Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Klutch 5875877

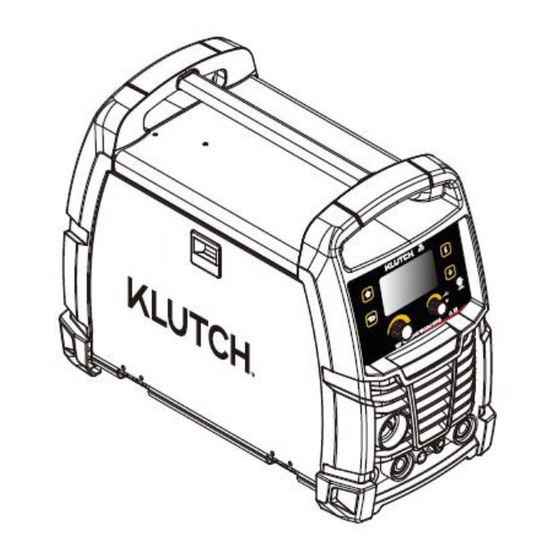

- Page 1 MP 120/230V Welder 240A WARNING: Read carefully and understand all ASSEMBLY AND OPERATION INSTRUCTIONS before operating. Failure to follow the safety rules and other basic safety precautions may result in serious personal injury. Item #5875877 READ & SAVE THESE INSTRUCTIONS...

-

Page 2: Table Of Contents

Table of Contents GENERAL SAFETY INSTRUCTION.......................2 Know Your Welder............................. 6 Technical Data..............................9 Operational Approach............................10 Installation................................14 Wekl Cable Access Opening...........................15 Spare Part List..............................20 Trouble Shooting And Elimination Methods....................22 Main Circuit Chart..............................25 Complete Set Specification..........................26 Transport & Storage............................26 Quality Guarantee............................. 26... -

Page 3: General Safety Instruction

Operating Instructions and Parts Manual Please read and save these instructions. Read through this owner’s manual carefully before using product. Protect yourself and others by observing all safety information, warnings, and cautions. Failure to comply with instructions could result in personal injury and/or damage to product or property. - Page 4 -Do not overuse or overheat your welder. Allow proper cooling time between duty cycles. -Keep hands and fingers away from moving parts and stay away from the drive rolls. -Do not point MIG gun at any body part of yourself or anyone else. -Always use this welder in the rated duty cycle to prevent excessive heat and failure.

- Page 5 GENERAL SAFETY INSTRUCTION -Do not weld near materials that will emit toxic fumes when heated. Vapors from cleaners, sprays and degreasers can be highly toxic when heated. UV and IR Arc Rays The welding arc produces ultraviolet (UV) and infrared (IR) rays that can cause injury to your eyes and skin.

- Page 6 GENERAL SAFETY INSTRUCTION Sparks/Flying Debris Welding creates hot sparks that can cause injury. Chipping slag off welds creates flying debris. -Wear protective apparel at all times: ANSI-approved safety glasses or shield, welder’s hat and ear plugs to keep sparks out of ears and hair. Electromagnetic Field -Electromagnetic fields can interfere with various electrical and electronic devices such as pacemakers.

-

Page 7: Know Your Welder

Know Your Welder... - Page 8 Technical Specifications • Environmental condition • The surrounding temperature range • when working:-10~+40℃;During transport or in storage:-20~+55℃ • Relative humidity:when at 40℃: 50%;when at 20℃: 90%。 • Dust, acid , corrosive gas or matter in the air less than normal content Besides matter is produced in welding process.

- Page 9 • Post-gas function For protecting fiery welding area,there is 3s post-gas at the end of welding. • Stick welding function Adjusting function switch to Stick welding on the front panel. • Remark & Sign of Illustration ground connection —transformer—rectifier 1 ph static frequency changer MIG/MAG.

-

Page 10: Technical Data

Technical Data 4.1 Main technical data project unit MP 120/230 Welder 240A voltage frequency 50/60 50/60 Max rated input current Rated capacity No Loading voltage Welding voltage 16~18.5 16~24 Rated duty cycle Welding Wire diameter inch 0.25", 0.030", 0.035" Wire feed speed inch/min 100~500 Rated welding current(MIG... -

Page 11: Operational Approach

Operational Approach Workpiece before welding cleanup • Before test welding , wire, bevel and bevel around 10 ~ 20mm must be maintained within the range of clean , shall not affect the quality of welding rust, oil, water and paint and other foreign matter. •... - Page 12 Front Ctrl panel Reference Description LCD DISPLAY Home/Start Button Previous Screen Button Multi-Functiom Adustment/Selecti Knob Gas Purge Button Wire Jog Button Voltage Control Knob OPERATING INSTRUCTIONS High voltage danger from power source! Consult a qualified electrician for properinstallation of receptacle, ...

- Page 13 : Shows all process from function selection to welding. 1LCD 2 Gas-check button: press the button to check gas is working. 3 Wire-check button:press the button to test wire supply system. 4 Multi-function adjusting knob: For function selection; Press for confirming. Allows user to adjust the current and wire feeding speed accurately.

- Page 14 Welding display:Shows all selected parameters. * Under MIG welding, user can set wire feeding speed and voltage. Adjusting Multi-function knob to set electro-inductance, press the knob to progress basic parameter setting. Note: Note1:Basic parameter setting including:gas pre flow, slow wire feeding, gas post flow, operating, load and save function.

-

Page 15: Installation

Alarm interface:It shows the machine is overloaded and the internal temperature is too high. Weld output will turn off automatically but the fan will still be working. When the internal temperature is decreased, the alarm interface will turn off and the machine will be ready to weld. Installation lutch MP 120/230 Welder 240A emi-automatic gas welding enclosure protection class IP21S. -

Page 16: Wekl Cable Access Opening

SPOOL GUN ASSEMBLY This unit is set-up to accept the Quick Draw Spool gun only. The Quick Drow Spool Gun has three connection points at !he back of the spool gun (Flgure • The gas connection is a slide-on quick connector. •... - Page 19 Welding connection diagram Connection with power • user must connect the 4-pin power cable in the back of welding machine to the power outlet with breaker. • Must confirm the power supply voltage is consistent with the voltage in the nameplate on the welding machine.

- Page 20 Connection welding wire feed system 8 Connect the cable to plug into the current output Continental welder front panel below the " +" a very European socket , and tighten the European plug the other end of the wire feeder and the rear end of the European socket tighten to secure the connection .

-

Page 21: Spare Part List

Spare Part List Quick-wear part list Remark Exploded view Material Quantity name HANDLE 155200093 MIDDLE PLATE 125200083 PCB BOARD 125200084... - Page 22 GAS VALVE 1005200047 POWER CORD 1005200211 CABLE CONNECTOR 125200085 SWITCH 105700072 REAR PLASTIC PANEL 125200086 REAR PANEL 125200087 105200314 MIAN PCB 125200088 PCB SUPPORT PLATE 105200234 ENCLOSURE 125200089 BOTTOM PANEL 125200090 BEND 125300123 AIR VALVE JOINT SEAT 125200093 PEDAL SWITCH HARNESS 125200095 TRIGGER SWITCH HARNESS 105200059...

-

Page 23: Trouble Shooting And Elimination Methods

Trouble Shooting And Elimination Methods • failure analysis and troubleshooting (see Table 4) Failure Cause Failure Analysis troubleshooting Investigate the reasons No power Press the gun ofconnectingpower. Torch switch is broken Change the torch switch switch ,nowire 1 Wire feeder current Change potentiometer There are no-load regulatorpotentiome... - Page 24 at the entrance , and Guidewire tube imports from Shorten the distance between the two evenbend wirewheel too far , the guide is not good Wire wheel groove horizontal section Adjusted so that in a straight line the guide wire die not in a straight line Wire hose ID is too small or too large Replace the appropriate wire...

- Page 25 • Common weld defects ( see Table 5 ) Weld defects Cause Analysis and Troubleshooting Wire and workpiece have excess oil, rust and water. CO2 gas shielded bad. (Low flow, lack of silico-manganese content in the wire, gas impurities, nozzle clogging, leakage, Vent Excess wind over speed) Wire and workpiece have excess oil, rust and water.

-

Page 26: Main Circuit Chart

Main Circuit Chart lutch MP 120/230 Welder 240A inverter gas protection welder main circuit diagram... -

Page 27: Complete Set Specification

Complete Set Specification * Welder 1 pc * Product certification 1 pc * Warranty Card 1 pc * Product Manual 1 pc Optional accessories * Torch 1 pc * Control cables, welding cables 1 pc * Ground cable (with ground clamp ) 1 pc * Small accessories ( hose clamps, tip , etc.) 1 pc... - Page 28 Distributed by: Northern Tool & Equipment Company, Inc. Burnsville, Minnesota 55306www.northerntool.com Made in China...

Need help?

Do you have a question about the 5875877 and is the answer not in the manual?

Questions and answers

how do we program the welder to operate

To program and operate the Klutch welder model 5875877:

1. Connect Components:

- Connect the welding wire feed system using the "+" socket on the front panel.

- Attach the 6-core control cable between the wire feeder and the 6-pin socket on the front panel.

- Connect the torch to the front panel interface and tighten.

- Attach the grounding cable to the "-" socket on the right side of the front panel and clamp the other end to the workpiece.

2. Power and Safety:

- Ensure the welder is properly grounded.

- Use only the supplied adapter for connecting the power cord.

- Keep the POWER switch OFF during setup.

- Avoid operating in wet or humid conditions and store in a dry, ventilated location.

3. Front Control Panel Usage:

- Use the LCD display to view settings.

- Use the multi-function adjustment/select knob to set parameters.

- Use the voltage control knob to adjust output voltage.

- Use the Home/Start button to begin operation.

- Use the Gas Purge and Wire Jog buttons for gas and wire feed control.

4. Maintenance:

- Only professionals should perform maintenance.

- Before use, check insulation resistance if the machine was unused for a long time.

- Avoid live maintenance work.

5. Operation:

- Wear protective gear.

- Keep the area clear of flammable materials.

- Shut off power and gas when welding is complete or unattended.

These steps configure the welder for safe and proper operation.

This answer is automatically generated