Summary of Contents for Lincoln Electric Fleet 400

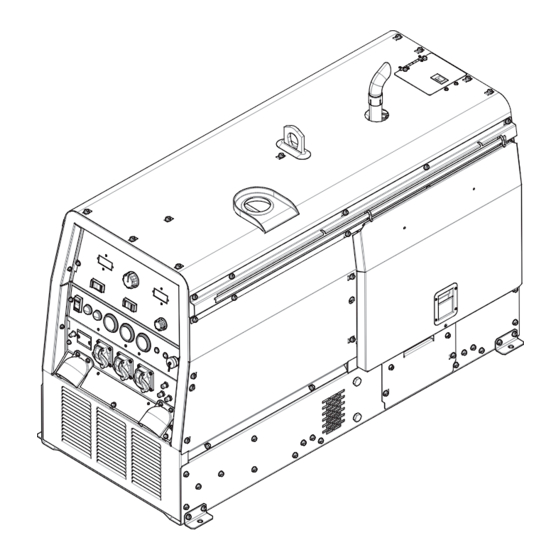

- Page 1 Fleet ™ 400 For use with machines having Code Numbers: Fleet ™ 400: 12587 SERVICE MANUAL SVM284 | Issue D ate 18-Apr © Lincoln Global, Inc. All Rights Reserved.

- Page 2 THANK YOU FOR SELECTING A QUALITY PRODUCT BY KEEP YOUR HEAD OUT OF THE FUMES. DON’T get too close to the arc. LINCOLN ELEC TRIC. Use corrective lenses if necessary to stay a reasonable distance away from the arc. READ and obey the Safety Data PLEASE EXAMINE CARTON AND EQUIPMENT FOR Sheet (SDS) and the warning label DAMAGE IMMEDIATELY...

- Page 3 MAGNETIC FIELDS MAY W117.2-1974. A Free copy of “Arc Welding Safety” booklet BE DANGEROUS E205 is available from the Lincoln Electric Company, 22801 St. Clair Avenue, Cleveland, Ohio 44117-1199. 2.a. Electric current flowing through any conductor BE SURE THAT ALL INSTALLATION, OPERATION, causes localized Electric and Magnetic Fields (EMF).

- Page 4 S FETY ELECTRIC SHOCK ARC RAYS CAN BURN. CAN KILL. 3.a. The electrode and work (or ground) circuits are 4.a. Use a shield with the proper filter and cover plates to protect your electrically “hot” when the welder is on. Do eyes from sparks and the rays of the arc when welding or not touch these “hot”...

- Page 5 S FETY WELDING AND CUTTING CYLINDER MAY EXPLODE IF SPARKS CAN CAUSE DAMAGED. FIRE OR EXPLOSION. 7.a. Use only compressed gas cylinders containing the correct shielding gas for the process used 6.a. Remove fire hazards from the welding area. If and properly operating regulators designed for this is not possible, cover them to prevent the welding sparks the gas and pressure used.

-

Page 6: Table Of Contents

LINCOLN ELECTRIC Fleet™ 400 Service Manual Fleet™ 400 Service Manual Last update: 2018/04/01 FLEET™ 400 ..............................1 Service Manual ..............................1 Troubleshooting & Repair ..........................3 HOW TO USE TROUBLESHOOTING GUIDE ..................... 3 PC BOARD TROUBLESHOOTING PROCEDURES ....................4 Troubleshooting guide ............................5 Test Procedures .............................. - Page 7 LINCOLN ELECTRIC Fleet™ 400 Service Manual CHOKE TEST PROCEDURE ..........................54 PIPE/GOUGE RANGE SWITCH AND WELD MODE SWITCH TEST PROCEDURE ..........56 Removal And Replacement Procedures ...................... 59 FLASHING DIODE (D1) & FIELD DIODE (D2) REMOVAL AND REPLACEMENT PROCEDURE ......59 FRONT PANEL REMOVAL AND REPLACEMENT PROCEDURE ...............

-

Page 8: Troubleshooting & Repair

Troubleshooting & Repair HOW TO USE TROUBLESHOOTING GUIDE Service and repair should be performed by only Lincoln Electric Factory Trained Personnel. Unauthorized repairs performed on this equipment may result in danger to the technician and machine operator and will invalidate your factory warranty. For your safety and to avoid Electrical Shock, please observe all safety notes and precautions detailed throughout this manual. -

Page 9: Pc Board Troubleshooting Procedures

ELECTRIC SHOCK can kill. remove them until installation is complete. • If you return a PC board to The Lincoln Electric Company • Have an electrician install and service this for credit, it must be in the static-shielding bag. This will equipment. -

Page 10: Troubleshooting Guide

7. Perform the Stator Voltage Test Procedure. If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877. - Page 11 5. Perform the Stator Voltage Test Procedure. If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877.

- Page 12 1800 rpm. If not the machine can produce. perform engine maintenance. 3. If the current is correct try If the Fleet 400 has meters, increasing the “ARC FORCE” make sure that they read the setting. same as the load bank meters.

- Page 13 7. Replace the weld control board. If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877.

- Page 14 6. Replace the weld control board. If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877.

- Page 15 3. The weld control board may be defective. If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877.

- Page 16 (size, length, coils or bad connections). If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877.

- Page 17 Diagram. temperature condition. If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877.

- Page 18 3. Fuel injector may be clogged or malfunctioning. If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877.

- Page 19 3. The air filter may be clogged, replace if necessary. If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877.

-

Page 20: Test Procedures

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877. - Page 21 LINCOLN ELECTRIC Fleet™ 400 Service Manual REPLACEMENT PROCEDURE 1. Position the long case side panel onto the machine. 2. Using a 1/2” nutdriver, tighten the four bottom screws securing the long case side panel to the machine. 3. Remove the fuel cap.

- Page 22 LINCOLN ELECTRIC Fleet™ 400 Service Manual Figure F.2 – Long case side panel location...

-

Page 23: Chopper Module Capacitor Discharge Procedure

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877. - Page 24 LINCOLN ELECTRIC Fleet™ 400 Service Manual Figure F.3 – Chopper module board location Figure F.4 – Chopper module board discharge...

-

Page 25: Brush And Slip Ring Service Procedure

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877. - Page 26 LINCOLN ELECTRIC Fleet™ 400 Service Manual SEATING BRUSHES: 11. If brushes have been replaced, repositioned or are not making full contact with the slip rings, it may be necessary to re-seat them. This can be done by placing a strip of 180 grit sandpaper between the slip rings and the brushes, with the abrasive side against the brushes.

-

Page 27: Flashing Diode (D1) & Field Diode (D2) Test Procedure

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877. - Page 28 LINCOLN ELECTRIC Fleet™ 400 Service Manual Figure F.5 – Flashing diode (D1) & field diode (D2) location Figure F.6 – Flashing diode (D1) & field diode (D2) lead locations...

-

Page 29: Engine Shutdown Relay Test Procedure

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877. - Page 30 LINCOLN ELECTRIC Fleet™ 400 Service Manual Table F.2 – Engine shutdown relay resistance tests TEST POINT TEST POINT EXPECTED READING MACHINE CONDITION TERMINAL 87 TERMINAL 30 OPEN NO POWER APPLIED TO (HIGH RESISTANCE) RELAY COILS. TERMINAL 87A TERMINAL 30 CLOSED...

- Page 31 LINCOLN ELECTRIC Fleet™ 400 Service Manual Figure F.8 – Engine shutdown relay terminal locations and schematic...

-

Page 32: Engine Alternator Test Procedure

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877. - Page 33 LINCOLN ELECTRIC Fleet™ 400 Service Manual 15. If the meter reads correctly, check the connections between the alternator and the battery. See Wiring Diagram. 16. If the voltage at both of the above test points reads the same or less than the battery voltage measurement in Step 3, the alternator is defective.

-

Page 34: Rotor Resistance And Ground Test Procedure (Static)

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877. - Page 35 LINCOLN ELECTRIC Fleet™ 400 Service Manual Figure F.9 – Capacitor lead and terminal locations...

-

Page 36: Rotor Resistance And Ground Test Procedure (Dynamic)

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877. -

Page 37: Rotor Voltage Test Procedure

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877. -

Page 38: Flashing Voltage Test Procedure (Engine Not Running)

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877. -

Page 39: Stator Voltage Test Procedure

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877. - Page 40 LINCOLN ELECTRIC Fleet™ 400 Service Manual 12. If these voltage readings are not within the specified limits, check for loose connections or broken wires between the test points and the stator windings. If there are no wiring problems, the stator is defective and should be replaced.

-

Page 41: Output Rectifier Bridge Test Procedure

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877. - Page 42 LINCOLN ELECTRIC Fleet™ 400 Service Manual ground from each terminal should be very high, 500,000 (500K) ohms minimum. If the resistance reading is less than specified, the rectifier is grounded and should be replaced. 9. If using diode checker or a multi-meter with diode check functionality, read and understand the instructions that accompany your test equipment.

- Page 43 LINCOLN ELECTRIC Fleet™ 400 Service Manual Figure F.12 – Output rectifier bridge lead locations...

-

Page 44: Chopper Module Board Function Test Procedure

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877. - Page 45 16. If the voltage drops to 0 VDC after leads 23 and 25 have been disconnected and the modules are not shorted, the weld control board is driving the chopper module. 17. Turn off the engine on the Fleet 400 machine. 18. Reconnect leads 23 and 25 and perform the Weld Control Board PWM Gate Signal Test Procedure.

- Page 46 LINCOLN ELECTRIC Fleet™ 400 Service Manual Figure F.13 – Chopper module board location Figure F.14 – Chopper module board terminal locations...

- Page 47 LINCOLN ELECTRIC Fleet™ 400 Service Manual Figure F.15 – Welder output terminal locations...

-

Page 48: Chopper Module Board Resistance Test Procedure

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877. - Page 49 LINCOLN ELECTRIC Fleet™ 400 Service Manual Table F.5 – Chopper module board diode tests TEST POINT (+) TEST POINT (–) EXPECTED RESULT 0.3 VDC – 0.7 VDC 1.0 VDC – 1.4 VDC 0.3 VDC – 0.7 VDC 0.3 VDC – 0.7 VDC 1.0 VDC –...

- Page 50 LINCOLN ELECTRIC Fleet™ 400 Service Manual Figure F.17 – Chopper module board terminal locations...

-

Page 51: Weld Control Board Pwm Gate Signal Test Procedure

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877. - Page 52 LINCOLN ELECTRIC Fleet™ 400 Service Manual Figure F.18 – Weld control board plug locations Figure F.19 – Weld control board plug J3 lead locations...

-

Page 53: Weld Control Board Feedback Test Procedure

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877. - Page 54 LINCOLN ELECTRIC Fleet™ 400 Service Manual The shunt used in this machine will produce 50 millivolts at a load of 400 amps or 8 amps per millivolt. To calculate the correct millivolt signal for a given load, divide the number of amps displayed on the ammeter by 8.

- Page 55 LINCOLN ELECTRIC Fleet™ 400 Service Manual Figure F.21 – Weld control board plug J3 and J6 lead locations...

-

Page 56: Output Control And Arc Force Potentiometer Test Procedure

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877. - Page 57 LINCOLN ELECTRIC Fleet™ 400 Service Manual Table F.6 – Output control and arc force potentiometer test points POTENTIOMETER TEST POINTS OHMMETER READING OUTPUT CONTROL J7-5 (75) TO J7-1 (77) ABOUT 10K OHMS VALUE SHOULD SWEEP SMOOTHLY FROM 10K TO 0...

- Page 58 LINCOLN ELECTRIC Fleet™ 400 Service Manual Figure F.23 – Weld control board plug J7 lead locations...

-

Page 59: Choke Test Procedure

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877. - Page 60 LINCOLN ELECTRIC Fleet™ 400 Service Manual Figure F.24 – Choke assembly location Figure F.25 – Negative output terminal location...

-

Page 61: Pipe/Gouge Range Switch And Weld Mode Switch Test Procedure

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877. - Page 62 LINCOLN ELECTRIC Fleet™ 400 Service Manual 17. Place the upper control panel into the closed position. 18. Using a 3/8” nutdriver, attach the four screws securing the upper control panel to the machine. 19. Perform the Case Cover Replacement Procedure.

- Page 63 LINCOLN ELECTRIC Fleet™ 400 Service Manual Figure F.26 – Pipe/gouge range switch and weld mode switch locations Figure F.27 – Pipe/gouge range switch and weld mode switch lead locations...

-

Page 64: Removal And Replacement Procedures

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877. - Page 65 LINCOLN ELECTRIC Fleet™ 400 Service Manual 6. Perform the Retest After Repair Procedure. Figure F.28 – Flashing diode (D1) & field diode (D2) lead locations Figure F.29 – Diode mounting hardware locations...

-

Page 66: Front Panel Removal And Replacement Procedure

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877. - Page 67 LINCOLN ELECTRIC Fleet™ 400 Service Manual 11. Using a 7/16” nutdriver and a 7/16” open-end wrench, remove the nut, lock washer and flat washer securing leads to 12V run insulated stud. See Wiring Diagram. Cut cable ties as necessary. 12. Label and disconnect any other leads and plugs necessary to allow for the removal of front panel assembly.

- Page 68 LINCOLN ELECTRIC Fleet™ 400 Service Manual Figure F.30 – Positive and negative output terminal locations Figure F.31 – Front panel mounting screw locations...

-

Page 69: Output Rectifier Bridge Removal And Replacement Procedure

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877. - Page 70 LINCOLN ELECTRIC Fleet™ 400 Service Manual 2. Using a 1/2” nutdriver, attach the two nuts, lock washers and four flat washers securing the output rectifier bridge to the fuel tank shelf. 3. Carefully apply a thin coating of Penetrox heat sink compound to the mating surfaces of the leads.

- Page 71 LINCOLN ELECTRIC Fleet™ 400 Service Manual Figure F.33 – Output rectifier bridge mounting nut locations...

-

Page 72: Chopper Module Board Removal And Replacement Procedure

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877. - Page 73 LINCOLN ELECTRIC Fleet™ 400 Service Manual 2. Using a 3/16” Allen wrench, attach the two screws securing the front chopper mounting bracket to the chopper module board. 3. Carefully position the chopper module board onto the chopper and choke bracket.

- Page 74 LINCOLN ELECTRIC Fleet™ 400 Service Manual Figure F.35 – Chopper module board rear mounting bracket location Figure F.36 – Chopper module board front mounting bracket location...

-

Page 75: Weld Control Board Removal And Replacement Procedure

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877. - Page 76 LINCOLN ELECTRIC Fleet™ 400 Service Manual Figure F.37 – Weld control board plug locations Figure F.38 – Weld control board mounting hardware locations...

-

Page 77: Choke Removal And Replacement Procedure

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877. - Page 78 LINCOLN ELECTRIC Fleet™ 400 Service Manual 7. Perform the Retest After Repair Procedure. Figure F.39 – Choke terminals and mounting hardware location...

-

Page 79: Pipe/Gouge Range Switch Removal And Replacement Procedure

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877. - Page 80 LINCOLN ELECTRIC Fleet™ 400 Service Manual Figure F.40 – Upper control panel mounting screw locations Figure F.41 – Pipe/gouge range switch lead and mounting tab locations...

-

Page 81: Weld Mode Switch Removal And Replacement Procedure

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877. - Page 82 LINCOLN ELECTRIC Fleet™ 400 Service Manual Figure F.42 – Upper control panel mounting screw locations Figure F.43 – Weld mode switch leads and mounting tab locations...

-

Page 83: Fuel Tank Removal And Replacement Procedure

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877. - Page 84 LINCOLN ELECTRIC Fleet™ 400 Service Manual NOTE: To avoid spills, temporarily wrap fuel hoses with paper towels to absorb any residual fuel. If there is any fuel left in the fuel tank, drain it into an appropriate fuel storage container.

- Page 85 LINCOLN ELECTRIC Fleet™ 400 Service Manual Figure F.45 – Flashing diode (D1) and field diode (D2) lead locations Figure F.46 – Fuel level sender lead locations...

- Page 86 LINCOLN ELECTRIC Fleet™ 400 Service Manual Figure F.47 – PC board shield mounting hardware location...

-

Page 87: Rotor And Stator Removal And Replacement Procedure

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877. - Page 88 LINCOLN ELECTRIC Fleet™ 400 Service Manual 11. Cut cable ties securing leads to the fuel tank tray and fan baffle. 12. Using a 1/2” nutdriver, remove the three screws securing the fuel tank tray to the fan baffle. See Figure F.49.

- Page 89 LINCOLN ELECTRIC Fleet™ 400 Service Manual 14. Carefully position the fan baffle into the machine. 15. Using a 1/2” nutdriver, attach the four screws securing the fan baffle to the machine. 16. Carefully position the fuel tank tray into the machine.

- Page 90 LINCOLN ELECTRIC Fleet™ 400 Service Manual Figure F.49 – Lift bail frame, fan baffle, chopper and choke bracket mounting screw locations Figure F.50 – Rotor and stator mounting hardware locations...

-

Page 91: Retest After Repair

LINCOLN ELECTRIC Fleet™ 400 Service Manual RETEST AFTER REPAIR Retest a machine: • If it is rejected under test for any reason that requires you to remove any part which could affect the machine’s electrical characteristics. • If you repair or replace any electrical components.

Need help?

Do you have a question about the Fleet 400 and is the answer not in the manual?

Questions and answers