Table of Contents

Advertisement

Quick Links

Installation and operating

manual

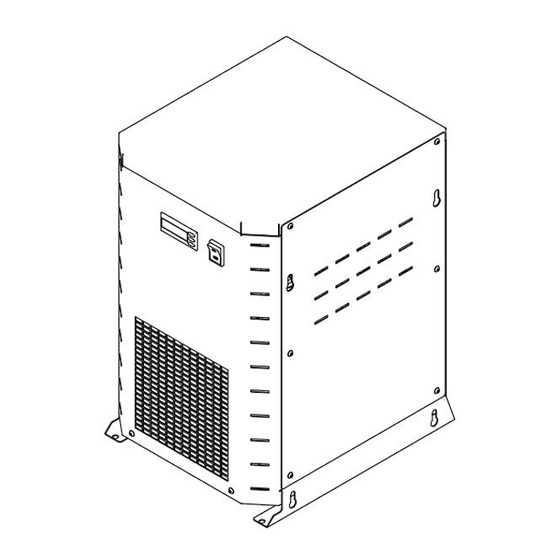

Refrigeration Dryer Series RDP 3400 - 7200

Please read the instructions carefully before installation or use. The proper and safe operation of

the refrigeration air dryer is ensured only by following the recommendations and conditions

stated in the instructions.

For additional questions, contact the manufacturer and inform him of the information on the data

plate found on the front of the dryer.

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for OMEGA AIR RDP 3400

- Page 1 Installation and operating manual Refrigeration Dryer Series RDP 3400 - 7200 Please read the instructions carefully before installation or use. The proper and safe operation of the refrigeration air dryer is ensured only by following the recommendations and conditions stated in the instructions.

- Page 2 Dear customer! Thank you for purchasing our product. In order for the product to serve well and reliably, please read these installation and operating instructions carefully. In order to avoid misuse of equipment and potential hazards for the operator, please read thoroughly and strictly follow the instructions contained in this installation and operating manual.

-

Page 3: Table Of Contents

Table of Contents 1 GENERAL INFORMATION ..........................4 1.1. D ............................4 EVICE INFORMATION 1.2. I .......................... 4 NFORMATION ON THE SUPPLIER 1.3 B ................................5 ASIC 1.4. R ..........................5 EFRIGERATION AIR DRYERS 1.5 P ..............................5 ROPER USE 2 SAFETY INSTRUCTIONS .......................... -

Page 4: General Information

1 General information 1.1. Device information Model of refrigeration air dryer: Serial number: Year of manufacture: Date of installation: Please fill in the fields carefully. Correct data enables proper and efficient maintenance of the device, selection of suitable spare parts and technical support. 1.2. -

Page 5: Basic

1.3 Basic Compressed air contains contaminants such as water, oil and particles. Impurities need to be removed or their concentration reduced to an acceptable level according to the requirements of the application. The ISO 8573-1 standard specifies the purity / quality of the air for contaminants. The humidity (water vapor content) can be expressed in terms of Pressure Dew Point (PDP). -

Page 6: Safety Instructions

2 Safety instructions Improper use of the compressed air system and electrical installations can lead to injury or death. ⚠ Improper handling (transport, installation, use, maintenance) of a refrigeration air dryer can lead ⚠ to serious injury or death. The result of improper use may be damage to the device and/or reduced efficiency of the dryer. - Page 7 Only use genuine spare parts. ⚠ Only use refrigeration air dryers for intended purpose. ⚠ When transporting the dryer, check and follow the local regulations for lifting and transporting ⚠ heavy objects. In the event of fire, do not use extinguishing water on the dryer and nearby objects. ⚠...

-

Page 8: Technical Specifications

3 Technical Specifications 3.1 Components Figure 2: Components (shown: RDP 7200) 21. Heat exchanger 3in1 16. Condenser 23. Compressor 17. Electronic condensate drain 18, 19, 20. Electric cabinet with HMI 12. Ambient air filter 29. Liquid separator... -

Page 9: Specifications

Heat Flow Connection Power supply Power/ Type Mass W x L x H drop flow rejec. Consumption Ph~V-Hz RDP 3400 3400 DN100 3~400-50* 12,0 / 4,9 4000 R134a 14,0 1044 x 1477 x 1797 RDP 4400 4400 DN125 3~400-50* 16,0 / 6,6... - Page 10 CORRECTION FACTORS To calculate the correct capacity of a given dryer based on actual operating conditions, multiply the nominal inlet flow by the appropriate correction factor(s). CORRECTED CAPACITY = NOMINAL FLOW CAPACITY x C OPERATING PRESSURE DEW POINT [bar] °C [psi] °F 37,4...

-

Page 11: Refrigeration Air Dryer Operation

4 Refrigeration air dryer operation The refrigeration air dryer is designed to remove moisture from the input air to achieve the desired dew point at the exit. All refrigeration air dryers described above operate according to the same principle. The operation of the refrigeration air dryer can be divided into two main circuits: Air and refrigeration circuit. -

Page 12: Refrigeration Air Dryer Components

5 Refrigeration air dryer components 5.1 Compressor The compressor sucks the gaseous phase of the refrigerant from the evaporator (low pressure side) and compresses it to the condensation pressure (high pressure side). Built-in compressors are manufactured by leading manufacturers and are designed for applications where high compression ratios and high temperature differences are present. -

Page 13: Hmi

5.4 HMI After the dryer is turned on, the heaters on the compressors start to heat the refrigerant. The counter is also initialized and hours counted are displayed. It is recommended that the heater runs for 12 hours before the dryer operates. Once the 12 hours pass, the dryer can be started by pressing the F1 button. When the F1 button is pressed, the heaters turn off and the starting sequence is initialized. -

Page 14: Expansion Valves

b) Operation of fan and compressor 1) Normal operation: • Compressor 1 is always running • Compressor 2 is regulated by condensation and evaporation pressure • Fan is regulated by condensation and evaporation pressure Dew point temperature in green color is displayed. •... -

Page 15: Electronic Condensate Drain

5.6. Electronic condensate drain The separator consists of a condensate reservoir in which the capacitive sensor continuously checks the level of the liquid. As soon as the tank is filled, the sensor sends the electronic board a signal and the membrane solenoid valve opens and releases the condensate from the system. For a complete drainage of the condensate, the valve opening time must be set precisely for each individual condensate outlet. -

Page 16: Safety Functions

.......................... ● The electromagnetic valve diaphragm is dirty - open the drain and clean it. The spout blows out air. ● The capacitive sensor is dirty - open the condensate separator and clean the plastic tube of the sensor. ●... -

Page 17: Efficiency

6 Efficiency The efficiency of the refrigeration air dryer and the desired pressure dew point temperature depends mainly on the right size of the RDP drier. To ensure efficient operation, the RDP refrigeration air dryers are available in a large number of sizes and operating conditions. It is advisable to provide the following information when ordering or technical assistance: •... -

Page 18: Installation

9 Installation 9.1 General requirements for installation The RDP refrigeration air dryer is designed to operate in an environment that ensures the following conditions: • Internal installation, clean and dry space Non-aggressive atmosphere • The minimum ambient temperature is +1,5 ° C •... -

Page 19: Installation Procedure

(7.7) 1. Compressor 6. Refrigeration air dryer 2. Air conveyor 7. Pressure vessel 3. Condensate Separator 8. Filter 4. Pre-filter (min. 5 micron) 9. Condensate drain 5. Bypass air valve Type A installation is recommended when the compressor operates at a reduced interruption rate and total consumption that equals the flow of the compressor. -

Page 20: Start-Up

The dryer must stand firmly on a horizontal basis. The tilt of the unit must not exceed ± 3 °. • The best way to achieve these conditions is to fasten the dryer with screws onto a horizontal base through the appropriate openings on the base. If the dryer is not installed properly, there may be improper operation. -

Page 21: Start-Up

Ensure that the connection to the compressed air system is correct! • • Ensure that the condensate piping is properly secured and connected to the collection system or collector • Ensure that the bypass air circuit is closed and that the dryer is insulated from the system •... -

Page 22: Troubleshooting Technical Problems

aluminium ribs of the condenser. Check the condensate drainage function. Finally check the operation of the device. Annually or every 1000 hours check for potential coolant leakage points. Measure and record the power consumption. Ensure that the measured values are within the limit values recorded in these instructions. -

Page 23: Warranty

● Leakage has occurred in the cooling circuit - contact a specialist in the field of refrigeration. ● Fan always on - PV pressure switch is defective - replace it. The dewpoint is too ● Ambient temperature is too low - establish nominal operating conditions. ●... -

Page 24: Maintenance Notebooks

1. The instructions were not followed for installation and maintenance 2. The unit was not used according to the instructions. 3. The unit operated even though the improper operation was apparent. 4. Non-original parts were used. 5. The unit did not work within the allowed technical parameters. 6. -

Page 27: Drawings Of Rdp Refrigeration Air Dryers

15 Drawings of RDP refrigeration air dryers... -

Page 29: Electro Schemes Of Rdp Refrigeration Air Dryer

16 Electro schemes of RDP refrigeration air dryer RDP 3400/4400/5400... - Page 35 EC Declaration of Conformity Omega Air d.o.o. Ljubljana Cesta Dolomitskega odreda 10 1000 Ljubljana Slovenia Declares that Product: RDP Model: RDP 20, RDP 35, RDP 50, RDP 75, RDP 100, RDP 140, RDP 180, RDP 235, RDP 300, RDP 380, RDP 480, RDP 600, RDP 750, RDP 950, RDP 1150, RDP 1300, RDP 1500, RDP 1900...

- Page 36 OMEGA AIR d.o.o. Ljubljana Cesta Dolomitskega odreda 10 SI-1000 Ljubljana, Slovenia T: +386 (0)1 200 68 00 info@omega-air.si www.omega-air.si...

Need help?

Do you have a question about the RDP 3400 and is the answer not in the manual?

Questions and answers