Summary of Contents for GESTRA MSB-1C

- Page 1 Continuous Steam Trap Monitor MSB-1C, MSB-1.2C Original Installation Instructions 851089-00...

-

Page 2: Table Of Contents

Contents Foreword ..........................3 Availability .............................3 Formatting features in the document ......................3 Safety ........................... 4 Use for the intended purpose .........................4 Basic safety notes ..........................4 Information on property damage or malfunctions ..................4 Qualification of personnel ........................4 Protective gear ............................5 Typographic features of warning notes ....................5 Formatting features for warnings of property damage ................5 Description .......................... -

Page 3: Foreword

The installation & operating manual is part of the MSB-1C equipment. Please hand over this installation & MSB-1.2C operating manual when selling the equipment or This continuous steam trap monitoring equipment is passing it on. -

Page 4: Safety

Only work on the steam traps if Use for the intended purpose the following conditions are satisfied: The MSB-1C and MSB-1.2C continuous steam trap Avoid skin contact with the monitored steam monitor is used to check steam traps for loss of trap and other plant components. -

Page 5: Protective Gear

Protective gear Typographic features of warning notes The operator must ensure that anyone working on the equipment must wear the required protective DANGER clothing and safety gear stipulated for the site of installation. The protective clothing must be suitable Notes with the heading DANGER warn for the used media and must protect the wearer against imminent dangerous situations that against safety and health hazards associated with a... -

Page 6: Description

Scope of supply and equipment specification Scope of supply The equipment assemblies are supplied individually and must be connected and installed before use. For MSB-1C or MSB-1.2C equipment, delivery includes the following: MSBS-1 sensor MSBA-1C or MSBA-1.2C pre-amplifier with connecting cable ... -

Page 7: Task And Function

Optional extras The following add-on equipment is available: Purpose Pressure-bearing screws (PBS) of steel or The MSB-1C or MSB-1.2C equipment is used to stainless steel monitor steam traps for loss of steam and banking 90° adapter (ADP) up of condensate. -

Page 8: Storing And Transporting The Equipment

Storing and transporting the Mounting and connecting the equipment equipment Storing the equipment Preparing installation Please observe the following items when storing Take the equipment out of the transport the equipment: packaging. The equipment and all assemblies must be ... -

Page 9: Mounting The Equipment

Drain pipes until they are empty. Mounting the equipment Switch the installation off and protect it against DANGER unauthorised or unintended re-activation. You will need the following tools to install and Incorrectly connected equipment can connect the equipment: cause fatal accidents or severe injuries. - Page 10 Fitting the sensor to the steam trap DANGER A loose pressure-bearing screw can lead to accidents resulting in very serious injury or death. Make sure that pressure-bearing screws do not come loose during installation and connection. The sensor with pressure-bearing screw (PBS) is attached to the outlet side of the thermostatic steam trap in place of the cover screw.

- Page 11 Mounting the sensor in the RFC clip Mount the MSBS... sensor (1) on the pipe using an RFC clip. Clips in various sizes are available as accessories. The adapter (12) is supplied with a clip for fastening it. The location of the sensor on the pipe must meet the following conditions: ...

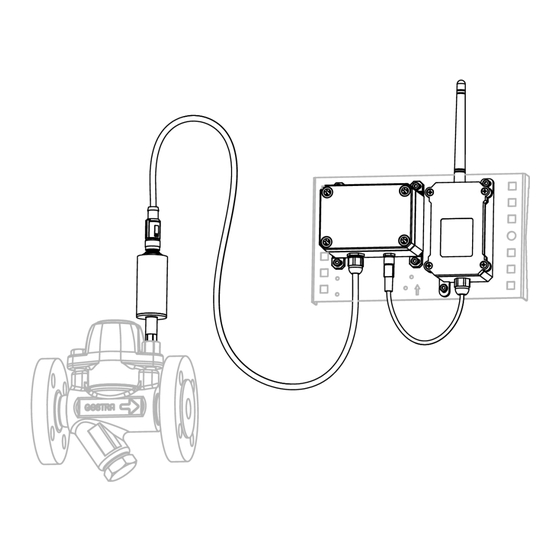

- Page 12 Installing the MSBA... pre-amplifier and Secure the MSBA... pre-amplifier (5) and MSBN... LoRa Node MSBN... LoRa node (3) in a suitable location. This could be a suitable insulated pipe, a wall, a Attention! mounting panel or a mounting system (accessory), for example, at a sufficient distance from the heat Incorrect installation can cause damage to cables or incorrect readings.

-

Page 13: Starting Up The Equipment

Starting up the equipment Operation Make sure that a configured LoRa gateway is You cannot perform work on the equipment during available. operation. You can find information on the LoRa gateway The readings are taken automatically at regular (accessory) in the manufacturer’s instruction intervals. -

Page 14: Removing External Dirt Deposits

Removing external dirt deposits Attention! If fluids penetrate the equipment it may get damaged. Make sure that fluids cannot get into the equipment. Use only a slightly moistened cloth to clean the equipment. To remove dirt deposits rinse the equipment with fresh water and wipe it with a clean, lint- free cloth. - Page 15 Spare parts for the MSB-1C, MSB-1.2C Designation Stock code MSB-1C MSB-1.2C MSBS-1 sensor 442261 2, 5 MSBA... pre-amplifier with connecting cable 442298 442299 3, 4 MSBN-1C EU/UK LoRa node with connecting cable 442335 For further spare part stock codes of versions for specific countries, see Installation & Operating Manual...

-

Page 16: Troubleshooting

Troubleshooting Problem Cause Action Cannot log in to the LoRa Login credentials not available. Contact your local sales partner. network server. Wrong login credentials Check entered values: entered. DevEUI: 16 hex digits AppEUI: 16 hex digits AppKEY: 32 hex digits LoRa node cannot be switched The battery is empty. - Page 17 “Live steam leakage” is shown Wrong equipment version Use a different equipment version. continuously, even though the (MSB-1C or MSB-1.2C) steam trap is intact. selected. “Steam trap OK” is displayed Wrong equipment version Use a different equipment version.

-

Page 18: Putting The Equipment Out Of Operation

Remove the sensor in reverse order to steam Putting the equipment out of trap installation. operation If necessary, fit the screw to the cover of the The LoRa node only needs to be switched off for steam trap, as described in the steam trap taking out of service or in the event of a Installation &... -

Page 19: Disposing Of The Equipment

Disposing of the equipment CAUTION Environmental damage may be caused by poisonous fluid residues. Before disposing of the equipment make sure that it is clean and free of fluid residues. For the disposal of all materials observe the pertinent legal regulations concerning waste disposal. -

Page 20: Technical Data

Technical data Dimensions and weights Dimensions mm Assembly Dimensions mm Weight g Length/heigh Width/ Depth diameter MSBS-1 sensor – MSBA-1C, MSBA-1.2C pre-amplifier Sensor connecting cable 1,000 – – – Pre-amplifier connecting cable – – – MSBN-1C LoRa node With connecting cable... -

Page 21: Electrical Data

2,000 m Protection against ingress of foreign bodies Suitable for industrial use Pollution degree Admissible ambient temperature –20 — 50 °C Pressure & temperature ratings MSB-1C, MSB-1.2C Assembly Storage/ IP rating operating temperature °C MSBS-1 sensor –20 — 50 IP64 MSBA-1C, MSBA-1.2C pre-amplifier... -

Page 22: Declaration Of Conformity - Standards And Directives

Declaration of Conformity and the relevant certificates. You can download the latest Declaration of Conformity at www.gestra.com. You can request the relevant certificates by writing to the following address: GESTRA AG Münchener Straße 77... - Page 24 You can find our authorized agents around the world at: www.gestra.com GESTRA AG UK Importer Münchener Strasse 77 28215 Bremen GESTRA UK Ltd Germany Phone +49 421 3503-0 Unit 1 Sopwith Park, Royce Close, +49 421 3503-393 West Portway Business Park, Andover, e-mail info@de.gestra.com...

Need help?

Do you have a question about the MSB-1C and is the answer not in the manual?

Questions and answers