Table of Contents

Advertisement

Quick Links

Operator's Manual

Dual Maverick

Register your machine:

www.lincolnelectric.com/register

Authorized Service and Distributor Locator:

www.lincolnelectric.com/locator

Save for future reference

Date Purchased

Code: (ex: 10859)

Serial: (ex: U1060512345)

IM10594

| Issue D ate Sep - 24

© Lincoln Global, Inc. All Rights Reserved.

450 INT - 50/60 HZ

®

For use with machines having Code Numbers:

13059

Need Help? Call 1.888.935.3877

to talk to a Service Representative

Hours of Operation:

8:00 AM to 6:00 PM (ET) Mon. thru Fri.

After hours?

Use "Ask the Experts" at lincolnelectric.com

A Lincoln Service Representative will contact you

no later than the following business day.

For Service outside the USA:

Email: globalservice@lincolnelectric.com

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Lincoln Electric Dual Maverick 450 INT

- Page 1 Operator’s Manual Dual Maverick 450 INT - 50/60 HZ ® For use with machines having Code Numbers: 13059 Need Help? Call 1.888.935.3877 Register your machine: to talk to a Service Representative www.lincolnelectric.com/register Authorized Service and Distributor Locator: Hours of Operation: www.lincolnelectric.com/locator 8:00 AM to 6:00 PM (ET) Mon.

-

Page 2: Safety Depends On You

THANK YOU FOR SELECTING A QUALITY PRODUCT BY KEEP YOUR HEAD OUT OF THE FUMES. LINCOLN ELEC TRIC. DON’T get too close to the arc. Use corrective lenses if necessary to stay a reasonable distance away from the arc. READ and obey the Safety Data PLEASE EXAMINE CARTON AND EQUIPMENT FOR Sheet (SDS) and the warning label DAMAGE IMMEDIATELY... -

Page 3: Section A: Warnings

P.O. Box 351040, Miami, Florida 33135 or CSA Standard causes localized Electric and Magnetic Fields (EMF). W117.2. A Free copy of “Arc Welding Safety” booklet E205 is available from the Lincoln Electric Company, 22801 and welding machines St. Clair Avenue, Cleveland, Ohio 44117-1199. - Page 4 SAFETY ELECTRIC SHOCK ARC RAYS CAN BURN. CAN KILL. 3.a. The electrode and work (or ground) circuits are 4.a. Use a shield with the proper lter and cover plates to protect your electrically “hot” when the welder is on. Do eyes from sparks and the rays of the arc when welding or not touch these “hot”...

- Page 5 SAFETY WELDING AND CUTTING CYLINDER MAY EXPLODE IF SPARKS CAN CAUSE DAMAGED. FIRE OR EXPLOSION. 7.a. Use only compressed gas cylinders containing the correct shielding gas for the process used 6.a. Remove re hazards from the welding area. If and properly operating regulators designed for this is not possible, cover them to prevent the welding sparks the gas and pressure used.

- Page 6 2004/108/EC. It was manufactured in conformity with a national standard that implements a harmonized standard: EN 60974-10 Electromagnetic Compatibility (EMC) Product Standard for Arc Welding Equipment. It is for use with other Lincoln Electric equipment. It is designed for industrial and professional use. Introduction All electrical equipment generates small amounts of electromagnetic emission.

- Page 7 SAFETY Electromagnetic Compatibility (EMC) The size of the surrounding area to be considered will depend on the structure of the building and other activities that are taking place. The surrounding area may extend beyond the boundaries of the premises. Methods of Reducing Emissions Mains Supply Welding equipment should be connected to the mains supply according to the manufacturer’s recommenda- tions.

-

Page 8: Table Of Contents

TABLE OF CONTENTS INSTALLATION ...........................SECTION A TECHNICAL SPECIFICATIONS ........................A-1 VRD (VOLTAGE REDUCTION DEVICE) .......................A-2 LOCATION AND VENTILATION ........................A-3 STORING ............................A-3 STACKING ............................A-3 ANGLE OF OPERATION ..........................A-3 LIFTING ............................A-3 HIGH ALTITUDE OPERATION ........................A-4 HIGH TEMPERATURE OPERATION ......................A-4 TOWING ............................A-4 VEHICLE MOUNTING ..........................A-4 PRE-OPERATION ENGINE SERVICE......................A-4 ............................A-4 FUEL - USE DIESEL FUEL ONLY .......................A-5... - Page 9 TROUBLESHOOTING ........................SECTION E DIAGRAMS ..........................SECTION G PARTS LIST....................PARTS.LINCOLNELECTRIC.COM CONTENT/DETAILS MAY BE CHANGED OR UPDATED WITHOUT NOTICE. FOR MOST CURRENT INSTRUCTION MANUALS, GO TO PARTS.LINCOLNELECTRIC.COM.

-

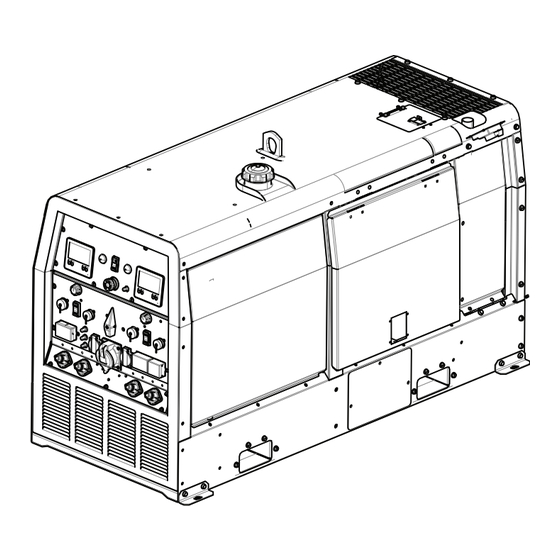

Page 10: Installation

DUAL MAVERICK 450 INT - 50/60 HZ INSTALLATION ® INSTALLATION TECHNICAL SPECIFICATIONS - DUAL MAVERICK 450 (K4381-1) CODE 12723 ® INPUT - DIESEL ENGINE Make/Model Description Speed (RPM) Displacement Starting Dry Capacities cu. in. (ltrs.) System 3 cylinder High Idle 3450 69 (1.1) 12VDC Battery &... -

Page 11: Safety Precautions

DUAL MAVERICK 450 INT - 50/60 HZ INSTALLATION ® SAFETY PRECAUTIONS The machine is shipped with the VRD switch in the “OFF” position. To turn it "ON" or "OFF": Only qualified personnel should install, use, or service this equipment. 1. Switch the High Idle/Run - Stop switch to the Stop position. 2. -

Page 12: Location And Ventilation

DUAL MAVERICK 450 INT - 50/60 HZ INSTALLATION ® LOCATION AND VENTILATION STORING 1. Store the machine in a cool, dry place when it is not in use. The welder should be located to provide an unrestricted ow of Protect it from dust and dirt. Keep it where it can’t be clean, cool air to the cooling air inlets and to avoid restricting the cooling air outlets. -

Page 13: High Altitude Operation

DUAL MAVERICK 450 INT - 50/60 HZ INSTALLATION ® HIGH ALTITUDE OPERATION VEHICLE MOUNTING The naturally aspirated engine will run correctly up to an attitude WARNING of 600 m (2000 ft.) If the engine is to operate at an attitude above this, an increase in smoke may be seen. -

Page 14: Fuel - Use Diesel Fuel Only

DUAL MAVERICK 450 INT - 50/60 HZ INSTALLATION ® FUEL - USE DIESEL FUEL ONLY IMPORTANT: To prevent ELECTRICAL DAMAGE WHEN: Fill the fuel tank with clean, fresh diesel fuel. The a) Installing new battery. capacity of the fuel tank is approximately 20 gallons b) Using a booster. -

Page 15: Case Front Controls

DUAL MAVERICK 450 INT - 50/60 HZ INSTALLATION ® DOWNHILL PIPE and CC-STICK modes if a remote control is CASE FRONT CONTROLS connected to the 6-Pin or 14 Pin Connectors, the output is 1. LCD SCREEN, IP67 RATED OPERATOR A - The LCD screen controlled by the remote and the output control on the displays information about welding mode, output voltage or machine is used to set the maximum current range for the... - Page 16 DUAL MAVERICK 450 INT - 50/60 HZ INSTALLATION ® 7. 20 AMP CIRCUIT BREAKER - Auxiliary output breaker protects the 380V, three phase receptacle. 8. POSITIVE AND NEGATIVE WELD TERMINAL OPERATOR B 9. 380V THREE PHASE AC EURO PLUG - European (IEC-309) receptacle rated up to 32 amps and is IP44 rated.

-

Page 17: Welding Terminals

DUAL MAVERICK 450 INT - 50/60 HZ INSTALLATION ® WELDING TERMINALS WELDING OUTPUT CABLES From the main screen select MIG / FCAW / TIG welding. Press With the engine off, connect the electrode and work cables to the knob to select screen that shows Weld Output Override. (Figure terminals provided. -

Page 18: Remote Control

DUAL MAVERICK 450 INT - 50/60 HZ INSTALLATION ® CABLE INDUCTANCE AND ITS EFFECTS ON REMOTE CONTROL WELDING The Dual Maverick ® 450 is equipped with a 6-pin and a 14-pin Excessive cable inductance will cause the welding performance to connector. -

Page 19: Connection Of Wire Feeders With Control Cable (14 Pin

DUAL MAVERICK 450 INT - 50/60 HZ INSTALLATION ® CONNECTION OF WIRE FEEDERS WITH CONTROL CABLE (14 PIN) WARNING Shut off welder before making any electrical connections. CONNECTION OF LF-72, LF-74, FLEX FEED 74 HT, FLEX FEED 84, LN-25 PRO DUAL POWER TO THE DUAL MAVERICK ®... -

Page 20: Connection Of Across The Arc Wire Feeders To The Dual Maverick ® 450

DUAL MAVERICK 450 INT - 50/60 HZ INSTALLATION ® CONNECTION OF ACROSS THE ARC WIRE FEEDERS TO THE DUAL MAVERICK ® These connections instructions apply to both the LN-25 Pro and Activ8 models. The feeders have an internal contactor and the electrode is not energized until the gun trigger is closed. - Page 21 DO NOT USE THESE DEVICES WITH THIS PRODUCT. The Lincoln Electric Company is not responsible for any damage to electrical components improperly connected to this product. A-12...

-

Page 22: Operation

DUAL MAVERICK 450 INT - 50/60 HZ OPERATION ® OPERATION FOR AUXILIARY POWER: SAFETY PRECAUTIONS Start the engine and set the IDLER control switch to the desired Read and understand this entire section before operating mode. Full power is available regardless of the welding operating your Dual Maverick 450. -

Page 23: Break-In Period

The Dual Maverick 450 is not recommended for pipe thawing. ® BREAK-IN PERIOD Lincoln Electric selects high quality, heavy-duty industrial engines GENERATOR for the portable welding machines we offer. While it is normal to The Dual Maverick 450 provides smooth 220 VAC single phase ®... -

Page 24: Engine Operation

DUAL MAVERICK 450 INT - 50/60 HZ OPERATION ® ENGINE OPERATION TYPICAL FUEL CONSUMPTION STARTING THE ENGINE Refer to Table B.2 for typical fuel consumption of the Dual Maverick 450 Engine for various operating settings. ® 1. Open the engine service compartment door and check that TABLE B.2 the fuel shutoff valve on the fuel lter separator located on TYPICAL DUAL MAVERICK 450 FUEL CONSUMPTION... -

Page 25: Welder Operation

DUAL MAVERICK 450 INT - 50/60 HZ OPERATION ® WELDER OPERATION DOWNHILL PIPE Welding DUTY CYCLE This slope controlled mode is intended for "out-of-position" and "down hill" pipe welding where the operator would like to control Duty Cycle is the percentage of time the load is being applied in a the current level by changing the arc length. - Page 26 DUAL MAVERICK 450 INT - 50/60 HZ OPERATION ® with an Amptrol or Arc Start Switch: • Set the MODE to the TOUCH START TIG setting. TIG Welding • Set the "IDLER" Switch to the "AUTO/IDLE/RUN" position. The TOUCH START TIG is for DC TIG (Tungsten Inert Gas) welding. •...

-

Page 27: Wire Welding-Cv

DUAL MAVERICK 450 INT - 50/60 HZ OPERATION ® TABLE B.3 TYPICAL CURRENT RANGES FOR TUNGSTEN ELECTRODES ) - ( 1%, 2% Thoriated 1%, 2% Thoriated Aluminum Stainless Steel Tungsten Tungsten .010 (.25) 2-15 (2-4) (2-4) #4, #5, #6 0.020 (.50) 5-20 5-10... -

Page 28: Auxiliary Power Operation

DUAL MAVERICK 450 INT - 50/60 HZ OPERATION ® SIMULTANEOUS WELDING AND AUXILIARY AUXILIARY POWER OPERATION POWER LOADS Start the engine and set the IDLER control switch to the desired operating mode. Full power is available regardless of the welding It must be noted that the speci ed auxiliary power ratings are with control settings, if no welding current is being drawn. -

Page 29: Display Operation

DUAL MAVERICK 450 INT - 50/60 HZ OPERATION ® FIGURE B.2 DISPLAY OPERATION: SEE FIG B.2 1. HOME - Brings up the home screen (main menu) 2. REMOTE CONTROL - Toggles the remote control ON / OFF MAVERICK 3. HELP - Displays additional information describing the function 4. -

Page 30: Stick Welding

DUAL MAVERICK 450 INT - 50/60 HZ OPERATION ® STICK WELDING Stick Manual entry operates like a traditional welding machine. Simply Welding set the desired preset amperage or voltage and begin to weld. The “Preset” screen appears when welding is not active. It shows the amount of fuel on the left hand side;... - Page 31 DUAL MAVERICK 450 INT - 50/60 HZ OPERATION ® Stick Options All weld modes support using a remote control like K857-1. Plug the remote into the 6 pin connector on the front of the machine. Remote Press the remote button on the display to toggle between control at the Control Force Range...

- Page 32 DUAL MAVERICK 450 INT - 50/60 HZ OPERATION ® MIG/FCAW WELDING Manual entry operates like a traditional welding machine. Simply MIG/FCAW-GS Welding set the desired preset amperage or voltage and begin to weld. The “Preset” screen appears when welding is not active. It shows the amount of fuel on the left hand side;...

- Page 33 DUAL MAVERICK 450 INT - 50/60 HZ OPERATION ® Wire Diameter Wire Diameter 0.025” / 0.6mm Wire Feed Select Maximum WFS 0.030” / 0.8mm Speed Expected 0.035” / 0.9mm Wire 0.040” / 1.0mm Diameter Press knob 0.045” / 1.2mm for weld page 0.052”...

- Page 34 DUAL MAVERICK 450 INT - 50/60 HZ OPERATION ® SET-UP The set-up allows for customization of the Maverick. Options Set-up available in the Set-up menu are: • AUTO-START: NO LOAD PERIOD • TAP START ACTIVE PERIOD • AUTO-START: ON/OFF Press knob to select •...

- Page 35 DUAL MAVERICK 450 INT - 50/60 HZ OPERATION ® Auto-Start: No Load Period Display Brightness Display Brightness Auto-Start: No Load Period Brightness: 100 Period (10-120 min): 120 Press knob to select Press knob to select Autostart time Restore Factory Settings Tap Start Active Period Tap Start Active Period Factory Reset...

- Page 36 DUAL MAVERICK 450 INT - 50/60 HZ OPERATION ® DO NOT FORGET THE PIN! The PIN may only be reset by a Lincoln Authorized Service Shop. Rotate the knob to adjust the value of the PIN. Press the knob to advance to the next number.

- Page 37 DUAL MAVERICK 450 INT - 50/60 HZ OPERATION ® Diagnostic Information Variable Speed On/Off Engine Part #: Perkins 403D-11Tap Feature: ON Weld PCB HW: G9022-1 Weld PCB SW: A-17 Machine K#: K4833-1 Code #: 12723 Display #: CR9060 Press knob ECG Fault Press knob to select...

- Page 38 DUAL MAVERICK 450 INT - 50/60 HZ OPERATION ® MACHINE SELECT AUXILIARY POWER FREQUENCY Display Brightness Diagnostic Information New PCB Calibration Variable Speed On/Off Restore Factory SettingsMachine Machine Select Press knob to select Enter the correct K# and Code # for the welder the PCB is being installed on.

-

Page 39: Accessories

DUAL MAVERICK 450 INT - 50/60 HZ ACCESSORIES ® ACCESSORIES OPTIONAL FIELD INSTALLED ACCESSORIES K2636-1 Medium Trailer K2639-1 Fender Kit K2640-1 Cable Rack K2641-2 Four Wheel Trailer K857 Remote Control K857-1 Remote Control K2613-5A1 Ln-25 PRO with K126 PRO Gun K126-12 K126 PRO Gun KP1696-068 Drive Roll Kit K12038-2 Invertec PC610 Plasma... -

Page 40: Maintenance

DUAL MAVERICK 450 INT - 50/60 HZ MAINTENANCE ® MAINTENANCE TABLE D.1 SAFETY PRECAUTIONS WARNING • Have quali ed personnel do all maintenance and troubleshooting work. • Turn the engine off before working inside the machine or servicing the engine. •... - Page 41 450 INT - 50/60 HZ DUAL MAVERICK ® MAINTENANCE Service Instructions Service Instructions Single- and Two-Stage Engine Air Cleaners Single- and Two-Stage Engine Air Cleaners Inspect the New Filter for Damage Inspect the New Filter for Damage Remove the Filter Remove the Filter Inspect the new filter carefully, paying attention to Unfasten or unlatch the...

-

Page 42: Fuel Filters

DUAL MAVERICK 450 INT - 50/60 HZ MAINTENANCE ® NAMEPLATES / WARNING DECALS MAINTENANCE FUEL FILTERS Whenever routine maintenance is performed on this machine - or at least yearly - inspect all nameplates and labels for legibility. WARNING Replace those which are no longer clear. Refer to the parts list for the replacement item number. -

Page 43: Battery Handling

DUAL MAVERICK 450 INT - 50/60 HZ MAINTENANCE ® BATTERY HANDLING PREVENTING BATTERY DISCHARGE Turn the RUN/STOP switch to stop when engine is not running. WARNING GASES FROM BATTERY can explode. PREVENTING BATTERY BUCKLING Keep sparks, ame and cigarettes away from Tighten nuts on battery clamp until snug. -

Page 44: Troubleshooting

TROUBLESHOOTING How to Use Troubleshooting Guide WARNING Service and Repair should only be performed by Lincoln Electric Factory Trained Personnel. Unauthorized repairs performed on this equipment may result in danger to the technician and machine operator and will invalidate your factory warranty. For your safety and to avoid Electrical Shock, please observe all safety notes and precautions detailed throughout this manual. - Page 45 DUAL MAVERICK 450 INT - 50/60 HZ TROUBLESHOOTING ® Observe all Safety Guidelines detailed throughout this manual PROBLEMS POSSIBLE RECOMMENDED (SYMPTOMS) CAUSE COURSE OF ACTION AUXILIARY OUTPUT No auxiliary power 1. Check that the circuit breakers did not trip. If all recommended possible areas of 2.

- Page 46 DUAL MAVERICK 450 INT - 50/60 HZ TROUBLESHOOTING ® PROBLEMS POSSIBLE RECOMMENDED (SYMPTOMS) CAUSE COURSE OF ACTION WELDING No weld output 1. Verify the weld output is ON. A green icon with “Output ON” appears in the upper right corner of screen whenever weld output is ON.

- Page 47 DUAL MAVERICK 450 INT - 50/60 HZ TROUBLESHOOTING ® ENGINE FAULT FLASH CODES ON ECG FLASH CODE WILL ENGINE NUMBER FAULT SHUTDOWN? CORRECTIVE ACTION Unit not calibrated ECM requires calibration Excessive engine speed Check over-speed parameter setting Check electrical interference Check wiring and connectors Check ECM ground connections Check actuator connections and tment...

-

Page 48: Wiring Diagram

DUAL MAVERICK 450 INT - 50/60 HZ WIRING DIAGRAM ® G9022-1... -

Page 49: Dimension Print

DUAL MAVERICK 450 INT - 50/60 HZ DIMENSION PRINT ®... - Page 50 WARNING Do not touch electrically live parts or Keep flammable materials away. Wear eye, ear and body protection. electrode with skin or wet clothing. Insulate yourself from work and AVISO DE ground. Spanish PRECAuCION No toque las partes o los electrodos Mantenga el material combustible Protéjase los ojos, los oídos y el bajo carga con la piel o ropa moja-...

- Page 51 WARNING Keep your head out of fumes. Turn power off before servicing. Do not operate with panel open or Use ventilation or exhaust to guards off. remove fumes from breathing zone. AVISO DE Spanish PRECAuCION Los humos fuera de la zona de res- Desconectar el cable de ali- No operar con panel abierto o piración.

- Page 52 We respond to our customers based on the best information in our possession at that time. Lincoln Electric is not in a position to warrant or guarantee such advice, and assumes no liability, with respect to such information or advice.

Need help?

Do you have a question about the Dual Maverick 450 INT and is the answer not in the manual?

Questions and answers

How to fix actuator excessive current

How to fix execessive current limit