Summary of Contents for World Chemical YD-2500VK-CP Series

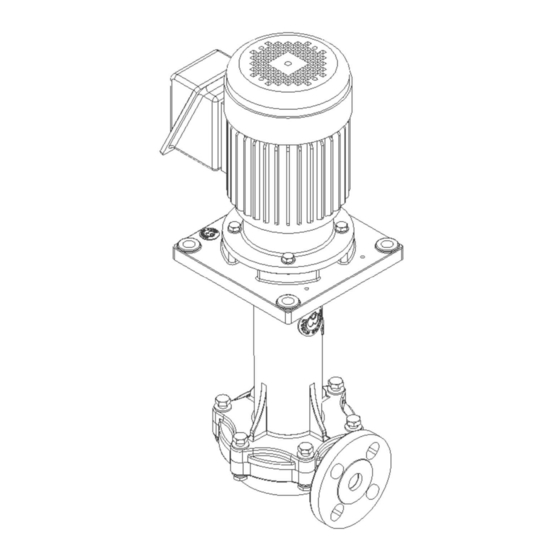

- Page 1 VERTICAL SEALLESS PUMP DRYFREE YD-2500VK-CP Series INSTRUCTION MANUAL Version: 20240706...

-

Page 2: Table Of Contents

Preface Thank you very much for purchasing World Chemical’s sealless vertical pump “DRYFREE”. DRYFREE is constructed of corrosion resistant materials such as CFR PP (Carbon fiber reinforced polypropylene) and easy to handle. Appropriate operation and maintenance is necessary for the pump’s... -

Page 3: Safety Precautions (To Be Observed At All Times)

Caution The bolts for suction flange should be used the bolt size considered the depth of casing and gasket for the casing tap as follows. Model The depth of suction tap YD-2500VK series M16 x 16 mm Safety Precautions (To be observed at all times) The following procedures are intended to protect you from personal injury and/or property damage. -

Page 4: Unpacking Check

When sending the pumps for repair or used pumps by courier, wash inside by fresh water and check no chemical liquid on. Then, pack the pumps wrapped with plastic bag and send them back. Dispose pumps treated adherent chemical liquid as industrial waste. 10. -

Page 5: Model Description

Model Description YD – 25 00 VK – CP – D E 5 1 - L Example Model (5) (6) (7) (1) Bore: Discharge bore Model Suction bore Discharge bore 2500VK (2) Motor output: 0.4kW (3) Main material: CFR PP (4) Gas seal material: FPM (5) O-ring material: E = EPDM, F = FPM (6) Motor frequency: 5 = 50Hz, 6 = 60Hz... -

Page 6: Outline Dimension

Outline dimension (Motor: Outdoor type without a water proof cover) Pump nameplate Cable connector Upper liquid level Lower liquid level Depth of the screw 16... -

Page 7: Installing / Piping Precautions

Installing / Piping precautions Installing level and liquid level of the suction tank The pump has no sliding type seal such as mechanical seal or grand packing. Regarding the install height standard of the pump, refer to the below pictures. The liquid level of the suction tank against the pump is the standard range between the max. - Page 8 Install the pump vertically on level surface where there is no influence of other machine’s vibration. An installation stand should be secured. Piping Use M 16 bolts for suction / discharge flanges and tighten them evenly with an appropriate torque. Recommend --- Torque for the suction side bolts : 6.0 N・m Torque for the discharge side bolts &...

-

Page 9: Operating Precautions

Operating precautions Cautions Never operate the pump with the suction valve closed. It may cause the pump damage by a rapid vacuum state. In the event of cavitation, stop the pump immediately. Do not operate the pump with air trapped. ... -

Page 10: Parts Description

Parts description / material / structure Name Material Remarks Motor Bolt SUS304 M8x25 with Washer Pump base GFR PP Bolt SUS304 M10x30 with Washer Gasket Air release bolt O-ring EPDM P-20 Counter face ring Alumina ceramics O-ring EPDM G-75 Dry seal φ25 Shaft sleeve Connecting pipe... -

Page 11: Assembly / Disassembly

Assembly / disassembly Caution / Warning Make sure to turn off the power before removing the pump and check the power off. Or put the sign “Working” near the power switch and announce it. Tape the tip of the cable which is removed from the terminal block with the insulation tape. Pay sufficient attention to the work. - Page 12 12. Connecting pipe 4) Fix the connecting pipe (12) and pump base (3). Remove the bolt (4), and pull up and remove the connecting pipe. 4. Bolt At that time, the O-ring (9) is removed. 9. O-ring 3. Pump base 5) Pull the shaft sleeve (11) up from the shaft and remove it.

- Page 13 7. O-ring 7) Remove the hex. bolt (2) and pump base (3). Additionally, remove the O-ring (7) which is fixed 3. Pump base 2. Bolt Pump assembly Rub all parts disassembled off with a clean cloth and assemble them the reverse of the assembly procedure after washing them with water.

- Page 14 Exploded view...

- Page 15 Working drawing of the discharge pipe for the in-tank type. (Sample) Standard Prepare the commercial PP elbow (25A: thread type, 1PF) Install the PP elbow. Standard Remove the discharge flange. Attach the thread processed pipe to the PP elbow. Move the discharge flange to the back.

-

Page 16: Maintenance

8. Maintenance Troubleshooting If a cause of pump failure is unknown, stop the pump and contact us or your distributor immediately. SYMPTON ON PUMP INSPECTION & PROBLEM CAUSE DISCHARGE VALVE DISCHARGE VALVE CORRECTION CLOSE OPEN ● Insufficient priming water. Pumping The Pressure / vacuum * Stop the pump and fill with failure... - Page 17 Inspection Daily inspection Check for no liquid leakage before operation. If any, stop the pump and take proper action(s) Check that the pump works smoothly without generating abnormal sounds or vibration. Check the liquid level in the tank and the suction pressure. ...

-

Page 18: Warranty Repair

Warranty / Repair Warranty period and coverage (1) The warranty period is 12 months from dispatched from our factory. (2) During warranty period, if the pump breaks down or is damaged at the use under the condition instructed in this manual due to manufacturing defect(s), the failure parts are repaired free of charge. (3) Even if the failure occurs within the warranty period, the followings are repaired or replaced for compensation in principle. - Page 19 WORCHEMI TAIWAN CO., LTD. / Taichung, Taiwan No.915, Zhongshan Rd., Shengang Dist., Taichung City 42955, TAIWAN TEL 886-4-2562-8358 FAX 886-4-2562-8351 WORLD CHEMICAL USA, INC. / California, U.S.A. 25691 Atlantic Ocean Dr.Unit B-15 Lake Forest, CA 92630, U.S.A. TEL 1-949-462-0900 FAX 1-888-860-3364 SUZHOU WORLD TECHNOLOGY CO., LTD.

Need help?

Do you have a question about the YD-2500VK-CP Series and is the answer not in the manual?

Questions and answers