Summary of Contents for Power-flo PF2025CU7 Series

- Page 1 INSTALLATION, SERVICE & PARTS MANUAL Series: PF2025CU7 PF2025CU9 PF3040CU9 PF4050CU9 Frame Mounted End Suction Pumps ISP No: end suction - 1/2021...

-

Page 2: General Safety Information

® Power-Flo is a registered trademark of Power-Flo Technologies Inc. Other brand and product names are trademarks or registered trademarks of their respective holders. Alteration Rights Reserved. 1/2008, 6/08, 3/09, 8/09, 3/2010, 12/10, 3/12, 1/13, 6/13, 9/2020, 1/2021... -

Page 3: Liquid Temperature

PF2025CU7 End Suction Pumps 2-1/2” 125 lb ANSI Flange Suction, SUCTION/ 2” 125 lb ANSI Flange Discharge. DISCHARGE locations depending on piping requirements. LIQUID 225°F Continuous TEMPERATURE Cast Iron ASTM A48 CASING Back Pull-Out design, with removing Suction & Discharge Piping. CASE WEAR RING Bronze C95200 CASE WORKING... - Page 4 PF2025CU7 End Suction Pumps Dimensions WARNING ! - DO NOT...

- Page 5 PF2025CU7 - 1750RPM End Suction Pumps Performance...

- Page 6 PF2025CU7 - 3500 RPM End Suction Pumps Performance...

- Page 7 PF2025CU9 End Suction Pumps 2-1/2” 125 lb ANSI Flange Suction, SUCTION/ 2” 125 lb ANSI Flange Discharge. DISCHARGE locations depending on piping requirements. LIQUID 225°F Continuous TEMPERATURE Cast Iron ASTM A48 CASING Back Pull-Out design, with removing Suction & Discharge Piping. CASE WEAR RING Bronze C95200 STUFFING BOX...

- Page 8 PF2025CU9 End Suction Pumps Dimensions WARNING ! - DO NOT...

- Page 9 PF2025CU9 - 1750RPM End Suction Pumps Performance...

- Page 10 PF2025CU9 - 3500 RPM End Suction Pumps Performance...

- Page 11 PF3040CU9 End Suction Pumps 4” 125 lb ANSI Flange Suction, SUCTION/ 3” 125 lb ANSI Flange Discharge. DISCHARGE locations depending on piping requirements. LIQUID 225°F Continuous TEMPERATURE Cast Iron ASTM A48 CASING Back Pull-Out design, with removing Suction & Discharge Piping. CASE WEAR RING Bronze C95200 CASE WORKING...

- Page 12 PF3040CU9 End Suction Pumps Dimensions WARNING ! - DO NOT...

- Page 13 PF3040CU9 - 1750RPM End Suction Pumps Performance...

- Page 14 PF3040CU9 - 3500 RPM End Suction Pumps Performance...

- Page 15 PF4050CU9 End Suction Pumps 5” 125 lb ANSI Flange Suction, SUCTION/ 4” 125 lb ANSI Flange Discharge. DISCHARGE locations depending on piping requirements. LIQUID 225°F Continuous TEMPERATURE Cast Iron ASTM A48 CASING Back Pull-Out design, with removing Suction & Discharge Piping. CASE WEAR RING Bronze C95200 CASE WORKING...

- Page 16 PF4050CU9 End Suction Pumps Dimensions WARNING ! - DO NOT...

- Page 17 PF4050CU9 - 1750RPM End Suction Pumps Performance...

- Page 18 PF4050CU9 - 3500 RPM End Suction Pumps Performance...

-

Page 19: Receiving And Installation

PF2025, PF3040, PF4050 End Suction Pumps Receiving & Installation Receiving Inspection Installation A gap of 3/4” to 1½” should be allowed between the base plate and foundation FOUNDATION - The pump foundation Upon receiving the pump, it should be for grouting. Adjust the metal supports or inspected for damage or shortages. -

Page 20: Installation

PF2025, PF3040, PF4050 End Suction Pumps Installation GROUTING The unit will be in angular alignment Grouting compensates for unevenness in when the coupling faces are exactly the the foundation and prevents vibration and same distance apart at all points. (See shifting after mounting is complete. - Page 21 PF2025, PF3040, PF4050 End Suction Pumps Installation & Pre-Operation Pre-Operation SUCTION PIPING STARTING THE PUMP A horizontal suction line must have a On initial start up, the gate valve in the PRIMING gradual rise to the pump. Any high point discharge piping should be closed and CAUTION: Before starting the pump, the in the suction pipe can become lled with...

-

Page 22: Troubleshooting

PF2025, PF3040, PF4050 End Suction Pumps Trouble Shooting Locating Trouble 5. Pump Takes Too Much Power a. Speed too high - Compare Pump 1. No Liquid Delivered and motor nameplates a. Pump not primed - See Priming b. Head lower than rating - pumps too b. -

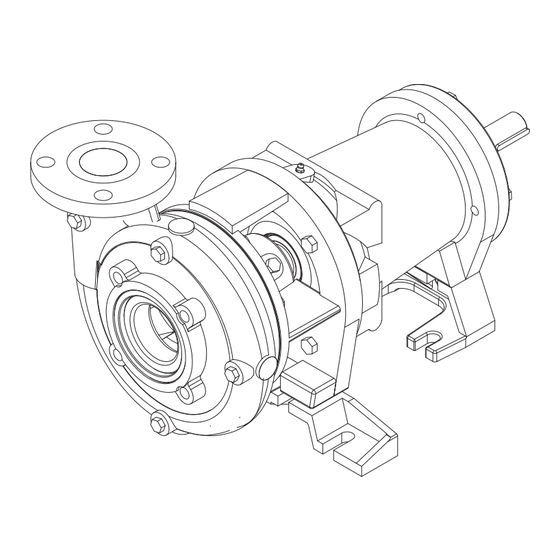

Page 23: Repair Parts

PF2025, PF3040, PF4050 End Suction Pumps For Repair Part Please supply: Model Number and MFG Date as shown on Repair Parts Name Plate, and Part Description and Part Number as shown on Parts List. Figure 3... -

Page 24: Parts List

PF2025, PF3040, PF4050 End Suction Pumps For Repair Part Please supply: Model Number and MFG Date as shown on Parts List Name Plate, and Part Description and Part Number as shown on Parts List. Ref. Name Part Numbers PF2025CU7 PF2025CU9 PF3040CU9 PF4050CU9 Frame 2... - Page 25 PF2025, PF3040, PF4050 End Suction Pumps Notes:...

- Page 26 PF2025, PF3040, PF4050 End Suction Pumps Notes:...

- Page 27 PF2025, PF3040, PF4050 End Suction Pumps Notes:...

-

Page 28: Limited Warranty

PF2025, PF3040, PF4050 End Suction Pumps LIMITED WARRANTY Manufacturer warrants, to the immediate purchaser and subsequent initial owner during the warranty period, every new pump to be free from defects in material and workmanship under normal use and service, when properly used and maintained, for a period of eighteen (18) months from date of manufacture or twelve (12) dated sales receipt noting the model and serial number of the pump.

Need help?

Do you have a question about the PF2025CU7 Series and is the answer not in the manual?

Questions and answers