Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Sinoboom AB10J

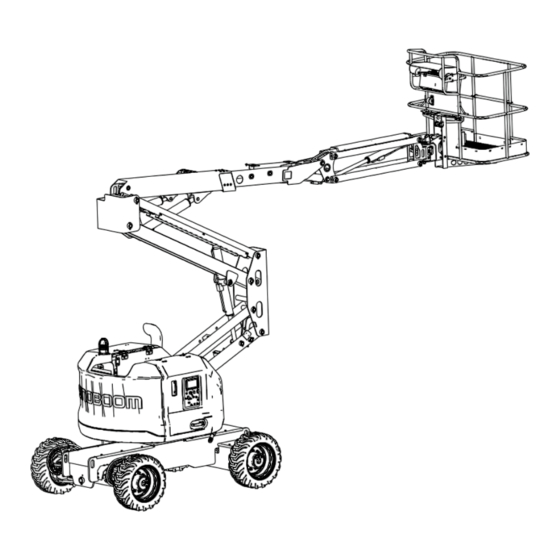

- Page 1 AB10J Maintenance Manual Maintenance Manual No: 504031110002-EN Manual Version: A June 2024 Manual 产品说明书 Translated version Preface to Maintenance Manual PRODU C T MAN U AL AB10J (AB10J/AB340J) 0403100100 to current 0608E (2132E) G T JZ 0808E (2732E) G T JZ...

- Page 3 Operating, servicing and maintaining this vehicle or equipment can expose you to chemicals including engine exhaust, carbon monoxide, phthalates and lead, which are known to the State of California to cause cancer and birth defects or other reproductive harm. To minimize exposure and avoid breathing exhaust, do not idle the engine except as necessary, service your vehicle or equipment in a well-ventilated area and wear gloves or wash your hands...

- Page 4 E-mail: info@sinoboom.com (China) / sales@sinoboom.com (except China) Address: No.128, East Jinzhou Avenue, Ningxiang High-tech Industrial Park, Changsha, Hunan, China Postal code: 410600 Copyright©Hunan Sinoboom Intelligent Equipment Co., Ltd. Hunan Sinoboom Intelligent Equipment Co., Ltd. retains the right of final interpretation of the manual.

- Page 5 To Users Thank you for choosing and using the machinery of Hunan Sinoboom In- telligent Equipment Co., Ltd. Use this machine only to transport tools to work locations and for performing tasks on the work platform. Only authorized personnel who have received appropriate MEWP training may operate this machine.

- Page 6 Manual Revision History: Ver- Date Description sion Original issue June 2024...

- Page 7 The manual applies to the following models and serial numbers: Metric Trade Imperial Trade Model Serial No. Name Name AB10J AB10J AB340J 0403100100 to current Note: • Check the machine model and serial number on the machine nameplate. The location of the name- plate can be found in the Decals Diagram section of the Operation Manual.

-

Page 9: Table Of Contents

Preventive Maintenance ... . . 23 5.6 Battery ......44 © June 2024 AB10J Maintenance Manual... - Page 10 Locking ......76 Weight Calibration ....110 © June 2024 AB10J Maintenance Manual...

- Page 11 Record ......125 13.2 Inspection and Preventive Maintenance Schedule..126 © June 2024 AB10J Maintenance Manual...

- Page 12 © June 2024 AB10J Maintenance Manual...

-

Page 13: Safety Warning Symbols And Signs

Indicates an imminently hazardous situation that, if not avoided, could result in death or serious injury. Indicates an imminently hazardous situation that, if not avoided, could result in minor or moderate injury. NOTICE Indicates information directly or indirectly related to personal safety, machine damage, or property loss. © June 2024 AB10J Maintenance Manual... - Page 14 Tipping hazard – never place ladders and use machine in strong, use machine in strong, push or pull objects suspend objects from scaffolding on the gusty winds gusty winds outside the platform the platform platform © June 2024 AB10J Maintenance Manual...

- Page 15 No smoking or open Lifting point Lashing point Tire ground pressure Hydraulic oil filler flames/sparks Do not use damaged Platform load capacity Tool or weight Fast/high speed Slow/low speed power cords Horn © June 2024 AB10J Maintenance Manual...

- Page 16 SAFETY WARNING SYMBOLS AND SIGNS This Page Intentionally Left Blank AB10J Maintenance Manual © June 2024...

-

Page 17: Maintenance Safety Precautions

Before and during inspection and maintenance proce- without the written permission of Hunan dures personnel shall use caution and take measures to Sinoboom Intelligent Equipment Co., Ltd. avoid dangerous situations. Those measures include, but are not limited to, the following: 1. -

Page 18: Maintenance Safety

The above listed requirements must be adhered to strictly during maintenance/inspection work. In addition, all other appropriate measures must be taken to ensure safety during maintenance work, taking account of the working environment. AB10J Maintenance Manual © June 2024... - Page 19 (such as a high - pressure water gun) to clean the machine. Do not direct water or steam ejected from the flushing equip- ment at electrical components, as this may cause short - circuits or electrical shocks. © June 2024 AB10J Maintenance Manual...

- Page 20 If treatment is not carried out im- can generate sparks. mediately, serious complications • Only approved non-flammable may result. cleaning solutions should be used on the machine. AB10J Maintenance Manual © June 2024...

- Page 21 • Batteries contain sulfuric acid and can produce explosive © June 2024 AB10J Maintenance Manual...

-

Page 22: Considerations After

2.4 CONSIDERATIONS AFTER MAINTENANCE 1. Check the machine functions so that faults such as oil leakage or poor operation can be detected as early as possible. AB10J Maintenance Manual © June 2024... -

Page 23: Technical Characteristics

0 - 0.5 mph 0 - 0.8 km/h Gradeability (4WD) 40%/22° Turntable slewing (angle/continuity) 355°/non-continuous Platform rotation angle 160° Maximum allowable inclination 3°/4.5° Turning radius (inside/outside) 1.5 m/3.9 m 4 ft 11 in/12 ft 10 in © June 2024 AB10J Maintenance Manual... - Page 24 90 lbf (restricted/unrestricted) Maximum allowable wind speed 28 mph 12.5 m/s Maximum allowable altitude 1000 m 3280 ft Allowable ambient temperature -20℃ – 40℃ –4℉ – 104℉ range Maximum allowable relative 90 % humidity © June 2024 AB10J Maintenance Manual...

-

Page 25: Function Speed

Perform this maneuver for two times. © June 2024 AB10J Maintenance Manual... -

Page 26: Weight Of Major Components

Jib assembly Cable track system Platform Counterweight 1000 2205 Slewing mechanism Telescopic cylinder Upper leveling cylinder Lower leveling cylinder Main boom lift cylinder Articulating boom lift cylinder Jib cylinder Swing cylinder Drive motor Drive reducer AB10J Maintenance Manual © June 2024... -

Page 27: Pressure Settings

The oil recommendations in this manual are for general operating conditions. For special environ- -22℃ – 25℃ ments or special operating requirements please Sinopec L-HS32 (-7.6℉ – 77℉) contact Sinoboom for special oil. < -22℃ Sinopec AE-VX (-7.6 ℉) © June 2024 AB10J Maintenance Manual... - Page 28 -25 – 40℃ (-13 – 104℉) 80W-90 -30 – 25℃ (-22 – 77℉) -35# Note: Sinoboom recommends Mobil gear oil. NOTICE Fuel Oil Please go to a certified gas station to purchase qualified fuel oil. It is recommended prepare an oil...

-

Page 29: Torque Specifications

40℃ (-31 – 104℉). If the machine is to be operated in special environments where the above antifreeze types Special Torque Requirements are not applicable, contact Sinoboom for appropriate antifreeze. Please refer to the table below for special torque requirements:... - Page 30 280 ± 20 Nm (207 ± 15 ft-lb) 540 ± 30 Nm (398 ± 22 ft-lb) G1-1/2A The hydraulic pipe fittings with Unified Thread Standard (UNC/UNF) thread must be installed with the following torques. AB10J Maintenance Manual © June 2024...

-

Page 31: Fastener Torque Specifications

100 Nm (74 ft-lb) 130 Nm (96 ft-lb) 155 Nm (114 ft-lb) 105 Nm (77 ft-lb) 135 Nm (100 ft-lb) 160 Nm (118 ft-lb) 1.25 150 Nm (110 ft-lb) 200 Nm (148 ft-lb) 230 Nm (170 ft-lb) © June 2024 AB10J Maintenance Manual... - Page 32 Table 3-16 Fastener torque specification – Unified Thread Standard bolts (UNF) Nominal Opposite nut size (s) Class 5 Class 8 diameter (in) 11.5 Nm (8 ft-lb) 16 Nm (11 ft-lb) 1/4-28 7/16" 23 Nm (17 ft-lb) 32 Nm (24 ft-lb) 5/16-24 1/2" © June 2024 AB10J Maintenance Manual...

-

Page 33: Hydraulic Hose Torque

260 ± 16 Nm (192 ± 12 ft-lb) M42 × 2 240 ± 15 Nm (177 ± 11 ft-lb) M45 × 2 250 ± 16 Nm (184 ± 12 ft-lb) 280 ± 18 Nm (207 ± 13 ft-lb) M52 × 2 © June 2024 AB10J Maintenance Manual... - Page 34 TECHNICAL CHARACTERISTICS This Page Intentionally Left Blank © June 2024 AB10J Maintenance Manual...

-

Page 35: Maintenance Instructions23

The frequency formed by a factory-trained service technician, a person of the inspection and maintenance must be increased recognized by Sinoboom as one who, by qualification, as required by environmental conditions, requirements certificate and training, has successfully demonstrated and frequency of usage. -

Page 36: Responsible Persons And Qualifica

1, 2 1, 2 1, 2 Axles/extending axles (if equipped) 1, 2, 3 1, 2, 3 1, 2, 3 Bearings 1, 2, 5, 12 1, 2, 5, 12 1, 2, 5, 12 Turntable assembly © June 2024 AB10J Maintenance Manual... - Page 37 Bleeding the oscillating cylinder (if NO.1 NO.1 NO.1 equipped) Hydraulic valves 1, 2, 5, 6 1, 2, 5, 6 1, 2, 5, 6 Counterbalance valve, check of the NO.1 NO.1 NO.1 locking function (if equipped) © June 2024 AB10J Maintenance Manual...

- Page 38 1, 3, 10 1, 3, 10 1, 3, 10 Drive brake Slewing brake 1, 3, 10 1, 3, 10 1, 3, 10 Other Operation Manual in the manuals compartment All decals/labels complete, clear and secure © June 2024 AB10J Maintenance Manual...

- Page 39 1, 2 1, 2 1, 2 and covers Greasing and lubricating according to specifications Functional test of all systems Paint and appearance Inspection date stamped on the chassis Notify Sinoboom of machine ownership (change) © June 2024 AB10J Maintenance Manual...

-

Page 40: General Maintenance

Operation Manual start up of the machine and tag the machine and this manual. accordingly. 2. All controls should be turned off to avoid accidental actuation of the control system. © June 2024 AB10J Maintenance Manual... - Page 41 7. High-strength bolts should be tightened in strict ac- cordance with the requirements of this manual. 8. Requirements for the acceptance of onsite machine installation work: © June 2024 AB10J Maintenance Manual...

- Page 42 Application of Insulating Silicone Grease to Electrical Connections Insulating silicone grease should be applied to all elec- trical connections for the purpose of: © June 2024 AB10J Maintenance Manual...

- Page 43 Do not mix petroleum-based oils with synthetic oils. © June 2024 AB10J Maintenance Manual...

-

Page 44: Major Modification And Repair

• Clean the bearing and pivot pin with a cleaning agent to remove all grease and oil. The compo- site bearing uses dry coupling which does not re- quire lubrication. © June 2024 AB10J Maintenance Manual... -

Page 45: Chassis And Turntable Assembly

See for details Travel Speed Reduction System 。 Fig. 1 Reverse position diagram Travel Speed Reduction System When the boom is in operating position, the travel speed of the machine is automatically limited to the operating travel speed. © June 2024 AB10J Maintenance Manual... -

Page 46: Chassis Oscillating System

Parts Manual of the corresponding machine. If you choose not to use the replacement tires recommended by Hunan Sinoboom Intelligent Equipment Co., Ltd., the following specifications should be adhered to: © June 2024... -

Page 47: Replace Tire And Wheel Assembly

Please refer to the recommended brand. torque settings in the table below. NOTICE Unless specifically approved by Sinoboom, do not replace foam-filled tires with pneumatic tires. Replace Tire and Wheel Assembly Tighten the wheel nuts to the specified torque to prevent the wheel from loosening. -

Page 48: Cap

3. Add oil as needed, until the oil is level with oil port 2. A Normal position - B Reverse position - engaged disengaged 4. Check the oil level in the other drive reducers by re- peating the above steps. © June 2024 AB10J Maintenance Manual... -

Page 49: Replace The Gear Oil In Drive

(as shown above). 5. After installation, fill appropriate amount of gear oil (refer to the Oil Specifications for the viscosity 2. Remove the oil plug from oil ports 1 and 2. grade). © June 2024 AB10J Maintenance Manual... -

Page 50: Slewing Mechanism

9. Connect the hydraulic hoses. chassis. The reducer drives the inner ring (worm gear) of the slewing bearing through the motor to achieve the rotation of the turntable. © June 2024 AB10J Maintenance Manual... -

Page 51: Lubricate Slewing Bearing

1. As shown in the figure below, connect the grease nipple on the slewing bearing and the nipple at posi- tion #1 using a hose. © June 2024 AB10J Maintenance Manual... -

Page 52: Check Slewing Bearing Bolts

(turntable counterweight). 7. Make sure that the feeler gauge does not penetrate under the bolt head to the bolt shaft. Fig. 10 Instruction for inserting a feeler gauge AB10J Maintenance Manual © June 2024... - Page 53 Fig. 11 Check Slewing Bearing Connecting Bolts (a) 1. Articulating boom fully lifted; 2. Main boom lifted to horizontal position; 3. Telescopic boom section fully extended; 4. Jib lifted to horizontal position; 5. Turntable rotated 90°; © June 2024 AB10J Maintenance Manual...

-

Page 54: Disassembly And Installation

Disassembling the slewing motor with a suitable container. Plug the lines and the ports. 1. Make sure the turntable is locked (lock the slewing pin if so equipped). © June 2024 AB10J Maintenance Manual... - Page 55 3. Check the clearance between the slewing bearing mounting surface and the chassis mounting surface with a feeler gauge, ensuring the clearance ≤ 0.2 mm (0.008 in). © June 2024 AB10J Maintenance Manual...

-

Page 56: Counterweight

3. Use suitable lifting equipment to support the counterweight. 4. Remove the bolts securing the counterweight to the turntable. 5. Slowly remove the counterweight by means of the lifting equipment. AB10J Maintenance Manual © June 2024... -

Page 57: Boom And Platform Assembly

The position of the jib is not taken into account. Fig. 1 Platform and Jib Structure © June 2024 AB10J Maintenance Manual... -

Page 58: Platform Controller

When disassembling the cylinder, use caution to prevent it from falling and getting damaged, and 6. Slowly remove the platform assembly with the aid of the lifting equipment. also to avoid impacts that could lead to high- pressure oil leaks. AB10J Maintenance Manual © June 2024... -

Page 59: Swing Cylinder

Plug the lines and the ports. 3. Support the swing cylinder with suitable lifting equipment. © June 2024 AB10J Maintenance Manual... -

Page 60: Boom

6. Remove the fastening bolts as indicated by the ar- rows above. 7. Take appropriate preventive measures and slowly remove the cable track assembly from the boom tube with the aid of the lifting equipment. AB10J Maintenance Manual © June 2024... - Page 61 4. Compare the measured thickness value of each wear pad with the value specified in the above table, and replace the wear pad assembly in time if the © June 2024 AB10J Maintenance Manual...

- Page 62 BOOM AND PLATFORM ASSEMBLY This Page Intentionally Left Blank AB10J Maintenance Manual © June 2024...

-

Page 63: Power System

Replace oil filter cartridge ☆ (oil pan depth: ★ ☆ 110 mm (4.33 in) type) 125 mm (4.92 in) 130 mm (5.12 in) Check radiator hoses and clamp ☆ bands Check the intake ☆ air line © June 2024 AB10J Maintenance Manual... - Page 64 As the engine owner, you are responsible for the performance of the required maintenance on the engine according to the above instruction. Fuel System Check the Fuel Level The fuel level can be checked from the energized turnta- ble or platform control panel. © June 2024 AB10J Maintenance Manual...

- Page 65 (5), and rinse the inside with kerosene. 5. Wipe the seal surface of the filter holder with clean, 4. Take out the element (4) and dip it in the kerosene non-fiber cloths. to rinse. © June 2024 AB10J Maintenance Manual...

- Page 66 After the fuel hose and the clamps have been changed, pump. bleed the fuel system. 5. If equipped with electrical fuel feed pump, turn the key on AC position and pump the fuel up for 10 to 15 seconds. AB10J Maintenance Manual © June 2024...

- Page 67 Fig. 8 Check the Coolant Level 1. Before changing the oil, warm up the engine so that the engine oil reaches approximately 80°C (176°F), 1. Turn off the engine. and then turn off the engine. © June 2024 AB10J Maintenance Manual...

- Page 68 2. Add correct coolant until the coolant level is even with the engine coolant supply port according to the Oil Specifications . Make sure that air bubbles do not develop as you add coolant. 3. Reinstall the radiator cap. AB10J Maintenance Manual © June 2024...

- Page 69 5. Tighten the clamp. It is recommended to replace the air cleaner element 6. Add correct coolant to the FULL mark according to every year or after 6 times of cleaning. the Oil Specifications . © June 2024 AB10J Maintenance Manual...

- Page 70 Check Fan Belt 3. Replace with a new fan belt. • Check the fan belt for damage. If the fan belt is damaged, replace it. 4. Install the alternator. 5. Check the fan belt tension. AB10J Maintenance Manual © June 2024...

-

Page 71: Auxiliary Power System

Besides, the auxiliary power system can also be utilized for override operation with an overloaded platform. © June 2024 AB10J Maintenance Manual... - Page 72 POWER SYSTEM This Page Intentionally Left Blank AB10J Maintenance Manual © June 2024...

-

Page 73: Hydraulic System

8. Hydraulic tank 9. Cycloid motor 10. Emergency power unit 11. Closed-circuit variable- 12. Open-circuit variable- displacement pump displacement pump 13. High-pressure filter 14. Telescoping counterbalance 15. Platform duplex valve manifold valve 16. Counterbalance valve © June 2024 AB10J Maintenance Manual... -

Page 74: Function Valves

Control the speed of main boom telescoping, 36.7 Nm (27 ft-lb) articulating boom lifting/lowering, platform leveling, 7–1 Solenoid valve steering, jib lifting up/down and platform rotating 36.7 Nm (27 ft-lb) Control the speed of main boom lifting/lowering 7–2 Solenoid valve © June 2024 AB10J Maintenance Manual... - Page 75 Limit the flow rate for platform leveling Flow valve Hydraulic lock 27.1 Nm (20 ft-lb) Lock the hydraulic oil circuit for platform leveling 25.8 – 28.5 Nm (19 – 21 ft- Control steering direction Solenoid valve © June 2024 AB10J Maintenance Manual...

- Page 76 33 – 35 Nm (24 – 26 ft-lb) Supply low-temperature hydraulic fluid Flush valve Damper 5 Nm (4 ft-lb) 12 – 15 Nm (9 – 11 ft-lb) Shuttle valve Switch between oil lines AB10J Maintenance Manual © June 2024...

- Page 77 Flow valve Control flow Damper 5 Nm (4 ft-lb) Oscillating Counterbalance Valve (PN.202040003891) Fig. 4 Table 8-4 Description Installation torque Function Counterbalance 40 - 45 Nm (29.5 - 33 ft-lb) Keep the load balanced valve © June 2024 AB10J Maintenance Manual...

- Page 78 HYDRAULIC SYSTEM Telescoping Counterbalance Valve (PN.202040003374) Fig. 5 Telescoping Counterbalance Valve (PN.202040003374) Table 8-5 Telescoping Counterbalance Valve (PN.202040003374) Description Installation torque Function Counterbalance Keep the load balanced valve Counterbalance Keep the load balanced valve O-ring AB10J Maintenance Manual © June 2024...

- Page 79 Table 8-6 Telescoping counterbalance valve (PN.202040003012) Description Installation torque Function Counterbalance 40 – 45 Nm (30 – 33 ft-lb) Keep the load balanced valve Counterbalance 45 – 50 Nm (33 – 37 ft-lb) Keep the load balanced valve O-ring © June 2024 AB10J Maintenance Manual...

- Page 80 Control the direction of platform rotation 1–1 Solenoid valve 40 – 45 Nm (30 – 33 ft-lb) Control the direction of jib up/down movement 1–2 Solenoid valve Damper 5 Nm (3.7 ft-lb) Damper 5 Nm (3.7 ft-lb) AB10J Maintenance Manual © June 2024...

- Page 81 Control the direction of platform rotation 1–1 Solenoid valve 40 – 45 Nm (30 – 33 ft-lb) Control the direction of jib up/down movement 1–2 Solenoid valve Damper 5 Nm (9 ft-lb) Damper 5 Nm (9 ft-lb) © June 2024 AB10J Maintenance Manual...

- Page 82 Leveling Counterbalance Valve (PN.202040000011) Fig. 10 Leveling Counterbalance Valve (PN.202040000011) Table 8-10 Leveling Counterbalance Valve (PN.202040000011) Description Installation torque Function Counterbalance 70 – 75 Nm (52 – 55 ft-lb) Keep the load balanced valve AB10J Maintenance Manual © June 2024...

-

Page 83: Valve (Pn.202040003136)

Bidirectional Counterbalance Valve (PN.202040003136) Fig. 11 Table 8-11 Description Installation torque Function Counterbalance 34 – 41 Nm (25 – 30 ft-lb) Keep the load balanced valve Plug 11 - 12 Nm (8 - 9 ft-lb) © June 2024 AB10J Maintenance Manual... - Page 84 45 – 50 Nm (33 – 37 ft-lb) Limit the maximum pressure for oscillating system valve Damper 5 Nm (9 ft-lb) 40 – 45 Nm (30 – 33 ft-lb) Keep oil flowing in one direction Check valve © June 2024 AB10J Maintenance Manual...

- Page 85 33.9 Nm (25 ft-lb) Control pressure of brake and high/low speed valve Damper 27.1 Nm (20 ft-lb) Control braking 3–1 Solenoid valve 27.1 Nm (20 ft-lb) Control high-low speed switching 3–2 Solenoid valve Damper Damper Damper © June 2024 AB10J Maintenance Manual...

-

Page 86: Hydraulic Oil

Description 3. Close the hydraulic shut-off valve located on the side of the tank. Oil return filter 4. Place a suitable container under the drain plug at Air filter the bottom of the tank. AB10J Maintenance Manual © June 2024... -

Page 87: Air Filter

7. Clean the hydraulic oil spilled during the process. 2. Place a beveled wooden block with the height of 8. Start the machine from the ground. 100 mm (3.9 in) in front of the machine. © June 2024 AB10J Maintenance Manual... -

Page 88: Oscillating Function Check

8. If the oscillating cylinder does not work properly have qualified maintenance personnel rectify the is- sue before you continue to operate the machine. Fig. 15 Diagram - Cylinder and Grease Nipple AB10J Maintenance Manual © June 2024... -

Page 89: Cylinder Drift Inspection

图 样 标 记 重 量 比 例 17.4787 3-position 4-way 101048050002 审 核 银友国 工 艺 共 页 第 页 刘奇志 日 期 2018.10.25 solenoid directional 100/3.94 0.39/0.015 34.4087 valve 46.7096 32.0000 34.4087 © June 2024 AB10J Maintenance Manual 16.0000 32.0000 16.0000... - Page 90 46.7096 Table 8-16 (continued) 28.5682 17.4787 Symbols Description 32.0000 46.7096 2-position 4-way 28.5682 34.4087 solenoid directional 16.0000 valve 棕 兰 黑 32.0000 28.5682 Priority valve 16.0000 17.4787 Check valve 46.7096 34.4087 32.0000 28.5682 16.0000 AB10J Maintenance Manual © June 2024...

-

Page 91: Hydraulic Schematic Diagram

HYDRAULIC SYSTEM 8.11 HYDRAULIC SCHEMATIC DIAGRAM Fig. 16 Hydraulic Schematic Diagram © June 2024 AB10J Maintenance Manual... - Page 92 HYDRAULIC SYSTEM This Page Intentionally Left Blank AB10J Maintenance Manual © June 2024...

-

Page 93: Electrical System

Improper connection may result in reduced per- decrease of 5 °C (40 °F). formance and damaged terminals, melting, or even fire. – Result 1: if the specific gravity reading of all battery cells is 1.250 or higher, and the © June 2024 AB10J Maintenance Manual... -

Page 94: Add Fluid

If excess deionized water has been added, suck it out. • If excess deionized water has been added and electrolyte overflows result, dilute the electrolyte overflows with clear water and suck it dry with a straw. © June 2024 AB10J Maintenance Manual... - Page 95 Fig. 4 Red rotating wheel 6. After the white buoy on the automatic water refilling valve floats up to the top, stop the water refilling de- vice to complete water refilling. © June 2024 AB10J Maintenance Manual...

- Page 96 4. After the white buoy on the automatic water refilling joint and female joint of water refilling bucket and valve floats up to the top, water refilling has been automatic water refilling system for automatic water completed. AB10J Maintenance Manual © June 2024...

-

Page 97: Equalization

12 V 1.277 2.122 6.37 12.73 1.258 2.103 6.31 12.62 1.238 2.083 6.25 12.50 1.217 2.062 6.19 12.37 1.195 2.040 6.12 12.24 1.172 2.017 6.05 12.10 1.148 1.993 5.98 11.96 1.124 1.969 5.91 11.81 © June 2024 AB10J Maintenance Manual... -

Page 98: Electrical Symbols

Do not store the battery longer than 6 months in Lithium battery hot or cold environments. 9.2 ELECTRICAL SYMBOLS Table 9-8 Toggle switch Symbols Description Buzzer Level switch Valve θ Oil temperature switch θ Two lines connected θ AB10J Maintenance Manual © June 2024 θ... - Page 99 Delay relay θ Fuel level sensor Power-off switch θ Horn Relay Key switch Warning light Preheating wire Valve Two lines not connected 棕 兰 Proximity switch pressure sensor 黑 28.5682 46.7096 28.5682 棕 兰 黑 © June 2024 AB10J Maintenance Manual...

-

Page 100: Electrical Schematic Diagram

DT224 XJ1-13/14 XJ1-3/4 C211 PWM_OUT_40 2414 DT223 XJ1-17/18 XJ1-1/2 C212 PWM_OUT_46 XJ1-15/16 PWM/OUT_45 XJ1-19/20 XJ1-11/12 OUT_24 XJ1-9/10 IN_48 OUT_23 CGNDS XJ1-7/8 IN_49 OUT_26 XJ1-5/6 2491 IN_50 OUT_25 Fig. 10 Electrical Schematic Diagram – Turntable AB10J Maintenance Manual © June 2024... - Page 101 V(C)_IN_59 PWM_OUT_38 1416 DT101 1043 V(C)_IN_60 PWM_OUT_39 1044 V(C)_IN_56 PWM_OUT_40 IN_47 OUT_24 HR102 1404 WS101 WS102 IN_48 OUT_23 IN_49 OUT_26 IN_50 OUT_25 HG101 1056 WL101 SH117 SBE101 Fig. 11 Electrical Schematic Diagram – Platform © June 2024 AB10J Maintenance Manual...

- Page 102 ELECTRICAL SYSTEM This Page Intentionally Left Blank AB10J Maintenance Manual © June 2024...

-

Page 103: Troubleshooting Guide

Jib rotate joystick data error CAN communication between the turntable and error platform Hydraulic system Check the hydraulic system pressure sensor and Hydraulic system pressure pressure sensor its wiring harness for proper function sensor error error © June 2024 AB10J Maintenance Manual... - Page 104 Check the wiring of the articulating boom lift Articulating boom lift Articulating boom lift solenoid solenoid valve, and check the solenoid valve solenoid valve fault valve fault © June 2024 AB10J Maintenance Manual...

- Page 105 Check the wiring of the articulating boom angle angle sensor fault sensor fault sensor Main boom angle Main boom angle sensor Check whether the main boom angle sensor is sensor comparison comparison error correctly installed error © June 2024 AB10J Maintenance Manual...

-

Page 106: Engine Fault Codes

Electrical failure Check whether the platform controller plug or the plug of the connecting cable between the platform controller and the turntable controller are in good contact Check whether the platform controller is malfunctioning AB10J Maintenance Manual © June 2024... - Page 107 (non-integrated slewing bearing) Check whether the circuit and the control program have Electrical failure any abnormalities Turntable rotating Insufficiently lubricated abnormally to the left/ slewing bearing or slewing Lubricate as needed right reducer © June 2024 AB10J Maintenance Manual...

- Page 108 Check whether the sensor is not calibrated Weight sensor not calibrated Check whether the wiring of the weighing sensor is No overload warning for rated load or calibrated incorrect with wrong lift height Check whether the sensor has any abnormalities AB10J Maintenance Manual © June 2024...

- Page 109 Inspect if the brake and two-speed valve element has normally but has seizure trouble with climbing a slope High-speed control pipe has Inspect if the damper of the brake and two-speed valve abnormal pressure relief element has clogging © June 2024 AB10J Maintenance Manual...

- Page 110 Check the engine oil level Abnormal engine oil, coolant Check the coolant level and coolant temperature switch Starting battery damaged or Inspect the battery voltage low battery level or insufficient Replace the starting battery cold starting current AB10J Maintenance Manual © June 2024...

- Page 111 TROUBLESHOOTING GUIDE Table 10-4 Engine Troubleshooting (continued) Fault Cause Solution Inspect the harness connector Electrical harness with poor Inspect the wiring circuit contact or abnormal wiring Re-plug the harness connector © June 2024 AB10J Maintenance Manual...

- Page 112 TROUBLESHOOTING GUIDE This Page Intentionally Left Blank AB10J Maintenance Manual © June 2024...

-

Page 113: Functions And Controls

5. Move the high/low engine speed selector switch at the platform controller upwards to switch the travel the platform control box to switch the engine speed speed to high speed. to high speed (if equipped with an engine). © June 2024 AB10J Maintenance Manual... -

Page 114: Tilt Protection Function

4.5°. At this point, the tilt alarm should be triggered, months or after 250 hours of operation. the chassis tilt indicator light should flash, and cer- tain functions should be restricted. The main boom may be retracted, the articulating boom may be © June 2024 AB10J Maintenance Manual... - Page 115 (if equipped) can lift and lower, the plat- form can be leveled manually within ±10°, the turntable can slew slowly, and the main boom © June 2024 AB10J Maintenance Manual...

- Page 116 FUNCTIONS AND CONTROLS This Page Intentionally Left Blank AB10J Maintenance Manual © June 2024...

-

Page 117: Control System

Therefore, persons who have not been professionally undergone professional training by Sinoboom. trained and authorized by Sinoboom may not Not meeting this requirement bears significant disassemble the respective housings, otherwise risk. - Page 118 Digital Input Info System Info Digital Output Info Proportional Valve EAT Info Engine Info Engine Fault Diagnoses Turntable Info Turntable Panel Info Platform Panel Info-Input Platform Panel Info-Output Platform Info Alarm Info Alarm Info Fault Info AB10J Maintenance Manual © June 2024...

-

Page 119: Main Interface After Booting

ON position, and turn the key switch to the ON position, and the system will be powered on. Fig. 2 Main Interface after Booting © June 2024 AB10J Maintenance Manual... -

Page 120: Description Of Icon Functions

Press and hold the icon for 3s to save the current page parameters Left arrow key and return to the previous menu /Press the icon to directly return to the previous menu Up/Down arrow key AB10J Maintenance Manual © June 2024... -

Page 121: Language Setting

12.5 TEST-RUN INFORMATION 1. Press on the main interface to enter CONFIGU- RATION interface. 2. According to the display interface navigation dia- gram, enter TEST-RUN INFO interface by pressing © June 2024 AB10J Maintenance Manual... -

Page 122: Weight Calibration

2. Enter the TEST-RUN INFO interface. 3. On the TEST-RUN INFO interface, press until Weight Calibration is displayed, and press to enter the WEIGHT CALIBRATION interface. AB10J Maintenance Manual © June 2024... -

Page 123: Advanced Setting

12.6 ADVANCED SETTING Personnel who have not been professionally trained and authorized by Sinoboom are not allowed to modify the advanced setting (including sensor configuration, turntable enable, Fig. 12 SENSOR CONFIGURATION interface standardization, proportional configuration, parameter restore/save and reserved setting);... -

Page 124: Standardization

3s to confirm the setting striction (WCS) option by pressing , and press (there will be the icon before the selected option after successful setting). and hold for 3s to confirm the setting. There will © June 2024 AB10J Maintenance Manual... -

Page 125: Proportional Configuration

PROPOR. CONFIG 4 interface. Fig. 15 PROPOR. CONFIG 1 interface 2. On the PROPOR. CONFIG 1 interface, press to select the parameter to be adjusted (the © June 2024 AB10J Maintenance Manual... - Page 126 Condition of fully raising: up limit switch is triggered or the (Up) main boom is positioned at an angle bigger than the set value. MB Telescope To set the time and speed proportion of main boom when Detection (Extend) fully extended. AB10J Maintenance Manual © June 2024...

- Page 127 Swing RPM (MB Condition: the retracting limit switch disengages or the Extend) main boom is longer than 1.2m. Telescope Velocity To set the extending/retracting speed with the main boom (maximum angle) at the max angle. © June 2024 AB10J Maintenance Manual...

-

Page 128: Parameter Restore/Save

Working time reset: used to clear the total working be the icon at the top of the interface). time (after clearing, the total working time is about 36.5h). Please use this function with caution. AB10J Maintenance Manual © June 2024... -

Page 129: Sensor Information

Fig. 23 SENSOR INFO 2 indicates that no output is detected), thus assisting in determining the trouble causes. • The configuration of output points is subject to the actual machine configuration. © June 2024 AB10J Maintenance Manual... -

Page 130: Proportional Information

1) If the machine does not need EAT, the status in- dicator will be off. • The configuration of proportional valves is subject to the actual machine configuration. Fig. 30 EAT INFO interface (without requiring EAT)-Equipped with Deutz engine Fig. 28 PROPORTIONAL INFO interface AB10J Maintenance Manual © June 2024... - Page 131 SCR system is faulted DEF level is normal DEF level indicator light Solid DEF level is too low Standstill regeneration is not performed or requested Standstill regeneration indica- tor light Solid Standstill regeneration is being performed © June 2024 AB10J Maintenance Manual...

- Page 132 Exhaust system is at normal temperature High exhaust temperature in- dicator light Solid Exhaust system temperature exceeds the set limit Regeneration execution is inactive Regeneration execution indi- Solid cator light Regeneration function is being executed © June 2024 AB10J Maintenance Manual...

-

Page 133: Turntable Panel Information

FORM PANEL INFO interface to check the input • The turntable panel information option is mainly used status of switches on the platform control panel (the to query the input status of switches on the turntable © June 2024 AB10J Maintenance Manual... -

Page 134: Alarm Information

Fig. 39 ALARM INFO interface 2. On the ALARM INFO interface, press to enter FAULT INFO interface. © June 2024 AB10J Maintenance Manual... - Page 135 Battery BMS Fault Codes section in the Main- tenance Manual (if the machine is equipped with any lithium battery). 5. Press successively to return to the main inter- face, and power off the machine as required. © June 2024 AB10J Maintenance Manual...

- Page 136 CONTROL SYSTEM This Page Intentionally Left Blank © June 2024 AB10J Maintenance Manual...

-

Page 137: Appendix

APPENDIX 13.1 MAJOR MODIFICATION AND REPAIR RECORD Major Modification and Repair Record Model Serial No. Machine Status Modified/Repaired Item Date Technician after Change © June 2024 AB10J Maintenance Manual... -

Page 138: Inspection And Preventive

1, 2, 6 1, 2, 6 1, 2, 6, 11 Central rotary joint Slewing motor 1, 6 1, 6 1, 6 Turntable slewing pin (if equipped) 1, 2, 3 1, 2, 3 1, 2, 3 © June 2024 AB10J Maintenance Manual... - Page 139 1, 5, 6, 11 Hydraulic tank return filter 1, 5, 6, 11 1, 5, 6, 11 1, 5, 6, 11 Hydraulic tank air filter 1, 5, 6 1, 5, 6, 11 1, 5, 6, 11 © June 2024 AB10J Maintenance Manual...

- Page 140 Operation Manual in the manuals compartment All decals/labels complete, clear and secure Annual inspection date of the machine No unapproved changes or additions All safety publications taken into account General structural components and weldments © June 2024 AB10J Maintenance Manual...

- Page 141 Functional test of all systems Paint and appearance Inspection date stamped on the chassis Notify Sinoboom of machine ownership (change) Note: Before each sale, lease or shipment delivery; In service for 3 months or 250 hours; or out of service for more than 3 months;...

- Page 142 APPENDIX This Page Intentionally Left Blank © June 2024 AB10J Maintenance Manual...

- Page 143 Always for Better Access Solutions Hunan Sinoboom Intelligent Equipment Co., Ltd. AS/N ZS 长沙市宁乡高新技术产业园区金洲大道东 128 号 No.128, East Jinzhou Avenue, Ningxiang High-tech Industrial Park, Changsha, Hunan, China 市宁乡高新技术产业园区金洲大道东 128 号 0086-0731-87116222 (Sales) & 0086-0731-87116333 (Service) . com . cn w .sinoboom. com . cn 金洲大道东...

Need help?

Do you have a question about the AB10J and is the answer not in the manual?

Questions and answers