Subscribe to Our Youtube Channel

Summary of Contents for Lincoln Electric 12596

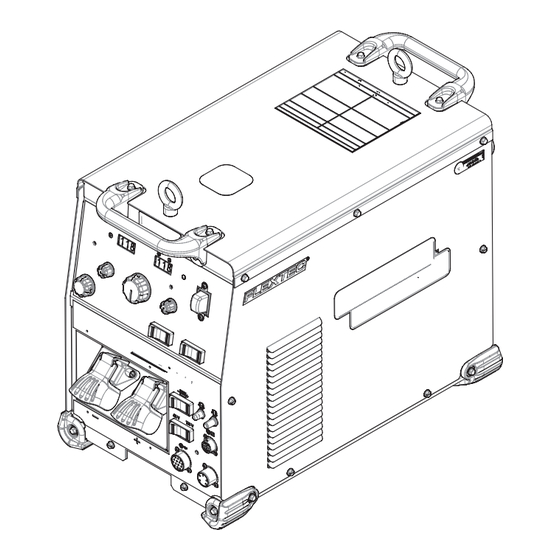

- Page 1 Flextec ® 650x For use with machines having Code Numbers: Flextec 650x: 12596 SERVICE MANUAL SVM278 | Issue D ate 17-Aug © Lincoln Global, Inc. All Rights Reserved.

- Page 2 THANK YOU FOR SELECTING A QUALITY PRODUCT BY KEEP YOUR HEAD OUT OF THE FUMES. DON’T get too close to the arc. LINCOLN ELEC TRIC. Use corrective lenses if necessary to stay a reasonable distance away from the arc. READ and obey the Safety Data PLEASE EXAMINE CARTON AND EQUIPMENT FOR Sheet (SDS) and the warning label DAMAGE IMMEDIATELY...

- Page 3 MAGNETIC FIELDS MAY W117.2-1974. A Free copy of “Arc Welding Safety” booklet BE DANGEROUS E205 is available from the Lincoln Electric Company, 22801 St. Clair Avenue, Cleveland, Ohio 44117-1199. 2.a. Electric current flowing through any conductor BE SURE THAT ALL INSTALLATION, OPERATION, causes localized Electric and Magnetic Fields (EMF).

- Page 4 S FETY ELECTRIC SHOCK ARC RAYS CAN BURN. CAN KILL. 3.a. The electrode and work (or ground) circuits are 4.a. Use a shield with the proper filter and cover plates to protect your electrically “hot” when the welder is on. Do eyes from sparks and the rays of the arc when welding or not touch these “hot”...

- Page 5 S FETY WELDING AND CUTTING CYLINDER MAY EXPLODE IF SPARKS CAN CAUSE DAMAGED. FIRE OR EXPLOSION. 7.a. Use only compressed gas cylinders containing the correct shielding gas for the process used 6.a. Remove fire hazards from the welding area. If and properly operating regulators designed for this is not possible, cover them to prevent the welding sparks the gas and pressure used.

- Page 6 LINCOLN ELECTRIC Flextec® 650x Service Manual Flextec® 650x Service Manual Last update: 2017/08/01 FLEXTEC® 650X .............................. 1 Service Manual ..............................1 Theory of Operation ............................3 INPUT SECTION ............................. 3 SWITCH BOARD AND MAIN TRANSFORMER ....................4 OUTPUT SECTION ............................5 DC BUS BOARD, USER INTERFACE BOARD AND VRD (VOLTAGE REDUCTION DEVICE) ........

- Page 7 LINCOLN ELECTRIC Flextec® 650x Service Manual OUTPUT RECTIFIER TEST PROCEDURE ......................27 USER INTERFACE BOARD TEST PROCEDURE....................30 SWITCH BOARD TEST PROCEDURE ......................34 CURRENT TRANSDUCER (LEM) TEST PROCEDURE ..................39 40VDC BUS BOARD TEST PROCEDURE ......................42 MAIN TRANSFORMER TEST PROCEDURE ....................45 INPUT RECTIFIER TEST PROCEDURE ......................

- Page 8 LINCOLN ELECTRIC Flextec® 650x Service Manual Theory of Operation Figure E.1 – Input section Input Section The three phase input voltage (380/460/575 VAC) is applied to the Flextec 650x via the line switch. This three phase AC voltage is applied to the three phase input rectifier and two phases are applied to the T2 auxiliary transformer through a reconnect voltage panel.

- Page 9 LINCOLN ELECTRIC Flextec® 650x Service Manual Figure E.2 – Switch board and main transformer Switch board And Main Transformer The main function of the switch board is to receive the DC voltage from the input rectifier and process and convert this rectified primary power. The switch board provides pulse width modulated power to the primary winding of the main welding transformer.

- Page 10 LINCOLN ELECTRIC Flextec® 650x Service Manual Figure E.3 – Output section Output Section The 20kHz. AC output from the main welding transformer is applied to the output rectifier bridge. The resultant DC+ power is coupled, through the current transducer and output choke, to the positive output terminal.

- Page 11 LINCOLN ELECTRIC Flextec® 650x Service Manual Figure E.4 – DC bus board, user interface board and VRD (voltage reduction device) DC Bus Board, User Interface Board And VRD (Voltage Reduction Device) The DC bus board receives an unregulated 72 VDC from the D3 rectifier/ C1 capacitor circuit. The DC bus board regulates this input to a constant 40 VDC supply.

- Page 12 LINCOLN ELECTRIC Flextec® 650x Service Manual CrossLinc™ Capability The Flextec 650x has the ability to communicate with compatible wire feeders such as the LN25x. The two machines communicate directly over the weld cables by pulsing the OCV voltage and wire feeder current draw.

- Page 13 LINCOLN ELECTRIC Flextec® 650x Service Manual Figure E.5 – Insulated gate bipolar transistor (IGBT) operation Insulated Gate Bipolar Transistor (IGBT) Operation The IGBT is a type of transistor. IGBTs are semiconductors well suited for high frequency switching and high current applications.

- Page 14 LINCOLN ELECTRIC Flextec® 650x Service Manual Figure E.6 – Pulse width modulation Pulse Width Modulation The term PULSE WIDTH MODULATION is used to describe how much time is devoted to conduction in the cycle. Changing the pulse width is known as MODULATION. Pulse Width Modulation (PWM) is the varying of the pulse width over the allowed range of a cycle to affect the output of the machine.

- Page 15 Troubleshooting & Repair HOW TO USE TROUBLESHOOTING GUIDE Service and repair should be performed by only Lincoln Electric Factory Trained Personnel. Unauthorized repairs performed on this equipment may result in danger to the technician and machine operator and will invalidate your factory warranty. For your safety and to avoid Electrical Shock, please observe all safety notes and precautions detailed throughout this manual.

- Page 16 ELECTRIC SHOCK can kill. remove them until installation is complete. • If you return a PC board to The Lincoln Electric Company • Have an electrician install and service this for credit, it must be in the static-shielding bag. This will equipment.

- Page 17 6. Perform the Fan And F.A.N. Circuit Test Procedure. If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877.

- Page 18 3. Perform the Switch Board Test Procedure. If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877.

- Page 19 If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877.

- Page 20 If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877.

- Page 21 Allow the machine to cool down and reset. If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877.

- Page 22 OFF and back ON to reset. If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877.

- Page 23 If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877.

- Page 24 LINCOLN ELECTRIC Flextec® 650x Service Manual Figure F.1 – Fuel cap, lift bail cover seal, rain cap, door slide rail, engine service access door, roof panel and fuel trough locations Figure F.2 – Case side mounting hardware locations...

- Page 25 If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877.

- Page 26 LINCOLN ELECTRIC Flextec® 650x Service Manual Figure F.3 – Switch board connections 207 and 209 location Figure F.4 – Capacitor (C1) location...

- Page 27 If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877.

- Page 28 LINCOLN ELECTRIC Flextec® 650x Service Manual Figure F.5 – Auxiliary transformer location Figure F.6 – Switch board plug J25 location...

- Page 29 LINCOLN ELECTRIC Flextec® 650x Service Manual Figure F.7 – Plug J20 lead locations...

- Page 30 If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877.

- Page 31 LINCOLN ELECTRIC Flextec® 650x Service Manual Figure F.8 – Switch board plug J25 location Figure F.9 – Plug J25 lead locations...

- Page 32 If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877.

- Page 33 LINCOLN ELECTRIC Flextec® 650x Service Manual Table F.1 – Output rectifier diode drop tests TEST POINT (POS) TEST POINT (NEG) EXPECTED READING TOP OUTPUT RECTIFIER OUTPUT RECTIFIER HEAT SINK 0.2V – 0.7V TERMINAL (X1) BOTTOM OUTPUT RECTIFIER OUTPUT RECTIFIER HEAT SINK 0.2V –...

- Page 34 LINCOLN ELECTRIC Flextec® 650x Service Manual Figure F.11 – Output rectifier lead location...

- Page 35 If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877.

- Page 36 LINCOLN ELECTRIC Flextec® 650x Service Manual Table F.3 – User interface board LED status LIGHT CONDITION MEANING STEADY GREEN SYSTEM OK. ALTERNATING GREEN AND A SYSTEM FAULT HAS OCCURRED. IF THE USER INTERFACE BOARD STATUS LED IS FLASHING ANY COMBINATION OF RED AND GREEN, ERRORS ARE PRESENT.

- Page 37 LINCOLN ELECTRIC Flextec® 650x Service Manual Figure F.12 – User interface board location Figure F.13 – User interface board plug and LED locations...

- Page 38 LINCOLN ELECTRIC Flextec® 650x Service Manual Figure F.14 – User interface board lead locations...

- Page 39 If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877.

- Page 40 LINCOLN ELECTRIC Flextec® 650x Service Manual Table F.5 – Switch board LED tests LED # COLOR FUNCTION GREEN + 15V POWER SUPPLY “OK” GREEN +5V CAN POWER SUPPLY “OK” GREEN +5V ISOLATED POWER SUPPLY “OK” GREEN DC BUS VOLTAGE EXCEEDS 50V GREEN FAN “ON”...

- Page 41 LINCOLN ELECTRIC Flextec® 650x Service Manual Table F.8 – Switch board voltage tests METER TEST POINTS DESCRIPTION EXPECTED READINGS CONDITIONS AND POLARITY 535 VDC TO 815 VDC CORRECT INPUT POWER APPLIED TO RECTIFIED AND DEPENDING UPON THE MACHINE. IF NOT CORRECT, FILTERED INPUT B209(+) TO B207(–)

- Page 42 LINCOLN ELECTRIC Flextec® 650x Service Manual Figure F.15 – Switch board location Figure F.16 – Switch board plug, terminal and LED locations...

- Page 43 LINCOLN ELECTRIC Flextec® 650x Service Manual Figure F.17 – Switch board lead locations...

- Page 44 If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877.

- Page 45 LINCOLN ELECTRIC Flextec® 650x Service Manual Table F.9 – DC supply voltages form switch board DESCRIPTION TEST POINT (+) TEST POINT (–) EXPECTED READING PLUG J22 PIN 4 PLUG J22 PIN 9 POSITIVE VOLTAGE SUPPLY +15 VDC (LEAD 216) (LEAD 218)

- Page 46 LINCOLN ELECTRIC Flextec® 650x Service Manual Figure F.19 – Switch board plug J22 location Figure F.20 – Switch board plug J22 lead locations...

- Page 47 If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877.

- Page 48 LINCOLN ELECTRIC Flextec® 650x Service Manual Table F.11 – 40VDC bus board voltage tests DESCRIPTION TEST POINT TEST POINT EXPECTED READING INPUT FROM AUXILIARY PLUG J1 PIN 1 (+) PLUG J1 PIN 4 (–) 65 – 75 VDC RECTIFIER (D3)

- Page 49 LINCOLN ELECTRIC Flextec® 650x Service Manual Figure F.22 – 40VDC bus board plug and LED locations Figure F.23 – 40VDC bus board lead locations...

- Page 50 If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877.

- Page 51 LINCOLN ELECTRIC Flextec® 650x Service Manual Table F.12 – Main transformer resistance tests DESCRIPTION TEST POINT TEST POINT EXPECTED READING SECONDARY WINDING SECONDARY WINDING LEAD X1 LEAD X3 VERY LOW RESISTANCE SECONDARY WINDING (DISCONNECTED FROM (DISCONNECTED FROM (LESS THAN ONE OHM)

- Page 52 LINCOLN ELECTRIC Flextec® 650x Service Manual Figure F.25 – Main transformer secondary lead locations...

- Page 53 If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877.

- Page 54 LINCOLN ELECTRIC Flextec® 650x Service Manual Figure F.26 – Input rectifier location Figure F.27 – Input rectifier detail...

- Page 55 If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877.

- Page 56 LINCOLN ELECTRIC Flextec® 650x Service Manual Table F.14 – Primary and secondary voltage tests DESCRIPTION TEST POINT TEST POINT EXPECTED READING PRIMARY VOLTAGE 380 VAC (460 VAC H1 to H3) PRIMARY VOLTAGE 460 VAC (460 VAC H1 to H3) PRIMARY VOLTAGE...

- Page 57 LINCOLN ELECTRIC Flextec® 650x Service Manual Figure F.29 – Circuit breaker (CB2) location Figure F.30 – Auxiliary rectifier lead locations...

- Page 58 If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877.

- Page 59 LINCOLN ELECTRIC Flextec® 650x Service Manual If no error 36 flashes and the thermo LED does not turn on, the user interface board may be faulty. Perform the User Interface Board Test Procedure. If any component tests faulty, replace the suspect component.

- Page 60 LINCOLN ELECTRIC Flextec® 650x Service Manual Figure F.33 – Thermostat location...

- Page 61 If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877.

- Page 62 LINCOLN ELECTRIC Flextec® 650x Service Manual Figure F.34 – Auxiliary rectifier location Figure F.35 – Auxiliary rectifier test points...

- Page 63 If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877.

- Page 64 LINCOLN ELECTRIC Flextec® 650x Service Manual Figure F.36 – Choke and choke lead 220 locations Figure F.37 – Positive output stud location...

- Page 65 If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877.

- Page 66 LINCOLN ELECTRIC Flextec® 650x Service Manual Table F.16 – Input switch resistance tests TEST POINT TEST POINT EXPECTED READING SWITCH POSITION VERY LOW RESISTANCE “ON” POSITION (LESS THAN ONE OHM) VERY LOW RESISTANCE “ON” POSITION (LESS THAN ONE OHM) VERY LOW RESISTANCE “ON”...

- Page 67 LINCOLN ELECTRIC Flextec® 650x Service Manual Figure F.39 – Input switch lead location...

- Page 68 If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877.

- Page 69 LINCOLN ELECTRIC Flextec® 650x Service Manual Figure F.40 – Thermostat 2 lead locations Figure F.41 – Thermostat 2 mounting screw locations...

- Page 70 If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877.

- Page 71 LINCOLN ELECTRIC Flextec® 650x Service Manual 4. Using a 7/16” nutdriver, attach the two screws, lock washers and flat washers securing each diode module to the heat sink. Repeat this step for each diode module. 5. Using a 7/16” nutdriver, attach the four nuts, lock washers and flat washers securing the copper plate to the output rectifier modules.

- Page 72 LINCOLN ELECTRIC Flextec® 650x Service Manual Figure F.43 – Output rectifier diode module mounting screw locations...

- Page 73 If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877.

- Page 74 LINCOLN ELECTRIC Flextec® 650x Service Manual Figure F.44 – User interface board plug locations Figure F.45 – User interface board mounting screw locations...

- Page 75 If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877.

- Page 76 LINCOLN ELECTRIC Flextec® 650x Service Manual 5. Connect plugs J20, J21, J22, J23, J25 and J26 to the switch board. See Wiring Diagram. 6. Perform the Case Cover Replacement Procedure. 7. Perform the Retest After Repair Procedure. Figure F.46 – Switch board plug and lead locations...

- Page 77 LINCOLN ELECTRIC Flextec® 650x Service Manual Figure F.47 – Switch board mounting hardware locations...

- Page 78 If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877.

- Page 79 LINCOLN ELECTRIC Flextec® 650x Service Manual REPLACEMENT PROCEDURE 1. Rout choke lead 220 thru the current transducer. See Wiring Diagram. 2. Carefully position the new current transducer into the machine. 3. Using a 11/32” nutdriver, attach the two nuts and washers securing the current transducer to the divider panel.

- Page 80 LINCOLN ELECTRIC Flextec® 650x Service Manual Figure F.49 – Switch board and heat sink assembly mounting screw locations Figure F.50 – Choke lead 220 and current transducer mounting hardware locations...

- Page 81 If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877.

- Page 82 LINCOLN ELECTRIC Flextec® 650x Service Manual Figure F.51 – 40VDC bus board plug locations Figure F.52 – 40VDC mounting nut locations...

- Page 83 If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877.

- Page 84 LINCOLN ELECTRIC Flextec® 650x Service Manual REPLACEMENT PROCEDURE 1. Carefully position the new main transformer into the machine. 2. Using a 3/8” nutdriver, attach the three screws securing the main transformer to the base of the machine. 3. Using two 1/2” open-end wrenches, attach the nut, lock washer, bolt and two flat washers securing the NEG lead to the main transformer.

- Page 85 LINCOLN ELECTRIC Flextec® 650x Service Manual Figure F.54 – Switch board and heat sink assembly mounting screw locations Figure F.55 – Main transformer lead and mounting screw locations...

- Page 86 If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877.

- Page 87 LINCOLN ELECTRIC Flextec® 650x Service Manual Figure F.56 – Input rectifier lead locations Figure F.57 – Input rectifier mounting hardware locations...

- Page 88 If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877.

- Page 89 LINCOLN ELECTRIC Flextec® 650x Service Manual 6. Perform the Case Cover Replacement Procedure. 7. Perform the Retest After Repair Procedure. Figure F.58 – Auxiliary transformer lead locations Figure F.59 – Mounting hardware and input rectifier locations...

- Page 90 If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877.

- Page 91 LINCOLN ELECTRIC Flextec® 650x Service Manual Figure F.60 – Auxiliary rectifier lead locations Figure F.61 – Auxiliary rectifier mounting nut location...

- Page 92 If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877.

- Page 93 LINCOLN ELECTRIC Flextec® 650x Service Manual REPLACEMENT PROCEDURE 1. Carefully position the choke assembly into the machine. 2. Using a 3/8” nutdriver, attach the four screws and washers securing the choke to the base of the machine. 3. Using a 3/4” open-end wrench, connect the NEG lead from the rear of the negative output stud.

- Page 94 LINCOLN ELECTRIC Flextec® 650x Service Manual Figure F.63 – Switch board and heat sink assembly mounting screw locations Figure F.64 – Choke lead 220 and NEG lead locations...

- Page 95 LINCOLN ELECTRIC Flextec® 650x Service Manual Figure F.65 – Choke assembly mounting screw locations...

- Page 96 LINCOLN ELECTRIC Flextec® 650x Service Manual RETEST AFTER REPAIR Retest a machine: • If it is rejected under test for any reason that requires you to remove any part which could affect the machine’s electrical characteristics. • If you repair or replace any electrical components.

- Page 97 LINCOLN ELECTRIC Flextec® 650x Service Manual 5. Replace the right case side; reconnect input power to the machine and energize. 6. The display should read “Cur CAL”. 7. Rotate the Hot Start knob clockwise to enable the output which will be indicated by the scrolling message “Adj Pot So rEAL Cur = 300A”...

Need help?

Do you have a question about the 12596 and is the answer not in the manual?

Questions and answers