Table of Contents

Summary of Contents for First Co FRESH-PAK Eco EPE Series

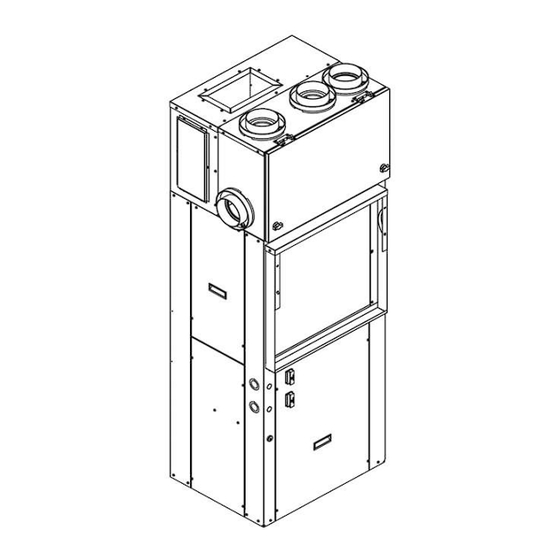

- Page 1 Installation, Operation, & Maintenance IOM 8507 Rev. A 09/23 EPE Low Ambient Heat Pumps Space Constrained Unit w/ Energy Recovery Ventilation ATTENTION Read all instructions thoroughly and retain all manuals for future reference.

- Page 2 FRESH-PAK IOM COPYRIGHT The Manufacturer works to continually improve its products and as a result, it reserves the right to change design and specifications without notice. The warranty may be void unless the Startup & Performance Checklist is completed and returned to the warrantor. If the FRESH-PAK unit is not installed properly the warranty will be void as the manufacturer cannot be held accountable for problems that stem from improper installation.

-

Page 3: Table Of Contents

FRESH-PAK IOM TABLE OF CONTENTS SAFETY CONSIDERATIONS MODEL NOMENCLATURE GENERAL INFORMATION INTRODUCTION STORAGE SHIPPING & PACKAGING LIST UNIT INSPECTION CHECKLIST UNIT DIMENSIONAL DATA UNIT PHYSICAL DATA ELECTRICAL DATA 12-20 INSTALLATION INSTALLATION PRECAUTIONS UNIT LOCATION UNIT CLEARANCE REQUIREMENTS WALL SLEEVE INSTALLATION 14-15 PACKAGED UNIT INSTALLATION 16-17... -

Page 4: Safety Considerations

FRESH-PAK IOM SAFETY CONSIDERATIONS 1. READ THE ENTIRE MANUAL BEFORE STARTING THE INSTALLATION. 2. These instructions are intended as a general guide and do not supersede national, state, or local codes in any way. 3. Altering the product, improper installation, or the use of unauthorized factory parts voids all warranty or implied warranty and may result in adverse operation and/or performance or may result in hazardous conditions to service personnel and occupants. -

Page 5: Model Nomenclature

FRESH-PAK IOM MODEL NOMENCLATURE FIGURE 1 - Model Nomenclature ECO Series EPE – IOM (Rev. A 08/23) -

Page 6: General Information

FRESH-PAK IOM GENERAL INFORMATION INTRODUCTION Clear surrounding area of all tools, equipment, and The Fresh Pak Low Ambient Heat Pumps models are debris before operating this unit. Space Constrained Heat Pumps combined with an integrated Energy Recovery Ventilation (ERV) system. These instructions are given for the installation of the ERV's provide pre-conditioned fresh outdoor air to your Eco Series FRESH-PAK specifically. -

Page 7: Shipping & Packaging List

FRESH-PAK IOM SHIPPING & PACKAGING LIST SHIPPING INSTRUCTIONS FRESH-PAK units must remain in the upright position throughout the shipping and handling process to maintain the proper compressor oil level. PACKAGE LIST The units will be shipped with the following. Quantities listed in Paratheses. 1. -

Page 8: Unit Inspection Checklist

FRESH-PAK IOM UNIT INSPECTION CHECKLIST REMOVE SHIPPING SCREWS (6) Before preparing unit for installation, complete the FRONT SIDE OF UNIT inspection procedures below. 1) Visually inspect unit for any shipping damage. Damage must be reported immediately to the shipping company to make a claim. 2) Ensure that the carrier makes proper notation of any shortages or damage on all copies of the freight bill and completes a common carrier... -

Page 9: Unit Dimensional Data

FRESH-PAK IOM UNIT DIMENSIONAL DATA FIGURE 5 - Dimension ECO Series EPE – IOM (Rev. A 08/23) -

Page 10: Unit Physical Data

FRESH-PAK IOM UNIT PHYSICAL DATA PHYSICAL DATA FRESH-PAK Model EHE182**C EHE242**C EHE302**C Compressor (Quantity) Scroll (1) Factory Charge (R410A) lb. [kg] [2.5] [2.36] [2.67] ID MOTOR Motor (Quantity) Fan Motor Type Motor HP OD MOTOR Motor (Quantity) Fan Motor Type Motor HP ID BLOWER Blowers (Quantity) -

Page 11: Electrical Data

FRESH-PAK IOM ELECTRICAL DATA EPE LOW AMBIENT ELECTRICAL DATA (208/230-1PH-60Hz) BLOWER DATA CONDENSER DATA ELECTRIC HEAT MIN. CIRCUIT AMPACITY MAX. CIRCUIT PROTECTION Evaporator CONDENSER UNIT MODEL COMPRESSOR CKT1 CKT2 CKT1 CKT2 Motor MOTOR VOLT. VOLT. 240V 208V 230V 208V 230V 208V 230V 208V... -

Page 12: Installation

FRESH-PAK IOM INSTALLATION INSTALLATION PRECAUTIONS WARNING CAUTION When soldering and brazing, it is recommended that fire extinguishers be available. When soldering and brazing close Always wear all appropriate personal protection Equipment to valves or sensitive components, heat shields or wet rags when installing and servicing units. -

Page 13: Unit Location

FRESH-PAK IOM INSTALLATION (continued) UNIT LOCATION This FRESH-PAK unit is certified for through-the-wall, indoor, up-flow vertical position installation only. This appliance is not design certified for installation in mobile homes, recreational vehicles, or outdoors. A factory approved wall sleeve must be used to install the FRESH-PAK unit. -

Page 14: Unit Clearance Requirements

FRESH-PAK IOM INSTALLATION (continued) UNIT CLEARANCE REQUIREMENTS WALL SLEEVE INSTALLATION Service clearance must be provided for future Refer to installation instruction packed with the wall maintenance and service. A minimum of 29 in. [73.66 sleeve to assemble and mount into the wall. Before unit cm] open area must be left unobstructed in front of the installation, verify that sleeve components are not access panels. - Page 15 FRESH-PAK IOM INSTALLATION (continued) WALL SLEEVE INSTALLATION CONTINUED REAR INSTALLATION & DIMENSIONS Sleeve rough-in opening is 43-1/2 in. (H) [110.49 cm] x 26-3/4 in. (W) [67.94 cm]. Bottom of opening should be approximately 6 in. [15.24 cm] above the floor. ...

-

Page 16: Packaged Unit Installation

FRESH-PAK IOM INSTALLATION (continued) PACKAGED UNIT INSTALLATION FIGURE 11 - FRESH-PAK Unit Installation IMPORTANT Insulation is installed in indoor equipment to provide a barrier between outside air conditions surrounding the Damaged insulation must be repaired or replaced before the unit and the varying conditions inside the unit. If the unit is placed back into operation. - Page 17 FRESH-PAK IOM 8. Ensure that the wall sleeve is installed squarely and is INSTALLATION (continued) secured before installing the unit. PACKAGED UNIT INSTALLATION 1. Remove the two shipping brackets holding the unit to IMPORTANT the shipping pallet and remove unit from the shipping pallet.

-

Page 18: Ductwork

FRESH-PAK IOM INSTALLATION (continued) DUCTWORK Discharge ductwork is normally used with these units. When return air ductwork is required, the unit is supplied with 2 in. [5.08 cm] thick filter rack/duct collar for connection of return air ductwork. All ductwork must be installed in accordance with National Fire Protection Assoc. - Page 19 FRESH-PAK IOM FIGURE 15-ERV AIRFLOW PATHS ECO Series EPE – IOM (Rev. A 08/23)

-

Page 20: Condensate Drain

FRESH-PAK IOM INSTALLATION (continued) CONDENSATE DRAIN AIR FILTER The FRESH-PAK is designed so that the wall sleeve is the All indoor return air must be filtered. The preferred principle drain pan. Drain tubing is factory installed methods are listed below. which drains evaporator condensate though the bottom 1. -

Page 21: Electrical

FRESH-PAK IOM Thermostat is required with a fan signal (G) in all ELECTRICAL operating Modes (FIGURE 19 - Non-Ventilation HIGH VOLTAGE Thermostat Connections). Thermostat connections and All wiring must comply with local and national code functions are as follows: requirements. Units are provided with wiring diagrams THERMOSTAT CONNECTIONS KEY and nameplate data to provide information required for LETTER... -

Page 22: Controls

FRESH-PAK IOM CONTROLS ECO SEQUENCE OF OPERATIONS – COOL MODE FIGURE 20 - ECO Sequence of Operations - Cool Mode ECO Series EPE– IOM (Rev. A 08/23) -

Page 23: Eco Sequence Of Operations - Heat Mode

FRESH-PAK IOM CONTROLS (continued) ECO SEQUENCE OF OPERATIONS - HEAT MODE FIGURE 21 - ECO Sequence of Operations - Heat Mode ECO Series EPE – IOM (Rev. A 08/23) -

Page 24: Eco Series Control Module

FRESH-PAK IOM CONTROLS (continued) ECO SERIES CONTROL MODULE FIGURE 22 - ECO Series Control Module POWER-UP ANTI-SHORT CYCLE DELAY When power is first applied to the control, the board will The anti-short cycle timer prevents the compressor from enter a 5 minute random start delay before allowing being re-started unless it has been off for at least 3 normal operation of system ouputs. -

Page 25: Cooling Operation

FRESH-PAK IOM CONTROLS (continued) DEFROST CYCLE COOLING OPERATION While in defrost, the control de-energizes the outdoor STEADY STATE COOLING fan, energizes the reversing valve and auxiliary heat If the control recognizes cooling mode (“Y” and “O” outputs. A timer on the control accumulates defrost energized), the reversing valve energizes when the compressor run time. -

Page 26: Continuous Fan Operation

FRESH-PAK IOM CONTROLS (continued) CONTINUOUS FAN OPERATION If no other thermostat inputs are present, the low-speed evaporator fan output will be energized when the “G” thermostat input is active. If either of the “Y”, “AUX” OR “E” inputs are present, the operation of the evaporator fan will be based upon those inputs, and the “G”... -

Page 27: Erv Control Module

FRESH-PAK IOM CONTROLS (continued) ERV CONTROL MODULE (OPTIONAL) FIGURE 23 - ERV Control Module ERV CONTROL MODULE KEY INTERFACE TYPE NOTE Analog Input B1, B2, B3, B4 1: Resistor NTC10k Analog Input X1, X2 1: Measuring 0---10V 2) Tacho pulse (max. 300Hz) Analog / Digital (Binary) Input AI, BI 1: Measuring 0---10V... -

Page 28: Erv Default Configuration

FRESH-PAK IOM CONTROLS (continued) ERV DEFAULT CONFIGURATION The controller’s I/O are pre-configured for the following applications: Supply exhaust fan speed control Outside air damper control (on off) Contact input for rapid ventilation (Fan boost) and occupied operating mode ... -

Page 29: Normal Modes

FRESH-PAK IOM CONTROLS (continued) OPERATING MODE SETTING ERV DEFAULT CONFIGURATION The settings for the operating modes define the specific OPERATING MODE CATEGORIES settings for the supply and exhaust fans for all operating The following selectable operating modes belong to modes and for the speed and flow control strategies. operating mode categories. - Page 30 FRESH-PAK IOM CONTROLS (continued) C DE-ICING (PASSIVE, UNCONTROLLED) off time with assigned temperature and minimum off Passive Energy Recovery units are basically just heat time with assigned temperature can be configured. exchangers. They receive warm and humid air on one DE-ICING WITH REDUCED FAN SPEED STARTED BY TEh OR side and cold on the other which will eventually cumulate ice on the surfaces when the conditions are...

-

Page 31: Startup Sequences

FRESH-PAK IOM CONTROLS (continued) SHUTDOWN SEQUENCES ERV DEFAULT CONFIGURATION Executed after normal operation or if startup is OUTSIDE AIR DAMPERS (DMPSHOFFOA11Y) interrupted after step 4 is finished. Shutdown sequence When ventilation is active the outside air dampers are is not used in emergency situations. always open. -

Page 32: Blower Speed Control

FRESH-PAK IOM CONTROLS (continued) BLOWER SPEED CONTROL FIGURE 24 - Control Box Detail FRESH-PAK units are equipped with a direct drive ECM blower motor. See the BLOWER DATA section for airflow at different external static pressure. Select the motor speed according to the airflow and external static pressure. See wiring diagram located on unit. -

Page 33: Blower Data

FRESH-PAK IOM BLOWER DATA EPE BLOWER DATA-18K CFM vs EXTERNAL STATIC PRESSURE (IWC) MODEL Motor Speed NUMBER T1 (G) T2 (Y1) EPE18 T3 (Y2 HS) T4 (AUX) T5 (AUX HS) T1 (G) T2 (Y1) EPE18 T3 (Y2 HS) T4 (AUX) T5 (AUX HS) 1020 T1 (G) - Page 34 FRESH-PAK IOM EPE BLOWER DATA-24K CFM vs EXTERNAL STATIC PRESSURE (IWC) MODEL Motor Speed NUMBER T1 (G) T2 (Y1) EPE24 T3 (Y2 HS) T4 (AUX) T5 (AUX HS) 1005 T1 (G) T2 (Y1) EPE24 T3 (Y2 HS) T4 (AUX) 1012 T5 (Defrost) 1143 1100...

- Page 35 FRESH-PAK IOM EPE BLOWER DATA-30K CFM vs EXTERNAL STATIC PRESSURE (IWC) MODEL Motor Speed NUMBER T1 (G) T2 (Y1) 1041 EPE30 T3 (Y2 HS) 1143 1100 1068 1039 1011 T4 (AUX) T5 (AUX HS) 1062 1020 T1 (G) T2 (Y1) 1041 EPE30 T3 (Y2 HS)

-

Page 36: Field Erv Accessories

FRESH-PAK IOM FIELD ERV ACCESSORIES FIELD ERV ACCESSORIES CONNECTIONS FIGURE 25 - Field ERV Accessories Connections ECO Series EPE– IOM (Rev. A 08/23) - Page 37 FRESH-PAK IOM FIELD ERV ACCESSORIES VERSION 1 (ANALOG) INSTALLATION 1. Power down FRESH-PAK unit. IMPORTANT 2. Find the 120V relay in the FRESH-PAK control box. Refer to the applicable wiring diagram Installation must be Manufacturer Approved. Remove the 24V leads from the relay. 3.

- Page 38 FRESH-PAK IOM FIELD ERV ACCESSORIES (continued) VERSION 2 (DIGITAL) CO2/Humidity Sensor 1. Power down FRESH-PAK unit. 1. Power down FRESH-PAK unit. 2. Refer to the Installation instructions provided 2. Refer to the Installation instructions provided with the 120V digital timer switch. The switch with the 24V Sensor.

-

Page 39: Location Of Major Components

FRESH-PAK IOM LOCATION OF MAJOR COMPONENTS FIGURE 30 - Location of Major Components ECO Series EPE – IOM (Rev. A 08/23) -

Page 40: Wiring Diagrams

FRESH-PAK IOM WIRING DIAGRAMS FIGURE 31 – WD85X001 ERV Wire Diagram ECO Series EPE– IOM (Rev. A 08/23) - Page 41 FRESH-PAK IOM WIRING DIAGRAMS (continued) FIGURE 31 - WD85X017 Wiring Diagram (5KW EPE) ECO Series EPE – IOM (Rev. A 08/23)

- Page 42 FRESH-PAK IOM WIRING DIAGRAMS (continued) FIGURE 32 - WD85X018 Wiring Diagram (7KW-10KW EPE) ECO Series EPE– IOM (Rev. A 08/23)

-

Page 43: Circuit Schematic

FRESH-PAK IOM CIRCUIT SCHEMATIC HEAT PUMP FIGURE 33 - Circuit Schematic (Heat Pump) ECO Series EPE – IOM (Rev. A 08/23) -

Page 44: Startup Instructions

FRESH-PAK IOM 3. Return fan switch to “Auto”, indoor blower should STARTUP INSTRUCTIONS de-energize. PRE-STARTUP CHECKS 4. Set system switch to “Cool” and lower the Before start-up, thoroughly check all the components. thermostat set point to coldest setting. The Optimal operation of equipment requires cleanliness. compressor should energize as well as the outdoor Often after installation of the equipment, additional fan and indoor blower. -

Page 45: Troubleshooting

FRESH-PAK IOM TROUBLESHOOTING PROBLEM POSSIBLE CAUSE CHECKS & CORRECTIONS Power supply off Apply power; close disconnect. Blown Fuse Replace fuse or reset circuit breaker. Check for correct fuses. If voltage is below minimum voltage specified on unit data plate, contact power Voltage supply low company. - Page 46 FRESH-PAK IOM TROUBLESHOOTING (continued) PROBLEM POSSIBLE CAUSE CHECKS & CORRECTIONS Recalculate heating and cooling loads. If not excessive, possibly adding Unit undersized insulation will rectify the situation. Loss of conditioned air by Check for leaks in ductwork or introduction of ambient air through doors or leaks windows.

-

Page 47: Erv Alarm Codes

FRESH-PAK IOM ERV ALARM CODES ALARM CODES (ERV) STATE SITUATION ALARM RELAY Normal Everything works normally Open Alarm, unacknowledged Problem detected by controller and alarm activated Closed Alarm, acknowledged Problem still existing, service man acknowledged the active alarm Open Normal, acknowledged Problem fixed / eliminated, alarm is acknowledged For A-Alarm: Reset pending to unlock unit Open... - Page 48 FRESH-PAK IOM ERV ALARM CODES (continued) B-ALARMS FIGURE 35 - B-Alarms Application Operation Key B-ALARMS APPLICATIONS OPERATION KEY ALARM LOCKED UNACKNOWLEDGED Table 15 - B-Alarms Application Operation Key ECO Series EPE– IOM (Rev. A 08/23)

-

Page 49: Available Parameters

FRESH-PAK IOM ERV ALARM CODES (continued) AVAILABLE PARAMETERS AVAILABLE PARAMETERS ACKNOWLEDGE AND RESET BACNET OBJECT R/RW NOTE A-Alarm acknowledgement AalmAck 1: Ready MVAL,137 2: Acknowledge 3: Reset Automatic return to 1 B-Alarm acknowledgement BalmAck 1: Ready MVAL,133 2: Acknowledge Automatic return to 1 A-ALARMS BACNET OBJECT R/RW... - Page 50 FRESH-PAK IOM ERV ALARM CODES (continued) CODE RANGES – HARDWARE CODE RANGES – HARDWARE ALARM PLANT CODE NAME/DESCRIPTION SOURCE BACNET OBJECT/COMMENT INFLUENCE OF ALARM CLASS LOCK 1001 System Stop Supply air temperature, Sensor fault Shutdown AHU TEh, Shutdown AHU/ No Heat 1002 Exhaust air temperature, sensor fault System...

- Page 51 FRESH-PAK IOM ERV ALARM CODES (continued) CODE RANGES – COMMUNICATION CODE RANGES – HARDWARE ALARM PLANT CODE NAME/DESCRIPTION SOURCE BACNET OBJECT/COMMENT INFLUENCE OF ALARM CLASS LOCK I/O extension module, Modbus POS9 Same reaction as for each 3005 System active only if device configured communication fault connection input Duct pressure sensor, Modbus...

-

Page 52: Maintenance & Service

FRESH-PAK IOM MAINTENANCE & SERVICE PREVENTIVE MAINTENANCE FILTER To achieve maximum performance and service life of The air filter and ERV filters should be cleaned or equipment, a formal schedule of regular maintenance replaced every 30 days or more frequently if severe should be established and adhered to. -

Page 53: Performance Tables

FRESH-PAK IOM PERFORMANCE TABLES ERV EFFECTIVENESS TABLE RECOVERY RELATIVE SUPPLY TEMPERATURE SUPPLY AIR FLOW HUMIDITY SENSIBLE LATENT TOTAL °C °F RH % Effectiveness % 62.4 41.9 54.7 70.7 53.6 65.4 59.7 38.5 52.7 65.4 41.9 56.2 Table 20 - ERV Effectiveness VENTILATION PERFORMANCE EXTERNAL STATIC SUPPLY... -

Page 54: Support Material

FRESH-PAK IOM SUPPORT MATERIAL ASHRAE 62.2 VENTILATION STANDARD TABLES ASHRAE 62.2 CFM Sizing Chart NUMBER OF BEDROOMS / CFM FLOOR AREA >7 < 1500 1501 – 3000 3001 – 4500 4501 – 6000 6001 – 7500 > 7500 ANSI/ASHRAE STANDARD 62.2-2010 – Ventilation Air Requirements; values in cfm. The above chart outlines the minimum requirements for continuous ventilation. - Page 55 FRESH-PAK IOM STARTUP & PERFORMANCE CHECKLIST INSTRUCTIONS FIGURE 36 - Startup & Performance Checklist (1 of 2) ECO Series EPE – IOM (Rev. A 08/23)

-

Page 56: Startup & Performance Checklist

FRESH-PAK IOM STARTUP & PERFORMANCE CHECKLIST (continued) FIGURE 37 - Startup & Performance Checklist (2 of 2) ECO Series EPE– IOM (Rev. A 08/23) -

Page 57: Notes

FRESH-PAK IOM NOTES ECO Series EPE – IOM (Rev. A 08/23) - Page 58 P.O. Box 270969 Dallas, TX 75227 www.firstco.com or www.ae-air.com The manufacturer works to continually improve its products. It reserves the right to change design and specifications without notice. ©2022 First Co., Applied Environmental Air...

Need help?

Do you have a question about the FRESH-PAK Eco EPE Series and is the answer not in the manual?

Questions and answers