Table of Contents

Advertisement

Quick Links

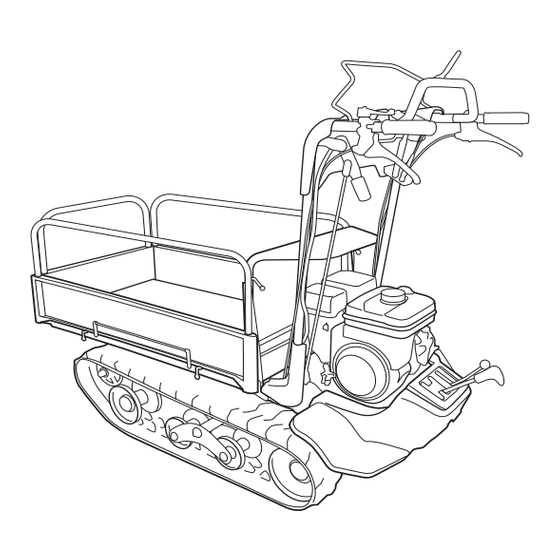

Off-road Rubber Track Carrier

BP419

Operator's Manual

Read this manual completely before operating or maintaining this machine.

Failure to follow safety precautions could result in serious injury or death.

Keep this manual for future reference by you and by all those who operate

and maintain this machine.

CHIKUSUI CANYCOM, INC.

90-1 Fukumasu, Yoshii-machi,

Ukiha-shi, Fukuoka, Japan 839-1396

Tel.+81-(0)943-75-2195 Fax.+81-(0)943-75-4396

3573 6103 001

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for CanyCom BP419

- Page 1 Failure to follow safety precautions could result in serious injury or death. Keep this manual for future reference by you and by all those who operate and maintain this machine. 3573 6103 001 CHIKUSUI CANYCOM, INC. 90-1 Fukumasu, Yoshii-machi, Ukiha-shi, Fukuoka, Japan 839-1396 Tel.+81-(0)943-75-2195 Fax.+81-(0)943-75-4396...

- Page 2 CHIKUSUI CANYCOM, INC. http://www.canycom.co.jp/ Sales Headquarters TEL +81-(0)943-75-2195 FAX +81-(0)943-75-4396 ■ Foreign Trade Center TEL +81-(0)3-3552-6277 FAX +81-(0)3-3552-6288 ■ Authorized Dealer All rights reserved. Unauthorized use or reproduction of this material is prohibited.

- Page 3 Notice to Users and Maintenance Personnel Thank you for purchasing this machine. This manual provides information needed for safe and effective use of this machine to those who operate or maintain this machine. Make sure to read and understand this manual thoroughly before operating this product.

-

Page 4: Notice To Owner

Notice to Owner • Be sure that everyone who uses this machine, including those who rent or lease this machine, receives a copy of this Operator's Manual and understands the importance of reading and following the information in this manual. Warning Terms Used in this Manual In this manual, the following four warning terms are used to signal the four levels of hazard (or seriousness of possible accidents). -

Page 5: Warranty And After-Sales Service

Warranty and After-Sales Service Warranty CHIKUSUI CANYCOM, INC. provides you a warranty through Canycom U.S.A. A copy of this warranty is reproduced in the back of the manual. After-Sales Service Consult your local CANYCOM dealer or our company’s sales department regarding service orders or any questions or problems that may arise when using this machine. -

Page 6: Table Of Contents

Contents 1. Safety Safety Labels ........1 Safety Precautions . - Page 7 Driving ........16 Starting .

- Page 8 Loading Deck ........45 Adjusting Slide Frame (Slide Frame Model) ......45 Electrical .

-

Page 9: Safety

• Replace these labels immediately if they have been removed, have fallen off or become illegible. Use the part number, on the label or shown in this manual, to order a replacement label from your CANYCOM representative. Slide Frame/ Three-way Folding Gate Model... - Page 10 Safety Scoop Bucket Model 3677 5043 001 3677 5042 001 WARNING! DANGER! Hot surfaces. Do Flammable liquid NOT touch. p r e s e n t . K e e p away all ignition sources. 3677 5043 001 3677 5042 001 3573 6061 000 WARNING! W ARNING!

-

Page 11: Safety Precautions

Safety Safety Precautions This section contains safety precautions to follow when operating and maintaining machine. Read and understand the precautions in this section as well as throughout this manual and follow them when operating or maintaining machine. Failure to follow safety precautions could result in property damage, serious injury or death to the operator or bystanders. -

Page 12: Preparation

Safety Preparation • Always wear protective footwear, long trousers, hardhat, safety glasses and ear protection when operating or servicing machine. Proper clothing will minimize the chance of injury. Do not operate machine if you have long hair, loose clothing, or jewelry; all of which can get tangled in moving parts. Do not operate machine barefoot or with open sandals. - Page 13 Safety General Driving • Do not operate engine in a confined space where dangerous carbon monoxide fumes can accumulate. • Do not touch engine, muffler or exhaust pipe while engine is running or soon after it has stopped. These areas will be very hot and can cause burns. •...

- Page 14 Safety • On a slippery surface, travel slowly and exercise caution to reduce the chance of skidding or sliding out of control. Never operate on ice. • Always make certain that there is no obstacle or person behind machine when backing up.

- Page 15 Safety • Never drive on a slope that you are not comfortable with. Avoid a slope that is so rough, slippery, or loose that you feel like you could tip over. • When driving down a slope, stop and shift to one of the first three gears (auxiliary transmission in Low).

- Page 16 Safety Loading and Driving with a Load • The maximum payload for this machine is 880lbs (400kg). Do not exceed this maximum payload under any circumstance. • Do not operate on a slope steeper than 20 degrees when carrying a load. Do not carry more than 440lbs (200kg) when operating on a slope between 15 and 20 degrees.

-

Page 17: Servicing

Safety Parking • Park machine on a flat, level and stable surface. Do not park in a dangerous place. Never park machine on a slope steeper than 15 degrees. Avoid parking on a slope less than 15 degrees. If parking on a slope less than 15 degrees is unavoidable, block tracks at the lower end of machine. -

Page 18: Controls And Components

Controls and Components Name and Function of Controls Forward Backward 3573M-0201-010US 1 Throttle Lever ... . Throttle Lever is used to control engine speed. 2 Drive Clutch Lever ..Drive Clutch Lever is used to engage or disengage drive clutch. - Page 19 Controls and Components 6 Starter Handle... . Starter Handle is used to start engine. 7 Shift Lever....Shift Lever is used to shift gears. 8 Auxiliary Transmission .

-

Page 20: Specifications

Specifications Product Specifications · Use this product properly after understanding its specifications thoroughly. BP419 Three-way Scoop Model and Type Slide Frame Folding Gate Bucket 175 (386) 190 (419) 190 (419) Machine Mass kg (lbs) Maximum Payload kN (lbs) 3.92 (880) 1725 (67.9) -

Page 21: Contents Of The Tool Bag

Specifications BP419 Three-way Scoop Model and Type Slide Frame Folding Gate Bucket Ignition System Electronic Spark Plug NGK BPR6HS Forward 1st km/h (mph) 0.4 (0.3) Forward 2nd km/h (mph) 0.7 (0.4) Forward 3rd km/h (mph) 1.2 (0.8) Forward 4th km/h (mph) 1.6 (1.0) -

Page 22: Operation

Operation Preparation Pre-start up Inspection Always perform an inspection before use. Refer to "Maintenance Schedule" (page 29) for the inspection schedule and procedure. Checking and Filling Fuel • Keep fire and spark away when handling fuel. • Always stop engine before refueling. •... -

Page 23: Adjusting Handle Lever Angle

Operation Adjusting Handle Lever Angle • Pinch hazard. Make certain that hands or fingers are not in the way to be caught when adjusting handle lever. • Make certain handle lever is securely locked after adjustment. Move handle lever back and forth to see if it is locked. Move up handle lever adjuster to unlock Handle Lever Adjuster handle lever. -

Page 24: Driving

This machine cannot perform adequately above that altitude. Using this machine under such conditions may result in an accident or cause damage to machine. If you need to use this machine above that altitude, contact your CANYCOM representative. -16-... - Page 25 Operation Make sure drive clutch lever is in [Stop] Drive Clutch Lever position. Stop NOTE • Electric start model is equiped with safety interlocking switch, and it can only be started when drive clutch lever is in [Stop] position. 3581M-0402-010E Make sure shift lever is in [N (neutral)] position.

- Page 26 Operation Move throttle lever a little toward [Fast] Throttle Lever position. Fast Slow 3561M-0402-050E Press down main switch and turn it to (run)] position until it locks in that position. Main Switch 3573M-0402-010US Pull starter handle rapidly to start engine. When engine starts, return handle gently 3583M-0402-060US Once engine starts, return throttle lever to...

-

Page 27: Driving

Operation Move choke lever back to the original ([Open]) position. Choke Lever 10. Run engine for about 5 minutes without load to warm up. Open NOTE • Drive machine gently in the first 40 to 50 hours of use after purchase for breaking-in. 3583M-0402-080 Driving •... - Page 28 Operation • Do not turn main switch to [ (stop)] position while driving. Make certain of the safety of your surround- Drive Clutch Lever ings. Make certain that drive clutch lever is in [Stop] Stop position. 3581M-0402-010E Move Shift lever and Auxiliary (aux.) shift lever into a desired position.

- Page 29 Operation Move drive clutch lever to [Run] position to Drive Clutch Lever start. 3581M-0402-040E Grasp left side clutch lever to turn left. Left Turn (Forward) Side Clutch Lever (Left) Left Turn (Backward) 3581M-0402-060E Grasp right side clutch lever to turn right. Right Turn (Forward) Side Clutch Lever (Right)

-

Page 30: Stopping

Operation Stopping • Do not make a sudden stop. The machine may skid or tip over. • Always park on a firm, level place. Never park on a potentially dangerous place. Move throttle lever toward [Slow] position to Throttle Lever slow down. -

Page 31: Parking

Operation Stop machine. High Move shift lever or auxiliary (aux.) shift lever Shift Lever firmly into a desired position. R1/R2 NOTE • Refer to "Product Specifications" (Page 12) Aux. Shift Lever for speed in each gear. • When it is difficult to shift gears, move drive 3575M-0402-080E clutch lever toward [Run] position slightly and try again. - Page 32 Operation Push main switch. It automatically turns to (stop)] position and engine stops. Main Switch 3573M-0402-020US Close fuel cock. Fuel Cock NOTE • Carbon deposit tends to accumulate on Close spark plug when running engine at low engine speed. When engine has been run at low engine speed for an extended period, run engine at high engine speed for a while 3583M-0402-180US...

-

Page 33: Working

• When lowering loading deck with a load on it, lower loading deck gently. • On three-way folding gate model, always remove tubular frame on front door before dumping. Raising Loading Deck (BP419 shown) Pull up dump lever to unlock loading deck. Keep pulling up dump lever to raise loading deck. -

Page 34: Using Safety Prop

Operation Lowering Loading Deck (BP419 shown) Hold and lower dump lever. Lower dump lever until it locks. Make sure dump lever is securely locked in the lowered position. NOTE Dump Lever • Always operate dump lever to raise or lower 3573M-0403-020E loading deck. -

Page 35: Using Slide Frame (Slide Frame Model)

Operation Using Slide Frame (Slide Frame Model) • Always lock slide frame when in use. • Do not extend slide frame beyond black line on slide frame rod. Slide frame may be damaged. Move down slide frame lock lever to unlock slide frame. -

Page 36: Using Side Gate (Three-Way Folding Gate Model)

Operation Using Side Gate (Three-way Folding Gate Model) • Lock front gate in vertical position or remove front gate when using machine with side gate in open position. • Always remove tubular frame on side gate when using machine with side gate in open position. -

Page 37: Maintenance

• Perform the pre-startup inspection (PSI) before each use, the monthly inspection once a month, and the yearly inspection once a year. • Some maintenance procedures described below may require special knowledge or tools and instruments. Contact your CANYCOM representative to perform such procedures. Schedule Item... - Page 38 Fasteners fastened. * this may be skipped if there is no gas leak found in these areas. Valve clearance shall be correct. Contact your CANYCOM Valve * this may be skipped if there is no noise due representative for √...

- Page 39 Maintenance Schedule Item Description Note Belt tension shall be properly adjusted. Inspecting/Adjusting: √ √ Page 41 Drive Belt Belt shall be free of damage, excessive wear, √ √ or dirt; shall be free of oil or grease. Clutch shall not make noise and shall √...

-

Page 40: List Of Fluids And Lubricants

Maintenance Schedule Item Description Note Shall be free of cracks, deformation, or √ √ Chassis corrosion. Fastening bolts or nuts shall not be loose or Frame √ √ missing. Shall be free of cracks or deformation. √ √ Body Panels Fastening bolts or nuts shall not be loose or √... -

Page 41: List Of Consumables And Spares

Maintenance List of Consumables and Spares • When replacing a consumable or spare, always use the CANYCOM genuine part. Item Part No. Schedule Qty. Engine Air Cleaner Element KA01091AA004 Replace if defective. Spark Plug (NGK BPR6HS) KE410009AA Replace if defective. -

Page 42: Removing And Installing Body Panels

Maintenance Removing and Installing Body Panels • Cut or pinch hazard exists when removing or installing body panels; beware of sharp edges and pinch points. • Make certain to reinstall panels after removing for repairs or inspection. Fender Removing Screw Remove two screws that secure fender. -

Page 43: Engine

Maintenance Engine • Always stop engine before servicing. • Allow engine to cool off before servicing. Engine is very hot after operation and may pose a burn hazard. • Keep fire and spark away when handling fuel. Engine Oil • Dispose of drained oil properly. •... - Page 44 Maintenance Filling Remove oil filler cap. Filler Cap Follow the instructions in "Operator's Manual for the Engine" to fill oil. Check oil level. Screw oil filler cap firmly back in place. 3583M-0505-010E Changing Drain Plug Have an appropriate oil drain pan. Remove fender.

-

Page 45: Air Cleaner

Maintenance Air Cleaner • Clean air cleaner element regularly. Dirty air cleaner element reduces engine performance and life. • Replace air cleaner element if damaged. Follow the instructions in "Operator's Air Cleaner Manual for the Engine" to clean or replace air cleaner element. -

Page 46: Fuel Filter

Maintenance Fuel Filter • Fuel is highly flammable. Keep fire and spark away when servicing fuel filter. • If fuel is spilt, wipe it off immediately. • Dispose of waste fuel properly. Follow the instructions in "Operator's Manual for the Engine" to clean fuel filter. Start engine and visually inspect fuel filter cup so that there is no leak. -

Page 47: Drive Train

Maintenance Drive Train • Stop engine when servicing drive train. • Allow machine to cool off before servicing. Engine is very hot after operation and may pose a burn hazard. • Dispose of drained oil and fluids properly. Track • Jack up machine securely when inspecting and adjusting track. Jack it up on a level ground. -

Page 48: Transmission Oil

Maintenance Adjusting Jack up machine so that it is parallel to the Track Tension Bolt ground. Lock Nut B Loosen lock nut A under machine. Loosen lock nut B and adjust track tension bolt so that the clearance between track and Lock Nut A center roller (clearance A) at the furthest is Lock Bolt... -

Page 49: Drive Belt

Maintenance Lift loading deck and support it with safety prop. Remove filler plug. Fill oil into filler. Install filler plug. Lower loading deck. Filler Plug 3572M-0506-040E Drive Belt • Adjust belt tension properly. Inproperly tensioned belt may reduce performance and its service life. Inspecting Remove fender. -

Page 50: Parking Brake

Maintenance Adjusting Move drive clutch lever to [Stop] position. Lock Nut Loosen lock nut. If belt slips, tighten adjust nut to tension belt. Adjust Nut If drive clutch does not disengage positively, loosen adjust nut. When adjustment is done, tighten lock nut. 3572M-0506-060E Parking Brake •... - Page 51 Maintenance Adjusting - on Handle Lever Lift loading deck and support it with safety Lock Nut prop. Move drive clutch lever to [Stop] position. Adjust Nut Loosen lock nut. Adjust using adjust nut on handle lever so that the amount of stretch is approximately 5 mm (0.20 in).

-

Page 52: Side Clutch

Maintenance Side Clutch Lift loading deck and support it with loading deck safety prop. Adjust side clutch with adjust nut so that the play on side clutch lever is between 1 and 5 mm (0.04 and 0.20 in). Undo safety prop and lower loading deck. 3572M-0506-100E Adjust Nut 3572M-0506-110E... -

Page 53: After Use Care

Maintenance After Use Care • Do not wash engine, control panel, electrical parts, or tank caps with air breather with running water; water may enter inside and cause rust or damage. • Clean machine after use; leaving dirt or foreign objects may cause damage. •... -

Page 54: Storage

Maintenance Storage • Fire hazard; do not store machine where there is a possiblity of ignition. • Do not wash engine or control panel with running water; water may enter inside and cause rust or damage. • Clean machine before storage; leaving dirt or foreign objects may cause rust or damage. -

Page 55: Troubleshooting

Troubleshooting chart below. If the malfunction or abnormal condition is not listed in the chart, or the suggested measure does not solve the problem, consult with your CANYCOM representative. • Some corrective measures listed below require special knowledge and/or equipment. - Page 56 Ref. Out of fuel. →Fill fuel. Page 14 Other (other than the →Please contact Engine stops abruptly. above). your CANYCOM representative. Air cleaner element is →Clean or replace air Page 37 clogged cleaner element. Irregular Idling Other (other than the →Please contact...

- Page 57 White or blue smoke Wrong engine oil. →Change oil. Page 35 comes out of exhaust Other (other than the →Please contact Engine above). your CANYCOM representative. →Please contact Accelerator lever is your CANYCOM catching representative. Transmission is not →Shift firmly.

- Page 58 Area Malfunction Possible Cause Corrective Measure Ref. Irregular noise or →Please contact Drive Train abnormal heat from your CANYCOM roller, sprocket, or idler. representative. Improperly adjusted →Adjust brake. Page 42 brake. Brake is wet with water. →Apply brake a few Brake does not work times to dry.

-

Page 59: Transporting

Transporting Hauling Loading and Unloading • Park transporter (truck) on a level ground. Always use chocks to secure wheels. • Do not allow bystandars to come close to machine or transporter when loading or unloading machine. • Use only the loading ramps with sufficient strength (to withstand the combined weight of machine and operator), width (more than 2 times the width of track), and length (more than 4 times the height of loading deck of transporter), and have anti-slip ramp surfaces.

Need help?

Do you have a question about the BP419 and is the answer not in the manual?

Questions and answers