Advertisement

Quick Links

Installation and operating

manual

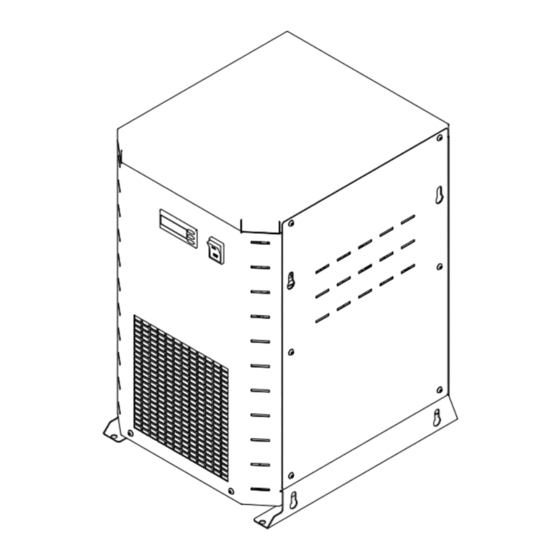

Refrigeration Dryer Series UDT 20 - 1900

Please read the instructions carefully before installation or use. The proper and safe operation of

the refrigeration air dryer is ensured only by following the recommendations and conditions

stated in the instructions.

For additional questions, contact the manufacturer and inform him of the information on the data

plate found on the front of the dryer.

3403348 - MANUAL for UDT 20-1900 - NO LOGO_EN_202112033

Advertisement

Subscribe to Our Youtube Channel

Summary of Contents for OMEGA AIR UDT 20

- Page 1 For additional questions, contact the manufacturer and inform him of the information on the data plate found on the front of the dryer. 3403348 - MANUAL for UDT 20-1900 - NO LOGO_EN_202112033...

- Page 2 Dear customer! Thank you for purchasing our product. In order for the product to serve well and reliably, please read these installation and operating instructions carefully. In order to avoid misuse of equipment and potential hazards for the operator, please read thoroughly and strictly follow the instructions contained in this installation and operating manual.

- Page 3 Table of Contents 1 GENERAL INFORMATION ..........................4 1.1. D ............................4 EVICE INFORMATION 1.2. I .......................... 4 NFORMATION ON THE SUPPLIER 1.3 B ................................5 ASIC 1.4. R ..........................5 EFRIGERATION AIR DRYERS 1.5 P ..............................5 ROPER USE 2 SAFETY INSTRUCTIONS ..........................

- Page 4 1 General information 1.1. Device information Model of refrigeration air dryer: Serial number: Year of manufacture: Date of installation: Please fill in the fields carefully. Correct data enables proper and efficient maintenance of the device, selection of suitable spare parts and technical support. 1.2.

- Page 5 1.3 Basic Compressed air contains contaminants such as water, oil and particles. Impurities need to be removed or their concentration reduced to an acceptable level according to the requirements of the application. The ISO 8573-1 standard specifies the purity / quality of the air for contaminants. The humidity (water vapor content) can be expressed in terms of Pressure Dew Point (PDP).

- Page 6 2 Safety instructions ⚠ Improper use of the compressed air system and electrical installations can lead to injury or death. ⚠ Improper handling (transport, installation, use, maintenance) of a refrigeration air dryer can lead to serious injury or death. The result of improper use may be damage to the device and/or reduced efficiency of the dryer.

- Page 7 ⚠ Only use genuine spare parts. ⚠ Only use refrigeration air dryers for intended purpose. ⚠ When transporting the dryer, check and follow the local regulations for lifting and transporting heavy objects. ⚠ In the event of fire, do not use extinguishing water on the dryer and nearby objects. ⚠...

- Page 8 3 Technical Specifications 3.1 Components Figure 2: Components (shown: UDT 100) 1. Heat exchanger 3in1 7. Switch 2. Condenser 8. Capillary tube 3. Compressor 9. Sensor for fan operation 4. Timed condensate drain 10. Filter / dehydrator 5. Controller 6. Hot gas bypass valve...

- Page 9 Carbon steel Casing corrosion protection Epoxy powder paint Evaporator Brazed plate stainless steel (UDT 20-1900) Evaporator insulation Flexible elastomeric foam Condenser Aluminium fin and copper tube (UDT 20-1900) Compressor Carbon steel Refrigerant piping Copper Controller enclosure Plastic SIZES Compressed air...

- Page 10 CORRECTION FACTORS To calculate the correct capacity of a given dryer based on actual operating conditions, multiply the nominal inlet flow by the appropriate correction factor(s). CORRECTED CAPACITY = NOMINAL FLOW CAPACITY x C OPERATING PRESSURE [bar] [psi] 0,39 0,60 0,77 0,86 0,93...

- Page 11 4 Refrigeration air dryer operation The refrigeration air dryer is designed to remove moisture from the input air to achieve the desired dew point at the exit. All refrigeration air dryers described above operate according to the same principle. The operation of the refrigeration air dryer can be divided into two main circuits: Air and refrigeration circuit.

- Page 12 5 Refrigeration air dryer components 5.1 Compressor The compressor sucks the gaseous phase of the refrigerant from the evaporator (low pressure side) and compresses it to the condensation pressure (high pressure side). Built-in compressors are manufactured by leading manufacturers and are designed for applications where high compression ratios and high temperature differences are present.

- Page 13 5.4 Controller RDC 2 At startup, the controller shows the time remaining until compressors starts by displaying COMP TIME X MIN. The value X can be changed by changing the parameter no. 5. The controller RDC 2 shows the temperature of the dew point reached by the refrigeration air dryer in the normal operation.

- Page 14 5.4.1 Electric scheme RDC 2 The controller has 3 outputs (230 V), for compressor, fan and drain. The other outputs are for alarm. The alarm is triggered via opto triac, which can handle 600VAC/50mA. Controller can also be turned OFF/ON via In. Remote by changing the parameter 13 (Remote control) from 0 to 1.

- Page 15 5.4.2 RDC 2 parameters Parameter Allowed to Parameter Press UP Press DOWN Default name change number Drain Cycle Increase Decrease Value value value Drain Period Increase Decrease 200 sec Value value value Increase Decrease value value Increase Decrease value value Increase Decrease Compressor...

- Page 16 In the following paragraph, a procedure to change the minimal compressor OFF time is shown. To change the minimal compressor OFF time, you must choose programming parameter no. 5 and change the value from default to the desired value. To do that you must: •...

- Page 17 5.4.3 RDC 2 MODBUS communication ADDRESS NAME TYPE VARIABLE X UNIT 40013 ADDRESS RDWR Address = X 40014 Service Time R_ONLY Service Time = X 40015 No. of alarms in last 24h R_ONLY Alarm 24 H Number= X 40016 No. of alarms since service R_ONLY Total Alarms = X 40017...

- Page 18 5.5 Expansion valves This valve injects a portion of the hot gases (taken from the compressor outlet) into the tube between the evaporator and the suction side of the compressor, thereby maintaining constant temperature / pressure of the evaporator at about +2 °...

- Page 19 5.7 Safety functions For protection against low-pressure, the low-pressure switch is added. Other safety functions are implemented in the controller. 5.7.1 Low-pressure switch LPS: Low-pressure protection device on the suction side of the compressor trips, if the pressure drops below the pre-set value. The values are automatically reset when the nominal conditions are restored. Calibrated pressure: R 134.a Stop 0.7 barg - Restart 1.7 barg 5.7.1 Safety functions of RDC 2 ALARM...

- Page 20 6 Efficiency The efficiency of the refrigeration air dryer and the desired pressure dew point temperature depends mainly on the right size of the UDT drier. To ensure efficient operation, the UDT refrigeration air dryers are available in a large number of sizes and operating conditions. It is advisable to provide the following information when ordering or technical assistance: •...

- Page 21 9 Installation 9.1 General requirements for installation The UDT refrigeration air dryer is designed to operate in an environment that ensures the following conditions: • Internal installation, clean and dry space • Non-aggressive atmosphere • The minimum ambient temperature is +1,5 ° C •...

- Page 22 9.2 Installation positioning Below are the two most common configurations of installations in which the UDT refrigeration air dryer is installed. The schemes below are not mandatory and they are just a sample. A different arrangement of components is always possible. 1.

- Page 23 If the dryer is not installed properly, there may be improper operation. Fastening the dryer with screws is not obligatory. UDT 20 - 235 drier models can be attached to • the wall with wall screws - the position of the holes in the illustration is shown.

- Page 24 10 Start-up 10.1 Before start-up Before start-up, check that the operating parameters correspond to the nominal values indicated on the data label of the dryer (frequency, air pressure, air temperature, ambient temperature, ...). This dryer has been fully tested, packaged and checked before shipping. Nevertheless, it may happen that it is damaged during transport.

- Page 25 12 Maintenance During the maintenance work on the refrigeration air dryer, turn it off and wait for at least 30 minutes for it to cool down. Some components can reach high temperature during operation. Avoid contact with these components until they completely cool down. Daily check that the dew point shown on the controller is appropriate.

- Page 26 ● The compressor does not work. ● Ambient temperature is too high, or ventilation is too low - ensure adequate ventilation. ● The inlet air is too hot. Establish normal operating conditions. ● The inlet pressure is too low. Establish normal operating conditions. ●...

- Page 27 14 Spare Parts PART DESCRIPTION NUMBER 1150 1300 1500 1900 2600 1401365 1401437 1401431 1401369 1401439 1401440 Compressor 1401441 1401374 1401375 1401376 1401410 1401421 2101729 2101700 Fan & Condenser pack 2101701 2101732 2101802 2101822 Condenser 2101839 2101855 1101981 Fan motor 2101864 Fan blade 2101865...

- Page 28 15 Warranty The warranty is valid for 12 months from the date of purchase and no more than 14 months from the date of dispatch. During this time, the parts that were originally incomplete will be repaired or replaced free of charge. This does not include travel costs, accommodation and food for our technicians.

- Page 29 16 Maintenance notebooks MAINTENANCE TYPE DATE SIGNATURE NOTES First installation...

- Page 31 17 Drawings of UDT refrigeration air dryers...

- Page 36 18 Electro schemes of UDT refrigeration air dryer UDT 20 - 180...

- Page 37 UDT 235 - 600...

- Page 38 UDT 750- 1900...

Need help?

Do you have a question about the UDT 20 and is the answer not in the manual?

Questions and answers