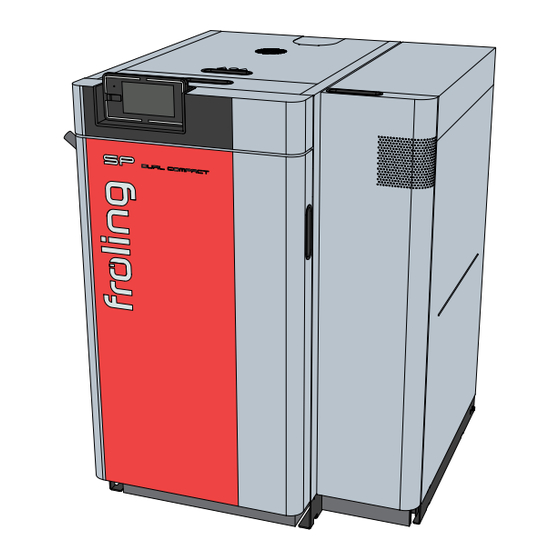

Fröling SP Dual compact Installation Instructions Manual

Dual fuel boiler

Hide thumbs

Also See for SP Dual compact:

- Installation instructions manual (80 pages) ,

- Service handbook (120 pages) ,

- Operating instructions manual (84 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Fröling SP Dual compact

- Page 1 Installation instructions Dual fuel boiler SP Dual compact (ESP) Translation of original German version of installation instructions for technicians. Read and follow all instructions and safety instructions. All errors and omissions excepted. M1821324_en | Edition 10/09/2024...

-

Page 2: Table Of Contents

Removing the pellet unit from the pallet................... 30 5.4.3 Operating and maintenance areas of the equipment............... 31 6 Installation ..............................33 6.1 Required tools and equipment ......................33 6.2 Accessories supplied ..........................33 M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP) - Page 3 Heating up for the first time...................... 86 8 Decommissioning ............................87 8.1 Mothballing............................87 8.2 Disassembly............................87 8.3 Disposal ..............................87 9 Appendix ..............................88 9.1 Pressure equipment regulation ......................88 M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP)

-

Page 4: General

1.1 About this manual These installation instructions contain information for the following sizes of SP Dual compact (ESP) boilers: 15, 20; M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP) -

Page 5: Disposal Of Packaging Materials

Disposal information Corrugated cardboard Paper collection Wood Check the regulations for correct disposal applicable in your local area Low Density Plastics collection Polyethylene (LDPE) LDPE Expanded polystyrene Plastics collection M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP) -

Page 6: Safety

The dangerous situation may occur and if measures are not observed it will lead to minor injuries. NOTICE The dangerous situation may occur and if measures are not observed it will lead to damage to property or pollution. M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP) -

Page 7: Qualification Of Assembly Staff

You must ensure that staff have the protective equipment specified by accident prevention regulations! ▪ During transport, erection and installation: - wear suitable work wear - wear protective gloves - wear safety shoes (min. protection class S1P) M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP) -

Page 8: Design Information

(Switzerland) UNI 8065 Technical standard regulating hot water preparation. DM 26.06.2015 (Ministerial Decree specifying the minimum requirements) Follow the instructions of this standard and any related updates. (Italy) M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP) -

Page 9: Regulations And Standards For Permitted Fuels

▪ The system must be protected against gnawing and nesting by animals (such as rodents) ▪ No flammable materials in proximity to the system ▪ Observe national and regional regulations regarding the installation of smoke detectors and carbon monoxide detectors M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP) -

Page 10: Chimney Connection/Chimney System

Please note within the permissible operating range of the boiler flue gas temperatures lower than 160K above room temperature may occur. M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP) -

Page 11: Connection Line To The Chimney

▪ 1.5 x nominal diameter of connection line for radiation shield with rear ventilation, but at least 200 mm (NM) NOTICE! The minimum distances must be observed in accordance with the standards and guidelines applicable in the region M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP) -

Page 12: Measuring Port

TRVB H 118 (only Austria) stipulates that an explosion flap must be installed in the connection line to the chimney, directly next to the boiler. It should be situated in such a way that is poses no risk to persons! M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP) -

Page 13: Electrostatic Particle Separator

▪ Locate the electrostatic particle separator in accordance with the planning for the flue gas system ▪ Install the electrostatic particle separator in accordance with the manufacturer's instructions supplied M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP) -

Page 14: Combustion Air

Boiler in room air-dependent operation Air extraction system (such as centralised dust extraction system, room ventilation) Under-pressure monitoring system Combustion air supply from outside M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP) - Page 15 The installation site must have a minimum volume in accordance with the applicable regional standards. Note on standards Austria: OIB Guideline 3 - Hygiene, health and environmental protection Germany: Model Firing Ordinance (MFeuV) M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP)

-

Page 16: Domestic Hot Water

1. For calculating the specific system volume, the smallest individual heating capacity is to be used for systems with several heat generators. 2. In systems with several heat generators with different specific water contents, the smallest specific water content is decisive in each case. M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP) - Page 17 ▪ Check the antifreeze dosage regularly according to the manufacturer's instructions ▪ Dispose of frost-protected heat transfer medium at the end of its shelf life and refill the system M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP)

-

Page 18: Pressure Maintenance Systems

These systems offer no oxygen removal for the purposes of corrosion control as required by VDI 2035 and in the interests of corrosion protection should not be used. M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP) -

Page 19: Storage Tank

As the boiler’s minimum continuous heat output is 30% above the nominal heat output, we as boiler manufacturer are obliged under EN 303-5:2021, Section 4.4.6 to advise that the Dual fuel boiler SP Dual compact must always be connected to a storage tank with adequate storage capacity. -

Page 20: Return Lift

Fit a microbubble separator in the pipes to the boiler Recommendation: Ä Follow the manufacturer's instructions! M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP) -

Page 21: Technical Information

Height of the flue gas pipe top connection 1385 Height of hose line connection 1255 Height, safety heat exchanger connection Height of return connection Height, drainage connection Height of connection for flow 1125 M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP) -

Page 22: Components And Connections

Immersion sleeve sensor connection for thermal discharge valve (installed by the 1/2“ IT customer) Position for boiler sensor and STL capillary (internal diameter) 16 mm 1. Included in delivery M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP) -

Page 23: Technical Specifications

Useful heat delivered at 30% of rated heat output (P Fuel efficiency at rated heat output (η 88.1 87.3 Fuel efficiency at 30% of rated heat output (η 85.7 85.7 M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP) - Page 24 The evaluation values reported are rounded to the nearest whole number. Values labelled with "<" represent the relative detection limit of the measuring methods or measuring device configurations used. M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP)

-

Page 25: Boiler Data For Planning The Flue Gas System

Combustion air volume at rated heat output m³/h 4.3.3 Data for planning a backup power supply Description Value Continuous output (single phase) 3680 Nominal voltage 230 ± 6% Frequency 50 ± 2% M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP) -

Page 26: External Suction Module

Length of suction module Width of suction module Height of suction module Total height incl. hose connection Return air line connection (line to suction point) Connection return air line (line from boiler) M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP) -

Page 27: Transport And Storage

If the system is to be assembled at a later stage: r Store components at a protected location, which is dry and free from dust Ä Damp conditions and frost can damage components, particularly electric ones! M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP) -

Page 28: Positioning

Remove the cardboard and take the pellet unit off the pallet Ü "Removing the pellet unit from the pallet" [} 30] Positioning using a crane r Attach the crane hook to the attachment point correctly and position the boiler M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP) -

Page 29: Positioning At The Installation Site

TIP: To make it easier to fit the cladding, position the boiler in free space in the installation room and only move it to its final position just before connecting it hydraulically. M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP) -

Page 30: Removing The Pellet Unit From The Pallet

Undo the screws on the top of the rear panel and lift off the rear panel r Open the insulated door and remove the cover plate from the top hinge M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP) -

Page 31: Operating And Maintenance Areas Of The Equipment

▪ Observe the applicable standards and regulations when setting up the system! ▪ Comply with additional standards for noise protection! (ÖNORM H 5190 - Noise protection measures) M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP) - Page 32 500 mm 815 mm 400 mm 500 mm / 200 1. Maintenance work to boiler’s heat exchanger only possible from front 2. Maintenance area to expand the WOS springs upwards M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP)

-

Page 33: Installation

Cleaning brush 30 x 20 x 90 Stoking rod Ash drawer with bracket Hook Ash shovel Spanner for door mountings Socket wrench for Lambda probe and heat exchanger cover Cleaning brush Ø 54 x 1350 M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP) -

Page 34: Assembly Overview S1 Turbo F (Esp)

6 | Installation 6.3 Assembly overview S1 Turbo F (ESP) M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP) - Page 35 Side panel cover WOS lever Automatic ignition (optional) Item Qty. Description Item Qty. Name Cover plate Gasket for basket plate Ignition unit Basket plate Gasket for the ignition unit Cable duct M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP)

-

Page 36: Assembly Overview Pellet Unit

Sound insulation dowel Ø 12 x 45 Suction module cover WOS drive (optional) Spring WOS shaft Pipe locking pin Bracket with WOS drive Spring cotter Ø 1.6 mm WOS cover plate WOS drive cover M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP) -

Page 37: Before Installation

Take out the top and bottom hinge pins and take off the fuel loading door r Remove the hinge and locking plate and reinstall them on the opposite side Ä Position the locking cam on the hinge as shown M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP) - Page 38 Slide the shaft retainers on to the hinge pins NOTICE! After changing over the door stops, check the seal and adjust it as necessary. Ü "Checking the seal on the doors" [} 39] Ü "Adjusting the doors" [} 40] M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP)

-

Page 39: Checking The Seal On The Doors

Ä If the paper can be pulled out: the door is not sealed properly – move the hinge or the locking plate backwards slightly Ü "Adjusting the doors" [} 40] M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP) -

Page 40: Adjusting The Doors

IMPORTANT: Align the locking plate and hinge identically at the top and bottom r Once the doors have been adjusted, check them again for leaks, Ü "Checking the seal on the doors" [} 39] M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP) -

Page 41: Preparing The Hydraulic Connection

(A) so that it is sealed tight r Undo the threaded socket from the pipe union provided and screw into the outfeed of the pellet unit (C) so that it is sealed tight M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP) -

Page 42: Positioning The Boiler On The Boiler Base Frame (Optional)

Remove the connecting piece r Turn the flue gas pipe connection to the top and refit the connection piece including the gasket - 4x M8 x 25 hexagon head screws M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP) -

Page 43: Retrofit Accessories

- 2x M8 x 25 hexagon head screws r Undo the screws on the heat exchanger cover and open the heat exchanger cover towards the rear - 2x M10 x >75 hexagon head screws M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP) - Page 44 - 2x M8 x 25 hexagon head screws r Slide the pins of the drive lever into the recess on the WOS lever and secure it with a spring cotter pin M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP)

-

Page 45: Electrostatic Particle Separator (Esp)

Remove the cover and gasket from the heat exchanger cover - 3x M6 x 12 raised-head screws r Open the heat exchanger cover from the rear and push round thermal insulation on to M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP) - Page 46 Working from above, insert the cleaning basket into the heat exchanger r Slide the lever p[late on to the cleaning basket and secure it with the shaft retainer M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP)

- Page 47 Close the heat exchanger cover and secure it - 2x M10 x 75 hexagonal head screws r Connect the HV cable to the electrode unit Ä The connector must click noticeably into place M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP)

-

Page 48: Install Firewood Boiler

Place the complete door bearing on to the boiler base and secure it from the bottom - 2x M6 x 12 hexagon head screws TIP: If the boiler has a pellet flange, it is recommended to fit the door stop on the left! M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP) - Page 49 Hang the spring am on the hook of the WOS lever and the left hand side panel r Thread the cover plate back on to the screw heads and tighten the screws M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP)

- Page 50 Mount the cover plate on the back panel at the cut-out for the flue pipe connection - 4x M4 x 10 raised-head screws r Attach the back panel to the side panel - 8x M4 x 10 raised-head screws M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP)

- Page 51 Use cable ties (C) to secure the cable in the intended position r Mount the cover plate on the back panel - 6x M4 x 10 raised-head screws M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP)

- Page 52 Tighten the inserted screws from the inside r Insert the spacer plate under the control panel (A) and secure it and the control panel - 2x M6 x 20 countersunk head screws M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP)

-

Page 53: Fitting The Air Control

Install the cover plate for the air control - 4x M4 x 10 raised-head screws M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP) -

Page 54: Installing The Wos Lever

- 1x M3 x 10 countersunk-head screw Ä NOTE: counter plate may already be mounted on one side r Attach the bottom of the insulated door the half-length taper grooved pin (A) M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP) - Page 55 Ä If necessary adjust the side panels at the brackets r When the positioning is correct, tighten the screws in the brackets r Close the round cutouts in the front cover plate using plastic plugs M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP)

-

Page 56: Fitting The Controller Box

- 2x M4 x 100 (A) raised-head screws with contact washers For boilers with automatic WOS: r Mount the cover on the drive unit - 2x M6 x 12 raised-head screws M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP) -

Page 57: Installing The Lambda Probe, Sensor And Thermal Discharge Valve

20 mm from the housing and secure it in position with the wing screw r Push the boiler temperature sensor and the STL capillary with the contact pressure spring (A) into the welded-in immersion sleeve NOTICE! Thermal discharge valve is not included M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP) - Page 58 Seal the immersion sleeve of the thermal discharge safety device in the sleeve r Slide the sensor and metal tube insulation into the immersion sleeve and secure with slotted screw M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP)

-

Page 59: Fitting The Pellet Unit

Remove the cover plate and thermal insulation from the firewood boiler flange r Completely press in and remove the perforations (A and B) on the side panel r Remove the blanking plate of the flange M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP) - Page 60 Completely screw in four adjusting screws (galvanized, yellow) on the flange Ä Adjusting screws function afterwards as the stop when setting the gap size IMPORTANT: Despite the aforementioned adjusting screws the flange seal is sufficiently compressed! M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP)

- Page 61 Screw the pellet unit to the flange of the firewood boiler using four M8 x 40 (B) hexagonal screws r Once you have done this, check that the clearance (C) between the firewood boiler insulation and the pellet unit is consistent M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP)

- Page 62 Tighten all of the screw connections (A and B) once again r Attach the base frame of the pellet unit both front and back to the firewood boiler using two screws and spacer washers M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP)

-

Page 63: Fitting The Air Connection

Attach the cover plate of the combustion chamber cover to the bolts (A) and flip the cover plate up r Fit the insulated door on the bolts r Install cover plate on the top hinge M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP) - Page 64 Loosen the screwed connection on the adjustment angle and correct the gap Ä Use the top screws (A) to adjust the gap from side to side Ä Use the front screw (B) to adjust the gap at the top M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP)

-

Page 65: Connecting The Discharge System

Ä If the suction module is positioned at a maximum distance of 2 m to the boiler, the power supply line can be plugged in as is. When distances are greater the power supply line must be lengthened accordingly on-site M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP) - Page 66 Fix the second part of the return-air line to the under-pressure side (position 2) with a hose clamp and lay the line to the boiler NOTICE! When connecting the lines, pay attention to equipotential bonding, Ü "Assembly information for hose lines" [} 68] M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP)

-

Page 67: Connecting The Hose Lines

Run the return air line (A) to the left connection r Run the suction hose (B) to the right connection NOTICE! Ensure the potential equalisation matches the discharge system assembly instructions when connecting the hose lines! M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP) -

Page 68: Assembly Information For Hose Lines

▪ The return-air line can be made up of several sections, but consistent potential equalisation must be established throughout the line. ▪ For systems over 35 kW, only suction hoses with PU inlet are recommended due to the increased load M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP) -

Page 69: Potential Equalisation

Ä TIP: If stiffness occurs when trying to attach the hoses to the connectors, pour a few drops of water onto the pipe (do not use lubrication grease!) r Secure the hose line with a hose clamp M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP) -

Page 70: Electrical Connection

Remove the cable ties from the tag connector r Bind the individual cores together with cable ties (A) r Attach cable and cable ties to the strain reliefs on the boiler M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP) -

Page 71: Board Overview

High-limit thermostat STB Return mixer module (optional) Main switch Hydraulic module Device connection terminal Service interface Mains connection plug Item Designation Item Designation Digital module Pellet module Pellet module expansion M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP) -

Page 72: Connect The Firewood Boiler Components

(Saugzug) (NOT-HALT) KM-02 Boiler display KM-16 Door switch KM-07 Servo-motor KM-17 WOS monitoring (for automatic WOS) KM-10 High-limit thermostat KM-25 Boiler sensor KM-13 Lambda probe KM-27 Induced draught fan M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP) -

Page 73: Connect The Components Of The Pellet Unit

Open the insulated door of the pellet unit and remove the cover plate behind the door r Run the cable through the perforated opening (A) to the firewood boiler controller box and plug into the boards: M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP) - Page 74 (Netz) KM08 (Kombiantrieb) KM28 5V/P3 (Pumpe 1) KM09 (Verriegelung) KM10 (STB) KM27 KM11 (Saugzug) (NOT-HALT) KM-08 Primary air KM-17 WOS monitoring (for automatic WOS) KM-09 Lock KM-18 temperature sensor M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP)

- Page 75 HY0.02 FRHYU22 (Bus) Mains fuse Module address HY0.03 / HY0.04 HY0.13 HY0.14 HY0.15 (Pumpe _.1) (Pumpe _.2) (Netz) (Bus) HY-01 Bus connection (alternatively on the return mixer module) HY-02 M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP)

-

Page 76: Potential Equalisation

NOTICE! Compliance with additional information in the relevant boiler controller documentation is mandatory! 6.10.4 Potential equalisation r The potential equalisation on the boiler base must comply with current directives, regulations and standards. M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP) -

Page 77: Mains Connection

Insert the pipe union as shown and fit to the screw connections Ä Do not forget to fit the seals provided! r Hang the cover plate on the screw heads and secure it with screws M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP) - Page 78 ▪ Ideally it should be installed in the return line. Follow the manufacturer’s installation instructions We recommend installing some sort of monitoring device (such as a thermometer) Internal pipe connection ▪ Pellet unit outfeed to return firewood boiler (included in delivery) M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP)

-

Page 79: Final Installation Steps

Thread the cover through at the rear and fix it at the front with two M5 x 12 screws (A) r Place the front cover on the boiler r Slide the floor insulation underneath the boiler from the front M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP) - Page 80 Secure the cover with a retaining screw r Stick the supplied quick reference guide to the insulated door of the pellet unit in a visible location r Close the insulated door M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP)

-

Page 81: Positioning The Boiler Stickers

6.12.1 Positioning the boiler stickers r Remove the protective film from the sticker r Position the backing film featuring “SP DUAL COMPACT” in the upper left corner of the insulated door, ensuring all of the air bubbles have been removed... -

Page 82: Insulate The Connection Line

Glue the half shells to each other 6.12.4 Install the brackets for accessories r Using appropriate fasteners, attach the brackets to the wall on the boiler r Attach the accessories to the brackets M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP) -

Page 83: Start-Up

Check that the drives and servo motors are working and turning in the right direction r Check that the door contact switch is working efficiently. NOTICE! Check the digital and analogue inputs and outputs - See the instruction manual for the boiler controller. M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP) -

Page 84: Initial Startup

▪ stack split wood and store in such a way that it is protected from the elements ▪ If possible, stock fuel for the day in a warm place (e.g. in boiler room) (pre-heats the fuel!) M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP) -

Page 85: Fuels Permitted Under Certain Conditions

▪ Even when using the settings for dry fuel, burning wood briquettes can cause combustion problems. In such cases, repairs must be carried out by qualified staff. Please contact Froling customer services or your installer. M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP) -

Page 86: Non-Permitted Fuels

For this reason the following applies the first time you heat up the boiler: r Carry out initial start-up of the firewood boiler with less amount of fuel M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP) -

Page 87: Decommissioning

(e.g. AWG in Austria) r You can separate and clean recyclable materials and send them to a recycling centre. r The combustion chamber must be disposed of as builders' waste. M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP) -

Page 88: Appendix

9 | Appendix 9 Appendix 9.1 Pressure equipment regulation M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP) - Page 89 Notes M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP)

- Page 90 M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP)

- Page 91 M1821324_en | Installation instructions Dual fuel boiler SP Dual compact (ESP)

-

Page 92: Manufacturer's Address

Manufacturer’s address Froling srl Froling SARL Fröling Heizkessel- und Zweigniederlassung Behälterbau GesmbH Aschheim Industriestraße 12 Max-Planck-Straße 6 Via J. Ressel 2H 1, rue Kellermann A-4710 Grieskirchen 85609 Aschheim I-39100 Bolzano (BZ) F-67450 Mundolsheim +43 (0) 7248 606 0 +49 (0) 89 927 926 0 +39 (0) 471 060460 +33 (0) 388 193 269 info@froeling.com...

Need help?

Do you have a question about the SP Dual compact and is the answer not in the manual?

Questions and answers