Table of Contents

Advertisement

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for OMEGA AIR RDL 35

- Page 1 Installation and operating manual Refrigeration Dryer Series RDL 35 - 235 Please read the following instructions carefully before installing the product. Trouble free and safe operating of the product can only be guaranteed if recommendations and conditions stated in this manual are respected.

- Page 2 Dear customer! Thank you for purchasing our product. In order for the product to serve well and reliably, please read these installation and operating instructions carefully. In order to avoid misuse of equipment and potential hazards for the operator, please read thoroughly and strictly follow the instructions contained in this installation and operating manual.

-

Page 3: Table Of Contents

Table of Contents 1 GENERAL INFORMATION ..........................4 1.1. D ............................4 EVICE INFORMATION 1.2. I .......................... 4 NFORMATION ON THE SUPPLIER 1.3 B ................................5 ASIC 1.4. R ..........................5 EFRIGERATION AIR DRYERS 1.5 P ..............................5 ROPER USE 2 SAFETY INSTRUCTIONS .......................... -

Page 4: General Information

1 General information 1.1. Device information Model of refrigeration air dryer: Serial number: Year of manufacture: Date of installation: Please fill in the fields carefully. Correct data enables proper and efficient maintenance of the device, selection of suitable spare parts and technical support. 1.2. -

Page 5: Basic

1.3 Basic Compressed air contains contaminants such as water, oil and particles. Impurities need to be removed or their concentration reduced to an acceptable level according to the requirements of the application. The ISO 8573-1 standard specifies the purity / quality of the air for contaminants. The humidity (water vapor content) can be expressed in terms of Pressure Dew Point (PDP). -

Page 6: Safety Instructions

2 Safety instructions ⚠ Improper use of the compressed air system and electrical installations can lead to injury or death. ⚠ Improper handling (transport, installation, use, maintenance) of a refrigeration air dryer can lead to serious injury or death. The result of improper use may be damage to the device and/or reduced efficiency of the dryer. - Page 7 ⚠ Only use genuine spare parts. ⚠ Only use refrigeration air dryers for intended purpose. ⚠ When transporting the dryer, check and follow the local regulations for lifting and transporting heavy objects. ⚠ In the event of fire, do not use extinguishing water on the dryer and nearby objects. ⚠...

-

Page 8: Technical Specifications

3 Technical Specifications 3.1 Components Figure 2: Components (shown: RDL 235) 1. Heat exchanger 3in1 6. Main power switch 2. Condenser 7. Capillary tube 3. Compressor 8. Temperature sensor 4. Condensate drain 9. Filter / dehydrator 5. Controller... -

Page 9: Specifications

Power supply Power/ Cooling Heat Type Mass W x L x H drop flow rejec. Consumption Ph~V-Hz RDL 35 G 1/2” BSP-F <0,2 1~230-50* 0,17 / 0,13 R134a 0,230 220 x 532 x 665 RDL 75 G 3/4” BSP-F <0,2 1~230-50/230-60... - Page 10 CORRECTION FACTORS To calculate the correct capacity of a given dryer based on actual operating conditions, multiply the nominal inlet flow by the appropriate correction factor(s). CORRECTED CAPACITY = NOMINAL FLOW CAPACITY x C OPERATING PRESSURE DEW POINT [bar] °C [psi] °F 37,4...

-

Page 11: Refrigeration Air Dryer Operation

4 Refrigeration air dryer operation The refrigeration air dryer is designed to remove moisture from the input air to achieve the desired dew point at the exit. All refrigeration air dryers described above operate according to the same principle. The operation of the refrigeration air dryer can be divided into two main circuits: Air and refrigeration circuit. -

Page 12: Refrigeration Air Dryer Components

5 Refrigeration air dryer components 5.1 Compressor The compressor sucks the gaseous phase of the refrigerant from the evaporator (low pressure side) and compresses it to the condensation pressure (high pressure side). Built-in compressors are manufactured by leading manufacturers and are designed for applications where high compression ratios and high temperature differences are present. -

Page 13: Controller Rdc 3

5.4 Controller RDC 3 The controller can be started by holding SET + UP button for 3 seconds. For three phase dryers, it is recommended that the controller remains in OFF state for 2 hours before startup. At startup, the controller shows the time remaining until compressor starts by displaying t0 and remaining seconds. -

Page 14: Electric Scheme Rdc 3

5.4.1 Electric scheme RDC 3 The controller has 3 outputs (230 V), for compressor, fan and drain. The other outputs are for alarm. The alarm is triggered via opto triac, which can handle 600VAC/50mA. Controller can also be turned OFF/ON via In. Remote by changing the parameter 13 (Remote control) from 0 to 1. -

Page 15: Rdc 3 Parameters

5.4.2 RDC 3 parameters Press SET Press UP Press DOWN Default Range Increment DISPLAY SHOWS Press UP&DOWN parameter first Pn and then more than 3 secs number the Parameter value Drain Period Value Go to following SAVING Increase Decrease value 0-1000 secs 100 secs parameter... - Page 16 In the following paragraph, a procedure to change the minimal compressor OFF time is shown. To change the minimal compressor OFF time, you must choose programming parameter no. 4 and change the value from default to the desired value. To do that you must: •...

-

Page 17: Rdc 3 Modbus Communication

5.4.3 RDC 3 MODBUS communication ADDRESS NAME TYPE VARIABLE X UNIT 40013 ADDRESS RDWR Address = X 40014 Service Time R_ONLY Service Time = X 40015 No. of alarms in last 24h R_ONLY Alarm 24 H Number= X 40016 No. of alarms since service R_ONLY Total Alarms = X 40017... -

Page 18: Automatic Mechanical Condensate Drain

5.6. Automatic mechanical condensate drain Automatic mechanical condensate drain AOK 13PA has been developed for fully automatic discharging of condensate or any other non-aggressive fluid from compressed air system. The unit can be installed as external drain on any application specified below. Condensate accumulates in reservoir and when the level is high enough condensate is being discharged from the system without any air losses. -

Page 19: Capillary Tube

5.9 Capillary tube The capillary tube is located between the condenser and the evaporator and functions as a metering device for reducing the pressure of the refrigerant. The pressure reduction is a design-based function. The length and inner diameter of the capillary tube are precisely dimensioned, ensuring good performance in all designed conditions. -

Page 20: Storing

8 Storing In order to prevent damage to the refrigeration air dryer during storage, the following conditions must be provided: • The dryer should only be stored in a dry and enclosed space. • During storage, the ambient temperature must be within the temperature range of 1 ° C to 45 °... -

Page 21: Installation Positioning

9.2 Installation positioning Below are the two most common configurations of installations in which the RDL refrigeration air dryer is installed. The schemes below are not mandatory and they are just a sample. A different arrangement of components is always possible. 1. -

Page 22: Installation Procedure

9.3. Installation procedure • The RDL refrigeration air dryer is typically delivered on the standard pallet on which it is screwed with four screws. • The RDL refrigeration air dryer can be lifted with forklift trucks. • Remove the screws and the pallet before positioning the dryer at the desired location. •... -

Page 23: Start-Up

10 Start-up 10.1 Before start-up Before start-up, check that the operating parameters correspond to the nominal values indicated on the data label of the dryer (frequency, air pressure, air temperature, ambient temperature, ...). This dryer has been fully tested, packaged and checked before shipping. Nevertheless, it may happen that it is damaged during transport. -

Page 24: Maintenance

12 Maintenance During the maintenance work on the refrigeration air dryer, turn it off and wait for at least 30 minutes for it to cool down. Some components can reach high temperature during operation. Avoid contact with these components until they completely cool down. Daily check that the dew point shown on the controller is appropriate. - Page 25 ● The dryer does not start. ● Dew point sensor incorrectly detects temperature - check if the sensor is fully inserted into the sleeve. ● The compressor does not work. ● Ambient temperature is too high, or ventilation is too low - ensure adequate ventilation.

-

Page 26: Spare Parts

FAN - DIFFUSER 2108663 FAN - BLADE 2108665 HOUSING RDL 35 - 100 - COVER 3514100 HOUSING RDL 35 - 100 - SUPPORT BODY 3514099 HOUSING RDL 35 - 100 - BASE 3513865 HOUSING RDL 180 - 235 COVER 3514102... -

Page 27: Warranty

15 Warranty The warranty is valid for 12 months from the date of purchase and no more than 14 months from the date of dispatch. During this time, the parts that were originally incomplete will be repaired or replaced free of charge. This does not include travel costs, accommodation and food for our technicians. -

Page 28: Maintenance Notebooks

16 Maintenance notebooks MAINTENANCE TYPE DATE SIGNATURE NOTES First installation... - Page 29 MAINTENANCE TYPE DATE SIGNATURE NOTES...

-

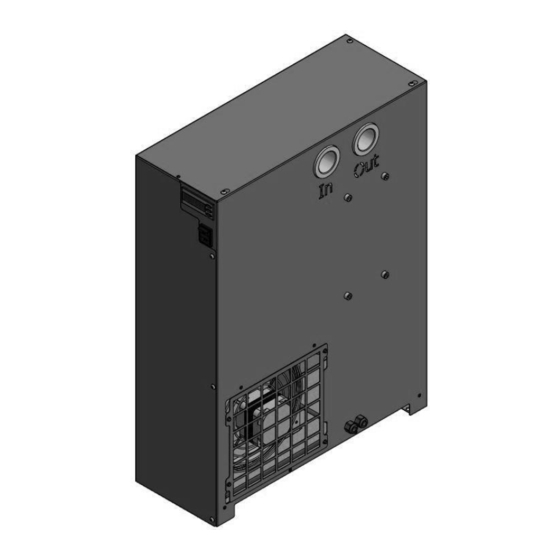

Page 30: Drawings Of Rdl Refrigeration Air Dryers

17 Drawings of RDL refrigeration air dryers... -

Page 32: Electro Schemes Of Rdl Refrigeration Air Dryer

18 Electro schemes of RDL refrigeration air dryer RDL 35 - 235... - Page 33 1000 Ljubljana Slovenia Declares that Product: RDL Model: RDL 35, RDL 75, RDL 100, RDL 180, RDL 235 Description: Compressed air refrigeration dryer Is in conformity with the following directives Pressure Equipment Directive (PED) 2014/68/EU Electromagnetic Compatibility Directive (EMC) 2004/108/EC...

- Page 34 OMEGA AIR d.o.o. Ljubljana Cesta Dolomitskega odreda 10 SI-1000 Ljubljana, Slovenia T: +386 (0)1 200 68 00 info@omega-air.si www.omega-air.si...

Need help?

Do you have a question about the RDL 35 and is the answer not in the manual?

Questions and answers