Table of Contents

Advertisement

Quick Links

Operator's Manual

™

Fleet

400

Register your machine:

www.lincolnelectric.com/register

Authorized Service and Distributor Locator:

www.lincolnelectric.com/locator

Save for future reference

Date Purchased

Code: (ex: 10859)

Serial: (ex: U1060512345)

IM10349

| Issue D ate Dec-17

© Lincoln Global, Inc. All Rights Reserved.

For use with machines having Code Numbers:

12587

Need Help? Call 1.888.935.3877

to talk to a Service Representative

Hours of Operation:

8:00 AM to 6:00 PM (ET) Mon. thru Fri.

After hours?

Use "Ask the Experts" at lincolnelectric.com

A Lincoln Service Representative will contact you

no later than the following business day.

For Service outside the USA:

Email: globalservice@lincolnelectric.com

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Lincoln Electric Fleet 400

- Page 1 Operator’s Manual ™ Fleet For use with machines having Code Numbers: 12587 Need Help? Call 1.888.935.3877 Register your machine: to talk to a Service Representative www.lincolnelectric.com/register Authorized Service and Distributor Locator: Hours of Operation: www.lincolnelectric.com/locator 8:00 AM to 6:00 PM (ET) Mon. thru Fri. Save for future reference After hours? Use “Ask the Experts”...

- Page 2 THANK YOU FOR SELECTING A QUALITY PRODUCT BY KEEP YOUR HEAD OUT OF THE FUMES. DON’T get too close to the arc. LINCOLN ELEC TRIC. Use corrective lenses if necessary to stay a reasonable distance away from the arc. READ and obey the Safety Data PLEASE EXAMINE CARTON AND EQUIPMENT FOR Sheet (SDS) and the warning label DAMAGE IMMEDIATELY...

- Page 3 W117.2-1974. A Free copy of “Arc Welding Safety” booklet E205 is available from the Lincoln Electric Company, 2.d. All welders should use the following procedures in order to 22801 St. Clair Avenue, Cleveland, Ohio 44117-1199.

- Page 4 SAFETY ELECTRIC SHOCK ARC RAYS CAN BURN. CAN KILL. 3.a. The electrode and work (or ground) circuits are 4.a. Use a shield with the proper filter and cover plates to protect your electrically “hot” when the welder is on. Do eyes from sparks and the rays of the arc when welding or not touch these “hot”...

- Page 5 SAFETY WELDING AND CUTTING CYLINDER MAY EXPLODE IF SPARKS CAN CAUSE DAMAGED. FIRE OR EXPLOSION. 7.a. Use only compressed gas cylinders containing the correct shielding gas for the process used 6.a. Remove fire hazards from the welding area. If and properly operating regulators designed for this is not possible, cover them to prevent the welding sparks the gas and pressure used.

-

Page 6: Table Of Contents

TABLE OF CONTENTS INSTALLATION........................... SECTION A TECHNICAL SPECIFICATIONS......................A-1 LOCATION AND VENTILATION......................A-2 STACKING............................A-2 ANGLE OF OPERATION........................A-2 LIFTING............................A-2 HIGH ALTITUDE OPERATION......................A-2 HIGH TEMPERATURE OPERATION.....................A-2 TOWING............................A-3 VEHICLE MOUNTING.........................A-3 FUEL ............................A-3 ENGINE COOLING SYSTEM....................... A-3 BATTERY CONNECTION........................A-3 MUFFLER OUTLET PIPE........................A-3 SPARK ARRESTER..........................A-3 REMOTE CONTROL ......................... -

Page 7: Installation

FLEET INSTALLATION TECHNICAL SPECIFICATIONS - FLEET™ 400 (K3427-1) INPUT - DIESEL ENGINE Make/Model Description Speed (RPM) Displacement Starting System Capacities FUEL PERKINS 403D-15 (16 US GAL) 3 CYLINDER IDLE 1870 91 CU. IN. 60.6L DIESEL ENGINE 12VDC BATTERY 21.7 HP (16.2 kW) &... -

Page 8: Location And Ventilation

FLEET INSTALLATION INST LL TION LIFTING The Fleet™ 400 weighs approximately 1065 lbs (483Kg) with a SAFETY PRECAUTIONS empty fuel tank. A lift bail is mounted to the machine and should always be used when lifting the machine. WARNING Liftbale max lifting weight = 2585lbs Do not exceed max lifting weight. -

Page 9: Towing

FLEET INSTALLATION TOWING FUEL USE DIESEL FUEL ONLY- Use a recommended trailer for use with this equipment for road, in-plant and yard towing by a vehicle(1). If the user adapts a non- Low Sulphur fuel or ultra low sulphur fuel in Lincoln trailer, he must assume responsibility that the method of USA and CANADA only. -

Page 10: Remote Control

FLEET INSTALLATION current and duty cycle. Length refers to the distance from the welder to the work and back to the welder. Cable diameters are REMOTE CONTROL TABLE A.1 increased for long cable lengths to reduce voltage drops. The Fleet™ 400 is equipped with a 6-pin connector. When a remote control is connected to the 6-pin Connector, the auto- TOTAL COMBINED LENGTH OF ELECTRODE AND WORK CABLES sensing circuit automatically switches the OUTPUT control from... - Page 11 FLEET INSTALLATION Cable Installation RESIdUAL CURRENT dEVICE REAdY Install the welding cables to your Fleet™ 400 as follows. The Fleet™ 400 is configured to allow for the addition of a 1. The engine must be OFF to install welding cables. Residual Current Device (RCD) to protect the 3-230V Single Phase 2.

-

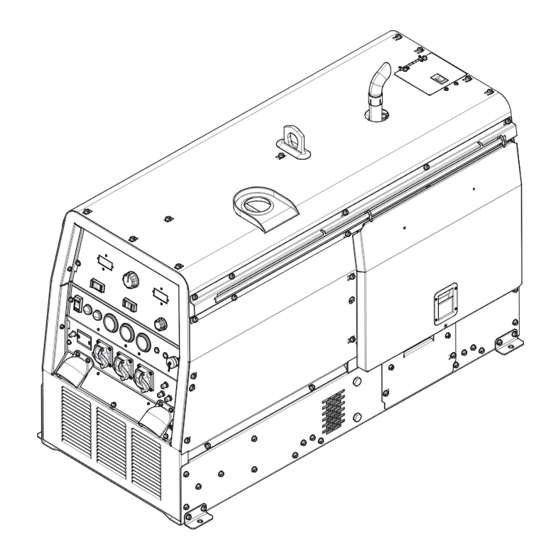

Page 12: Operation

Engine Instruction Manual. BREAK-IN PERIOd GENERAL dESCRIPTION Lincoln Electric selects high quality, heavy-duty industrial engines for the portable welding machines we offer. While it is normal to The Fleet™ 400 is a diesel engine powered DC multi-process see a small amount of crankcase oil consumption during initial welding power source and AC power generator. -

Page 13: Welding Controls

FIGURE B.1 FLEET OPERATION 4. ARC FORCE- The ARC FORCE dial is active in the PIPE/GOUGE mode when on low range, and in the CC-STICK mode. This WELdING CONTROLS control is not active in the PIPE/GOUGE mode when in high range (Figure B.1) or when in TIG mode. -

Page 14: Engine Operation

FLEET OPERATION ENGINE HOUR METER / FUEL GAUGE- Displays the total time that the engine has been running. This meter is useful for ENGINE OPERATION STARTING THE ENGINE scheduling prescribed maintenance. Shows fuel level. 11. ENGINE TEMPERATURE GAUGE- An indicator of engine temperature. -

Page 15: Welder Operation

FLEET OPERATION When in the touch start TIG mode and when a Amptrol is connected to the 6-Pin connector the OUTPUT CONTROL dial is WELdER OPERATION DUTY CYCLE used to set the maximum current range of the current control of the Amptrol. - Page 16 FLEET OPERATION TABLE B.3 TYPICAL CURRENT RANGES FOR TUNGSTEN ELECTRODES Tungsten Electrode DCEN (-) DCEP (+) Approximate Argon Gas Flow TIG TORCH Diameter in. (mm) Flow Rate C.F.H. ( l /min.) Nozzle Size (4), (5) 1%, 2% Thoriated 1%, 2% Thoriated Aluminum Stainless Steel Tungsten...

- Page 17 FLEET OPERATION TABLE B.2 TYPICAL FLEET™ 400 FUEL CONSUMPTION FUEL CONSUMPTION Test Condition US gal/hr (litres/hr) NO LOAD 0.45 ( 1.70) 200 A @ 28 V 100% 0.79 ( 2.98) 300 A @ 32 V 100% 1.12 (4.23) 400 A @ 25 V 100% 1.15 (4.36) NOTE: This data is for reference only.

-

Page 18: Accessories

FLEET ACCESSORIES CCESSORIES FIELD INSTALLED OPTIONS / ACCESSORIES are available at www.lincolnelectric.com. Follow these steps: 1. Go to www.lincolnelectric.com 2. At the top of the screen to the far left click on Equipment, click on Engine Driven Welders, click on Fleet on next shown scroll down to Fleet™... -

Page 19: Maintenance

FLEET MAINTENANCE M INTEN NCE SAFETY PRECAUTIONS ENGINE OIL CHANGE Drain the engine oil while the engine is warm to assure rapid and complete draining. It is recommended that each time WARNING the oil is changed the oil filter be changed as well. •... -

Page 20: Oil Filter Change

FLEET MAINTENANCE OIL FILTER CHANGE AIR CLEANER • Drain the oil. The diesel engine is equipped with a dry type air filter. Never apply oil to it. Service the air cleaner as follows: • Remove the oil filter with an oil filter wrench and drain the oil into a suitable container. - Page 21 FLEET MAINTENANCE Service Instructions Service Instructions Single- and Two-Stage Engine Air Cleaners Single- and Two-Stage Engine Air Cleaners Inspect the New Filter for Damage Inspect the New Filter for Damage Remove the Filter Remove the Filter Inspect the new filter carefully, paying attention to Unfasten or unlatch the the inside of the open end, which is the service cover.

-

Page 22: Fuel Filters

FLEET MAINTENANCE BLEEdING THE FUEL SYSTEM FUEL FILTERS You may need to bleed air from the fuel system if the fuel filter or WARNING fuel lines have been detached, the fuel tank has been ran empty or after periods of long storage. It is recommended that the fuel When working on the fuel system shutoff valve be closed during periods of non-use. -

Page 23: Engine Adjustment

FLEET MAINTENANCE CLEANING THE BATTERY ENGINE AdJUSTMENT Adjustments to the engine are to be made only by a Lincoln Keep the battery clean by wiping it with a damp cloth when dirty. Service Center or an authorized Field Service Shop. If the terminals appear corroded, disconnect the battery cables and wash the terminals with an ammonia solution or a solution of BATTERY MAINTENANCE... -

Page 24: Welder / Generator Maintenance

FLEET MAINTENANCE WELdER / GENERATOR MAINTENANCE STORAGE: Store in clean, dry protected areas. CLEANING: Blow out the generator and controls periodically with low pressure air. Do this at least once a week in particularly dirty areas. BRUSH REMOVAL AND REPLACEMENT: It’s normal for the brushes and slip rings to wear and darken slightly. -

Page 25: Troubleshooting

FLEET TROUBLESHOOTING HOW TO USE TROUBLESHOOTING GUIdE WARNING Service and Repair should only be performed by Lincoln Electric Factory Trained Personnel. Unauthorized repairs performed on this equipment may result in danger to the technician and machine operator and will invalidate your factory warranty. - Page 26 FLEET TROUBLESHOOTING PROBLEMS POSSIBLE RECOMMENDED Observe all Safety Guidelines detailed throughout this manual (SYMPTOMS) CAUSE COURSE OF ACTION Major Physical or Electrical Damage is 1. Contact your local Lincoln Authorized Field Evident. Service Facility. Engine will not "crank". 1. Battery is low, Charge Battery. 2.

- Page 27 FLEET TROUBLESHOOTING PROBLEMS POSSIBLE RECOMMENDED Observe all Safety Guidelines detailed throughout this manual (SYMPTOMS) CAUSE COURSE OF ACTION Engine shuts down while under a load. 1. High oil temperature Engine runs rough. 1. Dirty fuel or air filters. Inspect and clean/replace filters as needed.

- Page 28 FLEET TROUBLESHOOTING PROBLEMS POSSIBLE RECOMMENDED Observe all Safety Guidelines detailed throughout this manual (SYMPTOMS) CAUSE COURSE OF ACTION Engine does not develop full power. Engine 1. Fuel filter clogged, Replace. runs rough. 2. Air filter clogged, clean or replace. 3. High idle setting incorrect, check adjust if required.

- Page 29 FLEET TROUBLESHOOTING PROBLEMS POSSIBLE RECOMMENDED Observe all Safety Guidelines detailed throughout this manual (SYMPTOMS) CAUSE COURSE OF ACTION No welding power output. 1. Poor work lead connection to work. Make sure work clamp is tightly connected to clean base metal. 2.

- Page 30 FLEET DIAGRAMS...

- Page 31 FLEET DIAGRAMS...

- Page 32 FLEET DIAGRAMS INSTRUCTIONS FOR INSTALLING A RESIDUAL CURRENT DEVICE TO PROTECT THE 230V SINGLE PHASE RECEPTACLE ON FLEET 400 (K3427-1) WARNING WARNING Do not operate with covers removed Disconnect input power before servicing MOVING PARTS can injure Stop Engine and disconnect negative...

- Page 33 FLEET DIAGRAMS 4. LOCATE LEADS 5B & CA (SEE FIGURE 2). CUT LEAD 5B AT DISTANCE GIVEN BELOW. STRIP BOTH ENDS OF CUT LEAD 13MM (.50 in.) CUT LEAD CA AT DISTANCE GIVEN BELOW. STRIP BOTH ENDS OF CUT LEAD 13MM (.50 in) FIGURE 2 230V EURO RECEPTACLES REAR VIEW...

- Page 34 FLEET DIAGRAMS FIGURE 3 230V EURO REAR VIEW RECEPTACLE TO STATOR WINDING FRONT VIEW PROTECTIVE BOOT 9. CHECK WIRING PER FIGURE 4 10. INSTALL LEFT SIDE CASE, RIGHT SIDE CASE PANELS AND SLIDING DOOR. 11. RECONNECT NEGATIVE BATTERY CABLE. THE UNIT IS NOW READY FOR OPERATION.

- Page 35 GND-C GND-G (BLUE) GND-C GND-D 5B CA UTRAL STUD ON AUXILIARY P WER RECEPTACLE PANEL THE LINCOLN ELECTRIC COMPANY World's Leader in Welding and Cutting Products A.02 Sales and Service through Subsidiaries and Distributors Worldwide Cleveland, Ohio 44117-1199 U.S.A. M26163PRINT...

- Page 36 Fleet 400 - 12587...

- Page 37 CASE FRONT & CONTROL PANEL ASSEMBLY P-1098-D LOWER CONTROL PANEL ASSEMBLY P-1098-E RECTIFIER FUEL TANK & INNER CONTROL P P-1098-F BASE & BATTERY P-1098-G ENGINE ASSEMBLY P-1098-H GENERATOR ASSEMBLY P-1098-J CASE BACK RADIATOR & LIFT BALE FRAME P-1098-K COVERS ASSEMBLY Fleet 400 - 12587...

- Page 38 Index of Sub Assemblies - 12587 P-1098-A.jpg Fleet 400 - 12587...

- Page 39 CONTROL PANEL ASSEMBLY 9SL17095 CONTROL PANEL 9ST10800-81 ROCKER SWITCHDPTT 9SM19685-68 POTTED CONTROL HARNESS 9SS31642 METER HOLE COVER 9SS9262-3 PLAIN WASHER 9ST4291-A LOCKWASHER 9SCF000005 #6-32HN 9ST10800-72 ROCKER SWITCH 9SM22778-3 KNOB 9SM22778-2 KNOB 1.5" 9SG8784 NAMEPLATE DECAL CARRIER Fleet 400 - 12587...

- Page 40 Case Front & Control Panel Assembly P-1098-C.jpg Fleet 400 - 12587...

- Page 41 THREAD FORMING SCREW (CUTTING) 9SS31570 COVER PLATE 9SS25322-2 RCD STRAP 9SS9225-63 THREAD FORMING SCREW (CUTTING) 9SS28115 MOUNTING STRAP ASSEMBLY 9SS28114 MOUNTING STRAP 9ST11267-A INSULATOR 9ST11267-B INSULATOR 9SCF000356 1/4-20X1.50HHB-FULL-GR2-E1817/1 9SS9262-98 PLAIN WASHER 9SE106A-2 LOCKWASHER 9SCF000017 1/4-20HN 9ST9187-13 #10-24HLN-1817/1-NYLON INSERT Fleet 400 - 12587...

- Page 42 PLAIN WASHER 9SE106A-2 LOCKWASHER 9SCF000017 1/4-20HN 9SS9262-27 PLAIN WASHER 9SE106A-1 LOCKWASHER 9SCF000010 #10-24HN 9SG8768 HARNESS 9SS24097-4 SHUNT & LEAD ASBLY 9SM20007 OUTPUT STUD COVER 9SS31569 OUTPUT STUD COVER PLATE painted BLACK 9SS9225-68 THREAD FORMING SCREW (CUTTING) Fleet 400 - 12587...

- Page 43 Lower Control Panel Assembly P-1098-D.jpg Fleet 400 - 12587...

- Page 44 PC BOARD & TANK SHIELD ASBLY 9SS9225-64 SELF TAPPING SCREW 9SL17082 PC BOARD SHIELD 9SG7637-4 WELD CONTROL PC BD ASBLY 9ST13637-5 DIODE-BRIDGE35A800VF-W1-PH 9SS10773-7 INSULATING WASHER 9ST9187-13 #10-24HLN-1817/1-NYLON INSERT 9SS10404-132 RESISTORWW25W105% 9SS31615-1 RESISTOR BRACKET MOUNT 9SS8025-92 SELF TAPPING SCREW Fleet 400 - 12587...

- Page 45 Rectifier, Fuel Tank, & Inner Control Panel Assembly PART NUMBER DESCRIPTION 9SM22151-1 TIMER DELAY RELAY 9SCF000119 #8-32X1.50RHS 9SS9262-3 PLAIN WASHER 9SE106A-1 LOCKWASHER 9SCF000042 #8-32HN 9SCF000010 #10-24HN 9ST12380-4 BUSHING 9SS9262-27 PLAIN WASHER 9SE106A-1 LOCKWASHER Fleet 400 - 12587...

- Page 46 Rectifier, Fuel Tank, & Inner Control Panel Assembly P-1098-E.jpg Fleet 400 - 12587...

- Page 47 STATOR FAN GUARD 9SL17079 STATOR FAN SHROUD 9SS13490-171A FILTER CAPACITOR 9SS22747 CAPACITOR BRKT ASBLY 9SS9225-64 SELF TAPPING SCREW 9SS9225-64 SELF TAPPING SCREW 9SL15862-1 MEGA BYPASS/VRD STABILIZER PC BD ASBLY 9SS14020-3 PLASTIC EXPANSION NUT 9SS8025-97 SELF TAPPING SCREW Fleet 400 - 12587...

- Page 48 9SM26012 CHOPPERS & CHOKE BRACKET 9SL12683-1 CHOPPER HEAT SINK & PC BD ASBLY 9SM19416-2 CHOKE ASBLY 9SM19685-69 PLUG AND LEAD ASSEMBLY 9SS10404-138 RESISTOR-WW100W505% 9SS9225-64 SELF TAPPING SCREW 9SCF000028 5/16-18X1.25HHCS 9SS9262-121 PLAIN WASHER 9SE106A-3 LOCKWASHER 9SCF000029 5/16-18HN Fleet 400 - 12587...

- Page 49 Base & Battery P-1098-F.jpg Fleet 400 - 12587...

- Page 50 PLAIN WASHER 9SE106A-12 LOCKWASHER 9SL16324 MUFFLER ASBLY 9SL17157 UPPER RADIATOR HOSE 9SL17144 LOWER RADIATOR HOSE 9SM26033 MUFFLER BRACKET 9ST10642-430 OIL DRAIN HOSE 9SS10888-27 HOSE CLAMP 9SS25362-1 HOSE NIPPLE 9SS32301 DRAIN VALVE RING 9SS24662 OIL DRAIN VALVE Fleet 400 - 12587...

- Page 51 Engine Assembly P-1098-G.jpg Fleet 400 - 12587...

- Page 52 9ST14731-61 METRIC SOCKET HD SCREW-M10 X 1.25 SS 9SS17400-1 LOCKWASHER-METRIC 9ST14731-5 METRIC HEX HD SCREW-M10 X 1.5 9SS17400-1 LOCKWASHER-METRIC 9SM18323-1 BRUSH HOLDER BRKT 9SM16158 BRUSH & BRUSH HOLDER ASBLY 9SS8025-91 SELF TAPPING SCREW 9SM26115 STATOR COVER Fleet 400 - 12587...

- Page 53 Generator Assembly P-1098-H.jpg Fleet 400 - 12587...

- Page 54 FUEL SHUT-OFF 9SS10888-35 HOSE CLAMP 9ST13777-1 HOSE CLAMP 9ST10642-269 FLEX TUBE 9SS9225-68 THREAD FORMING SCREW (CUTTING) 9SS28130 ENGINE SERVICE DECAL 9ST9187-16 1/4-20 HLN 9SG3098-10 LIFT FRAME ASSEMBLY 9SG8743 LIFT FRAME 9SS10227-61 LIFT BALE 9SM20840 FUEL PRE-FILTER/WATER SEPARATOR Fleet 400 - 12587...

- Page 55 Case Back, Radiator, & Lift Bale Frame P-1098-J.jpg Fleet 400 - 12587...

- Page 56 FAMILY NAME DECAL 9SG8770 WIRING DIAGRAM 9SS28039-1 DECAL GREEN INITIATIVE 9SL12084 FUEL TROUGH 9SS12934-1 COVER SEAL 9SS25896-3 DECAL WARNING 9ST13086-237 DECAL WARNING 9SM21436 CARBON MONOXIDE WARNING DECAL 9SS30277-3 WARRANTY DECAL 9SS20145-1 HOT SURFACE DECAL 9SM26024 RATING PLATE Fleet 400 - 12587...

- Page 57 Covers Assembly P-1098-K.jpg Fleet 400 - 12587...

- Page 58 WARNING Do not touch electrically live parts or Keep flammable materials away. Wear eye, ear and body protection. electrode with skin or wet clothing. Insulate yourself from work and AVISO DE ground. Spanish PRECAuCION No toque las partes o los electrodos Mantenga el material combustible Protéjase los ojos, los oídos y el bajo carga con la piel o ropa moja-...

- Page 59 WARNING Keep your head out of fumes. Turn power off before servicing. Do not operate with panel open or Use ventilation or exhaust to guards off. remove fumes from breathing zone. AVISO DE Spanish PRECAuCION Los humos fuera de la zona de res- Desconectar el cable de ali- No operar con panel abierto o piración.

-

Page 60: Diagrams

We respond to our customers based on the best information in our possession at that time. Lincoln Electric is not in a position to warrant or guarantee such advice, and assumes no liability, with respect to such information or advice.

Need help?

Do you have a question about the Fleet 400 and is the answer not in the manual?

Questions and answers