Summarization of Contents

PREFACE

General Precautions

Provides important precautions regarding the use and handling of Yaskawa products.

NOTES FOR SAFE OPERATION

WARNING and CAUTION Definitions

Defines the meaning of WARNING and CAUTION symbols used for safety.

Manual Structure

Classification by Area (A, B, C)

Classifies chapters into A (Selection), B (Design), and C (Maintenance) for user guidance.

Basic Terms

Servomotor, Servopack, Servodrive, Servo System

Defines key terminology used for servo components and systems.

Visual Aids

Explanation of Icons

Explains icons used for references, speed/torque mode, position mode, and digital operator.

CHAPTER 1 FOR FIRST-TIME USERS OF AC SERVOS

Basic Understanding of AC Servos

Covers basic configuration of servo mechanisms and technical terms.

Servo Mechanisms

Explains the fundamental concepts and definitions of servo mechanisms.

Servo Configuration

Details the components and configuration of a typical servo system.

Features of Σ-Series Servos

Highlights key features of SGM/SGMP servomotors and DR2 servopacks.

CHAPTER 2 BASIC USES OF Σ-SERIES PRODUCTS

Precautions

Provides essential notes for safe and correct usage of the servo products.

Installation

Guides on checking products upon delivery and installing servomotors and servopacks.

Connection and Wiring

Explains connecting peripheral devices and typical main circuit wiring.

Conducting a Test Run

Details the procedure for performing a full test run in two steps for safe operation.

CHAPTER 3 APPLICATIONS OF Σ-SERIES PRODUCTS

Setting User Constants According to Machine Characteristics

Covers setting user constants for motor rotation, overtravel limits, and torque restriction.

Setting User Constants According to Host Controller

Explains setting constants for speed/position references and I/O signals.

Setting Up the Σ Servopack

Details configuring user constants for jog speed, encoder pulses, and motor type.

Setting Stop Mode

Describes methods for adjusting offset, dynamic brake, zero-clamp, and holding brake.

Running the Motor Smoothly

Covers functions like soft start, smoothing, and gain adjustment for smooth operation.

Minimizing Positioning Time

Explains techniques for optimizing positioning time using autotuning and gain settings.

Forming a Protective Sequence

Details using I/O signals for servo alarm, ON signals, positioning complete, and speed coincidence.

Special Wiring

Provides guidance on wiring instructions, noise control, and connecting multiple drives.

CHAPTER 4 USING THE DIGITAL OPERATOR

Basic Operations

Covers connecting the digital operator and basic functions like alarm reset and mode selection.

Operation in Status Display Mode

Explains how to interpret the Servopack status via bit data and codes.

Operation in User Constant Setting Mode

Details how to set user constants using the digital operator's interface.

Operation in Monitor Mode

Describes how to monitor reference values, I/O status, and internal Servopack status.

Operation Using the Digital Operator

Explains simple motor checks and basic operations directly from the digital operator.

Autotuning

Guides on using the automatic tuning function to measure machine characteristics and set constants.

Reference Offset Automatic Adjustment

Explains how to automatically adjust reference voltage offsets for speed/torque control.

Speed Reference Offset Manual Adjustment Mode

Details manual adjustment of reference speed offsets for speed/torque control.

Clearing Alarm Trace-back Data

Describes the procedure to clear the alarm history stored in the Servopack.

Checking Motor Type

Explains how to select the motor type for proper system operation.

Checking Software Version

Explains how to check the software version of the Servopack.

CHAPTER 5 SERVO SELECTION AND DATA SHEETS

Selecting a Σ-Series Servo

Guides on selecting the appropriate Σ-Series Servomotor, Servopack, and Digital Operator.

SGM Servomotor

Presents ratings and specifications for SGM servomotors.

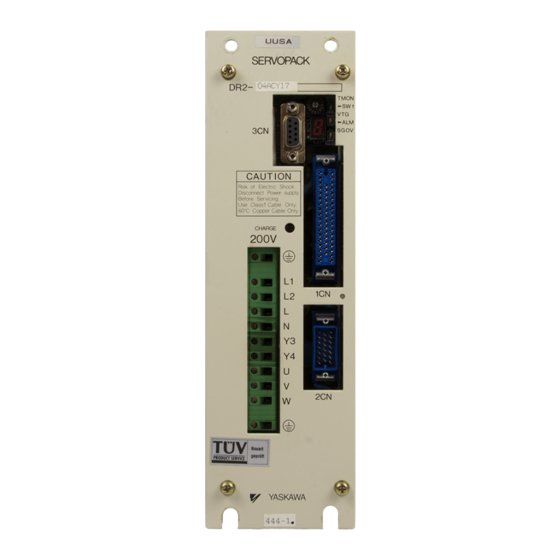

Servopack Ratings and Specifications

Provides detailed ratings and specifications for DR2 Servopacks.

Σ-Series Dimensional Drawings

Includes dimensional drawings for Σ-Series Servomotors, Servopacks, and Digital Operators.

Selecting Peripheral Devices

Guides on selecting peripheral devices like cables, connectors, and filters using flowcharts.

CHAPTER 6 INSPECTION, MAINTENANCE, AND TROUBLESHOOTING

Inspection and Maintenance

Details basic inspections and maintenance for servomotors and servopacks.

Servomotor Inspection and Maintenance

Provides simple daily inspection procedures and maintenance frequencies for servomotors.

Servopack Inspection and Maintenance

Outlines annual inspection procedures and part replacement schedules for servopacks.

Replacing Battery for Absolute Encoder

Explains the procedure for replacing the battery for absolute encoders.

Troubleshooting

Covers causes and remedies for problems with alarm displays and without alarm displays.

Troubleshooting Problems with Alarm Display

Lists common alarms, their causes, and remedies for troubleshooting.

CHAPTER 7 MEASURES TO SATISFY THE REQUIREMENTS OF EMC DIRECTIVE

What is European Safe Standard?

Explains EN standard, CE marking, and the EMC directive.

Measures to Satisfy the Requirements of EMC Directive

Details measures for adapting DR2 Servopack to EMC directives.

Applicable Servomotor

Specifies Yaskawa servomotors conforming to EN standard for EMC compliance.

Applicable Noise Filter

Recommends noise filters for Servopack types based on voltage and current ratings.

Motor Cables

Specifies motor cable requirements, including max. length.

Encoder Cables

Details connectors and cables for PG input (2CN) for incremental and absolute encoders.

Control I/O

Explains the use of connectors and plating for control I/O signals.

Digital Operator and Monitoring by Personal Computer

Advises using digital operator or PC for monitoring only during test runs.

The Core on the Cable

Provides instructions for attaching the core on the cable for noise reduction.

Wiring

Shows wiring examples for motors with brakes, including noise filters and cores.

Appendix A Differences Between DR2 and DR1, SGDA and SGD Servopacks

Comparison of the DR2 Servopack with the DR1 Servopack (1)

Compares features like speed loop, auto-tuning, and communication between DR2 and DR1 servopacks.

Comparison of the DR2 Servopack with the DR1 Servopack (2)

Compares DR2 servopack types, dimensions, terminals, and I/O signals against DR1.

Comparison of the SGDA Servopack with the SGD Servopack

Compares SGDA and SGD servopack features, including speed loop, auto-tuning, and motor compatibility.

Appendix B Servo Adjustment

Σ-Series AC Servopack Gain Adjustment

Provides basic rules for gain adjustment and methods for servo systems.

Adjusting a Servopack for Speed Control

Gives examples of adjusting gains for speed control using manual and auto-tuning methods.

Adjusting a Servopack for Position Control

Provides examples of adjusting gains for position control using auto-tuning and manual methods.

Guidelines for Gain Settings According to Load Inertia Ratio

Presents tables of load inertia values for reference when adjusting gain.

Appendix C List of I/O Signals

List of Input Signals in Speed/Torque Mode (1)

Details input signals for speed/torque control mode (1CN Terminal No.).

List of Input Signals in Speed/Torque Mode (2)

Details input signals for speed/torque control mode (1CN Terminal No.).

List of I/O Signals IN Position Control Mode (1)

Lists input signals for position control mode (1CN Terminal No.).

List of I/O Signals IN Position Control Mode (2)

Lists input signals for position control mode (1CN Terminal No.).

Appendix D List of User Constants

List of User Constants (User Constant Setting)

Lists user constants for speed/torque control, including gain, torque, and sequence settings.

List of User Constants (Memory Switch Setting)

Details memory switch settings for input signals, encoder, and control modes.

List of User Constants (Memory Switch Setting)

Details memory switch settings for operation, TGON, rotation direction, and home position.

List of User Constants (Memory Switch Setting)

Details memory switch settings for position control modes and contact input speed control.

List of User Constants (Memory Switch Setting)

Details memory switch settings for position control modes and contact speed control.

List of User Constants (Memory Switch Setting)

Details memory switch settings for error counter clear, torque reference filter, and reference pulse logic.

Appendix F Relationship between Reference Forms and User Constants

Relationship between Reference Forms and User Constants (1)

Shows relationships between reference forms and user constants for speed/torque control modes.

Relationship between Reference Forms and User Constants (2)

Shows relationships between reference forms and user constants for speed/torque control modes.

Relationship between Reference Forms and User Constants (3)

Shows relationships between reference forms and user constants for position control modes.

Relationship between Reference Forms and User Constants (4)

Details user constants for position control and contact speed control based on memory switch settings.

Appendix G Reviewing the Full-closed Loop Specifications

Grasping the Mechanical Specifications

Outlines methods for checking mechanical specifications for full-closed loop systems.

Linear Scale Specifications and Application Review at Full-closed System

Details linear scale specifications and provides application review for full-closed loop systems.

Need help?

Do you have a question about the SGM-08 and is the answer not in the manual?

Questions and answers