Advertisement

ISSUE: 0124

by forest

SHED INSTRUCTIONS

BASE KIT 5

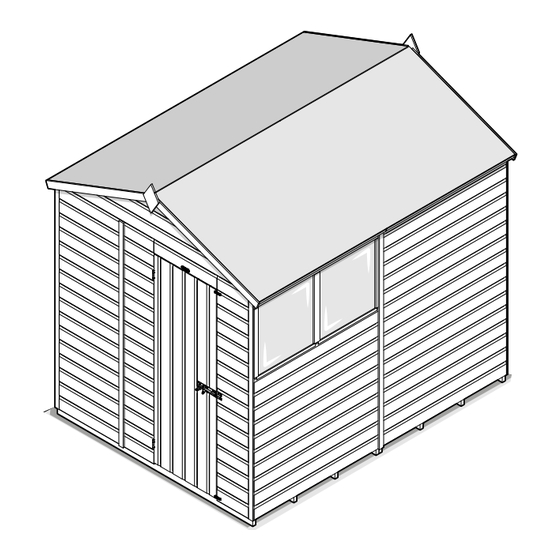

Apex/Reverse apex sheds with a single door & truss for roof structure

Please note these instructions are generic, any differences will be outlined in the steps.

Missing something or need more information?

Visit our website for spare instructions and

Call our aftersales team on

more information

0333 321 3142

www.forestgarden.co.uk

Forest Garden, Oak Drive, Hartlebury Trading Estate, Hartlebury, Worcestershire, DY10 4JB

EU Authorised Representative: Authorised Representative Service, 77 Camden Street Lower Dublin, D02 XE80, Ireland

Advertisement

Table of Contents

Summary of Contents for Forest garden BECKWOOD BASE KIT 5

- Page 1 Visit our website for spare instructions and Call our aftersales team on more information 0333 321 3142 www.forestgarden.co.uk Forest Garden, Oak Drive, Hartlebury Trading Estate, Hartlebury, Worcestershire, DY10 4JB EU Authorised Representative: Authorised Representative Service, 77 Camden Street Lower Dublin, D02 XE80, Ireland...

-

Page 2: Tools Required

BEFORE YOU START.. Please read through this guide to prepare yourself before assembling your shed. We recommend that you check all the components and fixings. Your parts list can be found on your shed label. All our sheds are constructed in the same way, they simply come with different components depending on the type of shed you have. - Page 3 CARE & ATTENTION To help you get the most out of our products it is useful to know a little more about the properties of timber, what is normal and how your shed may behave as the seasons change. Wood is an extremely durable material for construction but as a natural product when used outdoors it is susceptible to changes in the environment.

-

Page 4: Treatment Information

HEALTH & SAFETY We strongly recommend that PPE (Personal Protective Equipment) is used throughout your build to ensure you are protected from any potential health and safety risks. Do not exempt yourself from wearing PPE. Cut-Resistant Protective Glasses Protective Boots Protective Mask Working At Gloves... - Page 5 IDENTIFY YOUR CHOSEN SHED From the floor plans below, identify your shed based on the width, depth and roof type provided. You will need this to identify the side panel positions before assembling your shed. Use the key as a guide. 1ft Panel (295 x 1831mm) 4ft Panel (1180 x 1831mm) (With &...

- Page 6 FLOOR ASSEMBLY THERE ARE NO FIXINGS FOR THIS SECTION. Look through the different visuals and follow the step that suits your chosen shed. FLOOR BEARERS Before assembly, your Floor must be firm and level to ensure the shed lines up and is assembled properly. We recommend that there should be access to all sides of your shed for assembly and any maintenance.

-

Page 7: Window Assembly

WINDOW ASSEMBLY (PLEASE SKIP THIS SECTION IF YOUR SHED HAS NO WINDOWS) FIXING PACK CONTAINS: FIXING PACK CODE: SHEDWINFP You may receive more than one of the same fixing pack to provide enough fixings for the sheds with more windows. 1.6 x 30mm Nails 3.5 x 30mm Screws 3.5 x 25mm Screws... - Page 8 SCREWS WINDOW SILL(S) Using the positioned Z-Strip(s), position the Window Sill(s) flush to the top of the Z-Strip. Secure the Window Sill(s) using the L-Brackets to the Window Panel framework. Use 2 x L-Brackets per Window Sill. 2ft Window panel window sill size (28x28x534mm), 3ft Window panel window sill size (28x28x400mm), 4ft Window panel window sill size (28x28x548mm) STEP 2: SECURING THE TOP BOARD FLUSH TO THE TOP...

- Page 9 STEP 3: WINDOW ASSEMBLY SCREWS SCREWS WINDOW SITS INTO Z-STRIP Z-STRIP SITS ON TOP OF BOARD WINDOW POSITION SINGLE WINDOW INSIDE DOUBLE WINDOW INSIDE WINDOW & INTERIOR WINDOW STRIPS Position the Window onto the Z-Strip from the outside of your Window Panel. The Window will be placed up against the Top Board on the inside of your Window Panel.

-

Page 10: Side Panel Assembly

SIDE PANEL ASSEMBLY FIXING PACK CONTAINS: FIXING PACK CODE: SHEDPANELSFP 5 x 60mm Screws 4 x 50mm Screws 4 x 40mm Screws QTY: 3 QTY: 52 QTY: 2 STEP 1: SIDE PANEL ASSEMBLY LAY OUT YOUR PANELS WORK FROM BACK TO FRONT Lay out the panels around your shed Floor(s) to your desired panel We recommend starting in a back corner and then work configuration. - Page 11 STEP 2: SECURE SIDE PANELS TO FLOOR(S) SCREWS SCREWS SECURE 3FT - 4FT PANELS TO BEARER SECURE 1FT - 2FT PANELS TO BEARER SCREWS SCREWS SECURE PANELS TO BEARERS BENEATH ANGLE INTO BEARERS BENEATH SCREWS SCREWS SCREWS SECURE TO BEARERS OR FLOORBOARD SECURE PANELS TO BEARERS BENEATH BENEATH SECURE TO FLOOR BEARERS/FLOORBOARD BENEATH...

- Page 12 STEP 3: SECURE DOOR PANEL TO FLOOR SCREWS SCREWS SECURE DOOR PANEL TO BEARERS & FLOORBOARD BENEATH SCREWS SECURE DOOR PANEL TO BEARER BENEATH SECURE TO FLOOR BEARERS/FLOORBOARD BENEATH Secure the Door Panel to the Floor by screwing into the floor bearers beneath (50mm screws). Secure the Door Panel to the floorboards if there are no bearers beneath (40mm screws).

- Page 13 APEX SECTION ASSEMBLY FIXING PACK CONTAINS: FIXING PACK CODE: SHEDGABLEFP 4 x 50mm Screws QTY: 8 STEP 1: APEX SECTION ASSEMBLY APEX SHEDS SCREWS SECURING APEX SECTION TO SINGLE DOOR PANEL REVERSE APEX SHEDS SCREWS SECURING APEX SECTION TO SIDE PANEL APEX SECTIONS Position and secure the Apex Sections to the Side Panels as shown above.

- Page 14 COVER & DOOR STRIPS FIXING PACK CONTAINS: FIXING PACK CODE: SHEDSTRIPSFP 3.5 x 30mm Screws 4 x 50mm Screws QTY: 33 QTY: 4 STEP 1: DOOR BATTENS SCREWS SCREWS TOP DOOR BATTEN BOTTOM DOOR BATTEN DOOR BATTENS Secure the Door Battens to the Top and Bottom of the door opening framework. Ensure they are flush to the Panel framework and they are screwed in to the the bearers beneath.

- Page 15 STEP 3: COVER STRIPS CORNERS ADJOINING PANELS ADJOINING PANELS SCREWS SCREWS SCREWS COVER STRIPS Secure the Cover Strips to the corners and adjoining panels. Ensure they are flush to the bottom edge of the panels. Make sure to secure the Cover Strips to the framework behind and not into the joins of the panels. Cover strips size (1823mm)

- Page 16 TRUSS ASSEMBLY FIXING PACK CONTAINS: FIXING PACK CODE: SHEDTRUSSFP TRUSS FIXING PACK CODE: STPK21 M6 Nut QTY: 4 M6 x 25mm Washer Z-Brackets (28mm) Truss Brackets Hanger Brackets U-Brackets QTY: 4 QTY: 8 QTY: 2 QTY: 2 QTY: 2 (MSMTJB21) (MSTSB21) (MSUB) STEP 1: TRUSS ASSEMBLY...

- Page 17 SCREWS SCREWS SECURE HANGER BRACKETS SECURE TRUSS Position and secure the hanger bracket to the centre of Position and secure the assembled truss to the hanger brackets. The truss will be centralised inside your shed and your shed. There needs to be one on each side. facing the Apex Sections as shown above.

- Page 18 OSB ROOF SHEET & FELT FIXING PACK CONTAINS: FIXING PACK CODE: OSBSHEDROOFFP 3.5 x 30mm Screws Felt Tacks QTY: 60 QTY: 145 STEP 1: OSB ROOF SHEETS & ROOF STRIPS SCREWS OSB ROOF SHEETS & ROOF STRIPS Position and secure the Roof Strip(s) along the edge of each OSB Roof Sheet as shown above. The Roof Strip(s) will be the same length as the OSB sheet edge.

- Page 19 STEP 3: FELT 3 x FELT PIECES Measure out 3 equal lengths, cut with a sharp knife, overlap them on top, around the edges and fold the corners; tack to keep secure. Ensure there is a 50mm overhang at the bottom and work from the bottom to the top. Hammer the tacks into the felt at 150mm intervals.

- Page 20 STEP 2: FINIAL ASSEMBLY SCREWS FINIALS Position and secure the Finials to the Fascia’s as shown above. Ensure to secure through the Fascia’s into the framework behind. STEP 3: BADGE PINS PIN YOUR BADGE Position and secure your badge above the door opening, into the Door Panel framework behind with the pins provided.

- Page 21 SINGLE DOOR INSTALLATION FIXING PACK CONTAINS: FIXING PACK CODE: SHEDSINGLEDOORFP Turn Buttons Flush Hinges Padbolt (150mm) QTY: 2 QTY: 2 QTY: 1 Please take care when installing the security screws. Once the screws have been secured in place, you will be unable to unscrew them. STEP 1: DOOR HINGES HINGE POSITION SHIPLAP CLOSED DOOR...

- Page 22 STEP 2: DOOR FIXINGS FRAMEWORK SECURITY SECURITY PADBOLT Position and secure the Padbolt to the Doors framework. The front hole on the Padbolt will require the smaller security screw to be secured to the Door. Secure the Receiver to the Door Panels framework as shown above. Use a flat head screwdriver to install the security screws.

Need help?

Do you have a question about the BECKWOOD BASE KIT 5 and is the answer not in the manual?

Questions and answers