Summary of Contents for First Co AE-Air HydroTech WSV6090 Series

- Page 1 Installation, Operation, & Maintenance Manual IOM 8002 Rev. B 8/22 WSV6 090-120 Large Vertical Series Water Source Heat Pump...

- Page 2 WSV6 LARGE VERTICAL SERIES - IOM COPYRIGHT First Co. / AE-Air works to continuously improve its products and as a result, it reserves the right to change design and specifications without notice. The warranty may be void unless the Startup & Performance Checklist is completed and returned to the warrantor. If the HVAC unit is not installed properly, the warranty will be void, as the manufacturer cannot be held accountable for problems that stem from improper installation.

-

Page 3: Table Of Contents

WSV6 VERTICAL SERIES TABLE OF CONTENTS SAFETY CONSIDERATIONS MODEL NOMENCLATURE GENERAL INFORMATION INTRODUCTION STORAGE SHIPPING & PACKAGE LIST UNIT INSPECTION CHECKLIST UNIT DIMENSIONAL DATA 10-11 UNIT PHYSICAL DATA ELECTRICAL DATA INSTALLATION 12-18 ELECTRICAL APPLICATION 20-23 CONTROLS 24-32 PERFORMANCE DATA 33-35 WIRING DIAGRAMS 36-39 CIRCUIT SCHEMATIC... -

Page 4: Safety Considerations

WSV6 LARGE VERTICAL SERIES - IOM SAFETY CONSIDERATIONS 1. READ THE ENTIRE MANUAL BEFORE STARTING THE INSTALLATION. 2. These instructions are intended as a general guide and do not supersede national, state, or local codes in any way. 3. Altering the product, improper installation, or the use of unauthorized factory parts voids all warranty or implied warranty and may result in adverse operation and/or performance or may result in hazardous conditions to service personnel and occupants. - Page 5 WSV6 VERTICAL SERIES SAFETY CONSIDERATIONS CONTINUED Mechanical components and filters can become clogged These instructions are intended as an aid to qualified, with dirt and debris, which can cause damage to the licensed service personnel for proper installation, system.

-

Page 6: Model Nomenclature

WSV6 LARGE VERTICAL SERIES - IOM MODEL NOMENCLATURE FIGURE 1 – Model Nomenclature WSV6 Large Vertical Series – IOM... -

Page 7: General Information

WSV6 VERTICAL SERIES GENERAL INFORMATION DO NOT use these units as a source of heating or cooling Extreme caution must be taken that no internal damage during the construction process. Mechanical components will result from screws that are drilled into the cabinet. and filters can become clogged with dirt and debris, which can cause damage to the system. -

Page 8: Storage

WSV6 LARGE VERTICAL SERIES - IOM STORAGE Equipment should be stored in a clean dry, conditioned area with maximum temperatures up to 120°F [48.89°C] and minimum temperatures to 32°F [0°C]. Units should be stored upright and in an indoor environment. It is recommended to leave packaging on the unit until the installation is to begin. -

Page 9: Unit Inspection Checklist

WSV6 VERTICAL SERIES UNIT INSPECTION CHECKLIST Complete the inspection procedures below before preparing unit for installation: 1) Visually inspect unit for any shipping damage. Damage must be reported immediately to the shipping company to make a claim. 2) Ensure that the carrier makes proper notation of any shortages or damage on all copies of the freight bill and completes a common carrier inspection report. -

Page 10: Unit Dimensional Data

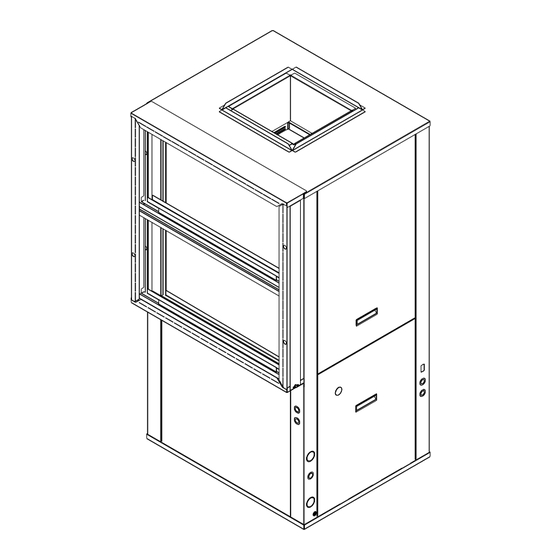

WSV6 LARGE VERTICAL SERIES - IOM UNIT DIMENSIONAL DATA TOP VIEW SIDE VIEW RETURN VIEW FIGURE 4 – Unit Dimensions WSV6 Large Vertical Series – IOM... -

Page 11: Unit Physical Data

WSV6 VERTICAL SERIES UNIT DIMENSIONAL DATA CONTINUED DIMENSIONAL DATA MODEL OVERALL CABINET SUPPLY CONNECTIONS WSV6090 (Top) 32.0 40.0 74.1 18.0 11.2 18.0 11.2 WSV6090 (Side) 32.0 40.0 74.1 18.0 52.4 11.2 18.0 11.2 WSV6120 (Top) 32.0 48.0 74.1 20.8 13.9 20.8 13.6 Table 1 - Unit Dimensional Data... -

Page 12: Electrical Data

WSV6 LARGE VERTICAL SERIES - IOM ELECTRICAL DATA ELECTRICAL DATA COMPRESSOR BLOWER MIN. CIRCUIT MAX. CIRCUIT MODEL VOLTAGE/PH/HZ AMPACITY PROTECTION 208-230V/3/60 25.0 35.2 460V/3/60 12.8 17.9 WSV6090 208-230V/3/60 25.0 2.0¹ 36.1 460V/3/60 12.8 2.0¹ 18.3 208-230V/3/60 28.2 45.5 460V/3/60 14.7 23.2 WSV6120 208-230V/3/60... - Page 13 WSV6 VERTICAL SERIES INSTALLATION CONTINUED REQUIREMENTS When servicing this equipment, because of high pressures, make sure the reversing valve, expansion device, filter drier and other components are specifically designed for R-410A refrigerant. ONLY USE service equipment specifically designated for use with R-410A.

- Page 14 WSV6 LARGE VERTICAL SERIES - IOM INSTALLATION CONTINUED MOUNTING DETAILS Locate the unit in an area that provides minimum clearance accesses as specified by FIGURE 5 & 6 – Unit Clearance Requirements. Also, refer to this figure for detailed information on unit dimensional sizes. Consider all additional clearances needed for water connections, electrical connections, duct connections and sufficient return airflow.

- Page 15 WSV6 VERTICAL SERIES INSTALLATION CONTINUED PIPING NOTES PIPING INSTALLATION All piping must be adequately sized to meet the designed water flow as specified for the specific application, and must adhere to all applicable codes. Piping connections on the equipment are not necessarily indicative of the proper Prior to making piping connections, contractor must clean supply and return line sizes.

- Page 16 WSV6 LARGE VERTICAL SERIES - IOM INSTALLATION CONTINUED PIPING INSTALLATION CONTINUED ANTIFREEZE Anti-freeze solutions must be utilized when low loop temperatures are expected to occur. In areas where entering loop temperatures drop below 50°F or where piping will be routed through areas subject to freezing, Do not allow hoses to rest against structural building antifreeze is needed.

- Page 17 WSV6 VERTICAL SERIES INSTALLATION CONTINUED CONDENSATE DRAINAGE Condensate drain lines must be properly installed with adequate slope away from unit to ensure proper drainage. A minimum trap of 1.5 inches must be installed to isolate the negative pressures of the drain pan from the drain line. Refer to Figure 8 –...

- Page 18 WSV6 LARGE VERTICAL SERIES - IOM INSTALLATION CONTINUED DISCHARGE DUCTING RETURN AIR DUCTING All ductwork should conform to industry standards of good Return air duct can be brought in through a wall grille and practice as described in ASHRAE System Guide. A field then to the unit.

-

Page 19: Electrical

WSV6 VERTICAL SERIES ELECTRICAL HIGH VOLTAGE LOW VOLTAGE THERMOSTAT A standard 24 VAC Heat Pump thermostat is required that will operate the reversing valve in the cooling mode. Thermostat connections and their functions are below in FIGURE 11 – Thermostat Connections as follows: Disconnect all power supplies before servicing. -

Page 20: Application

WSV6 LARGE VERTICAL SERIES - IOM APPLICATION rate for the unit. Nominal flow rate is 3 GPM per 12,000 COOLING TOWER/BOILER APPLICATION BTUH of cooling. To ensure optimum cooling and heating performance, the cooling tower and boiler loop temperature should be EXTENDED RANGE OPERATION maintained between 55-75°F in the heating mode and 60- 95°F in the cooling mode. - Page 21 WSV6 VERTICAL SERIES APPLICATION CONTINUED WATER WELL APPLICATION REQUIREMENTS: 50° Minimum Entering Water Temperature Cupronickel Refrigerant Heat Exchanger When a water well is used exclusively for supplying water to the heat pump, a cupronickel refrigerant heat exchanger is required and the well pump should operate only when the heat pump operate.

- Page 22 WSV6 LARGE VERTICAL SERIES - IOM APPLICATION CONTINUED HOT GAS REHEAT DEHUMIDIFICATION OVERVIEW Because ventilation air is introduced into buildings, indoor air quality (IAQ) and relative humidity (RH) are important issues to address in selecting heating and cooling equipment. With the Hydrotech WSV6 hot gas reheat dehumidification option, the return air from space is conditioned by a dedicated air-to-refrigerant coil and then reheated by a reheat coil to control space temperature and reduce space relative humidity.

- Page 23 WSV6 VERTICAL SERIES APPLICATION CONTINUED ANTIFREEZE CORRECTION FACTORS DATA ETHYLENE GLYCOL ANTIFREEZE COOLING CAPACITY 0.995 0.992 0.987 0.983 0.979 HEATING CAPACITY 0.991 0.982 0.977 0.969 0.961 PRESSURE DROP 1.070 1.130 1.180 1.260 1.280 Table 6 - Antifreeze Correction Factors Ethylene Glycol PROPYLENE GLYCOL ANTIFREEZE COOLING CAPACITY...

-

Page 24: Controls

WSV6 LARGE VERTICAL SERIES - IOM CONTROLS SEQUENCE OF OPERATION INITIAL CONDITION: START Comp = Off; Fan = Off AWAY CHIP = NOT INSERT LEGEND: Y = Call for Cooling Y = ON G = ON STAND BY G = Call for Fan HPS –... - Page 25 WSV6 VERTICAL SERIES CONTROLS CONTINUED WSCM CONTROL MODULE CONTROL FEATURES Anti-short Cycle Protection Test mode will be automatically exited after a 10 minute Random Start period. High and low Pressure Cut-out Water Coil Low Temperature Cut-out ...

- Page 26 WSV6 LARGE VERTICAL SERIES - IOM CONTROLS CONTINUED FIELD CONTROLLABLE FUNCTIONS DEHUMIDIFICATION MODE HOME SELECTION The system can operate in Dehumidification mode by If the switch is in the HOME position the heat pump will switching Dip 1.4 on the WSCM module. In this mode, the operate in its normal mode.

- Page 27 WSV6 VERTICAL SERIES CONTROLS CONTINUED WSCM SAFETY FEATURES CONDENSATE OVERFLOW SENSOR The condensate overflow sensor must sense overflow levels for 30 continuous second to initiate a COF fault. The condensate overflow sensor will be monitored during the compressor run cycle. LOW PRESSURE The low pressure switch must be open and remain open for 30 continuous seconds during the “on”...

- Page 28 WSV6 LARGE VERTICAL SERIES - IOM CONTROLS CONTINUED WSCM SAFETY FEATURES CONTROL BOARD LAYOUT LEGEND INPUT CONNECTION DESCRIPTION OUTPUT 24 VAC 24 VAC (Grounded Common) Input Call for Compressor CONTROLLER OPERATION CODES Input Call for Heating or Emergency DESCRIPTION OF OPERATION LED READOUT Heat Normal Mode...

- Page 29 WSV6 VERTICAL SERIES CONTROLS CONTINUED WSCM SAFETY FEATURES WSCM DIP SWITCH FUNCTIONS FUNCTION DIP SWITCH 1 Compressor Delay No Delay 5s Delay Motor Type PSC Motor Disconnect all power supplies before servicing. Lock Motor out/tag out to prevent accidental electrical shock. Blower Time Delay None Dehumidification...

- Page 30 WSV6 LARGE VERTICAL SERIES - IOM CONTROLS CONTINUED BLOWER SPEED CONTROL FIGURE 17 – WSV6120 Motor Connections Units with a Direct Drive (ECM) blower motor are equipped with 3 speeds, Low (X1), Medium (X2) and high (X1+X2). See Table 15 - WSV6090 Blower Data – Standard Motor (1.5HP) and Table 16 - WSV6090 Blower Data - High Static Motor (2.0HP) for airflow at different external static pressure.

- Page 31 WSV6 VERTICAL SERIES CONTROLS CONTINUED AIRFLOW SELECTION BELT TENSIONING The WSV6120 product is equipped with a belt driven 1) Verify that the belt is straight and aligned between blower refer to Error! Reference source not found.. The the motor sheave and pulley. airflow selection of the blower may be modified by 2) Loosen the four motor support bolts on either side adjusting the variable speed sheave or by changing the...

- Page 32 WSV6 LARGE VERTICAL SERIES - IOM CONTROLS CONTINUED BLOWER SPEED CONTROL FIGURE 18 – Blower Pulley Assembly BELT DEFLECTION FORCES BELT DEFLECTION FORCE BELT CROSS SMALLEST SHEAVE Unnotched Belt Notched Belt RPM RANGE SECTION DIAMETER RANGE Used Belt New Belt Used Belt New Belt 860 –...

-

Page 33: Performance Data

WSV6 VERTICAL SERIES PERFORMANCE DATA BLOWER DATA WSV6090 BLOWER DATA – STANDARD MOTOR (1.5 HP) CFM VS. STATIC PRESSURE (in. w.g.) FACTORY BLOWER SETTINGS MOTOR COOLING DESCRIPTION HEATING 1-10 MIN Airflow (CFM) 2555 2230 1980 Power (W) Airflow (CFM) 2900 2850 2800 2755 2705 Power (W) 1024 Airflow (CFM) - Page 34 WSV6 LARGE VERTICAL SERIES - IOM PERFORMANCE DATA CONTINUED PRESSURE & TEMPERATURE DATA WSV6090 PRESSURE & TEMPERATURE COOLING HEATING Entering Water Water Suction Discharge Air Temp Water Suction Discharge Air Temp Water Flow Rate Temp Pressure Pressure Drop Temp Rise Pressure Pressure Drop...

- Page 35 WSV6 VERTICAL SERIES PERFORMANCE DATA CONTINUED PRESSURE & TEMPERATURE DATA WSV6120 PRESSURE & TEMPERATURE COOLING HEATING Entering Water Water Suction Discharge Air Temp Water Suction Discharge Air Temp Water Flow Rate Temp Pressure Pressure Drop Temp Rise Pressure Pressure Drop Temp Rise °F psig...

-

Page 36: Wiring Diagrams

WSV6 LARGE VERTICAL SERIES - IOM WIRING DIAGRAMS WSV6 Large Vertical Series – IOM... - Page 37 WSV6 VERTICAL SERIES WIRING DIAGRAMS WSV6 Large Vertical Series – IOM...

- Page 38 WSV6 LARGE VERTICAL SERIES - IOM WIRING DIAGRAMS WSV6 Large Vertical Series – IOM...

- Page 39 WSV6 VERTICAL SERIES WIRING DIAGRAMS WSV6 Large Vertical Series – IOM...

-

Page 40: Circuit Schematic

WSV6 LARGE VERTICAL SERIES - IOM CIRCUIT SCHEMATIC FIGURE 23 - Circuit Diagram WSV6 Large Vertical Series – IOM... -

Page 41: Startup Instructions

WSV6 VERTICAL SERIES CIRCUIT SCHEMATIC HGRH FIGURE 24 - Circuit Diagram HGRH STARTUP INSTRUCTIONS activities occur. Protect the equipment from debris during PRE-STARTUP CHECKS: these construction phases. PRIOR TO THE STARTUP OF THE UNIT: Electrically ground the unit. Connect ground wire to 1. -

Page 42: Startup & Performance Checklist Instructions

WSV6 LARGE VERTICAL SERIES - IOM STARTUP INSTRUCTIONS CONTINUED 11. Check for vibrations, leaks, etc. PRIOR TO THE STARTUP OF THE UNIT: 12. Verify water flow rate is correct according to 9. Check that the water coil and piping had been leak specification. -

Page 43: Maintenance & Service

WSV6 VERTICAL SERIES MAINTENANCE & SERVICE PREVENTIVE MAINTENANCE CLEANING/FLUSHING To achieve maximum performance and service life of Before the unit is connected to the supply water, the water equipment, a formal schedule of regular maintenance circulating system must be cleaned and flushed to remove should be established and adhered to. -

Page 44: Troubleshooting

WSV6 LARGE VERTICAL SERIES - IOM TROUBLESHOOTING PROBLEM POSSIBLE CAUSE CHECKS & CORRECTIONS Power supply off Apply power; close disconnect. Blown Fuse Replace fuse or reset circuit breaker. Check for correct fuses. If voltage is below minimum voltage specified on unit dataplate, contact Voltage supply low lower power company. - Page 45 WSV6 VERTICAL SERIES TROUBLESHOOTING CONTINUED PROBLEM POSSIBLE CAUSE CHECKS & CORRECTIONS Unit oversized Recalculate heating and cooling loads. UNIT SHORT Thermostat installed near a supply air register, relocate thermostat. Check Thermostat CYCLES heat anticipator. Wiring and controls Loose connections in the wiring or a defective compressor contactor. Recalculate heating and cooling loads.

- Page 46 WSV6 LARGE VERTICAL SERIES - IOM TROUBLESHOOTING CONTINUED WSV6090 TROUBLESHOOTING PROBLEM POSSIBLE CAUSE CHECKS & CORRECTIONS Check that there is a 24VAC signal between the board fan relay and the NO FAN No Fan Signal X1, X2 connections on the motor. OPERATION Check that there is a 24VAC signal between the thermostat and unit WSV6090...

-

Page 47: Support/Reference Material

WSV6 VERTICAL SERIES SUPPORT/REFERENCE MATERIAL REFERENCE CALCULATIONS HEATING ABBREVIATIONS & DEFINITIONS LDB = EDB + LDB = Leaving air temperature dry bulb °F GPM x 500 EDB = Entering air temperature dry bulb °F LWT = EAT + GPM = Water flow rate gallons per minute cfm x 1.08 CFM = Airflow rate cubic feet per minute COOLING... -

Page 48: Startup & Performance Checklist

WSV6 LARGE VERTICAL SERIES - IOM STARTUP & PERFORMANCE CHECKLIST FIGURE 25 – Startup & Performance Checklist WSV6 Large Vertical Series – IOM... -

Page 49: Notes

WSV6 VERTICAL SERIES NOTES WSV6 Large Vertical Series – IOM... - Page 50 P.O. Box 270969 Dallas, TX 75227 www.firstco.com www.ae-air.com The manufacturer works to continually improve its products. It reserves the right to change design and specifications without notice. ©2022 First Co., Applied Environmental Air...

Need help?

Do you have a question about the AE-Air HydroTech WSV6090 Series and is the answer not in the manual?

Questions and answers