrier frequency and speed smoothing.

Frequency setting by analog input (terminal 2, 4)

Configuration of analog inputs for frequency setting, including selection, bias, and gain adjustment.

Misoperation prevention and parameter setting restriction

Settings to prevent misoperation, such as reset selection, parameter write disable, and password protection.

Selection of operation mode and operation location

Options for selecting operation modes (PU, External, Network) and controlling the inverter via various sources.

Communication operation and setting

Configuration for communication with computers via PU connector, including RS-485 and MODBUS RTU protocols.

TROUBLESHOOTING

Reset method of protective function

Procedures for resetting protective functions, including clearing internal thermal values and retry counts.

List of fault or alarm indications

A comprehensive list of operation panel indications for faults and alarms, with corresponding names and page references.

Causes and corrective actions

Detailed troubleshooting guide for error messages, warnings, and faults, including possible causes and corrective actions.

Correspondences between digital and actual characters

Mapping between digital characters displayed on the operation panel and their actual alphanumeric representations.

Check first when you have a trouble

Initial checks and troubleshooting steps for common issues like motor not starting or abnormal noise.

PRECAUTIONS FOR MAINTENANCE AND INSPECTION

Inspection items

Daily and periodic inspection guidelines to prevent faults due to environmental factors and part deterioration.

Measurement of main circuit voltages, currents and powers

Methods for measuring voltages, currents, and powers on the inverter's input and output sides using various instruments.

SPECIFICATIONS

Rating

Technical specifications including applicable motor capacity, rated capacity, current, voltage, and braking torque.

Common specifications

General specifications covering control methods, frequency ranges, input/output signals, protective functions, and environmental conditions.

Outline dimension drawings

Detailed physical dimensions and mounting information for the inverter and optional units.

Need help?

Do you have a question about the FR-D720S K Series and is the answer not in the manual?

Questions and answers