Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for TREND COMBI 1002

- Page 1 COMBI 1002...

-

Page 2: Table Of Contents

COMBI 1002 TECHNICAL DATA Dear Customer Thank you for purchasing this Trend product, we Jig thickness 16mm hope you enjoy many years of creative and productive use. Cutter size 12.7mm Please remember to return your guarantee card Workpiece thickness max. -

Page 3: Safety

COMBI 1002 SAFETY and balance at all times. Do not use recommended when working awkward or uncomfortable hand outdoors. Wear protective hair WARNING: positions. covering to contain long hair. Observe the safety regulations in the 17. Don’t abuse the cable. Never carry 5. - Page 4 15. All fastening screws and nuts should be adhered to. Recommended speeds ensure there is sufficient clearance be tightened using the appropriate are shown in the Trend Routing between cutter tip and inside edge of spanner or key and to the torque Catalogue and/or website.

-

Page 5: Items Enclosed

COMBI 1002 ITEMS ENCLOSED 1 0 0 ITEMS REQUIRED s 1/2” plunge router. s 30mm guide bush. s 12.7 diameter x 50mm cut router cutter with 1/2” shank. s Trestle x 2. s 100mm throat clamp x 2. s Hand tools. -

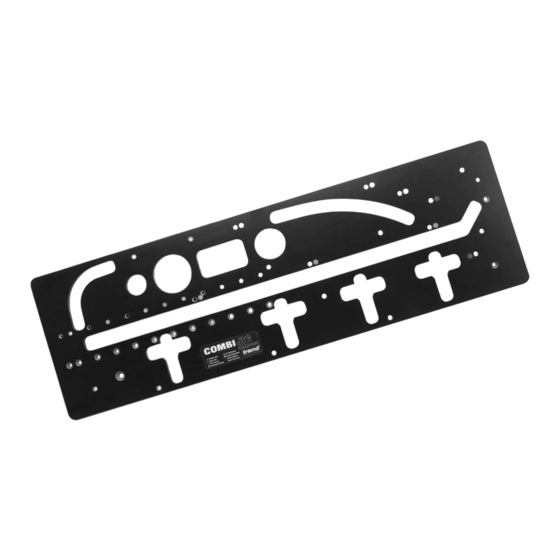

Page 6: Description Of Parts

COMBI 1002 DESCRIPTION OF PARTS E&F E&F Jig body Label Postform joint slot Female joint bush location hole Length setting stop location hole Male joint bush location hole Guide Bush / Accessary bolt on clamp holes Corner radius slot Cutter Checker... -

Page 7: Accessories Recommended Cutters

This can be achieved using Trend sub-bases and 30mm outside diameter guide bush ref. GB30. Trend sub-bases have a central recess to allow fitting of the Trend guide bush to most makes of routers and are available ready to fit the most popular makes. - Page 8 COMBI 1002 General instructions for fitting Sub-bases to Router 1. Fit line up guide bush onto sub-base, with screws supplied. 2. Fit 12.7mm ( ”) shank line up pin into collet of router. Plunge router until pin projects through base and lock plunge.

-

Page 9: Panel Connector Bolts

COMBI 1002 Panel Connector Bolts Ref. PC/10/M ( Pack of 10) Ref. PC/50/M ( Pack of 50) Ref. PC/100/M ( Pack of 100) Ref. PC/1000/M ( Pack of 1000) Panel butt connectors are essential for connecting worktops. They fit into the recess on the underside of the worktop and are tightened with a 10mm spanner. -

Page 10: Bolt-On Carry Case

COMBI 1002 Bolt-on Clamps Optional bolt-on clamps which fit directly onto COMBI1002. Fixing Bolt Kits are required for the clamps (1 off for PJ/CL/S and 2 off for PJ/CL/L). Ref. PJ/CL/S Short Clamp for COMBI1002 (1 off required) Ref. PJ/CL/L... -

Page 11: Assembly

COMBI 1002 ASSEMBLY Margin Distance Allow 8.5mm when cutting joints. Measure or Location Bush Identification use a batten of this thickness to aid Three location bushes are used in different holes setting out. Cutter in the jig to align the correct template aperture for the application. -

Page 12: Operation

COMBI 1002 OPERATION Setting the Length Stop Setting the Length Stop for the Female Cut Length stop on Carry out the setting operation first: underside. Retained s Fit bushes into Green dot location holes with screw & knob and offer the jig to the male worktop as shown. -

Page 13: Female Joint

COMBI 1002 Female Joint When cutting a joint, hold the router s Leave the two location bushes in holes guide bush hard against the template marked Green dot. (The Green dots must be and cut from left to right. It is uppermost). -

Page 14: Male Joint

COMBI 1002 Male Joint Routing the male part of the Joint Depending on accessibility lay female worktop into position on units. Lay male worktop on top and support other end. Using a pencil draw round the female cut onto the... - Page 15 COMBI 1002 s Insert both location bushes into Red dot Setting up length stop for out-of- holes. Red dot face uppermost. square joints s Lay jig across the worktop, ensure the location bushes touch the postform edge. Clamp jig in position with quick action...

-

Page 16: Cutting The Bolt Recesses

COMBI 1002 Setting bolt recess length stop Cutting the Bolt Recesses When the joint has been tested, proceed as follows to cut the recess for panel butt connectors on the underside of the worktop. Underside of worktop The same cutter and guide bush are retained... -

Page 17: Strengthening The Joint

‘sag’ and become misaligned; to reduce this the joint should be reinforced with a loose tongue or biscuit dowels. The biscuit jointing cutter set Trend Ref. 342 can be used with a portable router. The size of biscuit used should be No. 20. -

Page 18: Corner Radius & 22.5° Mitre Joint

COMBI 1002 Routing the Corner Radius Corner Radius Direction of Location bushes Special Note: Due to the nature of this router travel (Black dot) particular edge laminate, the corner radius will be more awkward to laminate. Insert the three location bushes in holes marked Black dot as shown opposite. -

Page 19: Curved Peninsular

COMBI 1002 Routing the Curved Peninsular Curved Peninsular Insert the three location bushes in holes Location bushes (White dot) marked White dot as shown below. Locate the template on the worktop as illustrated ensuring that location bushes are touching the worktop edge. Clamp into position with quick action clamps. -

Page 20: 45° End Cut

COMBI 1002 45° End Cut Routing the 45° End Cut Insert the three location bushes into holes marked Grey dot as shown below. Locate the template on the worktop as illustrated ensuring that bushes are touching the worktop edge. Clamp using two quick... -

Page 21: Cable Tidy Inserts & 35Mm Circular Hinge

COMBI 1002 Cable Tidy Inserts & 35mm Circular Hinge The cable Tidy Insert template is for use with three sizes of plastic inserts, 60mm diameter and 80mm diameter round inserts and a 105mm x 55mm rectangle insert. For 60mmØ insert... -

Page 22: Cutter/Guide Bush Concentricity Checker

COMBI 1002 Cutter/ Guide Bush Concentricity MAINTENANCE Checker The jig has been designed to operate over a s Isolate power to the router. long period of time with a minimum of s Place jig on a support with the cutter/guide maintenance. -

Page 23: Spare Parts List

COMBI 1002 COMBI 1002 - SPARE PARTS LIST v1.0 05/2003 Qty. Desc. Ref. Combi 1002 Jig COMBI/1002 Alloy Bush CJ/BUSH Length Setting Stop CJ/LSK Machine Screw Csk M8 x 50mm slot WP-SCW/41 Washer 8.5mm x 32mm x 1.0mm WP-WASH/17 Knob M8 WP-KNOB/10 Combi Jig ‘O’... -

Page 24: Spare Parts Diagram

COMBI 1002 COMBI 1002 - SPARE PARTS DIAGRAM v1.0 04/2003 -23-... -

Page 25: Trouble Shooting

COMBI 1002 TROUBLE SHOOTING Fault Cause Remedy s Joint does not fit correctly Cutter or guide bush is the Check concentricity of cutter at the radius. incorrect diameter or location with guide bush. Cutter 12.7mm bushes are not against diameter with 30mm diameter worktop edge. - Page 26 RECYCLABLE www.trend-uk.com © Copyright Trend 2011. No part of this publication may be reproduced, stored or transmitted in any form without prior permission. Our policy of continuous improvement means that specifications may change without notice. Trend Machinery and Cutting Tools...

Need help?

Do you have a question about the COMBI 1002 and is the answer not in the manual?

Questions and answers