Table of Contents

Advertisement

Quick Links

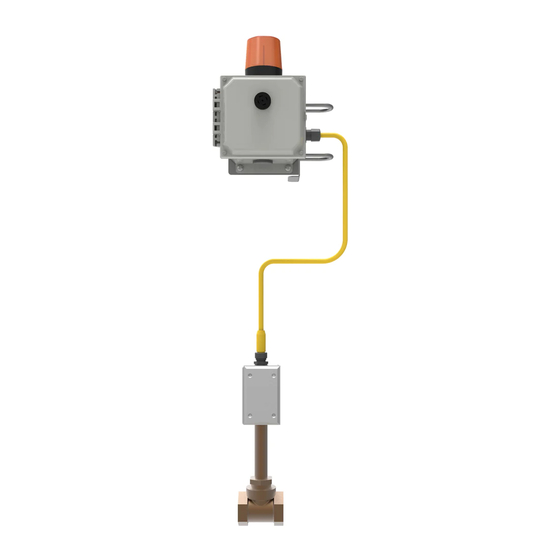

S19-324DGW shown

215-1846 Rev. G: ECO 20-05-028

© 2020 Bradley

Page 1 of 12

6/11/2020

Installation

S19-323

NEMA 3R

S19-324

NEMA 4X

Emergency Signaling System

Table of Contents

Pre-Installation Information . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Install Flow Switch and Mount Assembly . . . . . . . . . . . . . . . . 6

Connect Signaling Assembly to Flow Switch . . . . . . . . . . . . . . 7

Complete Electrical Supply Connections . . . . . . . . . . . . . . . . . 7

Test the Signaling System . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Remote Sensing Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Servicing of Lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Service Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-12

Menomonee Falls, WI 53052 USA

P.O. Box 309

800 BRADLEY (800 272 3539)

+1 262 251 6000

bradleycorp.com

Advertisement

Table of Contents

Summary of Contents for Bradley S19-323E

-

Page 1: Table Of Contents

Service Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-12 S19-324DGW shown P.O. Box 309 Menomonee Falls, WI 53052 USA 215-1846 Rev. G: ECO 20-05-028 800 BRADLEY (800 272 3539) © 2020 Bradley +1 262 251 6000 Page 1 of 12 6/11/2020... -

Page 2: Pre-Installation Information

Failure to do so may result in major product and/or property damage. Constant power supply to safety equipment is necessary for it to function. Avoid cleaners containing organic solvents, alcohols and hydrocarbons. Rinse with potable water after cleaning. Bradley • 215-1846 Rev. G: ECO 20-05-028 6/11/2020... - Page 3 The ANSI/ISEA Z358.1 standard requires an uninterrupted supply of flushing fluid. Bradley plumbed emergency fixtures require a minimum of 30 PSI (0.21MPa) flowing pressure.

-

Page 4: Components

Tee 1/2" (eyewash) 2-3/8" (60mm) for or 1-1/4" (drench eyewash or shower) NPT Inlet 3-9/16" (91mm) for and Outlet drench shower System is prewired. Installer connects ONLY ground black and white wires. Bradley • 215-1846 Rev. G: ECO 20-05-028 6/11/2020... - Page 5 ONLY ground black Body and white wires. Brass Adapter and Tee 2-3/8" (60mm) for 1/2" (eyewash) eyewash or or 1¼" (drench 3-9/16" (91mm) for shower) NPT Inlet drench shower and Outlet Bradley • 215-1846 Rev. G: ECO 20-05-028 6/11/2020...

-

Page 6: Install Flow Switch And Mount Assembly

U-bolts and nuts . • The signaling system can also be bolted to a flat surface such as a wall (hardware for this type of installation is NOT supplied) . Bradley • 215-1846 Rev. G: ECO 20-05-028 6/11/2020... -

Page 7: Connect Signaling Assembly To Flow Switch

. Compliance and conformity to Turn on supply power to the signaling local codes and ordinances is system .Test the signaling system at the responsibility of the installer. this time . Bradley • 215-1846 Rev. G: ECO 20-05-028 6/11/2020... -

Page 8: Test The Signaling System

. Signaling System Maintenance The Bradley Emergency Signaling System is designed to be virtually maintenance free . An occasional damp cloth wiping of the clear dust cover is all that is needed to ensure maximum visual attention-getting ability . -

Page 9: Servicing Of Lights

. which attach the light to the enclosure and remove light . This is a sealed light and has no serviceable components, the complete housing must be replaced . Bradley • 215-1846 Rev. G: ECO 20-05-028 6/11/2020... -

Page 10: Troubleshooting

Check that there is 24VDC being supplied from the power supply mounted on the print circuit board in the signal station enclosure . Component failure . Check light connections and filament in the light . Bradley • 215-1846 Rev. G: ECO 20-05-028 6/11/2020... -

Page 11: Service Parts

Qty. Description 160-467 Screw, 1/4-20x3/4 PN 300 SS 142-002AV Washer, .265x.500x.0.63 Flat 304SS 161-060 Nut, 1/4-20 SS Nylon Insert 269-594 U-Bolt, SS 161-065 Nut, 3/8-16 Hex 18-8SS 161-171 3/4 NPSM Conduit Locknut Bradley • 215-1846 Rev. G: ECO 20-05-028 6/11/2020... - Page 12 Screw, 1/4-20x3/4 PN 300 SS 142-002AV Washer, .265x.500x.0.63 Flat 304SS 161-060 Nut, 1/4-20 SS Nylon Insert 269-594 U-Bolt, SS 161-065 Nut, 3/8-16 Hex 18-8SS 161-171 3/4 NPSM Conduit Locknut (for mounting to heat trace unit) Bradley • 215-1846 Rev. G: ECO 20-05-028 6/11/2020...

Need help?

Do you have a question about the S19-323E and is the answer not in the manual?

Questions and answers