Table of Contents

Advertisement

Quick Links

Installation, Operation, & Maintenance Manual

IOM8404

Rev. E 1/24

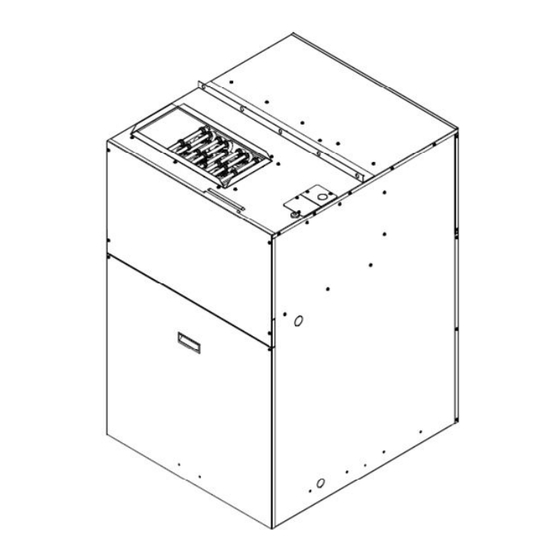

FPH SERIES

Vertical Packaged Heat Pump Unit W/Electric Heat

ATTENTION:

Installer

Read this manual before

starting installation.

Affix these instructions on or

adjacent to the heat pump.

Consumer

Read these instructions

thoroughly and retain all

manuals for future reference.

Advertisement

Table of Contents

Summary of Contents for First Co AE-Air FIRST-PAK FPH Series

- Page 1 Installation, Operation, & Maintenance Manual IOM8404 Rev. E 1/24 FPH SERIES Vertical Packaged Heat Pump Unit W/Electric Heat ATTENTION: Installer Read this manual before starting installation. Affix these instructions on or adjacent to the heat pump. Consumer Read these instructions thoroughly and retain all manuals for future reference.

- Page 2 FIRST-PAK COPYRIGHT First Co. works to continuously improve its products and as a result, it reserves the right to change design and specifications without notice. The warranty may be void unless the Startup & Performance Checklist is completed and returned to the warrantor. If the FIRST- PAK FPH is not installed properly, the warranty will be void, as the manufacturer cannot be held accountable for problems that stem from improper installation.

-

Page 3: Table Of Contents

– FIRST-PAK TABLE OF CONTENTS SAFETY CONSIDERATIONS MODEL NOMENCLATURE UNIT DIMENSIONAL DATA UNIT PHYSICAL DATA ELECTRICAL DATA RATING COOLING AND HEATING PERFORMANCE GENERAL INFORMANTION INTRODUCTION STORAGE SHIPPING AND PACKAGING LIST UNIT INSPECTION CHECKLIST INSTALLATION 13-20 REQUIREMENTS INSTALLATION PRECAUTIONS UNIT LOCATION UNIT CLEARANCE REQUIREMENTS WALL SLEEVE INSTALLATION UNIT SUPPORT... -

Page 4: Safety Considerations

– FIRST-PAK SAFETY CONSIDERATIONS 1. READ THE ENTIRE MANUAL BEFORE STARTING THE INSTALLATION. 2. These instructions are intended as a general guide and do not supersede national, state, or local codes in any way. 3. Altering the product, improper installation, or the use of unauthorized factory parts voids all warranty or implied warranty and may result in adverse operation and/or performance or may result in hazardous conditions to service personnel and occupants. - Page 5 – FIRST-PAK SAFETY CONSIDERATIONS CONTINUED WARNING WARNING Improper installation, adjustment, alteration, service, or HIGH VOLTAGE! maintenance can cause property damage, personal injury or loss of life. Refer to the user’s information manual provided Disconnect all power before servicing. Failure to do so may with this unit.

-

Page 6: Model Nomenclature

– FIRST-PAK MODEL NOMENCLATURE FIGURE 1 - MODEL NOMENCLATURE FPH SERIES – IOM (REV. E 1/24) -

Page 7: Unit Dimensional Data

– FIRST-PAK UNIT DIMENSIONAL DATA FIGURE 2 - Unit Dimensions FPH SERIES – IOM (REV. E 1/24) -

Page 8: Unit Physical Data

– FIRST-PAK UNIT PHYSICAL DATA FPH MODEL FPH03E1012C FPH05E1012C FPH07E1012C FPH05E1018C FPH07E1018C FPH10E1018C Compressor Type Rotary (1) Rotary (1) Rotary (1) Scroll (1) Scroll (1) Scroll (1) (Qty) Factory Charge 3.76 [1.71] 3.76 [1.71] 3.76 [1.71] 5.9 [2.68] 5.9 [2.68] 5.9 [2.68] (R410A) lbs. -

Page 9: Electrical Data

– FIRST-PAK ELECTRICAL DATA CONDENSER MIN. CIRCUIT MAX. OVERCURRENT INDOOR MIN. MAX. COMPRESSOR MOTOR AMPACITY (MCA) PROTECTION (MOP) MOTOR VOLTAGE VOLTAGE MODEL VOLTAGE- CIRCUIT NUMBER PH-HZ CIRCUIT 1* CIRCUIT 2* CIRCUIT 1* (L1-L2) (L3-L4) (L1-L2) (L3-L4) 208V 240V 208V 240V 208V 240V 208V 240V... -

Page 10: General Informantion

– FIRST-PAK GENERAL INFORMATION This heat pump is designed for through-the-wall indoor CAUTION installation only. Installation of this equipment, wiring, ducts, and any related components must conform to DO NOT use these units as a source of heating or cooling current agency codes, state laws, and local codes. -

Page 11: Storage

– FIRST-PAK STORAGE Equipment should be stored in a clean dry, conditioned area with maximum temperatures up to 120°F [48.89°C] and minimum temperatures to 32°F [0°C]. Units should be stored upright and in an indoor environment. It is recommended to leave packaging on the unit until the installation is to begin. -

Page 12: Unit Inspection Checklist

– FIRST-PAK Slide out the cooling chassis, check to make sure that the UNIT INSPECTION CHECKLIST refrigerant piping is free from any kinks, no visible refrigerant leak sign and there is no interference between unit piping and sheet metal or electrical wires. Refer to FIGURE 3 –... -

Page 13: Installation

– FIRST-PAK INSTALLATION REQUIREMENTS UNIT LOCATION Follow manufacturer’s installation instructions, as well as This product is certified for through the wall, indoor, up- local and municipal building codes. In addition, the flow vertical position installation only. This appliance is not installation shall conform to the following National Fire design certified for installation in mobile homes, Protection Association (NFPA) Standards:... -

Page 14: Unit Clearance Requirements

– FIRST-PAK UNIT CLEARANCE REQUIREMENTS A heat pump installed in a garage must also be protected The interior of the unit may be installed with zero from damage by vehicles. clearances to adjacent combustible surfaces. Please check local codes. Service clearance must be provided for future maintenance and service. -

Page 15: Wall Sleeve Installation

– FIRST-PAK WALL SLEEVE INSTALLATION Refer to installation instruction packed with the wall sleeve to assemble and mount into the wall. Before unit installation, make sure sleeve components are not damaged. Check all seals to ensure that they are in position and un- damaged. -

Page 16: Unit Support

– FIRST-PAK UNIT SUPPORT Things to consider prior to constructing the platform: The FIRST-PAK wall sleeve is not intended or designed to 1. Accurately measure the unit and choose a strong provide complete support for the FIRST-PAK unit. building material for the support structure. Additional support is required. -

Page 17: Packaged Unit Installation

– FIRST-PAK PACKAGED UNIT INSTALLATION NOTE Insulation is installed on the indoor section of the unit to provide a barrier between outside air conditions Locate the unit in an area that provides minimum surrounding the unit and the varying conditions inside the clearance to all service access panels. - Page 18 – FIRST-PAK PACKAGED UNIT INSTALLATION 7. Inspect the sleeve seal, which is supplied with the sleeve, to ensure that it is properly secured and NOTE aligned refer to FIGURE 12 – Wall Sleeve Seal). 8. For shipping purposes, the supply flanges are Check nameplate voltage, amperage and fuse size for shipped flat.

-

Page 19: Ductwork

– FIRST-PAK DUCTWORK IMPORTANT Supply and must be ducted to the unit. IMPORTANT The supply duct connection must be sized to a minimum of the same size as the unit discharge air opening. IMPORTANT All ductwork must be installed in accordance with National Fire Protection Assoc. -

Page 20: Air Filter

– FIRST-PAK AIR FILTER 1. The heat pump unit ships with factory-installed 1” disposable MERV3/4 filter which attaches to the inlet of the evaporator coil. AIR FILTER 2. A same size washable filter can be used to replace the existing disposable filter. FRONT 3. - Page 21 – FIRST-PAK CAUTION 208/230 VOLT OPERATION All 208/230 Volt units are factory wired for 230 Volt Any device that has been furnished by the factory for operation. For 208 Volt operation, field installation must be wired in strict accordance with moving/changing/rewiring the line voltage tap on the 24 the associated wiring diagram.

-

Page 22: Wiring Diagrams

– FIRST-PAK WIRING DIAGRAMS FPH SERIES – IOM (REV. E 1/24) - Page 23 – FIRST-PAK WIRING DIAGRAMS FPH SERIES – IOM (REV. E 1/24)

- Page 24 – FIRST-PAK WIRING DIAGRAMS FPH SERIES – IOM (REV. E 1/24)

- Page 25 – FIRST-PAK WIRING DIAGRAMS FPH SERIES – IOM (REV. E 1/24)

-

Page 26: Startup Instructions

– FIRST-PAK STARTUP INSTRUCTIONS PRE-STARTUP CHECKS: UNIT STARTUP: 1. Ensure that power is connected to the unit and the WARNING local disconnect is switched to ON position. 2. Turn on the power. Electrically ground the unit. Connect ground wire to 3. -

Page 27: Unit Operations

– FIRST-PAK UNIT OPERATIONS COOLING MODE When a call for cooling is made (“Y” and “O” input is energized), the reversing valve energizes. The compressor will energize after 3 minute short cycle period. Unit will operate in cooling mode. The low pressure switch will be bypassed for the first 3 minutes after compressor is energized. - Page 28 – FIRST-PAK OVERFLOW PROTECTION Limit Condensate overflow located in the bottom of the Switch evaporator drain pan shuts off the compressor if it senses the condensate in the drain pan rises above maximum level. FIGURE 23 – Auto-Reset Temperature Limit Switch Fuse Link Heating...

- Page 29 ESP may cause unit not working properly and even PERFORMANCE DATA damage the unit. For applications requiring higher static operation, please contact factory or First Co. sales representative. Unit performance is rated at 0.3” static. For applications with higher external static such as long return or supply duct, blower speed taps should be changed to make sure unit will run properly and efficiently.

-

Page 30: Blower Performance

– FIRST-PAK *Data is subject to change. Please verify most current information on www.firstco.com www.AE-Air.com websites. FPH SERIES – IOM (REV. E 1/24) - Page 31 – FIRST-PAK *Data is subject to change. Please verify most current information on www.firstco.com www.AE-Air.com websites. FPH SERIES – IOM (REV. E 1/24)

-

Page 32: Maintenance & Service - Electric Heat

– FIRST-PAK MAINTENANCE & SERVICE – ELECTRIC HEAT To ensure maximum performance and service life of WARNING equipment, a formal schedule of regular preventative maintenance must be established and adhered to. Failure to establish and perform a preventative ELECTRIC SHOCK, FIRE OR maintenance program can void the manufactures warranty. -

Page 33: Maintenance & Service - Heat Pump System

– FIRST-PAK VIEW PORTS FIGURE 28 – Remove Heating Module FIGURE 29 – View Ports MAINTENANCE & SERVICE – HEAT PUMP SYSTEM REFRIGERATION SYSTEM TROUBLESHOOTING COOLING CHASSIS REMOVAL Refrigerant service ports are located in the return air To fix a refrigerant leak or replace refrigeration section of the unit. - Page 34 – FIRST-PAK RELEASE TAB LOW VOLTAGE HIGH VOLTAGE HIGH VOLTAGE FIGURE 34- Line Voltage Connector RELEASE TAB FIGURE 32 – Electrical Power Disconnection FIGURE 35- High Voltage Connector WARNING 4) Slide-out cooling chassis. FIGURE 33– Slide Out Cooling Chassis. ELECTRIC SHOCK HAZARD Check motor connections to ensure they are secure and in accordance with the unit wiring diagram.

- Page 35 – FIRST-PAK Evaporator and condenser coil side panels can be removed from the chassis section to access the two TXV's. Remove this side panel FIGURE 37- TXV Location Inside Remove this side panel to serve indoor TXV to serve outdoor TXV FIGURE 36- TXV Location Outside COOLING CHASSIS REASSEMBLY FILTER...

-

Page 36: Startup & Performance Checklist

– FIRST-PAK STARTUP & PERFORMANCE CHECKLIST CUSTOMER STARTUP DATE JOB # ADDRESS SERVICING COMPANY TECHNICIAN MODEL # SERIAL # PHONE # INSTALLATION CHECK LIST Inspect the unit for transit damage and report any damage on the carrier’s freight bill. Check model number to insure it matches the job requirements. Install field accessories and unit adapter panels as required. - Page 37 – FIRST-PAK STARTUP & PERFORMANCE CHECKLIST CONTINUED UNIT OPERATION HEATING MODE 1 ELECTRIC HEATER AMPS 2 INDOOR BLOWER AMPS 3 TEMPERATURE RISE Supply Air Temperature – Return Air Temperature Temperature Rise 4 TOTAL EXTERNAL STATIC Supply External Static Return External Static Total External Static COOLING MODE 5 INDOOR BLOWER AMPS...

-

Page 38: Notes

– FIRST-PAK NOTES FPH SERIES – IOM (REV. E 1/24) - Page 39 PA IOM P.O. Box 270969 Dallas, TX 75227 www.firstco.com or www.ae-air.com The manufacturer works to continually improve its products. It reserves the right to change design and specifications without notice. ©2023 First Co., Applied Environmental Air...

Need help?

Do you have a question about the AE-Air FIRST-PAK FPH Series and is the answer not in the manual?

Questions and answers