Table of Contents

Advertisement

TopPage

[1] SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

[2] EXTERNAL VIEW AND INTERNAL STRUCTURE . . . . . . . . . . . . . 2-1

[3] ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

[4] MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

[5] DISASSEMBLY AND ASSEMBLY. . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

[6] OPERATIONAL DESCRIPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

[7] ELECTRICAL SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Parts marked with "

" are important for maintaining the safety of the set. Be sure to replace these parts with

specified ones for maintaining the safety and performance of the set.

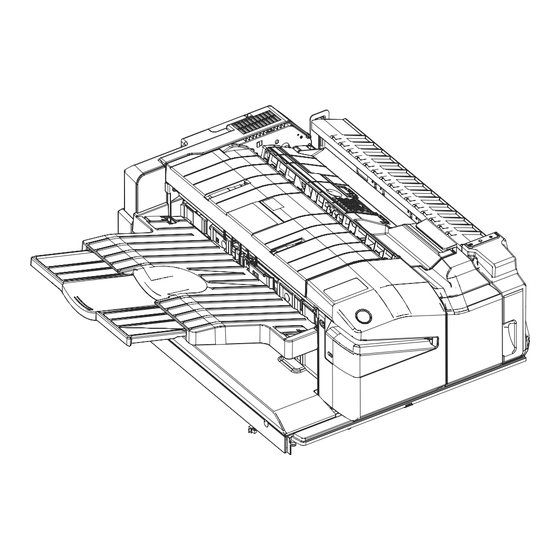

SERVICE MANUAL

DIGITAL MULTIFUNCTIONAL

SYSTEM OPTION

FINISHER

PUNCH UNIT

MODEL

CONTENTS

SHARP CORPORATION

CODE: 00ZMXFN27/S2E

MX-FN27

MX-PN14

This document has been published to be used

for after sales service only.

The contents are subject to change without notice.

Advertisement

Table of Contents

Need help?

Do you have a question about the MX-FN27 and is the answer not in the manual?

Questions and answers