Summary of Contents for Daikin FVXM25B2V1B

- Page 1 Installer reference guide Split system air conditioners CVXM20B2V1B FVXM25B2V1B FVXM35B2V1B FVXM50B2V1B FVXTM30B2V1B...

- Page 2 Table of contents Table of contents 1 About the documentation About this document..............................2 General safety precautions About the documentation.............................. 2.1.1 Meaning of warnings and symbols........................ For the installer ................................2.2.1 General................................2.2.2 Installation site............................... 2.2.3 Refrigerant — in case of R410A or R32......................2.2.4 Electrical.................................

- Page 3 Table of contents Closing the unit................................9.2.1 To close the electrical wiring box and close the terminal block..............9.2.2 To re-install the front grille..........................9.2.3 To re-install the front panel........................... 10 Configuration 10.1 To set a different channel of the indoor unit infrared signal receiver................11 Commissioning 11.1 Overview: Commissioning..............................

- Page 4 WARNING Make sure installation, servicing, maintenance, repair and applied materials follow the instructions from Daikin (including all documents listed in “Documentation set”) and, in addition, comply with applicable legislation and are performed by qualified persons only. In Europe and areas where IEC standards apply, EN/IEC 60335-2-40 is the applicable standard.

- Page 5 A subset of the latest technical data is available on the regional Daikin website (publicly accessible). ▪ The full set of the latest technical data is available on the Daikin Business Portal (authentication required). CVXM-B, FVXM-B, FVXTM-B Installer reference guide Split system air conditioners 4P769827-3E –...

- Page 6 General safety precautions 2 General safety precautions 2.1 About the documentation ▪ The original instructions are written in English. All other languages are translations of the original instructions. ▪ The precautions described in this document cover very important topics, follow them carefully.

- Page 7 WARNING Improper installation or attachment of equipment or accessories could result in electrical shock, short-circuit, leaks, fire or other damage to the equipment. ONLY use accessories, optional equipment and spare parts made or approved by Daikin unless otherwise specified. WARNING Make sure installation, testing and applied materials comply with applicable legislation (on top of the instructions described in the Daikin documentation).

- Page 8 General safety precautions CAUTION Wear adequate personal protective equipment (protective gloves, safety glasses,…) when installing, maintaining or servicing the system. CAUTION Do NOT touch the air inlet or aluminium fins of the unit. CAUTION ▪ Do NOT place any objects or equipment on top of the unit. ▪...

- Page 9 For FVXTM-B in a room with dimensions as specified in “To determine the minimum floor area” in General safety precaution. WARNING Make sure installation, servicing, maintenance and repair comply with instructions from Daikin and with applicable legislation (for example national gas regulation) and are executed ONLY by authorised persons. WARNING ▪...

- Page 10 General safety precautions NOTICE ▪ Do NOT re-use joints and copper gaskets which have been used already. ▪ Joints made in the installation between parts of the refrigerant system shall be accessible for maintenance purposes. CAUTION Field-made refrigerant joints indoors shall be tightness tested. The test method shall have a sensitivity of 5 grams per year of refrigerant or better under a pressure of at least 0,25 times the maximum allowable pressure.

- Page 11 General safety precautions Ceiling-mounted Wall-mounted Floor-standing unit unit unit m (kg) m (kg) A m (kg) A ≤1.842 — ≤1.842 — ≤1.842 — 1.843 28.9 1.843 3.64 1.843 4.45 3.95 4.83 34.0 4.34 5.31 41.2 5.79 49.0 4.74 5.13 6.39 57.5 7.41 66.7...

- Page 12 General safety precautions WARNING Take sufficient precautions in case of refrigerant leakage. If refrigerant gas leaks, ventilate the area immediately. Possible risks: ▪ Excessive refrigerant concentrations in a closed room can lead to oxygen deficiency. ▪ Toxic gas might be produced if refrigerant gas comes into contact with fire. WARNING ALWAYS recover the refrigerant.

- Page 13 General safety precautions Then A siphon tube is NOT present Charge with the cylinder upside down. ▪ Open refrigerant cylinders slowly. ▪ Charge the refrigerant in liquid form. Adding it in gas form may prevent normal operation. CAUTION When the refrigerant charging procedure is done or when pausing, close the valve of the refrigerant tank immediately.

- Page 14 General safety precautions WARNING ▪ After finishing the electrical work, confirm that each electrical component and terminal inside the switch box is connected securely. ▪ Make sure all covers are closed before starting up the unit. CAUTION ▪ When connecting the power supply: connect the earth cable first, before making the current-carrying connections.

- Page 15 Specific installer safety instructions 3 Specific installer safety instructions Always observe the following safety instructions and regulations. INFORMATION ▪ Units CVXM-B, FVXM-B contains refrigerant leakage sensor, special requirement for unit with refrigerant leakage sensor applies. ▪ Unit FVXTM-B is WITHOUT the refrigerant leakage sensor, use graph for minimum floor area in the General safety precautions.

- Page 16 Specific installer safety instructions "7 Piping installation" [ 38]) Piping installation (see WARNING ▪ Take precautions to avoid excessive vibration or pulsation to refrigeration piping. ▪ Protect the protection devices, piping and fittings as much as possible against adverse environmental effects. ▪ Provide space for expansion and contraction of long runs of piping.

- Page 17 Specific installer safety instructions WARNING ▪ If the power supply has a missing or wrong N-phase, equipment might break down. ▪ Establish proper earthing. Do NOT earth the unit to a utility pipe, surge absorber, or telephone earth. Incomplete earthing may cause electrical shocks. ▪...

- Page 18 About the box 4 About the box Keep the following in mind: ▪ At delivery, the unit MUST be checked for damage and completeness. Any damage or missing parts MUST be reported immediately to the claims agent of the carrier. ▪...

- Page 19 About the box 1× 1× 1× 1× 2× 1× 2× 1× 1× 2× 1× 2× 2× a Installation manual b Operation manual c General safety precautions d Mounting plate e Titanium apatite deodorising filter f Drain hose g Insulation piece h Wireless remote control (user interface) i Wireless remote control j Dry battery AAA.LR03 (alkaline) for wireless remote control...

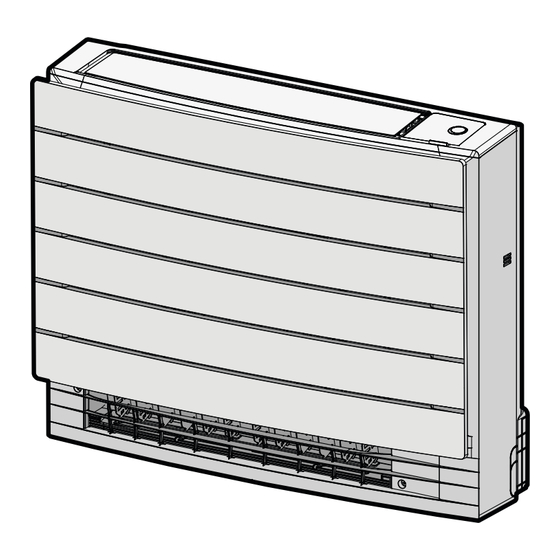

- Page 20 About the unit 5 About the unit WARNING: MILDLY FLAMMABLE MATERIAL The refrigerant inside this unit is mildly flammable. 5.1 System layout a Indoor unit b Drain piping c Refrigerant piping (gas and liquid) d Outdoor unit 5.2 Operation range Use the system in the following temperature and humidity ranges for safe and effective operation.

- Page 21 INFORMATION: Declaration of conformity ▪ Daikin Industries Czech Republic s.r.o. declares that the radio equipment type inside of this unit is in compliance with Directive 2014/53/EU. ▪ This unit is considered as combined equipment according to the definition of Directive 2014/53/EU.

- Page 22 About the unit ▪ Smartphone or tablet with minimum supported version of Android or iOS, specified on app.daikineurope.com ▪ Internet line and communicating device, such as modem, router, etc. ▪ Wireless LAN access point. ▪ Installed free ONECTA application. To install the ONECTA app 1 Go to Google Play (for Android devices) or the App Store (for iOS devices) and search for "ONECTA".

- Page 23 Unit installation 6 Unit installation WARNING Installation shall be done by an installer, the choice of materials and installation shall comply with the applicable legislation. In Europe, EN378 is the applicable standard. In this chapter Preparing the installation site ..............................6.1.1 Installation site requirements of the indoor unit....................

- Page 24 Unit installation WARNING If appliances contain R32 refrigerant, then the floor area of the room in which the appliances are installed, operated and stored must be larger than the minimum floor area A (m²), for units CVXM, FVXM refer to the "To determine the minimum floor area" [ 25], for FVXTM-B refer to General safety precautions.

- Page 25 Unit installation ▪ Sound sensitive areas (e.g. near a bedroom), so that the operation noise will cause no trouble. ▪ Spacing. Mind the following requirements: (65) ≥50 ≥50 (mm) A Front view B Side view a If the refrigerant charge is ≥1.843 kg, install unit ≤60 mm above the floor. To determine the minimum floor area ▪...

- Page 26 Unit installation m (kg) H=≥2.2 m H=2.0 m H=1.8 m 1.843 3.64 4.00 4.45 3.75 4.13 4.58 3.95 4.34 4.83 4.15 4.56 5.07 4.34 4.78 5.31 4.54 4.99 5.55 4.74 5.21 5.79 4.94 5.43 6.03 5.13 5.65 6.27 5.33 5.86 6.51 5.53 6.08 6.76 5.73 6.30...

- Page 27 Unit installation m (kg) H=≥2.2 m H=2.0 m H=1.8 m 8.00 8.79 9.77 8.29 9.12 10.13 8.59 9.45 10.50 8.88 9.77 10.86 9.18 10.10 11.22 9.48 10.42 11.58 9.77 10.75 11.94 12,00 11,00 10,00 9,00 8,00 7,00 6,00 5,00 1,843 1,9 m [kg] Minimum floor area m Total refrigerant charge in the system H Ceiling height of the room...

- Page 28 Unit installation 3 Remove the front panel. 6.2.2 To remove the front grille 1 Remove the front panel. See "6.2.1 To remove the front panel" [ 27]. 2 Remove the 4 screws, remove the grille from 4 tabs on the top and remove the front grille while pulling it toward you.

- Page 29 Unit installation a Screw b Wiring box cover c Tabs 6.3 Mounting the indoor unit 6.3.1 To install the indoor unit Installation options There are 3 possible type of installation for the indoor unit. A Floor (exposed) installation B Wall (exposed) installation C Half concealed installation a Mounting plate b Skirting board...

- Page 30 Unit installation b Left-back piping hole location c Right-back piping hole location d Left/right piping hole location e Left-bottom piping hole location f Right-bottom piping hole location 1 Drill a wall hole, depending on which side piping is taken out. See "6.3.2 ...

- Page 31 Unit installation h Right-bottom piping hole location 6 Temporarily secure the mounting plate on the wall. 7 Make sure the mounting plate is level. 8 Mark the centres of the drilling points on the wall. 9 Secure the mounting plate on the wall using 5 screws M4×25L (field supply). 5×...

- Page 32 Unit installation 4× a Alignment symbol 16 When the complete installation is finished, attach the front panel and the front grille in their original position. Half-concealed installation (mm) 6‒3 Indoor unit installation drawing: Half-concealed installation A Front view B Side view C Top view a Extra filler board b Screw hole 6×...

- Page 33 Unit installation 19 Drill a wall hole, depending on which side piping is taken out. See "6.3.2 To drill a wall hole" [ 33]. 20 Remove the slit portions using nippers. See "6.3.3 To remove the slit portions" [ 34]. 21 Open the front panel, remove the front grille, remove the top and side casings.

- Page 34 Unit installation 6.3.3 To remove the slit portions For side piping (left/right) and bottom piping (left/right) slit portions must be removed. Remove slit portions according to where the piping is taken out. a Bottom frame b Slit portion for side piping on the front grille (same on the other side) c Slit portion for side piping on the bottom frame (same of the other side) d Slit portion for the bottom piping 1 Cut off the slit portion using nippers.

- Page 35 Unit installation NOTICE ▪ Install the drain hose with a downward slope. ▪ Traps are NOT permitted. ▪ Do NOT put the end of the hose in water. ▪ Drain hose. Drain hose (accessory) is 220 mm long and with 18 mm outer diameter on the connecting side.

- Page 36 Unit installation (mm) a Drain hose (accessory) b Vinyl chloride drain pipe (VP-30) (field supply) c Reducer (field supply) d Vinyl chloride drain pipe (VP-20) (field supply) 6.4.3 To check for water leaks 1 Remove the air filters. 2 Gradually pour approximately 1 l of water in the drain pan, and check for water leaks.

- Page 37 Unit installation 2 Fix the holder (accessory) to the wall or a similar location using 2 M3×20L screws (field supply). 3 Insert the wireless remote control into the holder. CVXM-B, FVXM-B, FVXTM-B Installer reference guide Split system air conditioners 4P769827-3E – 2024.09...

- Page 38 Piping installation 7 Piping installation In this chapter Preparing refrigerant piping ..............................7.1.1 Refrigerant piping requirements ........................... 7.1.2 Refrigerant piping insulation ..........................Connecting the refrigerant piping............................7.2.1 About connecting the refrigerant piping....................... 7.2.2 Precautions when connecting the refrigerant piping ................... 7.2.3 Guidelines when connecting the refrigerant piping .....................

- Page 39 Piping installation Flare connections Only use annealed material. Piping temper grade and thickness Outer diameter (Ø) Temper grade Thickness (t) Ø 6.4 mm (1/4") Annealed (O) ≥0.8 mm 9.5 mm (3/8") 12.7 mm (1/2") Depending on the applicable legislation and the maximum working pressure of the unit (see "PS High"...

- Page 40 Piping installation 7.2.2 Precautions when connecting the refrigerant piping INFORMATION Also read the precautions and requirements in the following chapters: ▪ "2 General safety precautions" [ 6] ▪ "7.1 Preparing refrigerant piping" [ 38] DANGER: RISK OF BURNING/SCALDING NOTICE ▪ Use the flare nut fixed to the unit. ▪...

- Page 41 Piping installation NOTICE Do NOT open the refrigerant stop valve before checking the refrigerant piping. When you need to charge additional refrigerant it is recommended to open the refrigerant stop valve after charging. 7.2.3 Guidelines when connecting the refrigerant piping Take the following guidelines into account when connecting pipes: ▪...

- Page 42 Piping installation a Cut exactly at right angles. b Remove burrs. 3 Remove the flare nut from the stop valve and put the flare nut on the pipe. 4 Flare the pipe. Set exactly at the position as shown in the following figure. Flare tool for R32 Conventional flare tool (clutch type)

- Page 43 Piping installation a Refrigerant pipe connection b Refrigerant piping (field supply) c Slit d Tape e Insulation piece (accessory) 5 Check refrigerant piping joints for leaks after charging refrigerant. CAUTION Field-made refrigerant joints indoors shall be tightness tested. The test method shall have a sensitivity of 5 grams per year of refrigerant or better under a pressure of at least 0,25 times the maximum allowable pressure.

- Page 44 Electrical installation 8 Electrical installation In this chapter About connecting the electrical wiring ..........................8.1.1 Precautions when connecting the electrical wiring ....................8.1.2 Guidelines when connecting the electrical wiring ....................8.1.3 Specifications of standard wiring components ..................... To connect the electrical wiring to the indoor unit ....................... To connect optional accessories (wired user interface, central user interface, wireless adapter, etc.)......

- Page 45 Electrical installation WARNING ▪ If the power supply has a missing or wrong N-phase, equipment might break down. ▪ Establish proper earthing. Do NOT earth the unit to a utility pipe, surge absorber, or telephone earth. Incomplete earthing may cause electrical shocks. ▪...

- Page 46 Electrical installation Method 2: Using round crimp-style terminal (recommended) 1 Strip insulation from wires and slightly twist the end of each wire. 2 Install a round crimp-style terminal on the end of the wire. Place the round crimp-style terminal on the wire up to the covered part and fasten the terminal with the appropriate tool.

- Page 47 Electrical installation 8.1.3 Specifications of standard wiring components Component Interconnection cable Voltage 220~240 V (indoor↔outdoor) Wire size Only use harmonized wire providing double insulation and suitable for applicable voltage 4-core cable 1.5 mm²~2.5 mm (based on outdoor unit) 8.2 To connect the electrical wiring to the indoor unit Electrical work should be carried out in accordance with the installation manual and the national electrical wiring rules or code of practice.

- Page 48 Electrical installation 8.3 To connect optional accessories (wired user interface, central user interface, wireless adapter, etc.) 1 Remove the electrical wiring box cover. 2 Connect the optional adapter wire to the S21 connector. To connect the optional adapter wire to the option, refer to the installation manual of the optional adapter.

- Page 49 Finishing the indoor unit installation 9 Finishing the indoor unit installation 9.1 To finish the indoor unit installation 1 After the drain piping, refrigerant piping and the electrical wiring are finished. Wrap the refrigerant pipes and the interconnection cable with insulation tape. Overlap at least half the width of the tape with each turn.

- Page 50 Finishing the indoor unit installation 9.2.3 To re-install the front panel 1 Insert the front panel into the grooves of the unit (3 places) and attach the string. 2 Close the front panel and slide both sliders until they click. 3 Push on the sides of the front panel to make sure the front panel is securely fixed.

- Page 51 6 Press the indoor unit ON/OFF switch while the Daikin eye is blinking. INFORMATION If the setting could NOT be completed while the Daikin eye was blinking, repeat the setting process from the beginning. 7 When the setting is complete, press...

- Page 52 Configuration Result: The user interface will return to the home screen. CVXM-B, FVXM-B, FVXTM-B Installer reference guide Split system air conditioners 4P769827-3E – 2024.09...

- Page 53 11 Commissioning NOTICE General commissioning checklist. Next to the commissioning instructions in this chapter, a general commissioning checklist is also available on the Daikin Business Portal (authentication required). The general commissioning checklist is complementary to the instructions in this chapter and can be used as a guideline and reporting template during commissioning and hand-over to the user.

- Page 54 Commissioning The insulation resistance of the compressor is OK. There are NO damaged components or squeezed pipes on the inside of the indoor and outdoor units. There are NO refrigerant leaks. The correct pipe size is installed and the pipes are properly insulated. The stop valves (gas and liquid) on the outdoor unit are fully open.

- Page 55 Hand-over to the user 12 Hand-over to the user Once the test run is finished and the unit operates properly, make sure the following is clear for the user: ▪ Make sure that the user has the printed documentation and ask him/her to keep it for future reference.

- Page 56 Disposal 13 Disposal NOTICE Do NOT try to dismantle the system yourself: dismantling of the system, treatment of the refrigerant, oil and other parts MUST comply with applicable legislation. Units MUST be treated at a specialised treatment facility for reuse, recycling and recovery. CVXM-B, FVXM-B, FVXTM-B Installer reference guide Split system air conditioners...

- Page 57 A subset of the latest technical data is available on the regional Daikin website (publicly accessible). ▪ The full set of the latest technical data is available on the Daikin Business Portal (authentication required). 14.1 Wiring diagram Translation of wiring the diagram notes...

- Page 58 Technical data Symbol Meaning Printed circuit board Pushbutton ON/OFF, operation switch BZ, H*O Buzzer Capacitor AC*, CN*, E*, HA*, HE*, HL*, HN*, HR*, Connection, connector MR*_A, MR*_B, S*, U, V, W, X*A, K*R_*, NE D*, V*D Diode Diode bridge DIP switch Heater FU*, F*U, (for characteristics, refer to Fuse...

- Page 59 Technical data Symbol Meaning Insulated gate bipolar transistor (IGBT) Circuit breaker Q*DI, KLM Earth leak circuit breaker Overload protector Thermo switch Residual current device Resistor Thermistor Receiver Limit switch Float switch S*NG Refrigerant leak detector S*NPH Pressure sensor (high) S*NPL Pressure sensor (low) S*PH, HPS* Pressure switch (high)

- Page 60 Optional equipment Equipment made or approved by Daikin that can be combined with the product according to the instructions in the accompanying documentation. Field supply Equipment NOT made by Daikin that can be combined with the product according to the instructions in the accompanying documentation.

- Page 64 4P769827-3E 2024.09...

Need help?

Do you have a question about the FVXM25B2V1B and is the answer not in the manual?

Questions and answers