Advertisement

Quick Links

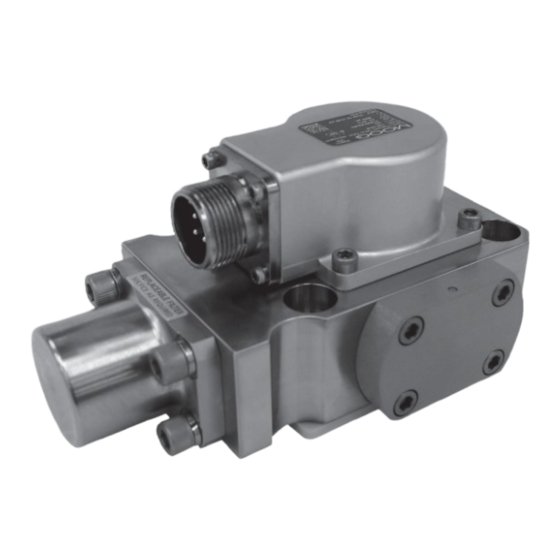

1. INTRODUCTION

This manual provides instructions and procedures necessary to install,

operate and troubleshoot the Moog Inc. Series 730 Electrohydraulic Industrial

Servovalve. Troubleshooting instructions are outlined to permit the identification

of the specific component(s) suspected of failure.

2. OPERATION

The Moog Inc. Series 730 Electrohydraulic Servovalve consists of a

polarized electrical torque motor and two stages of hydraulic power amplification.

The motor armature extends into the air gaps of the magnetic flux circuit and

is supported in this position by a flexure tube member. The flexure tube acts as

a seal between the electromagnetic and hydraulic sections of the valve. The two

motor coils surround the armature, one on each side of the flexure tube.

The flapper of the first stage hydraulic amplifier is rigidly attached to the

midpoint of the armature. The flapper extends through the flexure tube and

passes between two nozzles, creating two variable orifices between the nozzle

tips and the flapper. The pressure controlled by the flapper and nozzle variable

orifice is fed to the end areas of the second stage spool.

The second stage is a conventional four-way spool design in which output

flow from the valve, at a fixed valve pressure drop, is proportional to spool

displacement from the null position. A cantilever feedback spring is fixed to the

flapper and engages a slot at the center of the spool. Displacement of the spool

deflects the feedback spring which creates a force on the armature/flapper

assembly.

Input signal induces a magnetic charge in the armature and causes a

deflection of the armature and flapper. This assembly pivots about the flexure tube

and increases the size of one nozzle orifice and decreases the size of the other.

This action creates a differential pressure from one end of the spool to

the other and results in spool displacement. The spool displacement causes a

force in the feedback wire which opposes the original input signal torque. Spool

movement continues until the feedback wire force equals the input signal force.

DISASSEMBLY, MAINTENANCE, OR REPAIR OTHER THAN IN ACCORDANCE WITH THE

INSTRUCTIONS HEREIN OR OTHER SPECIFIC WRITTEN DIRECTIONS FROM MOOG

WILL INVALIDATE MOOG'S OBLIGATIONS UNDER ITS WARRANTY.

CAUTION

730 Series Installation and

Operation Instruction

Electrohydraulic Servovalve

ELECTROHYDRAULIC VALVE CUT-AWAY

Internal Filter

Inlet Orifice

Magnet

Coil

Armature

Flapper

Spool

Auxiliary First

Stage Pressure

Control Port

Return

Figure 1

Field Replaceable Filter

Upper Polepiece

Flexure Tube

Lower Polepiece

Nozzle

Feedback Wire

Pressure

Control Port

Advertisement

Summary of Contents for Moog 730 Series

- Page 1 1. INTRODUCTION Electrohydraulic Servovalve This manual provides instructions and procedures necessary to install, operate and troubleshoot the Moog Inc. Series 730 Electrohydraulic Industrial Servovalve. Troubleshooting instructions are outlined to permit the identification of the specific component(s) suspected of failure. 2. OPERATION The Moog Inc.

- Page 2 It is often desirable to adjust the flow null of a servovalve independent of other system parameters. The “mechanical null adjustment” on the Moog 730 Series servovalve allows at least ±20% adjustment of flow null. The Disconnect electrical lead to servovalve.

- Page 3 Moog for repair. Moog does not authorize any facilities other than Moog or Visually inspect filter orifice assemblies for damage or foreign material. Moog subsidiaries to repair its servovalves. It is recommended you contact Discard O-Rings and filters.

- Page 4 4 X PORT PER SAE J1926 Figure 4 1.0625-12 UN-2B DASH 12 STR THD O-RING PRESS BOSS (.75 TUBE OD REF) Moog Inc., East Aurora, NY 14052-0018 PORT PER SAE J1926 2.11 1.23 .4375-20 UNF-2B Telephone:+1-716-652-2000 DASH 4 STR THD O-RING Fax:+1-716-687-7910 4.22...

Need help?

Do you have a question about the 730 Series and is the answer not in the manual?

Questions and answers