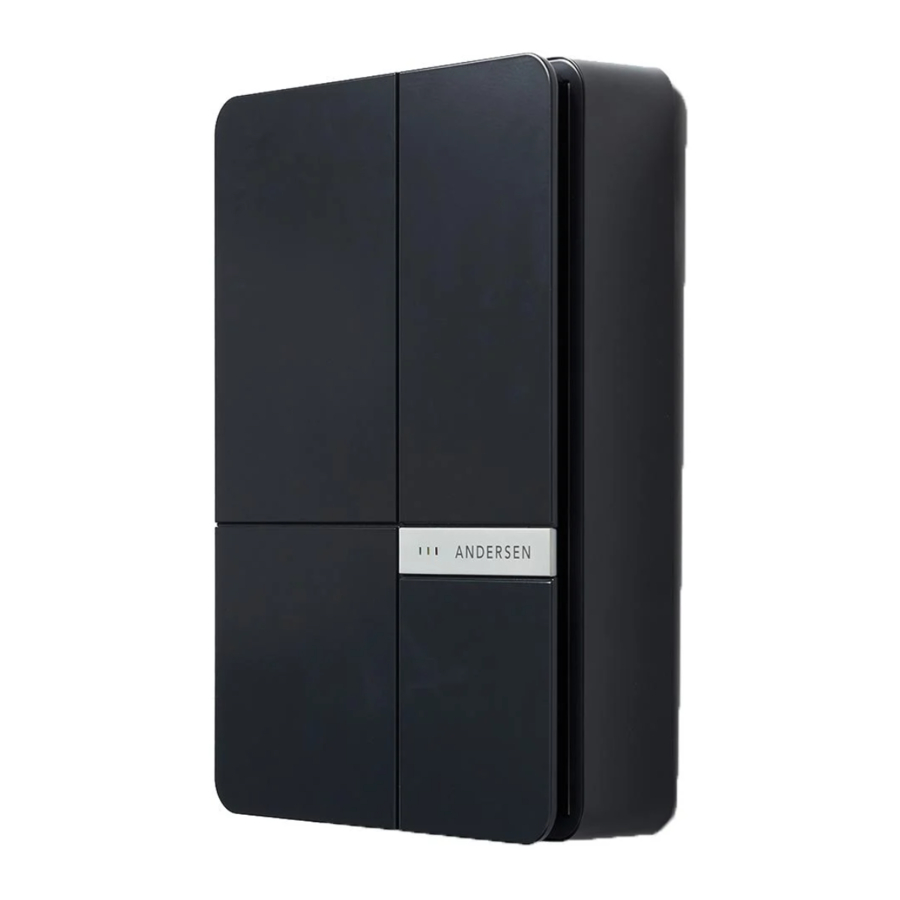

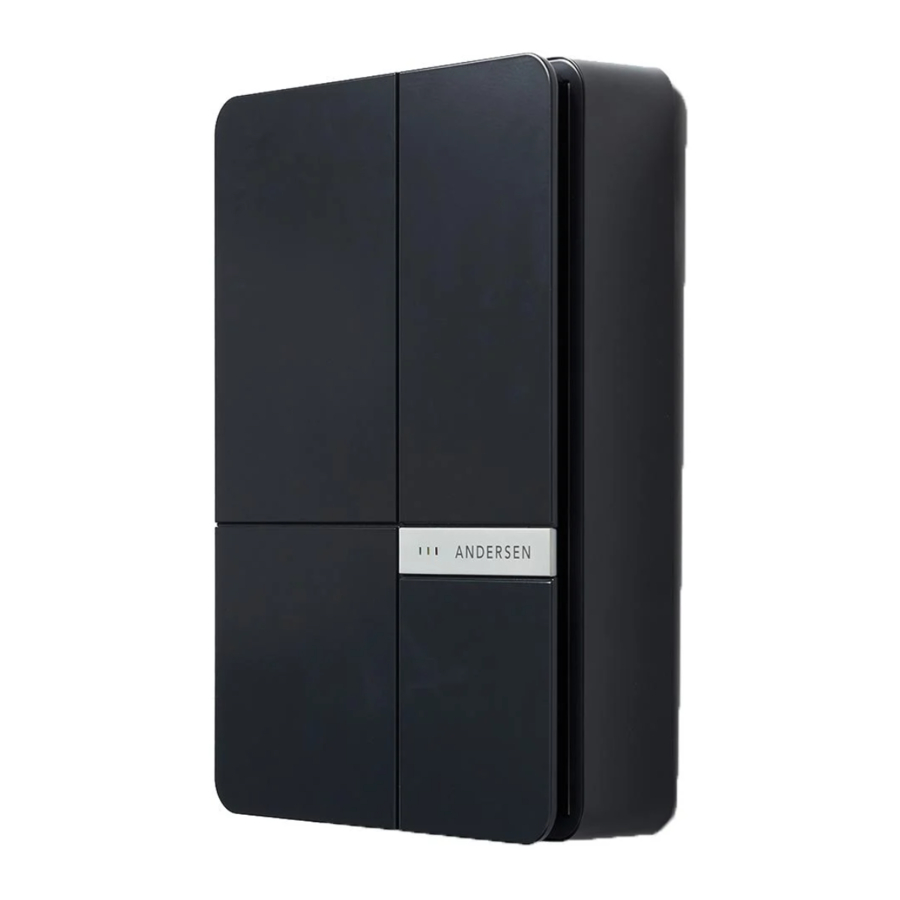

Andersen A2 Manual

- Installer manual (28 pages) ,

- Quick start manual (24 pages) ,

- Manual (16 pages)

Advertisement

- 1 Introduction

- 2 Needed

- 3 SETUP MULTI FUNCTION OPERATION

- 4 OPERATION LED STATUS

- 5 ERROR & UPDATE LED STATUS

- 6 Step 1: Fix A2 unit to the wall

- 7 Step 2: Prepare A2 core for supply cable entry

- 8 Step 3: Terminate supply power cable

- 9 Step 4: Terminate sensor cables

- 10 Step 5: Terminate vehicle side charging cable

- 11 Step 6: Fit weather project covers

- 12 Step 7: Fit side panels

- 13 Step 8: Fit cable brushes

- 14 Step 9: Fit lid panel

- 15 Step 10: Fit bottom panel

- 16 Step 11: Fit front panel

- 17 Commissioning an Andersen A2 charge point

- 18 CT CLAMP POSITIONS

- 19 Documents / Resources

Introduction

The Andersen A2 should only be installed by an electrician with the appropriate knowledge and qualifications. The installation must comply with the current editions of the IET Code of Practice for Electric Vehicle Charging Equipment installation and IET BS 7671 Requirements for Electrical Installations. Failure to do so could result in injury or death.

It is the responsibility of the installer and/or designer to determine the correct cabling and protective devices where external influences could have an effect on inbuilt protection.

It is also the responsibility of the installer to apply or notify the relevant DNO with the installation details of the charge point and property in accordance with ENA guidance.

Opening of containment should only be carried out when the supply is isolated from the mains. The undertaking of any live testing should only be carried out by a person or persons qualified to do so.

The installation instructions should be followed closely to ensure correct installation and commissioning. Failure to follow these instructions could result in damage to the Andersen Charge point, existing installation or supplier's equipment,

During and on completion of the installation, it shall be inspected, tested and certified to verify that it complies with the current electrical regulations and standards as applicable.

Before the Andersen A2 is put into service, we as the manufacturer require the installer to simulate a charge with a recognised EVSE adaptor and multifunction tester to prove operation and functionality. Use of this equipment should only be undertaken by someone who has an understanding of its functions and has the experience and knowledge to do so.

Needed

2mm & 3mm

Hex keys

Philips head Screwdriver (cross head)

SETUP MULTI FUNCTION OPERATION

Reset RCM (Two button presses)

Enter Network setup mode (Three button presses)

Exit Network setup mode (One button press)

Enter unit reset mode (Five button presses)

OPERATION LED STATUS

System powering up. (Red, Amber, Green LED flash together twice a second)

Standby State (solid green)

Vehicle connected state (solid green & solid amber)

Vehicle charging state (solid amber)

Charge point locked or awaiting scheduled charge (solid green & solid red)

Wi-fi Setup (Amber LED flashes once per second)

ERROR & UPDATE LED STATUS

Disconnected from network/cloud (green LED flash every 5 seconds)

RCM or charge error (flashes red every second)

Firmware upgrade (sequence of green, amber, red for duration of upgrade)

CT Clamp disconnected (Amber and Red LED flashing)

Reboot. (Red, Amber, Green LED flashes 4 times per second.)

Step 1: Fix A2 unit to the wall

The mounting hardware (screws, wall plugs etc) must be selected to be appropriate for the specific structure of the mounting wall.

We don't provide these screws.

Step 2: Prepare A2 core for supply cable entry

Default cable entry is from the rear, See Fig: 1

Step 3: Terminate supply power cable

Step 4: Terminate sensor cables

Solar Advanced CT sensor cable*

Optional

Recommended cable:

Shielded twisted pair e.g. CAT5e/CAT6

Please refer to installer commissioning guides to complete this setup correctly.

Solar Basic/Adaptive Fuse CT sensor cable*

Optional

Recommended cable:

Shielded twisted pair e.g. CAT5e/CAT6

Step 5: Terminate vehicle side charging cable

Step 6: Fit weather project covers

Step 7: Fit side panels

Please remember, the unit must be mounted as flush & flat against the wall as possible.

Step 8: Fit cable brushes

Step 9: Fit lid panel

- Install lid panel into the lid core.

TIP: Position the lid evenly between the side panels which have already been fitted. Squeeze these parts together until it clicks in to place.

![Andersen - A2 - Installation - Step 8 Installation - Step 8]()

- Insert and tighten lid fixing screws

![Andersen - A2 - Installation - Step 9 Installation - Step 9]()

TIP: Grip lid tightly whilst tightening locating screws, to make sure lid does not roll to the right.

Step 10: Fit bottom panel

- Fit bottom cover

![Andersen - A2 - Installation - Step 10 Installation - Step 10]()

- Tighten screws to 0.7Nm

![Andersen - A2 - Installation - Step 11 Installation - Step 11]()

Step 11: Fit front panel

Commissioning an Andersen A2 charge point

What you will need

A smart phone (iPhone or Android) with Bluetooth enabled A wireless broadband router and the Wi-Fi password

The multi-function button

You will need to use the multi-function button, during this process, to put the charge point into the network set-up mode. The button can be found on the underside of the of your charge point, on the lower left hand side.

Open the Andersen App

Ensure you are logged out

Press the toolbox located in the bottom right of the screen.

Follow the steps on the next screen to connect your charge point.

On your charge point, find and firmly press the multi-function button three times.

You should now see the LED status light repeatedly flash orange.

The Andersen App will start scanning for your charge point using Bluetooth. Tap the 'Connect' Button on the app to enter set-up.

Once the Andersen App has found all available networks, please select the Wi-Fi you wish to connect to and enter the Wi-Fi password.

Once you have connected to the Wi-Fi network successfully your signal strength will be displayed here along with confirmation of connection

You will now be prompted to enter a pin. If you are a current Andersen affiliate you may already have this pin. Altentively, please contact us.

Telephone: 01234 916125

Your installer commissioning is now complete.

We recommend you become an Andersen affiliate. Please scan the QR code below to submit an application to allow us to fully support you.

CT CLAMP POSITIONS

| Technical Data | |

| Mounting Location 1 | The mounting wall must be capable of supporting at least four times the weight of the unit (44kg) and must follow code of practice guidelines |

| Charging Mode | Mode 3 (IEC 61851-1 complaint communication protocol |

| Display | Status lights- Warm white, Hall sensor operated and internal courtesy light. |

| Charging Current | Single Phase / 3 phase units 6A to 32A Per Phase |

| Variable Current | Singe Phase Only 6A - 32A CT Monitored (Adaptive Fuse) |

| Connector Type | Type tethered cable IEC 62196-2 compliant |

| Compliance | RED 2014/53/EU, LVD 2014/35/EU, EMC 2014/30/EU, EN 61851-1:2019, EN 62196, EN 62955:2018, ROHS 2011/65/EU, WEEE 2012/19/EU, CE and UKCA Certified. |

| Ingress Protection | Enclosure, core and plug compartment IP65. |

| Operating Specification | Humidity to 95% RH non condensing -25 Celsius to +40 Celsius |

| Security | Remote software enabled charge point locking, 128-bit data SSL AES encryption for smart connectivity, Bluetooth with TLS encryption. |

| Fault Monitoring | Realtime health monitor system, start-up self-test, Earth monitoring, Welded contactor monitor, PME monitoring. |

| Enclosure Core Material | Polycarbonate Blend |

| Finish Material | Aluminimum Nylon Coated, Accoya |

| Shipped Weight | 15-16kg |

| Electrical Specifications | |

| Rated Power | 7kW (1-phase) / 22kW (3-phase) |

| Rated Supply Voltage | 230V AC Single Phase or 400V AC 3-Phase (+/- 10%) |

| Operating Voltage / Frequency | 207V - 253V AC at 5Hz |

| Rated Current | 32 Amps |

| PEN fault detection | Conforming to 722.411.4.1 (iii) (iv) |

| Earth Leakage Protection 2 | Internal 6mA DC protection (EN 62955) 30mA AC |

| Standby Power 3 | 10 Watts |

| CT Sensor Voltage | 0.333V |

| CT Sensor Specification | 0 - 120 Amps / 25mm maximum cable size split core |

| EVOFLEK Charging Cable 4 | 4mm Live Conductors / 32 A max current. High Performance ultra flexible cable |

| Installation | |

| Mounting | Flush mounting location using 4x fixing points |

| Cable Entry | Rear / Bottom (Lower left below cable terminations) 20mm removable compression gland. |

| Cable Sizing | 4mm 2 - 10mm 2 |

| Dimensions Unboxed | 494 x 348 x 148 mm (metal) 156mm (wood) |

| Height | Installed between 0.75m - 1.2m from ground level |

| CT Sensor Cable | Maximum extended length 30 metres unshielded CAT5/6 OR 50 metres shielded CAT6 data cable. |

| Recommended Upstream Protection | 40A RCBO (BSO EN 61009)) or Type A RCD / RCCB (BSO EN 61008) + 40A MCB (BSO EN 60898) - B curve for 1 phase / C curve for 3 phase. |

| Installed Weight | 9.5kg - 11.2kg |

| Device Connection | |

| Internet Connection | Wi-Fi - 802.11 b/g/n support, 802.11 n (2.4 GHz), up to 150 Mbps |

| Bluetooth | Bluetooth BLE 5 (set-up only) |

| Device Support | Apple iOs mobile device / Android mobile devices |

| EVSE Regulations | Compliant with The Electric Vehicles (Smart Charge Points) regulations 2021. |

- The mounting wall must be capable of supporting at least four times the weight of unit (44kg) and must be fire resistant.

- The mounting hardware (screws, wall plugs etc) must be selected to be appropriate for the specific structure of the mounting wall.

- The cable used must be approved to a local national regulations and standards.

- The upstream protection must be approved to local national regulations and standards. The disconnection devices, isolators, etc. must be nearby and easily accessible at all times.

Danger to life due to electrical voltage! Injuries due to electric shock! and/or burns, possibly resulting in death, are possible. During all work, make sure at all times that power to the system is switched off and secured so it cannot inadvertently be switched on.

- Before commissioning the device, check that all screw and terminal connections are tight.

- The termination panel covers must never be left opened without supervision. Fit the termination panel cover when you leave the charge point.

- Do not make any unauthorised changes or modifications to the charge point

- Repair work to the charge point may only be completed by the manufacturer or a trained expert.

- Do not remove any identifiers such as safety symbols, warning instructions, rating plates, labels or cable markings.

- Ensure that the charging cable is not mechanically damaged (kinked, jammed or run over) and that the contact area does not come into contact with heat sources, dirt or water.

Safety notice:

- Switch off on all poles and from all sources.

- Secure to prevent it being switched on again.

- Verify isolation from the supply.

- Earth and short-circuit.

- Cover neighbouring live parts and cordon off danger areas.

Ensure that the charge point is not damaged by incorrect handling (housing cover, internal parts, etc.)

On outdoor installations, do not open the termination panel cover in damp conditions.

- Do not tighten the securing screws with force.

- The installation area must be completely flat, do not bend the housing.

- Electronic components may be damaged if handled. Before handling modules, perform an electrically discharge process by touching a metallic earthed object.

A failure to follow the safety information may result in a danger of death, injury and damage to the device. The device manufacturer cannot accept any liability for claims resulting from this.

We're here to help

Send us an email

helpdesk@andersen-ev.com

Call us

Mon-Fri 08:00 - 19:00

Sat 09:00 - 14:00

+44 (0) 1234 916125

Documents / Resources

References

Download manual

Here you can download full pdf version of manual, it may contain additional safety instructions, warranty information, FCC rules, etc.

Advertisement

Need help?

Do you have a question about the A2 and is the answer not in the manual?

Questions and answers