Table of Contents

Advertisement

Quick Links

Operator's Manual

Flextec

Register your machine:

www.lincolnelectric.com/register

Authorized Service and Distributor Locator:

www.lincolnelectric.com/locator

Save for future reference

Date Purchased

Code: (ex: 10859)

Serial: (ex: U1060512345)

IM10415

| Issue D ate May-17

© Lincoln Global, Inc. All Rights Reserved.

65 x

®

For use with machines having Code Numbers:

12719

Advertisement

Table of Contents

Summary of Contents for Lincoln Electric 12719

- Page 1 Operator’s Manual Flextec 65 x ® For use with machines having Code Numbers: 12719 Register your machine: www.lincolnelectric.com/register Authorized Service and Distributor Locator: www.lincolnelectric.com/locator Save for future reference Date Purchased Code: (ex: 10859) Serial: (ex: U1060512345) IM10415 | Issue D ate May-17...

- Page 2 THANK YOU FOR SELECTING A QUALITY PRODUCT BY KEEP YOUR HEAD OUT OF THE FUMES. DON’T get too close to the arc. LINCOLN ELEC TRIC. Use corrective lenses if necessary to stay a reasonable distance away from the arc. READ and obey the Safety Data PLEASE EXAMINE CARTON AND EQUIPMENT FOR Sheet (SDS) and the warning label DAMAGE IMMEDIATELY...

- Page 3 W117.2-1974. A Free copy of “Arc Welding Safety” booklet E205 is available from the Lincoln Electric Company, 2.d. All welders should use the following procedures in order to 22801 St. Clair Avenue, Cleveland, Ohio 44117-1199.

- Page 4 SAFETY ELECTRIC SHOCK ARC RAYS CAN BURN. CAN KILL. 3.a. The electrode and work (or ground) circuits are 4.a. Use a shield with the proper filter and cover plates to protect your electrically “hot” when the welder is on. Do eyes from sparks and the rays of the arc when welding or not touch these “hot”...

- Page 5 SAFETY WELDING AND CUTTING CYLINDER MAY EXPLODE IF SPARKS CAN CAUSE DAMAGED. FIRE OR EXPLOSION. 7.a. Use only compressed gas cylinders containing the correct shielding gas for the process used 6.a. Remove fire hazards from the welding area. If and properly operating regulators designed for this is not possible, cover them to prevent the welding sparks the gas and pressure used.

-

Page 6: Table Of Contents

TABLE OF CONTENTS Page Installation....................... Section A Technical Specifications....................... A-1, A-2 Safety Precautions........................A-3 VRD™ (Voltage Reduction Device)......................A-3 Select Suitable Location....................... A-3 Lifting...........................A-3 Stacking..........................A-3 Environmental Limitations....................A-3 Input and Grounding Connections..................A-3 High Frequency Protection....................A-3 High Temperature Operation......................A-3 Input Connection .........................A-4 Input Fuse and Supply Wire Considerations..................A-4 Input Voltage Selection.........................A-4 Cable Connections........................ - Page 7 FLEXTEC 650x INSTALLATION TECHNICAL SPECIFICATIONS - FLEXTEC 650X POWER SOURCE-INPUT VOLTAGE AND CURRENT Model Duty Cycle Input Voltage ± 10% Input Amperes Power Factor @ Idle Power Effective Rated Output 60% rating 61 / 50 / 40 230 MAX.( Fan On) K4376-1 380 / 460 / 575 / 3 / 50 / 60 100% rating...

- Page 8 FLEXTEC 650x INSTALLATION WELDING PROCESS OUTPUT RANGE (AMPERES) OCV (U OCV (U PROCESS GMAW (CV) 40-815 GTAW (CC) 10-815 SMAW (CC) 15-815 40-815 FCAW-G (CV) FCAW-S (CV) 40-815 SAW (CV) 40-815 PHYSICAL DIMENSIONS MODEL HEIGHT WIDTH DEPTH WEIGHT 165lbs (74.8kg)* 29.33 in (745 mm) K4376-1 21.8 in (554 mm)

-

Page 9: Installation

FLEXTEC 650x INSTALLATION INSTALLATION WARNING LIFTING The FLEXTEC 650x has 2 lifting eyelets and 2 handles that can be used to lift the machine. Both handles or both eyelets should be ELECTRIC SHOCK can kill. used when lifting the FLEXTEC 650x. •... -

Page 10: High Temperature Operation

FLEXTEC 650x INSTALLATION HIGH TEmPERATURE OPERATION INPUT FUSE AND SUPPLY WIRE CONSIDERATIONS WELDER OUTPUT RATINGS AT 55°C Refer to Specification in this Installation Section for recommended ELEVATED TEMPERATURES fuse, wire sizes and type of the copper wires. Fuse the input AMPS Duty Cycle Volts... -

Page 11: Cable Connections

FLEXTEC 650x INSTALLATION CAbLE CONNECTIONS See FIGURE A.2 for locating 5, 12 and 14 pin connectors on the front of the FLEXTEC 650x. FIGURE A.2 12-PIN ACCESSORY CONNECTIVITY Function Wiring A ArcLink CAN B ArcLink CAN C Remote potentiometer, common 12-pin remote D Remote potentiometer wiper control... -

Page 12: Output Cable Guidelines

FLEXTEC 650x INSTALLATION The following recommendations apply to all output polarities and weld modes: RECOmmENDED ELECTRODE AND WORk CAbLE • Select the appropriate size cables per the “Output Cable SIZES FOR ARC WELDING Guidelines” (See Table A.1). Excessive voltage drops General Guidelines caused by undersized welding cables and poor connections often result in unsatisfactory welding performance. -

Page 13: Control Cable Connections, Paralleling

FLEXTEC 650x INSTALLATION CONTROL CAbLE CONNECTIONS Regarding cable placement, best results will be obtained when General Guidelines control cables are routed separate from the weld cables. This minimizes the possibility of interference between the high currents flowing through the weld cables, and the low level signals in the Genuine Lincoln control cables should be used at all times (except control cables. - Page 14 FLEXTEC INSTALLATION CONNECTING LF-72 AND LF-74 TO THE FLEXTEC 650x WIRE FEEDER 14-PIN CONTROL CABLE K1797-XX LF-72 ELECTRODE LF-74 Flextec 650x WORK CONTROL SETTING WELD MODE CV, CV-INNERSHIELD WELD TERMINALS LOCAL REMOTE/LOCAL (REMOTE IF K2329-1 INSTALLED) VOLTMETER POLARITY PROCESS DEPENDENT...

- Page 15 FLEXTEC INSTALLATION CONNECTING LN-10 AND DH-10 TO THE FLEXTEC 650x WIRE FEEDER 14-PIN CONTROL CABLE K1501-XX LN-10 DH-10 Flextec 650x ELECTRODE WORK CONTROL SETTING WELD MODE CV, CV-INNERSHIELD WELD TERMINALS REMOTE/LOCAL REMOTE VOLTMETER POLARITY PROCESS DEPENDENT LN-10,DH-10 CONTROL SWITCH SETUP Setting the DIP Switches Initial set up of the LN-10, DH-10 control for the system components being used and for general operator preferences...

- Page 16 FLEXTEC INSTALLATION CONNECTING LN-25 PRO, LN-25 PIPE, ACTIV8 TO THE FLEXTEC 650x WIRE FEEDER LN-25 PRO LN-25 PIPE Flextec 650x ELECTRODE ACTIV8 WORK CLIP WORK CONTROL SETTING WELD MODE CV, CV-INNERSHIELD WELD TERMINALS REMOTE/LOCAL LOCAL PROCESS DEPENDENT VOLTMETER POLARITY CONNECTING LN-25 PRO DUAL POWER TO THE FLEXTEC 650x WIRE FEEDER CONTROL CABLE K1797-XX LN-25 PRO...

- Page 17 FLEXTEC INSTALLATION CONNECTING LN-7 TO THE FLEXTEC 650x WIRE FEEDER 14-PIN CONTROL CABLE K1818-XX LN-7 Flextec 650x ELECTRODE WORK CONTROL SETTING CV, CV-INNERSHIELD WELD MODE WELD TERMINALS REMOTE/LOCAL LOCAL VOLTMETER POLARITY PROCESS DEPENDENT CONNECTING LN-8 AND LN-9 TO THE FLEXTEC 650x WIRE FEEDER 14-PIN CONTROL CABLE K1820-XX LN-8...

- Page 18 FLEXTEC INSTALLATION CONNECTING NA-3, NA-5 TO THE FLEXTEC 650x WIRE FEEDER 14-PIN CONTROL CABLE K1820-XX NA-3 NA-5 Flextec 650x ELECTRODE WORK FOR NA-3, NA-4 WIRE FEEDERS ONLY: - MOVE JUMPER LEAD ON VARIABLE VOLTAGE BOARD TO "L" PIN. FOR NA-5 WIRE FEEDER ONLY: - MOVE "BLUE"...

-

Page 19: Operation

FLEXTEC 650x OPERATION OPERATION SAFETY PRECAUTIONS Read this entire section of operating instructions before operating the machine. WARNING ELECTRIC SHOCK can kill. • Unless using cold feed feature, when feeding with gun trigger, the electrode and drive mechanism are always electrically energized and could remain energized several seconds after the welding ceases. -

Page 20: Graphic Symbols

FLEXTEC 650x OPERATION GRAPHIC SYmbOLS THAT APPEAR ON THIS mACHINE OR IN THIS mANUAL REDUCED OPEN INPUT POWER CIRCUIT VOLTAGE OPEN CIRCUIT VOLTAGE INPUT VOLTAGE OUTPUT VOLTAGE HIGH TEMPERATURE INPUT CURRENT CIRCUIT BREAKER OUTPUT CURRENT PROTECTIVE WIRE FEEDER GROUND WARNING or CAUTION POSITIVE OUTPUT Read &... -

Page 21: Product Description

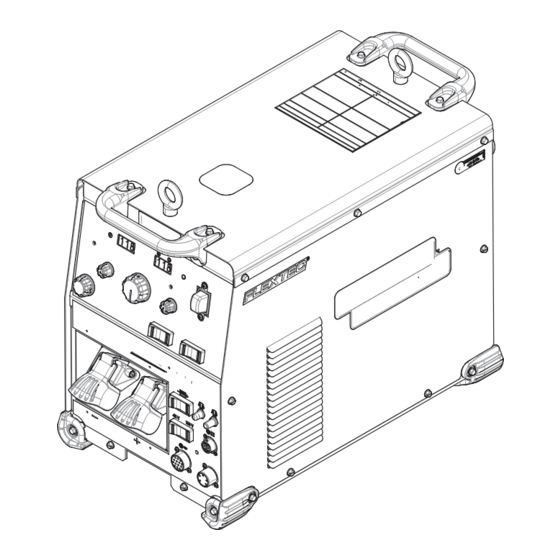

FLEXTEC 650x OPERATION PRODUCT DESCRIPTION RECOmmENDED PROCESSES The FLEXTEC 650x is a multi-process CC/CV DC inverter and is The FLEXTEC 650x is designed for CC-SMAW, CC-GTAW (lift tig), rated for 650 amps, 44 volts at a 100% duty cycle. The CV-GMAW, CV-FCAW-S, CV-FCAW-G and CV-SAW welding FLEXTEC 650x is intended for both factory and field operation. - Page 22 FLEXTEC 650x OPERATION 10. Wire Feeder Voltmeter polarity selection switch CASE FRONT CONTROL DESCRIPTIONS 11. 115V or 42V wire feeder selector switch (See Figure B.1) 1. Power Switch: Controls input power to the Flextec 650x 12. 14-pin wire feeder circular connector 2.

-

Page 23: Case Back Controls

FLEXTEC 650x OPERATION CASE bACk CONTROLS (See Figure B.2) 1. Input Power Cord Access Hole. 2. Access Panel – Allows access for connecting input power and configuring the machine. 3. Input Power Reconnect – Configures the machine for the input supply voltage. 4. -

Page 24: Internal Controls

FLEXTEC 650x OPERATION INTERNAL CONTROLS - ENAbLING VRD, mULTI-WELD AND CURRENT/VOLTAGE CALIbRATION Internal Controls Description The User Interface pc board has one bank of dip switches (See Figure B.3 Item 1). As shipped from the factory and under normal conditions, dip switch #2 is ‘on’ position and all others are in the ‘off’... -

Page 25: Power-Up Sequence

Many variables beyond the control of The • Full range selection of arc control from -10 to +10. In CV Lincoln Electric Company affect the results obtained in mode, this control is an inductance control. In stick mode, applying these programs. - Page 26 FLEXTEC 650x OPERATION Control - Local/Remote Toggle Switch bASIC mODES OF OPERATION • Set the switch to “local” to control output at the Flextec via the Output Control dial. SMAW • Set the switch to “remote” to control output via a remote device (K857-2 hand amptrol or K870-2 foot amptrol) This weld mode is a constant current (CC) mode featuring connected to the 12-pin remote connector or a wire feeder...

- Page 27 FLEXTEC 650x OPERATION GTAW CV-Gas This weld mode is a constant current (CC) mode featuring This weld mode is a constant voltage (CV) mode featuring continuous control from 10 – 815 amps. It is intended for the continuous control from 10 to 45 volts. It is intended for the GTAW tig welding processes.

- Page 28 FLEXTEC 650x OPERATION CV-Innershield CV-SAW This weld mode is a constant voltage (CV) mode featuring This weld mode is a constant voltage (CV) mode featuring continuous control from 10 to 45 volts. It is intended for the continuous control from 10 to 45 volts. It is intended for the CV- FCAW-S welding process and arc gouging.

- Page 29 FLEXTEC 650x OPERATION Arc Link CrossLinc™ This weld mode is intended to unlock basic non-synergic and CrossLinc™ is a new welding system communication technology. synergic modes intended for use with compatible ArcLink wire When using a CrossLinc™ enabled power source such as the feeders.

-

Page 30: Accessories

FLEXTEC 650x ACCESSORIES OPTIONS / ACCESSORIES TIG Options General Options Pro-Torch™ TIG Torches – PTA-9, PTA- K2149-1 Work Lead Package. 17, PTA-26 – 2 piece power cord. Foot Amptrol - Provides 25 ft. (7.6 m) of K1842-10 10ft. Weld Power Cable (Lug to Lug). remote current control for TIG welding. -

Page 31: Maintenance

FLEXTEC 650x MAINTENANCE MAINTENANCE PERIODIC mAINTENANCE WARNING Safety Precautions Thermal Protection Thermostats protect the machine from excessive operating temperatures. Excessive temperatures may be caused by a lack of ELECTRIC SHOCK can kill. cooling air or operating the machine beyond the duty cycle and output rating. -

Page 32: Voltage Calibration

FLEXTEC 650x MAINTENANCE VOLTAGE CALIbRATION TO RESTORE FACTORY CURRENT CALIbRATION 1. Connect a resistive load bank to the machine configured for 1. Connect the resistive load bank and test voltmeter to the 300A/20V (750A/50V equivalent). welding output terminals. 2. Connect a certified calibrated voltmeter to the output circuit. 2. -

Page 33: How To Use Troubleshooting Guide

FLEXTEC 650x TROUBLESHOOTING TROUBLESHOOTING How to Use troUblesHooting gUide WARNING Service and Repair should only be performed by Lincoln Electric Factory Trained Personnel. Unauthorized repairs performed on this equipment may result in danger to the technician and machine operator and will invalidate your factory warranty. - Page 34 FLEXTEC 650x TROUBLESHOOTING Observe all Safety Guidelines detailed throughout this manual PROBLEMS POSSIBLE RECOMMENDED (SYMPTOMS) CAUSE COURSE OF ACTION BASIC MACHINE PROBLEMS Major physical or electrical damage is 1. Contact your local authorized Lincoln evident when the sheet metal covers are Electric Field Service facility for technical removed.

- Page 35 FLEXTEC 650x TROUBLESHOOTING USING THE STATUS LED TO TROUbLESHOOT Included in this section is information about the fault codes SYSTEm PRObLEmS indicated on the status lights and some basic troubleshooting charts for both machine and weld performance. Errors are displayed on the amperage and voltage display meters. The status lights on the main control board and the switch pc In addition, there are status lights on the control pc board and the board are dual-color LED’s.

- Page 36 FLEXTEC 650x DIAGRAMS FRONT OF MACHINE...

- Page 37 FLEXTEC 650x DIAGRAMS...

- Page 38 Flextec 650X (CCC) - 12719...

- Page 39 Index of Sub Assemblies - 12719 PART NUMBER DESCRIPTION P-1132-A INDEX OF SUB ASSEMBLIES P-1132-C CASE FRONT ASSEMBLY P-1132-D DIVIDER PANEL ASSEMBLY P-1132-E BASE ASSEMBLY P-1132-F CASE BACK ASSEMBLY P-1132-G COVERS ASSEMBLY Flextec 650X (CCC) - 12719...

- Page 40 Index of Sub Assemblies - 12719 P-1132-A.jpg Flextec 650X (CCC) - 12719...

- Page 41 9ST9695-2 LOCKWASHER 9SCF000002 #4-40HN 9SS17062-12 CONNECTOR CAP 9SS17062-11 CABLE CONNECTOR CAP 9SS17062-10 CABLE CONNECTOR CAP 9SCF000010 #10-24HN 9SE106A-1 LOCKWASHER 9SL17083-1 POTTED CONTROL HARNESS 9SS32071-4 USER INTERFACE PC BD ASBLY 9ST10082-30 SEMS SCREW 9SS9262-97 PLAIN WASHER Flextec 650X (CCC) - 12719...

- Page 42 SELF TAPPING SCREW 9SS29541-3 POWER SWITCH REWORK 9SS28393-5 OUTPUT SNUBBER ASBLY 9SS9262-1 PLAIN WASHER 9SE106A-15 LOCKWASHER 9SCF000021 1/2-13X1.00HHCS 9SCF000010 #10-24HN 9SE106A-1 LOCKWASHER 9SS9225-68 THREAD FORMING SCREW (CUTTING) 9SS9262-183 PLAIN WASHER 9SS9225-66 SELF TAPPING SCREW 9ST4550-5 EYEBOLT Flextec 650X (CCC) - 12719...

- Page 43 Case Front Assembly P-1132-C.jpg Flextec 650X (CCC) - 12719...

- Page 44 9ST9695-17 LOCKWASHER 9SCF000412 1/4-20 X .50 HHCS 9ST13260-4 DECAL-EARTH GROUND CONN 9ST12386 FUSE HOLDER 9ST9447-91 SOCKET HEAD CAP SCREW #8-32X.50 SS 9ST10728-72 FUSE - 7.5A 9SS28930 FUSE DECAL 9SM22714 TRANSFORMER BAFFLE 9SS8025-68 SELF TAPPING SCREW Flextec 650X (CCC) - 12719...

- Page 45 CURRENT TRANSDUCER 9SS28515 TRANSDUCER SPACER 9SS9225-36 THREAD FORMING SCREW (CUTTING) 9ST14605 INSULATOR 9ST11267-B INSULATOR 9SS31808 INSULATION 9SS9225-68 THREAD FORMING SCREW (CUTTING) 9SS18491-1 MOV ASBLY 9SL10033-12 AUX TRANSFORMER ASBLY 9SS9225-68 THREAD FORMING SCREW (CUTTING) 9SE106A-2 LOCKWASHER Flextec 650X (CCC) - 12719...

- Page 46 Divider Panel Assembly P-1132-D.jpg Flextec 650X (CCC) - 12719...

- Page 47 LOCKWASHER 9SCF000029 5/16-18HN 9SL16016 OUTPUT RECTIFIER ASSEMBLY 9SM22697-1 HEAT SINK 9SS25520S DIODE MODULE ASBLY 9SCF000013 1/4-20X.625HHCS 9SS9262-98 PLAIN WASHER 9ST12735-4 SPRING WASHER 9ST9447-91 SOCKET HEAD CAP SCREW #8-32X.50 SS 9SS28865 HEATSINK SUPPORT 9SS9262-98 PLAIN WASHER Flextec 650X (CCC) - 12719...

- Page 48 SELF TAPPING SCREW 9SS23224 BUS BAR 9SCF000028 5/16-18X1.25HHCS 9SS9262-30 PLAIN WASHER 9SE106A-3 LOCKWASHER 9SCF000029 5/16-18HN 9SM22858-1 DIVIDER SUPPORT 9SS9225-68 THREAD FORMING SCREW (CUTTING) 9SM25001 RESISTOR ASSEMBLY 9SS10404-139 RESISTORWW225W5010% 9ST11827-59 CARRIAGE BOLT 9ST9764-6 INSULATOR 9SE106A-2 LOCKWASHER 9SCF000017 1/4-20HN Flextec 650X (CCC) - 12719...

- Page 49 Base Assembly P-1132-E.jpg Flextec 650X (CCC) - 12719...

- Page 50 HANDLE SUPPORT BRACKET 9SG6525-3 HANDLE 9SS9225-66 SELF TAPPING SCREW 9SS9225-68 THREAD FORMING SCREW (CUTTING) 9SS9262-183 PLAIN WASHER 9SS9225-66 SELF TAPPING SCREW 9SS22752-50 RATING PLATE 9SM22683 RECONNECT DOOR 9SS9225-68 THREAD FORMING SCREW (CUTTING) 9ST4550-5 EYEBOLT 9ST13259-4 GROUNDING DECAL Flextec 650X (CCC) - 12719...

- Page 51 Case Back Assembly P-1132-F.jpg Flextec 650X (CCC) - 12719...

- Page 52 THREAD FORMING SCREW (CUTTING) 9SG7027-2 RIGHT CASE SIDE 9SG7030 CASE TOP WRAPAROUND 9SS9225-66 SELF TAPPING SCREW 9SG8737 WIRING DIAGRAM 9SS20601-6 WARNING DECAL 9SS30277-2 WARRANTY DECAL 9SM22461 FAMILY NAME DECAL 9SS27368-4 DECAL LE LOGO 9SS28039-2 DECAL GREEN INITIATIVE Flextec 650X (CCC) - 12719...

- Page 53 Covers Assembly P-1132-G.jpg Flextec 650X (CCC) - 12719...

- Page 54 WARNING Do not touch electrically live parts or Keep flammable materials away. Wear eye, ear and body protection. electrode with skin or wet clothing. Insulate yourself from work and AVISO DE ground. Spanish PRECAuCION No toque las partes o los electrodos Mantenga el material combustible Protéjase los ojos, los oídos y el bajo carga con la piel o ropa moja-...

- Page 55 WARNING Keep your head out of fumes. Turn power off before servicing. Do not operate with panel open or Use ventilation or exhaust to guards off. remove fumes from breathing zone. AVISO DE Spanish PRECAuCION Los humos fuera de la zona de res- Desconectar el cable de ali- No operar con panel abierto o piración.

- Page 56 We respond to our customers based on the best information in our possession at that time. Lincoln Electric is not in a position to warrant or guarantee such advice, and assumes no liability, with respect to such information or advice.

Need help?

Do you have a question about the 12719 and is the answer not in the manual?

Questions and answers