Summary of Contents for World Chemical DRYFREE YD-20Y0VK-CP

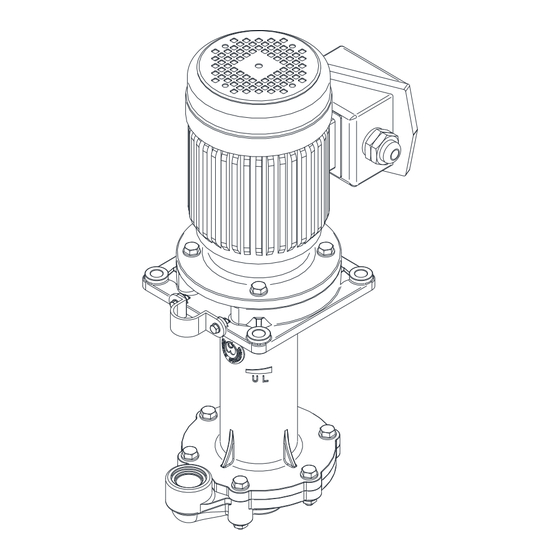

- Page 1 Vertical Sealless Pump DRYFREE Y D – 2 0 Y 0 V K – C P Instruction Manual Version: 20230704...

-

Page 2: Table Of Contents

PREFACE Thank you for purchasing World Chemical's vertical sealless pump "Dryfree." "Dryfree" is a hassle-free, easy-to-handle pump with major components made of high corrosion resistance resin such as CFR PP (Carbon Fiber Reinforced Polypropylene). Using this "Dryfree" effective for a long time requires proper operation and maintenance. Please read this operation manual before use. -

Page 3: For Safety Use Of Vertical Sealless Pump Yd-20Y0Vk-Cp

For safety use of Vertical Sealless Pump YD-20Y0VK-CP (Notice) The suction opening and discharge opening of this pump consist of tapered female pipe thread. Before connecting a suction/discharge pipe or strainer, apply a resin valve socket on the pipe connection part (For details, refer to "4. Piping"). Pump suction opening screw standard: Rc1 (screw depth 25mm) Pump discharge opening screw standard: Rc3/4 (screw depth 25mm) Safety Precautions (must be observed) - Page 4 Warning (1) Using pumps with dangerous liquid or atmosphere. When using pumps to transfer dangerous liquid, observe the equipment standards set forth by law and make sure to perform daily inspection to prevent liquid leakage. Operating the pump with any abnormality such as liquid leakage may cause a physical injury or major accident such as an explosion or fire.

- Page 5 Caution (1) Out of the specification is prohibited. Do not use the pump with any specification other than listed on the pump specification or nameplate. Especially, check the motor power supply specifications (phase, voltage and frequency) before connecting. Wrong use may cause a physical injury or damage of the pump or peripheral devices.

-

Page 6: Unpacking Check

Dry seal specification: FPM O-ring material E: EPDM D: FPM (DAI-EL) Frequency 5: 50Hz 6: 60Hz Specific gravity limit 1: 1.1 Special Category None: Standard, V: Non-standard voltage, X: Special specification, Other: According to World Chemical's specifications... -

Page 7: Specifications

Specifications Bore Motor Standard Approximate Frequency Model Suc.×Disc. Output Performance Weight Mm (in.) kW (HP) m-L/min (Ft-GPM) 20Y0VK-CP-DE51 25A×20A 4-60 (‘1.0 x ‘1.0) (1/4) (13 – 16) 20Y0VK-CP-DE61 25A×20A 4-60 (‘1.0 x ‘1.0) (1/4) (13 – 16) 20Y0VK-CP-DD51 25A×20A 4-60 (‘1.0 x ‘1.0) (1/4) (13 –... -

Page 8: Dimensions And Part Configuration

Dimensions and Part Configuration (Motor dimensions are for outdoor models without drip-proof cover) 4 - dia. 12 hole ケーブルグランド Cable ground 液面上限 Max. liquid level Rc3/4 液面下限 Min. liquid level Part name Quantity Material Remarks Motor FC, etc. Hexagon head bolt (M8×25) SUS304 With washer Seal case... -

Page 9: Installing And Piping Precautions

Installing and Piping Precautions 1. Pump installation level and suction tank liquid level The pump has no fixed sliding type liquid sealing such as a mechanical seal or a gland packing. Regarding the standard installation height, refer the following installation example and fix the mount of the pump. - Page 10 4. Piping Connecting pipes When connecting pipes to the suction inlet / discharge outlet of the pump, use a resin valve sockets. When setting valve sockets, put a sealing tape at the threads 5 to 6 times. Additionally, insert O-rings between the suction inlet / discharge outlet of the pump and the valve sockets for connecting the pipes.

-

Page 11: Operating Precautions

6. Operating precautions 1. Caution If operating the pump during closing the valve on the suction inlet, a vacuum state is suddenly created in the pump and it may damage the pump, so make sure to prevent such the operation. -

Page 12: Maintenance And Check

7. Maintenance and check 1. Troubleshooting If the cause of failure is unknown, stop the pump immediately and contact your supplier. Phenomenon in the pump Failure Cause Inspection and measures Discharge valve Discharge valve closed open Pressure gauge / ● Insufficient amount of ○... -

Page 13: Daily Check

Pump ● Loose fixing bolt ○ Tighten it vibrates ● Closed suction pipe, ○ Clean and remove cause cavitation occurred of cavitation ● Impeller and casing in ○ Remove cause or replace contact ● Worn motor bearing ○ Replace bearing or motor 2. -

Page 14: Disassembling And Assembling

8. Disassembling and Assembling Cautions and Warnings Make sure to turn off the power before removing the pump. Additionally, place "At Work" sign around the power switch to keep everyone informed. The tip of the cable removed from the terminal block is wrapped with insulating tape for insulation. The working should be treated with enough care. -

Page 15: Exploded View

Exploded view Hexagon head 六角ナット(M8) nut (M8) ケーシング Casing Oリング O-ring (カウンターフェースリング用) (for counter face ring) Oリング O-ring (ケーシング用) (for casing) カウンターフェースリング Counter face ring インペラ Impeller シールケース Seal case ドライシール Dry seal スペーサーリング Spacer ring コネクティングパイプ Connecting pipe O-ring Oリング(インペラ用)... - Page 16 ■ Note 1: Cautions on loosening/tightening the impeller. Wrench Wrench As shown in the left figure, insert the 17mm wrench from the gas vent hole of the pump base to lock the motor shaft. After that, turn the impeller counterclockwise to loosen it.

- Page 17 ■ Note 3: Adjusting the height of the dry seal. Impeller ⑧ Dry seal ⑥ Counter face ring ④ Seal case ③ 13.5mm (1) Before assembling the connecting pipe, the impeller and dry seal do trial fitting and adjust the height of the dry seal. (2) Use the jig as shown in the lift figure to adjust that the dimension from the counter face ring to the top of...

-

Page 18: Warranty And Repair

Warranty / Repair Warranty period and coverage (1) The warranty period is 12 months from dispatched from our factory. (2) During warranty period, if the pump breaks down or is damaged at the use under the condition instructed in this manual due to manufacturing defect(s), the failure parts are repaired free of charge. - Page 19 WORCHEMI TAIWAN CO., LTD. / Taichung, Taiwan No.915, Zhongshan Rd., Shengang Dist., Taichung City 42955, TAIWAN TEL 886-4-2562-8358 FAX 886-4-2562-8351 WORLD CHEMICAL USA, INC. / California, U.S.A. 25691 Atlantic Ocean Dr.Unit B-15 Lake Forest, CA 92630, U.S.A. TEL 1-949-462-0900 FAX 1-888-860-3364 SUZHOU WORLD TECHNOLOGY CO., LTD.

Need help?

Do you have a question about the DRYFREE YD-20Y0VK-CP and is the answer not in the manual?

Questions and answers