Summarization of Contents

About these instructions

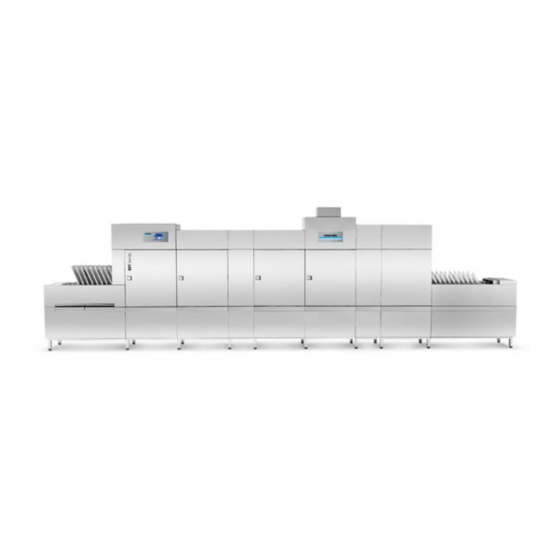

Designated use

Specifies the intended applications for MTR and MTF series dishwashing machines for catering use.

Safety Notes

Non-designated use

Details prohibited uses of the dishwashing machine to prevent damage or injury.

General safety notes

Provides fundamental safety precautions for operating the dishwashing machine.

Electrical Safety

Ensures safe operation by verifying correct electrical connections and protective circuits.

Maintenance and Repair Work

Guidelines for performing maintenance and repairs safely and correctly.

Handling Chemicals

Precautions for safely handling detergents, rinse aids, and other chemicals.

Daily Cleaning and Care

Daily cleaning procedures to maintain machine hygiene and function.

Before Working with the Machine

Checking for Completeness

Verifying the delivery note and checking for any transport damage upon receipt.

Initial Start-up

Steps required for the initial setup and commissioning of the machine.

Controls

Switching on the Screen

Instructions on how to activate the machine's touchscreen display.

Menu Levels

Describes the two menu levels: washing personnel and kitchen manager.

Screen Saver

Details on the screen saver function and how it activates.

Operation

Making Ready for Operation

Procedures to prepare the machine for operation, including automatic start-up.

Before Switching on the Machine

Essential checks and actions before powering on the dishwashing machine.

Switching On

Steps to power on the machine and initiate the heating and filling process.

Washing with Standard Programmes

Overview of the three standard washing programmes and their transport speeds.

Starting / Stopping Transport

How to start, stop, and change the transport speed of the conveyor belt.

Having the Transport Run Backwards

Procedure to reverse the conveyor belt to clear jams.

Washing (MTF Series Machines)

Specific instructions for loading and washing items in MTF series machines.

Washing (MTR Series Machines)

Specific instructions for loading and washing items in MTR series machines.

Container Programme

Details on the specific programme for washing catering containers.

Breaks in Operation

Guidance on managing short breaks during operation to maintain temperatures.

Washing with Special Programmes

Information on available special programmes and their default settings.

Example: Glasswashing Programme

Demonstrates using the glasswashing programme with osmosis water.

Routine Checks

Procedures for performing regular checks on the machine's status and performance.

Water Change in Zone 1

Procedure for draining and refilling the tank in the first zone if heavily contaminated.

Switching Off the Machine

Steps to safely turn off the dishwashing machine.

Maintenance and Care

Every Day

Daily tasks to ensure the machine remains clean and functional.

Cleaning the Grease Filter

Procedure for cleaning the grease filter to protect the exhaust air system.

Cleaning Programme

How to use the machine's automated cleaning programme.

Checking External Water Treatment

Ensuring the correct level of regeneration salt for water treatment.

Every Month

Monthly maintenance tasks for the dishwashing machine.

Cleaning the Roof Cleaning Jet

Instructions for cleaning the roof cleaning jets in each machine zone.

Cleaning the Exhaust Air System

Procedure for cleaning the exhaust air pipes.

Cleaning the Dirt Trap

How to clean the debris filter in the dirt trap.

Descaling

Instructions for descaling the machine to prevent limescale buildup.

Maintenance by Customer Service

Recommendation for regular servicing by a Winterhalter technician.

Changing the Detergent Product

Procedure for safely changing detergent products and readjusting dosing equipment.

Taking Out of Service for a Long Time

Taking Back into Service

Steps to follow when putting the machine back into operation after a long period of inactivity.

Organisation of the Washing Process

Structural Requirements

Key requirements for the washing area to ensure hygienic washing.

Organisation

Operational guidelines for loading, washing, and hygiene practices.

Requirements on the Dishwashing Machine

Ensuring machine settings and maintenance meet hygiene standards.

Requirements on the Dishes

Criteria for crockery to ensure optimal washing and drying.

Malfunctions

Malfunctions: Display by Symbols on the Screen

Troubleshooting guide for errors indicated by symbols on the machine's display.

Malfunctions: Display by Fault Code on the Screen

Information on interpreting and resolving malfunctions shown as fault codes.

Malfunctions: Poor Washing Result

Diagnosing and fixing common issues leading to poor washing results.

Info Menu

How to Call up the Info Menu

Instructions on accessing the machine's information display.

PIN Menu

How to Call up the PIN Menu

Steps to access the PIN-protected menu for advanced settings.

The PIN Menu

Overview of the PIN menu functions.

Hygiene Logbook

Accessing and reviewing the machine's hygiene and operational logbook.

Operating Data

Reading and interpreting the machine's operational statistics.

Automatic Start-up

Setting up automatic start-up schedules for the machine.

How to Program Automatic Start-up

Detailed guide for programming weekly and special day automatic start-ups.

General Settings

Accessing and modifying general machine settings.

Date, Time, °Celsius / °Fahrenheit

Setting the date, time, and temperature units on the machine.

Setting the Contrast

Adjusting the screen contrast for better readability.

Setting the Language

Selecting the desired display language for the user interface.

GSM Module (Option)

Define Mobile Phone Number for Text Message Transfer

Configuring the machine to send fault messages via SMS.

Define E-mail Address for Data Transfer

Configuring the machine to send fault messages via email.

Technical Data

Technical Data

Presents factory settings for temperature and hygiene logbook.

Screen Factory Settings

Details on screen configuration and maintenance interval settings.

Operating Conditions

Specifies operating temperature, humidity, and storage conditions.

Emissions

Information on noise and exhaust air emissions from the machine.

Connecting External Dosing Equipment

Installing the Conductivity Electrode

Procedure for installing the conductivity electrode in the wash zone.

Installing the Dosing Tube (Detergent)

Steps to install and route the detergent dosing tube.

Installing the Dosing Tube (Rinse Aid)

Procedure for installing and routing the rinse aid dosing tube.

Electrical Connection

Connecting the external dosing equipment to the machine's electrical terminals.

Commissioning the Dosing Equipment

Steps to commission the external dosing equipment after installation.

Machines with Automated Powder Dosing

Installation of Powder Dosing Device

Instructions for drilling holes and installing a powder dosing device.

Need help?

Do you have a question about the MTF Series and is the answer not in the manual?

Questions and answers