Summary of Contents for Omron R88D-KNA5L-ML2

- Page 1 Cat. No. I572-E2-02 Accurax G5 servo system with built-in MECHATROLINK-II Model: R88D-KN_-ML2 Servo Drives R88M-K_ Servomotors USER’S MANUAL WWW.BSNEW.IR...

- Page 2 WWW.BSNEW.IR...

- Page 3 Introduction Introduction Thank you for purchasing the Accurax G5 Series. This user's manual explains how to install and wire the Accurax G5 Series, set parameters needed to operate the G5 Series, and remedies to be taken and inspection methods to be used should problems occur. Intended Readers This manual is intended for the following individuals.

- Page 4 Failure that could not be predicted with the level of science and technology available when the product was shipped from OMRON f) Failure caused by a natural disaster or any other reason for which OMRON is not held responsible Take note that this warranty applies to the product itself, and losses induced by a failure of the product are excluded from the scope of warranty.

- Page 5 5. Scope of Service The price of this product excludes costs of service such as dispatching engineers. If you have any request regarding service, consult your OMRON sales representative. OMNUC G5-Series AC Servo Drives Users Manual (Built-in MECHATROLINK-II communications type)

-

Page 6: Safety Precautions Document

Safety Precautions Document Safety Precautions Document So that the Accurax G5-Series Servomotor and Servo Drive and peripheral equipment are used safely and correctly, be sure to peruse this Safety Precautions document section and the main text before using the product in order to learn all items you should know regarding the equipment as well as all safety information and precautions. - Page 7 When using this product, be sure to install the covers and shields as specified and use the product according to this manual. If the product has been stored for an extended period of time, contact your OMRON sales representative. Danger Be sure to ground the frame ground terminals of the Servo Drive and motor to 100 Ω...

- Page 8 Safety Precautions Document Danger Do not place flammable materials near the motor, Servo Drive or Regeneration Resistor. Fire may result. Install the motor, Servo Drive and Regeneration Resistor to non-flammable materials such as metals. Fire may result. When you perform a system configuration using the safety function, be sure to fully understand the relevant safety standards and the descriptions in the operation manual, and apply them to the system design.

- Page 9 Safety Precautions Document Storage and Transportation Caution When transporting the product, do not hold it by the cables or motor shaft. Injury or failure may result. Do not overload the products. (Follow the instruction on the product label.) Injury or failure may result. Use the motor eye-bolts only when transporting the motor.

- Page 10 Safety Precautions Document Installation and Wiring Caution Do not step on the product or place heavy articles on it. Injury may result. Do not block the intake or exhaust openings. Do not allow foreign objects to enter the product. Fire may result. Be sure to observe the mounting direction.

- Page 11 Safety Precautions Document Operation and Adjustment Caution Conduct a test operation after confirming that the equipment is not affected. Equipment damage may result. Before operating the product in an actual environment, check if it operates correctly based on the parameters you have set. Equipment damage may result.

- Page 12 Safety Precautions Document Location of Warning Label This product bears a warning label at the following location to provide handling warnings. When handling the product, be sure to observe the instructions provided on this label. Warning label display location (R88D-KN02H-ML2) Instructions on Warning Label Disposal When disposing of the battery, insulate it using tape, etc.

-

Page 13: Items To Check After Unpacking

Connectors, mounting screws, etc. other than those in the table below are not supplied. They must be prepared by the customer. If any item is missing or a problem is found such as Servo Drive damage, contact the OMRON dealer or sales office where you purchased your product. -

Page 14: Manual Revision History

Manual Revision History Manual Revision History The manual revision symbol is an alphabet appended at the end of the manual number found in the bottom left-hand corner of the front or back cover. Example I572-E2-01 Revision Revision date Description of revision and revised page symbol March 2009 First print... -

Page 15: Structure Of This Document

Structure of This Document Structure of This Document This manual consists of the following chapters. Read the necessary chapter or chapters referring to below. Outline Features and This chapter explains the features of this product, name of each part, Chapter 1 System and applicable EC directives and UL standards. -

Page 16: Table Of Contents

Table Of Contents Introduction ....................1 Items Requiring Acknowledgment ............2 Safety Precautions Document ...............4 Items to Check after Unpacking ............11 Manual Revision History ..............12 Structure of This Document ..............13 Chapter1 Features and System Configuration Outline ....................1-1 Outline of the OMNUC G5 Series ................1-1 Features of the OMNUC G5 Series ................1-1 System Configuration ................ - Page 17 Table Of Contents Control I/O Connector Specifications (CN1) .............. 3-13 Control Input Circuits ....................3-15 Control Input Details ....................3-16 Control Output Circuits ....................3-18 Control Output Details ....................3-19 Encoder Connector Specifications (CN2) ..............3-23 External Encoder Connector Specifications (CN4)............ 3-23 Monitor Connector Specifications (CN5) ..............

- Page 18 Table Of Contents Chapter5 BASIC CONTROL Mode Position Control ..................5-1 Parameters Requiring Settings ..................5-1 Related Functions ......................5-2 Parameter Block Diagram for POSITION CONTROL mode ........5-3 Speed Control ..................5-4 Parameters Requiring Settings ..................5-4 Related Functions ......................5-4 Parameter Block Diagram for SPEED CONTROL mode ..........5-5 Torque Control ..................

- Page 19 Table Of Contents 6-10 Gain Switching 3 Function..............6-36 Operating Conditions ....................6-36 Parameters Requiring Settings.................. 6-36 Operation Example ....................6-37 Chapter7 Safety Function Safe Torque OFF (STO) Function ............7-1 Functional Safety ......................7-1 I/O Signal Specifications....................7-2 Operation Example.................7-4 Connection Examples................7-6 Chapter8 Parameters Details Basic Parameters ...................8-1 Gain Parameters ..................8-8...

- Page 20 Table Of Contents Basic Settings ......................10-13 10-5 Damping Control ................10-21 Outline of Operation ....................10-21 Parameters Requiring Settings ................10-22 10-6 Adaptive Filter ................... 10-25 Parameters Requiring Settings ................10-26 Operating Procedure ....................10-27 10-7 Notch Filter ..................10-28 Parameters Requiring Settings ................10-29 10-8 Disturbance Observer Function ............

- Page 21 Table Of Contents Appendix Parameter List ..................A-1 Index OMNUC G5-Series AC Servo Drives Users Manual (Built-in MECHATROLINK-II communications type) WWW.BSNEW.IR...

- Page 22 WWW.BSNEW.IR...

- Page 23 Features and System Configuration This chapter explains the features of this product, name of each part, and applicable EC directives and UL standards. 1-1 Outline ................1-1 1-2 System Configuration ..........1-3 1-3 Names and Functions ..........1-4 1-4 System Block Diagrams..........1-6 1-5 Applicable Standards ..........1-11 OMNUC G5-Series AC Servo Drives Users Manual (Built-in MECHATROLINK-II communications type) WWW.BSNEW.IR...

-

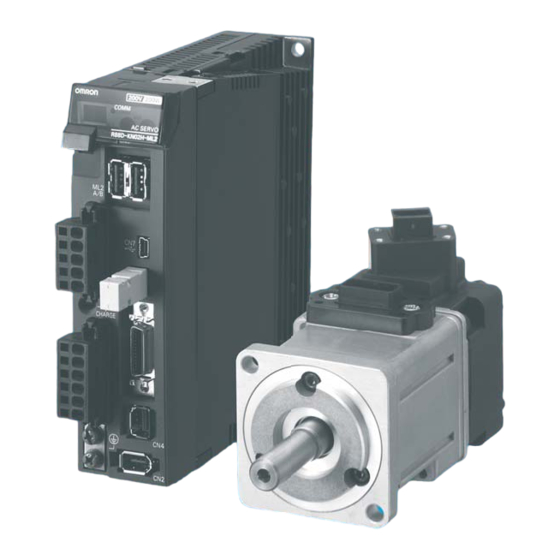

Page 24: Outline

1-1 Outline 1-1 Outline Outline of the Accurax G5 Series The Accurax G5-Series AC Servo Drives (Built-in MECHATROLINK-II communications support type) are a series of Servo Drives supporting the MECHATROLINK-II high-speed motion field network. When you use it with the MECHATROLINK-II Position Control Unit (CJ1W-NCF71, CS1W- NCF71, CJ1W-MCH72 or other), you can create a sophisticated positioning control system. - Page 25 1-1 Outline Two damping filters are provided to enable switching the damping frequency automatically according to the rotation direction and also via an external signal. In addition, the settings can be made easily merely by just setting the damping frequency and filter values, and you are assured of stable operation even if the set values are inappropriate.

-

Page 26: System Configuration

1-2 System Configuration 1-2 System Configuration OMNUC G5-Series AC Servo Drives Users Manual (Built-in MECHATROLINK-II communications type) WWW.BSNEW.IR... -

Page 27: Names And Functions

1-3 Names and Functions 1-3 Names and Functions This section describes the name and functions of the Servo Drive. Servo Drive Part Names The Servo Drive Part Names are defined as shown below. MECHATROLINK-II status LED indicator Display area Analog monitor connector (CN5) Rotary switches for node address setting MECHATROLINK-II... -

Page 28: Servo Drive Functions

1-3 Names and Functions Servo Drive Functions The functions of each part are the followings: Display Area A 2-digit 7-segment LED indicator shows the node address, alarm codes, and other Servo Drive status. Charge Lamp Lits when the main circuit power supply is turned ON. MECHATROLINK-II Status LED Indicator Indicates the communications status of the MECHATROLINK-II. -

Page 29: System Block Diagrams

1-4 System Block Diagrams 1-4 System Block Diagrams Size A: R88D-KNA5L/-01L/-01H/-02H-ML2 Size B: R88D-KN02L/-04H-ML2 Size C: R88D-KN04L/-08H-ML2 − − ± • OMNUC G5-Series AC Servo Drives Users Manual (Built-in MECHATROLINK-II communications type) WWW.BSNEW.IR... -

Page 30: System Block Diagrams

1-4 System Block Diagrams Size D: R88D-KN10H/-15H-ML2 − − ± • OMNUC G5-Series AC Servo Drives Users Manual (Built-in MECHATROLINK-II communications type) WWW.BSNEW.IR... - Page 31 1-4 System Block Diagrams Size D: R88D-KN06F/-10F/-15F-ML2 CN D CN A FUSE Internal Regen Resistor FUSE Fuse (not installed) CN B − CN C Voltage detection FUSE DC-DC − − SW power 15 V Relay Overcurrent Regeneration Current detection supply main Gate drive drive control...

- Page 32 1-4 System Block Diagrams Size E: R88D-KN20H-ML2 Size F: R88D-KN30H/-50H-ML2 CN C CN A FUSE Internal Regen Resistor Fuse (not installed) FUSE − CN B Voltage detection FUSE − SW power 15 V Relay Regeneration Overcurrent G G G R R R Current detection supply main Gate drive...

- Page 33 1-4 System Block Diagrams Size E: R88D-KN20F-ML2 Size F: R88D-KN30F/-50F-ML2 CN D CN A FUSE Internal Regen Resistor FUSE Fuse (not installed) CN B − CN C Voltage detection FUSE DC-DC − − SW power 15 V Relay Regeneration Overcurrent Current detection supply main Gate drive...

-

Page 34: Applicable Standards

1-5 Applicable Standards 1-5 Applicable Standards This section describes applicable EMC Directives. EC Directives Product Applicable standards directive Low voltage AC Servo Drive EN 61800-5-1 command AC Servomotor EN60034-1/-5 AC Servo Drive EN 55011 class A group 1 directives AC Servomotor IEC61800-3 EN61000-6-2 Note. - Page 35 Standard Models and External Dimensions Accurax This chapter explains the models of Servo Drive, Servomotor, and peripheral equipment, as well as the external dimensions and mounting dimensions. 2-1 Servo System Configuration ........2-1 2-2 How to Read Model............2-3 2-3 Standard Model List .............2-5 2-4 External and Mounting Dimensions......2-21 2-5 EMC Filter Dimensions..........2-52 OMNUC G5-Series AC Servo Drives Users Manual (Built-in MECHATROLINK-II communications type)

-

Page 36: Servo System Configuration

2-1 Servo System Configuration 2-1 Servo System Configuration OMNUC G5-Series AC Servo Drives Users Manual (Built-in MECHATROLINK-II communications type) WWW.BSNEW.IR... - Page 37 2-1 Servo System Configuration • • ML 2 ML 2 • • “ ” OMNUC G5-Series AC Servo Drives Users Manual (Built-in MECHATROLINK-II communications type) WWW.BSNEW.IR...

-

Page 38: How To Read Model

2-2 How to Read Model 2-2 How to Read Model This section describes how to read and understand the model numbers for Servo Drives and Servomotors. Servo Drive The Servo Drive model can be identified by the Servo Drive type, applicable Servomotor capacity, power supply voltage, etc. -

Page 39: Servomotor

2-2 How to Read Model Servomotor The model number provides information such as the Servomotor type, applicable motor capacity, rated rotation speed, and power supply voltage. OMNUC G5-Series AC Servo Drives Users Manual (Built-in MECHATROLINK-II communications type) WWW.BSNEW.IR... -

Page 40: Standard Model List

This section lists the standard models of Servo Drives, Servomotors, Cables, Connectors, and peripheral equipment. Servo Drive Model List The table below lists the Servo Drive models. Specifications Model Single-phase 100 VAC 50 W R88D-KNA5L-ML2 100 W R88D-KN01L-ML2 200 W R88D-KN02L-ML2 400 W R88D-KN04L-ML2 Single-phase/3-phase 200 VAC... -

Page 41: Servomotor Model List

2-3 Standard Model List Servomotor Model List The table below lists the Servomotor models by rated number of motor rotations. 3,000-r/min Servomotors Model With incremental encoder With absolute encoder Specifications Straight shaft Straight shaft Straight shaft Straight shaft without key with key and tap without key with key and tap... - Page 42 2-3 Standard Model List Model With incremental encoder With absolute encoder Specifications Straight shaft Straight shaft Straight shaft Straight shaft without key with key and tap without key with key and tap 50 W R88M-K05030L-B R88M-K05030L-BS2 R88M-K05030S-B R88M-K05030S-BS2 100 W R88M-K10030L-B R88M-K10030L-BS2 R88M-K10030S-B R88M-K10030S-BS2...

- Page 43 2-3 Standard Model List 2,000-r/min Servomotors Model With incremental encoder With absolute encoder Specifications Straight shaft Straight shaft Straight shaft Straight shaft without key with key and tap without key with key and tap 1 kW R88M-K1K020H R88M-K1K020H-S2 R88M-K1K020T R88M-K1K020T-S2 1.5 kW R88M-K1K520H R88M-K1K520H-S2 R88M-K1K520T...

- Page 44 2-3 Standard Model List 1,000-r/min Servomotors Model With incremental encoder With absolute encoder Specifications Straight shaft Straight shaft Straight shaft Straight shaft without key with key and tap without key with key and tap 900 kW R88M-K90010H R88M-K90010H-S2 R88M-K90010T R88M-K90010T-S2 200 V 2 kW R88M-K2K010H R88M-K2K010H-S2...

-

Page 45: Servo Drive And Servomotor Combination List

3,000-r/min Servomotors and Servo Drives Servomotor Voltage Servo Drive Rated With incremental With absolute output encoder encoder 50 W R88M-K05030L-x R88M-K05030S-x R88D-KNA5L-ML2 100 W R88M-K10030L-x R88M-K10030S-x R88D-KN01L-ML2 Single-phase 100 V 200 W R88M-K20030L-x R88M-K20030S-x R88D-KN02L-ML2 400 W R88M-K40030L-x R88M-K40030S-x... - Page 46 2-3 Standard Model List 2,000-r/min Servomotors and Servo Drives Servomotor Voltage Servo Drive Rated With incremental With absolute output encoder encoder 1 kW R88M-K1K020H-x R88M-K1K020T-x R88D-KN10H-ML2 Single-phase/ 3-phase 200 V 1.5 kW R88M-K1K520H-x R88M-K1K520T-x R88D-KN15H-ML2 2 kW R88M-K2K020H-x R88M-K2K020T-x R88D-KN20H-ML2 3 kW R88M-K3K020H-x R88M-K3K020T-x...

-

Page 47: Cables And Peripheral Devices Model List

2-3 Standard Model List Cables and Peripheral Devices Model List The table below lists the models of cables and peripheral devices. The cable include encoder cables, motor power cables, MECHATROLINK-II communications cables, and absolute encoder battery cables. The peripheral devices include External Regeneration Resistors. Encoder Cables (European Flexible Cables) Specifications Model... - Page 48 2-3 Standard Model List Motor Power Cables (European Flexible Cables) Model Specifications For motor without For motor with brake brake [100 V and 200 V] 1.5 m R88A-CAKA001-5SR-E For 3,000-r/min motors of 50 to 750 W It requires both, the R88A-CAKA003SR-E power cable R88A-- R88A-CAKA005SR-E...

- Page 49 2-3 Standard Model List Brake Cables (European Flexible Cables) Specifications Model [100 V and 200 V] 1.5 m R88A-CAKA001-5BR-E For 3,000-r/min motors of 50 to 750 W R88A-CAKA003BR-E R88A-CAKA005BR-E 10 m R88A-CAKA010BR-E 15 m R88A-CAKA015BR-E 20 m R88A-CAKA020BR-E Encoder Cables (Japanese Non-Flexible Cables) Specifications Model [100 V and 200 V]...

- Page 50 2-3 Standard Model List Motor Power Cables (Japanese Non-Flexible Cables) Model Specifications For motor without For motor with brake brake [100 V and 200 V] R88A-CAKA003S For 3,000-r/min motors of 50 to 750 W R88A-CAKA005S 10 m R88A-CAKA010S It requires both, the power cable R88A-- 15 m R88A-CAKA015S...

- Page 51 2-3 Standard Model List Brake Cables (Japanese Non-Flexible Cables) Specifications Model [100 V and 200 V] R88A-CAKA003B For 3,000-r/min motors of 50 to 750 W R88A-CAKA005B 10 m R88A-CAKA010B 15 m R88A-CAKA015B 20 m R88A-CAKA020B 30 m R88A-CAKA030B 40 m R88A-CAKA040B 50 m R88A-CAKA050B...

- Page 52 2-3 Standard Model List Motor Power Cables (Japanese Flexible Cables) Model Specifications For motor without For motor with brake brake [100 V and 200 V] R88A-CAKA003SR For 3,000-r/min motors of 50 to 750 W R88A-CAKA005SR 10 m R88A-CAKA010SR It requires both, the power cable R88A-- 15 m R88A-CAKA015SR...

- Page 53 2-3 Standard Model List Brake Cables (Japanese Flexible Cables) Specifications Model [100 V and 200 V] R88A-CAKA003BR For 3,000-r/min motors of 50 to 750 W R88A-CAKA005BR 10 m R88A-CAKA010BR 15 m R88A-CAKA015BR 20 m R88A-CAKA020BR 30 m R88A-CAKA030BR 40 m R88A-CAKA040BR 50 m R88A-CAKA050BR...

- Page 54 2-3 Standard Model List Absolute Encoder Battery Cables Specifications Model ABS battery cable (battery not supplied) 0.3 m R88A-CRGD0R3C ABS battery cable (R88A-BAT01G battery × 1 supplied) 0.3 m R88A-CRGD0R3C-BS Absolute Encoder Backup Battery Specifications Model 2,000 mA•h 3.6 V R88A-BAT01G Analog Monitor Cable Specifications...

- Page 55 Regeneration process capacity: 70 W, 47 Ω (with 170°C thermal sensor) R88A-RR22047S Regeneration process capacity: 180 W, 20 Ω (with 200°C thermal sensor) R88A-RR50020S Mounting Brackets (L-Brackets for Rack Mounting) Specifications Model R88D-KNA5L-ML2/-KN01L-ML2/-KN01H-ML2/-KN02H-ML2 R88A-TK01K R88D-KN02L-ML2/-KN04H-ML2 R88A-TK02K R88D-KN04L-ML2/-KN08H-ML2 R88A-TK03K R88D-KN10H-ML2/-KN15H-ML2/-KN06F-ML2/-KN10F-ML2/-KN15F-ML2 R88A-TK04K...

-

Page 56: External And Mounting Dimensions

The dimensional description starts with a Servo Drive of the smallest motor capacity, which is followed by the next smallest, and so on. Single-phase 100 VAC: R88D-KNA5L-ML2/-KN01L-ML2 (50 to 100 W) Single-phase/3-phase 200 VAC: R88D-KN01H-ML2/-KN02H-ML2 (100 to 200 W) Wall Mounting... - Page 57 2-4 External and Mounting Dimensions Front Mounting (Using Front Mounting Brackets) External dimensions Mounting dimensions 19.5 φ5.2 φ5.2 Square hole OMNUC G5-Series AC Servo Drives Users Manual (Built-in MECHATROLINK-II communications type) 2-22 WWW.BSNEW.IR...

- Page 58 2-4 External and Mounting Dimensions Single-phase/3-phase 100 VAC: R88D-KN02L-ML2 (200 W) Single-phase/3-phase 200 VAC: R88D-KN04H-ML2 (400 W) Wall Mounting External dimensions Mounting dimensions φ5.2 Front Mounting (Using Front Mounting Brackets) External dimensions Mounting dimensions 19.5 φ5.2 φ5.2 Square hole R2.6 2-23 OMNUC G5-Series AC Servo Drives Users Manual (Built-in MECHATROLINK-II communications type) WWW.BSNEW.IR...

- Page 59 2-4 External and Mounting Dimensions Single-phase/3-phase 100 VAC: R88D-KN04L-ML2 (400 W) Single-phase/3-phase 200 VAC: R88D-KN08H-ML2 (750 W) Wall Mounting External dimensions Mounting dimensions φ5.2 Front Mounting (Using Front Mounting Brackets) External dimensions Mounting dimensions 19.5 φ5.2 φ5.2 Square hole R2.6 OMNUC G5-Series AC Servo Drives Users Manual (Built-in MECHATROLINK-II communications type) 2-24 WWW.BSNEW.IR...

- Page 60 2-4 External and Mounting Dimensions Single-phase/3-phase 200 VAC: R88D-KN10H-ML2/-KN15H-ML2 (1 to 1.5 kW) Wall Mounting External dimensions Mounting dimensions φ5.2 Front Mounting (Using Front Mounting Brackets) External dimensions Mounting dimensions 19.5 φ5.2 φ5.2 φ5.2 Square hole R2.6 R2.6 2-25 OMNUC G5-Series AC Servo Drives Users Manual (Built-in MECHATROLINK-II communications type) WWW.BSNEW.IR...

- Page 61 2-4 External and Mounting Dimensions 3-phase 200 VAC: R88D-KN20H-ML2 (2 kW) Wall Mounting External dimensions Mounting dimensions 17.5 φ5.2 42.5 φ5.2 R2.6 R2.6 R2.6 R2.6 17.5 φ5.2 42.5 17.5 Front Mounting (Using Front Mounting Brackets) External dimensions Mounting dimensions 17.5 φ5.2 42.5 30.7...

- Page 62 2-4 External and Mounting Dimensions 3-phase 200 VAC: R88D-KN30H-ML2/-KN50H-ML2 (3 to 5 kW) Wall Mounting External dimensions φ5.2 R2.6 R2.6 R2.6 R2.6 φ5.2 Mounting dimensions φ5.2 2-27 OMNUC G5-Series AC Servo Drives Users Manual (Built-in MECHATROLINK-II communications type) WWW.BSNEW.IR...

- Page 63 2-4 External and Mounting Dimensions Front Mounting (Using Front Mounting Brackets) External dimensions 40.7 φ5.2 R2.6 R2.6 R2.6 R2.6 φ5.2 Mounting dimensions φ5.2 Square hole OMNUC G5-Series AC Servo Drives Users Manual (Built-in MECHATROLINK-II communications type) 2-28 WWW.BSNEW.IR...

- Page 64 2-4 External and Mounting Dimensions 3-phase 400 VAC: R88D-KN06F-ML2/-KN10F-ML2/-KN15F-ML2 (600 W to 1.5 Wall Mounting External dimensions Mounting dimensions φ5.2 14.5 Front Mounting (Using Front Mounting Brackets) External dimensions Mounting dimensions 19.5 φ5.2 φ5.2 φ5.2 Square hole R2.6 2-29 OMNUC G5-Series AC Servo Drives Users Manual (Built-in MECHATROLINK-II communications type) WWW.BSNEW.IR...

- Page 65 2-4 External and Mounting Dimensions 3-phase 400 VAC: R88D-KN20F-ML2 (2 kW) Wall Mounting External dimensions Mounting dimensions 17.5 φ5.2 42.5 φ5.2 R2.6 R2.6 φ5.2 17.5 Front Mounting (Using Front Mounting Brackets) External dimensions Mounting dimensions 17.5 φ5.2 30.7 42.5 φ5.2 Square hole R2.6 R2.6...

- Page 66 2-4 External and Mounting Dimensions 3-phase 400 VAC: R88D-KN30F-ML2/-KT50F-ML2 (3 to 5 kW) Wall Mounting External dimensions Mounting dimensions φ5.2 φ5.2 R2.6 R2.6 φ5.2 Front Mounting (Using Front Mounting Brackets) External dimensions Mounting dimensions φ5.2 40.7 φ5.2 Square hole R2.6 R2.6 φ5.2 2-31...

-

Page 67: Servomotor Dimensions

2-4 External and Mounting Dimensions Servomotor Dimensions In this description, the Servomotors are grouped by rated rotation speed. The description starts with a Servomotor of the smallest capacity, which is followed by the next smallest, and so on. 3,000-r/min Motors (100 V and 200 V) 50 W/100 W (without Brake) R88M-K05030x (-S2)/-K10030x (-S2) R88M-K05030x (-S2)/-K10030x (-S2) - Page 68 2-4 External and Mounting Dimensions 50 W/100 W (with Brake) R88M-K05030x-B (S2)/-K10030x-B (S2) R88M-K05030x-B (S2)/-K10030x-B (S2) Encoder connector Brake connector Motor connector 40×40 (Shaft end specifications with key and tap) 12.5 R3.7 M3 (depth 6) 1.5 min. Boss insertion position R4.2 (only for the ones with oil seal) 2−φ4.3...

- Page 69 2-4 External and Mounting Dimensions 200 W/400 W (without Brake) R88M-K20030x (-S2)/-K40030x (-S2) R88M-K20030x (-S2)/-K40030x (-S2) Encoder connector Motor connector 60×60 (Shaft end specifications with key and tap) 4−φ4.5 30 20 (200 W) 25 (400 W) 4h9 (200 W) 18 (200 W) 5h9 (400 W) 22.5 (400 W) M4, depth 8 (200 W)

- Page 70 2-4 External and Mounting Dimensions 750 W (without Brake) R88M-K75030H (-S2) R88M-K75030T (-S2) Encoder connector Motor connector 112.2 86.2 80×80 (Shaft end specifications with key and tap) 4−φ6 M5 (depth 10) Note. Models with a key and tap are indicated with S2 at the end of the model number. 750 W (with Brake) R88M-K75030H-B (S2) R88M-K75030T-B (S2)

- Page 71 2-4 External and Mounting Dimensions 1 kW/1.5 kW/2 kW (without Brake) R88M-K1K030H (-S2)/-K1K530H (-S2)/-K2K030H (-S2) R88M-K1K030T (-S2)/-K1K530T (-S2)/-K2K030T (-S2) 1 kW/1.5 kW/2 kW (with Brake) R88M-K1K030H-B (S2)/-K1K530H-B (S2)/-K2K030H-B (S2) R88M-K1K030T-B (S2)/-K1K530T-B (S2)/-K2K030T-B (S2) Motor and brake connector (Shaft end specifications with key and tap) Encoder connector 100×100 4−φ9...

- Page 72 2-4 External and Mounting Dimensions 3 kW (without Brake) R88M-K3K030H (-S2) R88M-K3K030T (-S2) 3 kW (with Brake) R88M-K3K030H-B (S2) R88M-K3K030T-B (S2) Motor and brake connector (Shaft end specifications with key and tap) 120×120 Encoder connector 4−φ9 M3, through M5 (depth 12) Dimensions (mm) Model R88M-K3K030x...

- Page 73 2-4 External and Mounting Dimensions 4 kW/5 kW (without Brake) R88M-K4K030H (-S2)/-K5K030H (-S2) R88M-K4K030T (-S2)/-K5K030T (-S2) 4 kW/5 kW (with Brake) R88M-K4K030H-B (S2)/-K5K030H-B (S2) R88M-K4K030T-B (S2)/-K5K030T-B (S2) Motor and brake connector (Shaft end specifications with key and tap) Encoder connector 130×130 4−φ9 M3, through...

- Page 74 2-4 External and Mounting Dimensions 3,000-r/min Motors (400 V) 750 W/1 kW/1.5 kW/2 kW (without Brake) R88M-K75030F (-S2)/-K1K030F (-S2)/-K1K530F (-S2)/-K2K030F (-S2) R88M-K75030C (-S2)/-K1K030C (-S2)/-K1K530C (-S2)/-K2K030C (-S2) 750 W/1 kW/1.5 kW/2 kW (with Brake) R88M-K75030F-B (S2)/-K1K030F-B (S2)/-K1K530F-B (S2)/-K2K030F-B (S2) R88M-K75030C-B (S2)/-K1K030C-B (S2)/-K1K530C-B (S2)/-K2K030C-B (S2) Motor and brake connector Encoder connector...

- Page 75 2-4 External and Mounting Dimensions 3 kW (without Brake) R88M-K3K030F (-S2) R88M-K3K030C (-S2) 3 kW (with Brake) R88M-K3K030F-B (S2) R88M-K3K030C-B (S2) Motor and brake connector (Shaft end specifications with key and tap) Encoder connector 120×120 4-φ9 M3, through M5 (depth 12) Dimensions (mm) Model R88M-K3K030x...

- Page 76 2-4 External and Mounting Dimensions 4 kW/5 kW (without Brake) R88M-K4K030F (-S2)/-K5K030F (-S2) R88M-K4K030C (-S2)/-K5K030C (-S2) 4 kW/5 kW (with Brake) R88M-K4K030F-B (S2)/-K5K030F-B (S2) R88M-K4K030C-B (S2)/-K5K030C-B (S2) Motor and brake connector (Shaft end specifications with key and tap) Encoder connector 130×130 4−φ9 M3, through...

- Page 77 2-4 External and Mounting Dimensions 2,000-r/min Motors (200 V) 1 kW/1.5 kW/2 kW/3 kW (without Brake) R88M-K1K020H (-S2)/-K1K520H (-S2)/-K2K020H (-S2)/-K3K020H (-S2) R88M-K1K020T (-S2)/-K1K520T (-S2)/-K2K020T (-S2)/-K3K020T (-S2) 1 kW/1.5 kW/2 kW/3 kW (with Brake) R88M-K1K020H-B (S2)/-K1K520H-B (S2)/-K2K020H-B (S2)/-K3K020H-B (S2) R88M-K1K020T-B (S2)-K1K520T-B (S2)/-K2K020T-B (S2)/-K3K020T-B (S2) Motor and brake connector (Shaft end specifications with key and tap)

- Page 78 2-4 External and Mounting Dimensions 4 kW/5 kW (without Brake) R88M-K4K020H (-S2)/-K5K020H (-S2) R88M-K4K020T (-S2)/-K5K020T (-S2) 4 kW/5 kW (with Brake) R88M-K4K020H-B (S2)/-K5K020H-B (S2) R88M-K4K020T-B (S2)/-K5K020T-B (S2) Motor and brake connector (Shaft end specifications with key and tap) Encoder connector 176×176 4−φ13.5 M3, through...

- Page 79 2-4 External and Mounting Dimensions 2,000-r/min Motors (400 V) 400 W/600 W (without Brake) R88M-K40020F (-S2)/-K60020F (-S2) R88M-K40020F (-S2)/-K60020F (-S2) 400 W/600 W (with Brake) R88M-K40020F-B (S2)/-K60020F-B (S2) R88M-K40020F-B (S2)/-K60020F-B (S2) Motor and brake connector Encoder connector 100×100 (Shaft end specifications with key and tap) M3, through 4−φ9 M5 (depth 12)

- Page 80 2-4 External and Mounting Dimensions 1 kW/1.5 kW/2 kW/3 kW (without Brake) R88M-K1K020F (-S2)/-K1K520F (-S2)/-K2K020F (-S2)/-K3K020F (-S2) R88M-K1K020C (-S2)/-K1K520C (-S2)/-K2K020C (-S2)/-K3K020C (-S2) 1 kW/1.5 kW/2 kW/3 kW (with Brake) R88M-K1K020F-B (S2)/-K1K520F-B (S2)/-K2K020F-B (S2)/-K3K020F-B (S2) R88M-K1K020C-B (S2)/-K1K520C-B (S2)/-K2K020C-B (S2)/-K3K020C-B (S2) Motor and brake connector (Shaft end specifications with key and tap) Encoder...

- Page 81 2-4 External and Mounting Dimensions 4 kW/5 kW (without Brake) R88M-K4K020F (-S2)/-K5K020F (-S2) R88M-K4K020C (-S2)/-K5K020C (-S2) 4 kW/5 kW (with Brake) R88M-K4K020F-B (S2)/-K5K020F-B (S2) R88M-K4K020C-B (S2)/-K5K020C-B (S2) Motor and brake connector Encoder connector 176×176 (Shaft end specifications with key and tap) 4-φ13.5 M3, through 10h9...

- Page 82 2-4 External and Mounting Dimensions 1,000-r/min Motors (200 V) 900 W (without Brake) R88M-K90010H (-S2) R88M-K90010T (-S2) 900 W (with Brake) R88M-K90010H-B (S2) R88M-K90010T-B (S2) × Dimensions (mm) Model R88M-K90010x 155.5 111.5 133.5 R88M-K90010x-Bx 180.5 136.5 158.5 Note. Models with a key and tap are indicated with S2 at the end of the model number. 2-47 OMNUC G5-Series AC Servo Drives Users Manual (Built-in MECHATROLINK-II communications type) WWW.BSNEW.IR...

- Page 83 2-4 External and Mounting Dimensions 2 kW/3 kW (without Brake) R88M-K2K010H (-S2)/-K3K010H (-S2) R88M-K2K010T (-S2)/-K3K010T (-S2) 2 kW/3 kW (with Brake) R88M-K2K010H-B (S2)/-K3K010H-B (S2) R88M/-K2K010T-B (S2)/-K3K010T-B (S2) Motor and brake connector Encoder connector 176×176 (Shaft end specifications with key and tap) 4−φ13.5 M3, through 10h9...

- Page 84 2-4 External and Mounting Dimensions 1,000-r/min Motors (400 V) 900 W (without Brake) R88M-K90010F (-S2) R88M-K90010C (-S2) 900 W (with Brake) R88M-K90010F-B (S2) R88M-K90010C-B (S2) × Dimensions (mm) Model R88M-K90010x 155.5 111.5 77.5 133.5 R88M-K90010x-Bx 180.5 136.5 74.5 158.5 Note. Models with a key and tap are indicated with S2 at the end of the model number. 2-49 OMNUC G5-Series AC Servo Drives Users Manual (Built-in MECHATROLINK-II communications type) WWW.BSNEW.IR...

- Page 85 2 kW/3 kW (without Brake) R88M-K2K010F (-S2)/-K3K010F (-S2) R88M-K2K010C (-S2)/-K3K010C (-S2) 2 kW/3 kW (with Brake) R88M-K2K010F-B (S2)/-K3K010F-B (S2) R88M-K2K010C-B (S2)/-K3K010C-B (S2) Motor and brake connector (Shaft end specifications with key and tap) Encoder connector 176×176 4−φ13.5 M3, through 10h9 M12 (depth 25) Dimensions (mm) Model...

-

Page 86: External Regeneration Resistor Dimensions

External Regeneration Resistor Dimensions External Regeneration Resistor R88A-RR08050S/-RR080100S Thermal switch output t1.2 R88A-RR22047S Thermal switch output t1.2 R88A-RR50020S WWW.BSNEW.IR... -

Page 87: Emc Filter Dimensions

2-5 EMC Filter Dimensions drive mounts output flexes External dimensions Mount dimensions Filter model R88A-FIK102-RE R88A-FIK104-RE R88A-FIK107-RE R88A-FIK114-RE R88A-FIK304-RE R88A-FIK306-RE R88A-FIK312-RE WWW.BSNEW.IR... -

Page 88: Mechatrolink-Ii Repeater Units

MECHATROLINK-II Repeater Units JEPMC-REP2000 (97) (34) (20) 14 10 Bottom Mounting Back Mounting M4 tap M4 tap WWW.BSNEW.IR... - Page 89 Specifications This chapter explains the general specifications, characteristics, connector specifications and I/O circuits of the Servo Drives, as well as the general specifications, characteristics, encoder specifications of the Servomotors. 3-1 Servo Drive Specifications ..........3-1 Overload Characteristics (Electronic Thermal Function) ... 3-31 3-3 ...........Servomotor Specifications 3-32 3-4 Cable and Connector Specifications ......3-57...

-

Page 90: Servo Drive Specifications

3-1 Servo Drive Specifications 3-1 Servo Drive Specifications Select the Servo Drive matching the Servomotor to be used. Refer to "Servo Drive and Servomotor Combination List"(P.2-10). General Specifications Item Specifications Ambient operating 0 to +55C, 90% RH max. (with no condensation) temperature and operating humidity Storage ambient temperature... -

Page 91: Characteristics

3-1 Servo Drive Specifications Characteristics 100-VAC Input Type R88D- R88D- R88D- R88D- Item KNA5L-ML2 KN01L-ML2 KN02L-ML2 KN04L-ML2 Continuous output current (rms) 1.2 A 1.7 A 2.5 A 4.6 A Input power Main Power supply circuit supply 0.4 KVA 0.4 KVA 0.5 KVA 0.9 KVA capacity... - Page 92 3-1 Servo Drive Specifications 200-VAC Input Type R88D- R88D- R88D- R88D- R88D- R88D- Item KN01H- KN02H- KN04H- KN08H- KN10H- KN15H- Continuous output current (rms) 1.2 A 1.6 A 2.6 A 4.1 A 5.9 A 9.4 A Input power Main Power supply circuit supply...

- Page 93 3-1 Servo Drive Specifications R88D- R88D- R88D- Item KN20H-ML2 KN30H-ML2 KN50H-ML2 Continuous output current (rms) 13.4 A 18.7 A 33.0 A Input power Main Power supply circuit supply 3.3 KVA 4.5 KVA 7.5 KVA capacity Power supply 3-phase 200 to 230 VAC (170 to 253 V) 50/60 Hz voltage Rated 11.8 A...

- Page 94 3-1 Servo Drive Specifications 400-VAC Input Type R88D- R88D- R88D- R88D- R88D- R88D- Item KN06F- KN10F- KN15F- KN20F- KN30F- KN50F- Continuous output current (rms) 2.9 A 2.9 A 4.7 A 6.7 A 9.4 A 16.5 A Main Power circuit supply 3-phase 380 to 480 VAC (323 to 528 V) 50/60 Hz voltage Input power...

- Page 95 3-1 Servo Drive Specifications Protective Functions Error detection Description Control power supply undervoltage The DC voltage of the main circuit fell below the specified value. Overvoltage The DC voltage in the main circuit is abnormally high. Main power supply undervoltage The DC voltage of the main circuit is low.

- Page 96 3-1 Servo Drive Specifications Error detection Description Absolute encoder status error The rotation of the absolute encoder is higher than the specified value. Encoder phase-Z error A phase Z pulse was not detected regularly. Encoder CS signal error A logic error was detected in the CS signal. An error was detected in external encoder connection and communications External encoder communications error data.

-

Page 97: Main Circuit And Motor Connections

3-1 Servo Drive Specifications Main Circuit and Motor Connections When wiring the main circuit, use proper wire sizes, grounding systems, and noise resistance. R88D-KNA5L-ML2/-KN01L-ML2/-KN02L-ML2/-KN04L-ML2/-KN01H-ML2/ -KN02H-ML2/-KN04H-ML2/-KN08H-ML2/-KN10H-ML2/-KN15H-ML2 Main Circuit Connector Specifications (CNA) Symbol Name Function Main circuit power R88D-KNxL-ML2 supply input (50 to 400 W) : Single-phase 100 to 115 VAC (85 to 127 V) 50/60 Hz... - Page 98 3-1 Servo Drive Specifications R88D-KN20H-ML2 Main Circuit Connector Specifications (CNA) Symbol Name Function Main circuit power supply R88D-KNxH-ML2 (2 kW) : input 3-phase: 200 to 230 VAC (170 to 253 V) 50/60 Hz Control circuit power R88D-KNx-ML2 : Single-phase 200 to 230 VAC (170 to 253 V) 50/ supply input 60 Hz Motor Connector Specifications (CNB)

- Page 99 3-1 Servo Drive Specifications R88D-KN30H-ML2/R88D-KN50H-ML2 Main Circuit Terminal Block Specifications Symbol Name Function Main circuit power supply R88D-KNxH-ML2 (3 to 5 kW): input 3-phase 200 to 230 VAC (170 to 253 V) 50/60 Hz Control circuit power R88D-KNxH-ML2 : Single-phase 200 to 230 VAC (170 to 253 V) supply input 50/60 Hz External Regeneration...

- Page 100 3-1 Servo Drive Specifications R88D-KN06F-ML2/-KN10F-ML2/-KN15F-ML2/-KN20F-ML2 Main Circuit Connector Specifications (CNA) Symbol Name Function Main circuit power supply R88D-KNxF-ML2 input (600 W to 2 kW) : 3-phase: 380 to 480 VAC (323 to 528 V) 50/60 Hz Motor Connector Specifications (CNB) Symbol Name Function...

- Page 101 3-1 Servo Drive Specifications R88D-KN30F-ML2/R88D-KN50F-ML2 Main Circuit Terminal Block Specifications (TB1) Symbol Name Function 24 V Control circuit power 24 VDC ± 15% supply input Main Circuit Terminal Block Specifications (TB2) Symbol Name Function Main circuit power supply R88D-KNxH-ML2 (3 to 5 kW): input 3-phase 380 to 480 VAC (323 to 528 V) 50/60 Hz External Regeneration...

-

Page 102: Control I/O Connector Specifications (Cn1)

3-1 Servo Drive Specifications Control I/O Connector Specifications (CN1) Control I/O Signal Connections and External Signal Processing 12 to 24 VDC +24 VIN 4.7 kΩ /ALM 10 Ω Alarm output Maximum ALMCOM General-purpose service 1 kΩ input 1 voltage OUTM1 10 Ω... - Page 103 3-1 Servo Drive Specifications Control I/O Signal List CN1 Control Inputs Signal Symbol CONTROL mode number Name Default Power supply input 12 to The input terminal + of the external power supply (12 +24 VIN 24 VDC. to 24 VDC) for sequence inputs General- Emergency These are the general-purpose inputs.

-

Page 104: Control Input Circuits

3-1 Servo Drive Specifications CN1 Pin Arrangement Absolute General-purpose encoder backup OUTM1 Output 1 Absolute battery input General-purpose encoder backup OUTM1COM BATGND Output 1 Common battery input /ALM Alarm Output Signal Ground Alarm Output ALMCOM Common General-purpose Input 1 12 to 24-VDC +24 VIN power supply input... -

Page 105: Control Input Details

3-1 Servo Drive Specifications Control Input Details This is the detailed information about the CN1 Connector input pins. General-purpose Inputs (IN1 to IN8) Pin 5 : General-purpose Input 1 (IN1) Pin 7 : General-purpose Input 2 (IN2) Pin 8 : General-purpose Input 3 (IN3) Pin 9 : General-purpose Input 4 (IN4) Pin 10 : General-purpose Input 5 (IN5) - Page 106 3-1 Servo Drive Specifications Forward Drive Prohibition Input (POT) and Reverse Drive Prohibition Input (NOT) The two signals are the inputs to prohibit forward and reverse rotation (over-travel inputs). When one input is ON, the Servo Drive can rotate in the specified direction. In the Drive Prohibition state, Servomotor switches to servo lock state after deceleration stop.

-

Page 107: Control Output Circuits

3-1 Servo Drive Specifications Monitor Inputs (MON0, MON1 and MON2) They are the monitor inputs. They do not give any influences to the operation. Only the host controller can monitor them. In factory setting, the MON0 is allocated to Pin 13. Forward External Torque Limit Input (PCL) and Reverse External Torque Limit Input (NCL) One of them turns ON when the torque is limited to the value set by the Forward External Torque... -

Page 108: Control Output Details

3-1 Servo Drive Specifications Control Output Details The chart below illustrates the timings of the command inputs after the control power-on. Enter the Servo ON, and the position, speed or torque command in the correct timing as shown in the chart. Control Output Sequence Control power supply (L1C and L2C) - Page 109 3-1 Servo Drive Specifications Alarm Output (/ALM) Pin 3: Alarm Output (/ALM) Pin 4: Alarm output common (ALMCOM) Function The output is turned OFF when the drive detects an error. This output is OFF at power supply ON, but turns ON when the drive's initial processing has been completed.

- Page 110 3-1 Servo Drive Specifications Motor Rotation Speed Detection Output (TGON) It turns on when the motor rotation speed exceeds the value set by the Rotation Speed for Motor Rotation Detection (Pn436). The output is effective both in forward and reverse directions regardless the actual direction that the motor rotates.

- Page 111 3-1 Servo Drive Specifications Speed Conformity Output (VCMP) The output turns ON when the motor rotation speed fills into the range set by the Speed Conformity Detection Range (Pn435). It is determined to be conforming when the difference between the commanded speed before acceleration or deceleration process inside the Drive and the motor rotation speed is within the set range of Speed Conformity Detection Range (Pn435).

-

Page 112: Encoder Connector Specifications (Cn2)

3-1 Servo Drive Specifications Encoder Connector Specifications (CN2) Symbol Name Function and interface number Encoder power supply +5 V Power supply output for the encoder Encoder power supply GND BAT+ Battery + Backup power supply output for the absolute encoder BAT−... - Page 113 3-1 Servo Drive Specifications Connection of External Encoder Input Signal and Processing of External Signals External encoder power supply output 52 V ± 5% 250 mA max +EXS −EXS Serial number 4.7 kΩ +EXA Phase A Photocoupler input 1.0 kΩ −EXA 4.7 kΩ...

- Page 114 3-1 Servo Drive Specifications Example of Connection with External Encoder 90° Phase Difference Input Type (Pn323 = 0) Drive side (CN4) External encoder side 52 V ± 5% 250 mA max +5 V Power supply area 4.7 kΩ +EXA Phase A Photocoupler input 1.0 kΩ...

- Page 115 3-1 Servo Drive Specifications Serial Communications Type, Absolute Encoder Specifications (Pn323 = 2) Absolute encoder by Mitutoyo Corporation Drive side (CN4) ABS ST771A/ST773A 3 • 4 • 11 +5 V E0V 2 1 • 2 • 13 REQ/ +EXS −REQ/ −...

-

Page 116: Monitor Connector Specifications (Cn5)

3-1 Servo Drive Specifications Monitor Connector Specifications (CN5) Monitor Output Signals List Monitor output (CN5) Symbol Name Function and interface Number Analog monitor output 1 Outputs the analog signal for the monitor. Default setting: Motor rotation speed 1 V/(1,000 r/min) You can use Pn416 and Pn417 to change the item and unit. -

Page 117: Usb Connector Specifications (Cn7)

3-1 Servo Drive Specifications USB Connector Specifications (CN7) Through the USB connection with computer, operations such as parameter setting and changing, monitoring of control status, checking error status and error history, and parameter saving and loading can be performed. Symbol Name Function and interface number... -

Page 118: Safety Connector Specifications (Cn8)

3-1 Servo Drive Specifications Safety Connector Specifications (CN8) Connection of Safety I/O Signals and Processing of External Signals 4 kΩ SF1+ 12 to 24 VDC 1 kΩ SF1− EDM+ Maximum service voltage : 30 VDC or less Maximum output current : 50 mADC 4 kΩ... - Page 119 3-1 Servo Drive Specifications Safety Input Circuit Servo Drive SF1+ 4.7 kΩ External power supply Photocoupler 12 VDC ± 5% to 1.0 kΩ input SF1− 24 VDC ± 5% 4.7 kΩ SF2+ Signal level Photocoupler ON level: 10 V or more 1.0 kΩ...

-

Page 120: Overload Characteristics (Electronic Thermal Function)

3-2 Overload Characteristics (Electronic Thermal Function) Overload Characteristics (Electronic Thermal Function) An overload protection function (electronic thermal) is built into the Servo Drive to protect the drive and motor from overloading. If an overload does occur, first eliminate the cause of the error and then wait at least 1 minute for the motor temperature to drop before turning ON the power again. -

Page 121: Servomotor Specifications

3-3 Servomotor Specifications 3-3 Servomotor Specifications The following Accurax G5-Series AC Servomotors are available. 3,000-r/min motors 2,000-r/min motors 1,000-r/min motors There are various options available, such as models with brakes, or different shaft types. Select a Servomotor based on the mechanical system's load conditions and the installation environment. -

Page 122: Characteristics

3-3 Servomotor Specifications Characteristics 3,000-r/min Motors 100 VAC Model (R88M-) K05030H K10030L K20030L K40030L K05030T K10030S K20030S K40030S Item Unit Rated output * Rated torque * N • m 0.16 0.32 0.64 Rated rotation speed r/min 3,000 Momentary maximum r/min 6,000 rotation speed Momentary maximum... - Page 123 3-3 Servomotor Specifications 100 VAC Model (R88M-) K05030H K10030L K20030L K40030L K05030T K10030S K20030S K40030S Item Unit Allowable angular 30,000 max. rad/s acceleration (Speed of 2,800 r/min or more must not be changed in less than 10 ms.) Brake limit 10 million times min.

- Page 124 3-3 Servomotor Specifications 200 VAC Model (R88M-) K05030H K10030H K20030H K40030H K05030T K10030T K20030T K40030T Item Unit Rated output * Rated torque * N • m 0.16 0.32 0.64 Rated rotation speed r/min 3,000 Momentary maximum r/min 6,000 rotation speed Momentary maximum N •...

- Page 125 3-3 Servomotor Specifications 200 VAC Model (R88M-) K75030H K1K030H K1K530H K75030T K1K030T K1K530T Item Unit Rated output * 1000 1500 Rated torque * N • m 3.18 4.77 Rated rotation speed r/min 3,000 Momentary maximum r/min 6,000 5,000 rotation speed Momentary maximum N •...

- Page 126 3-3 Servomotor Specifications AC200V Model (R88M-) K2K030H K3K030H K4K030H K5K030H K2K030T K3K030T K4K030T K5K030T Item Unit Rated output * 2000 3000 4000 5000 Rated torque * N • m 6.37 9.55 12.7 15.9 Rated rotation speed r/min 3000 Momentary maximum r/min 5000 4500...

- Page 127 3-3 Servomotor Specifications 400 VAC Model (R88M-) K75030F K1K030F K1K530F K2K030F K75030C K1K030C K1K530C K2K030C Item Unit Rated output * 1000 1500 2000 Rated torque * N • m 2.39 3.18 4.77 6.37 Rated rotation speed r/min 3,000 Momentary maximum r/min 5,000 rotation speed...

- Page 128 3-3 Servomotor Specifications 400 VAC Model (R88M-) K3K030F K4K030F K5K030F K3K030C K4K030C K5K030C Item Unit Rated output * 3000 4000 5000 Rated torque * N • m 9.55 12.7 15.9 Rated rotation speed r/min 3,000 Momentary maximum r/min 5,000 4,500 rotation speed Momentary maximum N •...

- Page 129 3-3 Servomotor Specifications *1. These are the values when the motor is combined with a drive at normal temperature (20°C, 65%). The momentary maximum torque indicates the standard value. *2. Applicable load inertia. The operable load inertia ratio (load inertia/rotor inertia) depends on the mechanical configuration and its rigidity. For a machine with high rigidity, operation is possible even with high load inertia.

- Page 130 3-3 Servomotor Specifications 3,000-r/min motor (200 VAC) The following graphs show the characteristics with a 3-m standard cable and a 200-VAC input. • R88M-K05030H/T (50 W) • R88M-K10030H/T (100 W) • R88M-K20030H/T (200 W) Power supply voltage Power supply voltage Power supply voltage (N •...

- Page 131 3-3 Servomotor Specifications 3,000-r/min motor (400 VAC) The following graphs show the characteristics with a 3-m standard cable and a 400-VAC input. • R88M-K75030F/C (750 W) • R88M-K1K030F/C (1 kW) • R88M-K1K530F/C (1.5 kW) Power supply voltage Power supply voltage Power supply voltage (N •...

- Page 132 3-3 Servomotor Specifications Use the following Servomotors in the ranges shown in the graphs below. Using outside of these ranges may cause the motor to generate heat, which could result in encoder malfunction. • R88M-K05030L/S/H/T • R88M-K10030L/S/H/T • R88M-K20030L/SH/T (50 W: With oil seal) (100 W: With oil seal) (200 W: With oil seal) Rated torque ratio [%]...

- Page 133 3-3 Servomotor Specifications 2,000-r/min Motors 200 VAC Model (R88M-) K1K020H K1K520H K2K020H K1K020T K1K520T K2K020T Item Unit Rated output * 1,000 1,500 2,000 Rated torque * N • m 4.77 7.16 9.55 Rated rotation speed r/min 2,000 Momentary maximum r/min 3,000 rotation speed Momentary maximum...

- Page 134 3-3 Servomotor Specifications 200 VAC Model (R88M-) K1K020H K1K520H K2K020H K1K020T K1K520T K2K020T Item Unit Allowable total work 7.8×10 1.5×10 1.5×10 Allowable angular rad/s 10,000 acceleration Brake limit 10 million times min. − Rating Continuous − Insulation class − Type F 200 VAC Model (R88M-) K3K020H...

- Page 135 3-3 Servomotor Specifications 200 VAC Model (R88M-) K3K020H K4K020H K5K020H K3K020T K4K020T K5K020T Item Unit Brake inertia kg • m 1.35×10 4.7×10 4.7×10 Excitation voltage * 24 VDC ± 10% Power consumption (at 20°C) Current consumption 0.90±10% 1.3±10% 1.3±10% (at 20°C) Static friction torque N •...

- Page 136 3-3 Servomotor Specifications 400 VAC Model (R88M-) K40020F K60020F K1K020F K1K520F K40020C K60020C K1K020C K1K520C Item Unit Rated output * 1,000 1,500 Rated torque * N • m 1.91 2.86 4.77 7.16 Rated rotation speed r/min 2,000 Momentary maximum r/min 3,000 rotation speed Momentary maximum...

- Page 137 3-3 Servomotor Specifications 400 VAC Model (R88M-) K2K020F K3K020F K4K020F K5K020F K2K020C K3K020C K4K020C K5K020C Item Unit Rated output * 2,000 3,000 4,000 5,000 Rated torque * N • m 9.55 14.3 19.1 23.9 Rated rotation speed r/min 2,000 Momentary maximum r/min 3,000 rotation speed...

- Page 138 3-3 Servomotor Specifications 400 VAC Model (R88M-) K2K020F K3K020F K4K020F K5K020F K2K020C K3K020C K4K020C K5K020C Item Unit Brake inertia kg • m 1.35×10 1.35×10 4.7×10 4.7×10 Excitation voltage * 24 VDC ± 10% Power consumption (at 20°C) Current consumption 0.79±10% 0.90±10% 1.3±10% 1.3±10%...

- Page 139 3-3 Servomotor Specifications *1. These are the values when the motor is combined with a drive at normal temperature (20°C, 65%). The momentary maximum torque indicates the standard value. *2. Applicable load inertia. The operable load inertia ratio (load inertia/rotor inertia) depends on the mechanical configuration and its rigidity. For a machine with high rigidity, operation is possible even with high load inertia.

- Page 140 3-3 Servomotor Specifications 2,000-r/min motor (400 VAC) The following graphs show the characteristics with a 3-m standard cable and a 400-VAC input. • R88M-K40020F/C (400 W) • R88M-K60020F/C (600 W) • R88M-K1K020F/C (1 kW) Power supply voltage Power supply voltage Power supply voltage (N •...

- Page 141 3-3 Servomotor Specifications 1,000-r/min Motors 200 VAC Model (R88M-) K90010H K2K010H K3K010H Item Unit K90010T K2K010T K3K010T Rated output * 2,000 3,000 Rated torque * N • m 8.59 19.1 28.7 Rated rotation speed r/min 1,000 Momentary maximum r/min 2,000 rotation speed Momentary maximum N •...

- Page 142 3-3 Servomotor Specifications 200 VAC Model (R88M-) K90010H K2K010H K3K010H K90010T K2K010T K3K010T Item Unit Allowable work per 1176 1372 1372 braking Allowable total work 1.5×10 2.9×10 2.9×10 Allowable angular rad/s 10,000 acceleration Brake limit 10 million times min. − Rating −...

- Page 143 3-3 Servomotor Specifications 400 VAC Model (R88M-) K90010F K2K010F K3K010F K90010C K2K010C K3K010C Item Unit Brake inertia kg • m 1.35×10 4.7×10 4.7×10 Excitation voltage * 24 VDC ± 10% Power consumption (at 20°C) Current consumption 0.79±10% 1.3±10% 1.4±10% (at 20°C) Static friction torque N •...

- Page 144 3-3 Servomotor Specifications *1. These are the values when the motor is combined with a drive at normal temperature (20°C, 65%). The momentary maximum torque indicates the standard value. *2. Applicable load inertia. The operable load inertia ratio (load inertia/rotor inertia) depends on the mechanical configuration and its rigidity. For a machine with high rigidity, operation is possible even with high load inertia.

-

Page 145: Encoder Specifications

3-3 Servomotor Specifications Encoder Specifications Incremental Encoder Specifications Item Specifications Encoder system Optical encoder 20 bits Number of output Phases A and B: 262,144 pulses/rotation pulses Phase Z: 1 pulse/rotation Power supply voltage 5 VDC ± 5% Power supply current 180 mA (max.) Output signals +S, −S... -

Page 146: Cable And Connector Specifications

3-4 Cable and Connector Specifications 3-4 Cable and Connector Specifications This section specifies the cables and connectors that are used to connect the Servo Drive and the Servomotor. Select ones in accordance with the Servomotor specifications. Encoder Cable Specifications These cables are used to connect the encoder between a drive and a motor. Select the cable matching the motor. - Page 147 3-4 Cable and Connector Specifications R88A-CRKCxNR-E Cable types (For both absolute encoders and incremental encoders: [100 V and 200 V] For 3,000-r/min motors of 1 kW or more, [400 V] 3,000-r/min motors, 2,000-r/min motors and 1,000-r/min motors) Outer diameter of Model Length (L) Weight...

-

Page 148: Motor Power Cable Specifications

3-4 Cable and Connector Specifications Motor Power Cable Specifications These cables connect the drive and motor. Select the cable matching the motor. All cables and connectors listed are flexible, shielded and have IP67 protection. Power Cables without Brakes (European Flexible Cables) R88A-CAKAxSR-E Cable types [100 V and 200 V] (For 3,000-r/min motors of 50 to 750 W) - Page 149 3-4 Cable and Connector Specifications R88A-CAGBxSR-E Cable types 200 V: (For 3,000-r/min motors of 1 to 2 kW, 2,000-r/min motors of 1 to 2 kW, 1,000-r/min motors of 900 W) 400 V: (For 3,000-r/min motors of 750W to 2 kW, 2,000-r/min motors of 400 W to 2 kW, 1,000-r/min motors of 900 W) Outer diameter of Model...

- Page 150 3-4 Cable and Connector Specifications R88A-CAGDxSR-E Cable types (For 3,000-r/min motors of 3 to 5 kW, 2,000-r/min motors of 3 to 5 kW, 1,000-r/min motors of 2 to 3 kW) Outer diameter of Model Length (L) Weight sheath R88A-CAGD001-5SR-E 1.5 m Approx.

- Page 151 3-4 Cable and Connector Specifications Power Cables with Brakes (European Flexible Cables) R88A-CAGBxBR-E Cable types 200 V: (For 3,000-r/min motors of 1 to 2 kW, 2,000-r/min motors of 1 to 2 kW, 1,000-r/min motors of 900 W) Outer diameter of Model Length (L) Weight...

- Page 152 3-4 Cable and Connector Specifications R88A-CAKFxBR-E Cable types 400 V: (For 3,000-r/min motors of 750W to 2 kW, 2,000-r/min motors of 400 W to 2 kW, 1,000-r/min motors of 900 W) Outer diameter of Model Length (L) Weight sheath R88A-CAKF001-5BR-E 1.5 m Approx.

- Page 153 3-4 Cable and Connector Specifications R88A-CAGDxBR-E Cable types (For 3,000-r/min motors of 3 to 5 kW, 2,000-r/min motors of 3 to 5 kW, 1,000-r/min motors of 2 to 3 kW) Outer diameter of Model Length (L) Weight sheath R88A-CAGD001-5BR-E 1.5 m Approx.

-

Page 154: Connector Specifications

3-4 Cable and Connector Specifications Connector Specifications Control I/O Connector (R88A-CNW01C) This is the connector to be connected to the drive's control I/O connector (CN1). Use this connector when preparing a control cable by yourself. Dimensions Connector plug model 10150-3000PE (Sumitomo 3M) Connector case model 10350-52A0-008 (Sumitomo 3M) t = 18... - Page 155 3-4 Cable and Connector Specifications R88A-CNK02R (motor side) Adaptive motors 100-V, 3,000-r/min motors of 50 to 400 W Use the following cable. 200-V, 3,000-r/min motors of 50 to 750 W Applicable wire: AWG22 max. Insulating cover outer diameter: 1.3 mm dia. max. Outer diameter of sheath: 5 ±...

- Page 156 3-4 Cable and Connector Specifications Power Cable Connector (R88A-CNK11A) This connector is used for power cables. Use it when preparing a power cable by yourself. 17.6 R5.5 14.7 28.8 Angle plug model JN8FT04SJ1 Angle plug direction can be reversed. (Japan Aviation Electronics) Socket contact model ST-TMH-S-C1B-3500-(A534G) (Japan Aviation Electronics) Brake Cable Connector (R88A-CNK11B)

-

Page 157: Analog Monitor Cable Specifications

3-4 Cable and Connector Specifications Analog Monitor Cable Specifications Analog Monitor Cable (R88A-CMK001S) Connection configuration and external dimensions Symbol Black White Cable: AWG24 × 3C UL1007 Connector housing: 51004-0600 (Molex Japan) Connector terminal: 50011-8100 (Molex Japan) 1,000 mm (1 m) OMNUC G5-Series AC Servo Drives Users Manual (Built-in MECHATROLINK-II communications type) 3-68 WWW.BSNEW.IR... - Page 158 3-4 Cable and Connector Specifications External Encoder Connector (R88A-CNK41L) Use this connector to connect to an external encoder in full closing control. (42.5) 13.6 (10.5) 10.4 Connector plug model MUF-PK10K-X (J.S.T. Mfg. Co., Ltd.) Safety I/O Signal Connector (R88A-CNK81S) Use this connector to connect to safety devices. φ6.7 3-69 OMNUC G5-Series AC Servo Drives Users Manual (Built-in MECHATROLINK-II communications type)

-

Page 159: Mechatrolink-Ii Communications Cable Specifications

3-4 Cable and Connector Specifications MECHATROLINK-II Communications Cable Specifications The MECHATROLINK-II Communications Cable is equipped with a connector on each end and a core. Cable Types Name Model Length (L) FNY-W6003-A5 0.5 m FNY-W6003-01 FNY-W6003-03 MECHATROLINK-II Communications FNY-W6003-05 Cable FNY-W6003-10 10 m FNY-W6003-20 20 m... - Page 160 3-4 Cable and Connector Specifications Wiring This is an example to connect a host controller and the Servo Drive by the MECHATROLINK- II Communications Cable. NC Unit Terminating Resistor Note 1.The cable between the two nodes (L1, L2 ... or Ln) must be 0.5 m or longer. Note 2.

-

Page 161: Control Cable Specifications

Connector case: EXT1 EXT1 10326-52A0-008 (Sumitomo 3M) EXT2 EXT2 EXT3 EXT3 [Terminal Block Connector] BATGND BATGND Connector socket: XG4M-2030 (OMRON) BKIRCOM BKIRCOM Strain relief: BKIR BKIR XG4T-2004 (OMRON) ALMCOM ALMCOM [Cable] Shell AWG28 × 3P + AWG28 × 7C UL2464 * Before you use, confirm that the signals of Servo Drive connector are set as shown above. - Page 162 3-4 Cable and Connector Specifications Connector-Terminal Block Conversion Unit (XW2B-20Gx) The Unit is used with a Connector Terminal Block Cable (XW2Z-xJ-B34). They convert the control input signal (CN1) of the G5-series Servo Drive into a terminal block. Terminal Block Models Model Description XW2B-20G4...

- Page 163 3-4 Cable and Connector Specifications XW2B-20G5 Dimensions Flat cable connector (MIL type plug) 112.5 φ Terminal block Note The pitch of terminals is 8.5 mm. Precautions for Correct Use When using crimp terminals, use crimp terminals with the following dimensions. Fork terminal Round terminal φ3.7 mm...

- Page 164 3-4 Cable and Connector Specifications XW2D-20G6 Dimensions (39.1) 17.6 2- φ 4.5 Precautions for Correct Use When using crimp terminals, use crimp terminals with the following dimensions. Round terminal Fork terminal φ3.2mm 5.8 mm max. 5.8 mm max. 3.2 mm Applicable crimp terminals Applicable wires Round terminals...

- Page 165 3-4 Cable and Connector Specifications Terminal Block Wiring Example The example is common for XW2B-20G4, -20G5, and XW2D-20G6. +24 V +24 V +24 V STOP EXT1 EXT3 BKIR EXT2 BATGND BKIRCOM ALMCOM 24 VDC 24 VDC *1. Assign the brake interlock output (BKIR) to CN1-1 pin. *2.

-

Page 166: External Regeneration Resistor Specifications

3-5 External Regeneration Resistor Specifications 3-5 External Regeneration Resistor Specifications External Regeneration Resistor Specifications R88A-RR08050S Regeneration Resistance Nominal Heat radiation Thermal switch Model absorption for 120°C value capacity condition output specifications temperature rise Operating temperature Aluminum R88A- 150°C ± 5% NC contact 50 Ω... - Page 167 3-5 External Regeneration Resistor Specifications R88A-RR50020S Regeneration Resistance Nominal Heat radiation Thermal switch Model absorption for 120°C value capacity condition output specifications temperature rise Operating temperature 200°C ± 7°C Aluminum R88A- NC contact 20 Ω 500 W 180 W 600 × 600, RR50020S Rated output: 250 VAC, Thickness: 3.0...

-

Page 168: Emc Filter Specifications

3-6 EMC Filter Specifications 3-6 EMC Filter Specifications Specifications Applicable Rated Leakage Filter Model Rated voltage Manufacturer servo drive current current R88D-KNA5L-ML2 R88D-KN01L-ML2 R88A-FIK102-RE 2.4 A R88D-KN02L-ML2 R88D-KN04L-ML2 R88A-FIK104-RE 4.1 A R88D-KN01H-ML2 250 VAC single- R88A-FIK102-RE 2.4 A phase R88D-KN02H-ML2... -

Page 169: Mechatrolink-Ii Repeater Unit Specifications

3-7 MECHATROLINK-II Repeater Unit Specifications 3-7 MECHATROLINK-II Repeater Unit Specifications The MECHATROLINK-II Repeater Units are necessary to extend the MECHATROLINK-II connection distance. Specifications FNY-REP2000 Item Description Between a Controller and a Repeater Unit: 50 m max Cable length Between a Repeater Unit and a Terminating Resistor: 50 m max Between a Controller and a Repeater Unit: 14 nodes in every 50 m, or 15 nodes in every 30 m, Between a Repeater Unit and a Terminating Resistor: 15 nodes in every 50 m, or... -

Page 170: Repeater Unit Part Names

3-7 MECHATROLINK-II Repeater Unit Specifications Repeater Unit Part Names Power-on LED (POWER) DIP switches (SW) CN1: transmitting (TX1) * Keep all pins off while use. CN2: communicating (TX2) MECHATROLINK-II communications connector (CN1 and CN2) Control power terminal (24-VDC and 0-VDC) Protective ground terminal 3-81 OMNUC G5-Series AC Servo Drives Users Manual (Built-in MECHATROLINK-II communications type) -

Page 171: Connection Method

3-7 MECHATROLINK-II Repeater Unit Specifications Connection Method This is an example to connect a Host Controller, a Repeater Unit and plural Servo Drives. MECHATROLINK-II MECHATROLINK-II 15 nodes max for less than 30-m distance 16 nodes max for less than 30-m distance 14 nodes max for a 30- to 50-m distance 15 nodes max for a 30- to 50-m distance 100 m max, equal to the maximum number of nodes connectable to a Controller... - Page 172 WWW.BSNEW.IR...

- Page 173 System Design Accurax This chapter explains the installation conditions, wiring methods including wiring conforming to EMC directives and regenerative energy calculation methods regarding the Servo Drive, Servomotor, as well as the performance of External Regeneration Resistors, and so on. 4-1 Installation Conditions ..........4-1 4-2 Wiring................4-7 4-3 Wiring Conforming to EMC Directives......4-21 4-4 Regenerative Energy Absorption......4-40...

-

Page 174: Installation Conditions

4-1 Installation Conditions 4-1 Installation Conditions Servo Drive Installation Conditions Dimension Conditions around Equipment Install drives according to the dimensions shown in the following illustration to ensure proper heat dispersion inside the drive and convection inside the panel. If the drives are installed side by side, install a fan for air circulation to prevent uneven temperatures inside the panel. - Page 175 4-1 Installation Conditions Ambient Temperature Control To operate in environments in which there is minimal temperature rise is recommended to maintain a high level of reliability. When the drive is installed in a closed space, such as a box, ambient temperature may rise due to temperature rise in each unit.

-

Page 176: Servomotor Installation Conditions

4-1 Installation Conditions Servomotor Installation Conditions Environment Operating Conditions The environment in which the motor is operated must meet the following conditions. Operating the motor out of the following ranges may result in malfunction of the motor. Operating ambient temperature: 0 to +40°C Operating humidity: 85% RH max. - Page 177 4-1 Installation Conditions When connecting to a V-belt or timing belt, consult the manufacturer for belt selection and tension. A radial load twice as large as the belt tension can be placed on the motor shaft. Do not allow the allowable radial load or more to be placed on the motor shaft.

- Page 178 4-1 Installation Conditions Radiator Plate Installation Conditions When you mount a Servomotor onto a small device, be sure to provide enough radiation space on the mounting area. Otherwise the Servomotor temperature rises too high to break. One of the preventive measures is to install a radiator plate between the motor attachment area and the motor flange.

-

Page 179: Decelerator Installation Conditions

4-1 Installation Conditions Decelerator Installation Conditions Using Another Company's Decelerator (Reference) If the system configuration requires another company's decelerator to be used in combination with an Accurax G5-Series motor, select the decelerator so that the load on the motor shaft (i.e., both the radial and thrust loads) is within the allowable range. -

Page 180: Wiring

Confirming to EMC Directives. 24 VDC *2. Recommended relay: MY relay by OMRON (24-V type) ALMCOM For example, MY2 relay by OMRON can be used with all G5-series motors with brakes because its rated 24 VDC OUTM1 induction load is 2 A (24 VDC). - Page 181 *2. Recommended relay: MY relay by /ALM OMRON (24-V type) For example, MY2 24 VDC relay by OMRON can be used with all ALMCOM G5-series motors with brakes because its rated induction load is 2 A (24 VDC). 24 VDC OUTM1 *3.

- Page 182 Wiring Confirming to EMC Directives. *2. Recommended relay: MY relay by /ALM OMRON (24-V type) For example, MY2 24 VDC relay by OMRON can be used with all ALMCOM G5-series motors with brakes because its rated induction load is 2 A (24 VDC). OUTM1 24 VDC *3.

- Page 183 Wiring Confirming to EMC Directives. *2. Recommended relay: MY relay by /ALM OMRON (24-V type) For example, MY2 24 VDC relay by OMRON can be used with all ALMCOM G5-series motors with brakes because its rated induction load is 2 A (24 VDC). OUTM1 24 VDC *3.

- Page 184 Wiring Confirming to EMC Directives. *2. Recommended relay: MY relay by /ALM OMRON (24-V type) For example, MY2 24 VDC relay by OMRON can be used with all ALMCOM G5-series motors with brakes because its rated induction load is 2 A (24 VDC). OUTM1 24 VDC *3.

- Page 185 4-2 Wiring R88D-KN30F-ML2/-KN50F-ML2 Ω Ω OMNUC G5-Series AC Servo Drives Users Manual (Built-in MECHATROLINK-II communications type) 4-12 WWW.BSNEW.IR...

-

Page 186: Main Circuit And Motor Connections

4-2 Wiring Main Circuit and Motor Connections When wiring the main circuit, use proper wire sizes, grounding systems, and noise resistance. R88D-KNA5L-ML2/-KN01L-ML2/-KN02L-ML2/-KN04L-ML2/-KN01H-ML2/ -KN02H-ML2/-KN04H-ML2/-KN08H-ML2/-KN10H-ML2/-KN15H-ML2 Main Circuit Connector Specifications (CNA) Symbol Name Function R88D-KNxL-ML2 (50 to 400 W) : Single-phase 100 to 120 VAC (85 to 127 V) 50/60 Hz... - Page 187 4-2 Wiring R88D-KN20H-ML2 Main Circuit Connector Specifications (CNA) Symbol Name Function Main circuit power supply R88D-KN20H-ML2 (2 kW) : input 3-phase: 200 to 230 VAC (170 to 253 V) 50/60 Hz Control circuit power R88D-KN20H-ML2 : supply input Single-phase 200 to 230 VAC (170 to 253 V) 50/60 Hz Motor Connector Specifications (CNB) Symbol Name...

- Page 188 4-2 Wiring R88D-GN30H/-GN50H-ML2 Terminal Block Specifications Symbol Name Function Main circuit power supply R88D-KNxH-ML2 (3 to 5 kW): 3-phase 200 to 230 VAC (170 to 253 input V) 50/60 Hz R88D-KNxH-ML2: Single-phase 200 to 230 VAC (170 to 253 V) 50/ Control circuit power 60 Hz supply input...

- Page 189 4-2 Wiring Control Circuit Connector Specifications (CNC) Symbol Name Function 24 V Control circuit power 24 VDC (21.6 to 26.4 V) supply input External Regeneration Resistor Connector Specifications (CND) Symbol Name Function External Regeneration Normally B2 and B3 are short-circuited. Resistor connection If there is high regenerative energy, remove the short-circuit bar terminals...

- Page 190 − Screw size − Tightening torque N•m *1. Connect OMRON Power Cables to the motor connection terminals. *2. Use the same wire sizes for B1 and B2. 4-17 OMNUC G5-Series AC Servo Drives Users Manual (Built-in MECHATROLINK-II communications type) WWW.BSNEW.IR...

- Page 191 N•m *1. The left value is for single-phase input and the right value is for 3-phase input. *2. Connect an OMRON power cable to the motor connection terminals. *3. Use the same wire sizes for B1 and B2. OMNUC G5-Series AC Servo Drives Users Manual (Built-in MECHATROLINK-II communications type) 4-18 WWW.BSNEW.IR...

- Page 192 − Tightening torque N•m *1. Connect OMRON Power Cables to the motor connection terminals. *2. Use the same wire sizes for B1 and B2. Wire Sizes and Allowable Current (Reference) The following table shows the allowable current when there are 3 power supply wires. Use a current below these specified values.

- Page 193 4-2 Wiring Terminal Block Wiring Procedure On a Servo Drive with 2.0 kW or less, a connector-type terminal block is used. The procedure for wiring these terminal blocks is explained below. Connector-type terminal block (Example of R88D-KN02H-ML2) 1. Remove the terminal block from the Servo Drive before wiring. The Servo Drive may be damaged if the wiring is done with the terminal block in place.

-

Page 194: Wiring Conforming To Emc Directives

Single-phase: 100 VAC Controller *1. For models with a single-phase power supply input (R88D-KNA5L-ML2/-KN01L-ML2/-KN02L-ML2/- KN04L-ML2/-KN01H-ML2/-KN02H-ML2/-KN04H-ML2/-KN08H-ML2), the main circuit power supply input terminals are L1 and L3. Ground the motor's frame to the machine ground when the motor is on a movable shaft. - Page 195 Industries Co., Ltd. Noise filter 3SUP-HU30-ER-6 3-phase 200 VAC (30 A) 3SUP-HL50-ER-6B 3-phase 200 VAC (50 A) See chapter 3 1-phase 200 VAC Rasmi 3-phase 400 VAC Servo Drive OMRON − Servomotor OMRON − Clamp core ZACT305-1330 − Controller Switch box −...

- Page 196 We recommend you to use the noise filter for the Servo Drive. Noise Filter for Power Supply Input Drive model Rated Leakage Current Model Phase Manufacturer Current (60 Hz) max R88D-KNA5L-ML2 Single- 1.0 mA R88D-KN01L-ML2 SUP-EK5-ER-6 phase (at 250 VAC) R88D-KN02L-ML2 R88D-KN04L-ML2 3.5 mA...

- Page 197 4-3 Wiring Conforming to EMC Directives For operations, if no-fuse breakers are installed at the top and the power supply line is wired from the lower duct, use metal tubes for wiring or make sure that there is adequate distance between the input lines and the internal wiring.

- Page 198 4-3 Wiring Conforming to EMC Directives Control Panel Structure Openings in the control panel, such as holes for cables, panel mounting holes, and gaps around the door, may allow electromagnetic waves into the panel. To prevent this, observe the recommendations described below when designing or selecting a control panel. Case Structure Use a metal control panel with welded joints at the top, bottom, and sides so that the surfaces are electrically conductive.

-

Page 199: Selecting Connection Component

20-ms allowable current that is greater than the total inrush current, shown in the following table. Inrush current (Ao-p) Drive model Main circuit Control circuit power supply power supply R88D-KNA5L-ML2 R88D-KN01L-ML2 R88D-KN02L-ML2 R88D-KN04L-ML2 R88D-KN01H-ML2 R88D-KN02H-ML2 R88D-KN04H-ML2 R88D-KN08H-ML2 R88D-KN10H-ML2... - Page 200 4-3 Wiring Conforming to EMC Directives Inrush current (Ao-p) Drive model Main circuit Control circuit power supply power supply R88D-KN06F-ML2 R88D-KN10F-ML2 R88D-KN15F-ML2 R88D-KN20F-ML2 R88D-KN30F-ML2 R88D-KN50F-ML2 Leakage Breaker Select leakage breakers designed for protection against ground faults. Because switching takes place inside the Servo Drives, high-frequency current leaks from the SW elements of the Servo Drive, the armature of the motor, and the cables.

- Page 201 4-3 Wiring Conforming to EMC Directives Surge Absorber Use surge absorbers to absorb lightning surge voltage and abnormal voltage from power supply input lines. When selecting surge absorbers, take into account the varistor voltage, the surge immunity and the energy tolerated dose. For 200-VAC systems, use surge absorbers with a varistor voltage of 620 V.

- Page 202 Noise Filter for Power Supply Input We recommend you to use the noise filter for the Servo Drive. Noise Filter for Power Supply Input Drive model Rated Model Phase Leakage Current Manufacturer Current R88D-KNA5L-ML2 R88D-KN01L-ML2 R88A-FIK102-RE 2.4 A R88D-KN02L-ML2 R88D-KN04L-ML2 R88A-FIK104-RE 4.1 A R88D-KN01H-ML2...

- Page 203 4-3 Wiring Conforming to EMC Directives 3SUP-HU30-ER-63SUP-HL50-ER-6B ±3.0 ±1.0 2-φ5.5 2-φ5.5×7 Ground terminal Attachment screw for cover M3 Cover Noise filter unit OMNUC G5-Series AC Servo Drives Users Manual (Built-in MECHATROLINK-II communications type) 4-30 WWW.BSNEW.IR...

- Page 204 4-3 Wiring Conforming to EMC Directives Circuit Diagram SUP-EK5-ER-6 3SUP-HQ10-ER-6 3SUP-HU30-ER-6 3SUP-HL50-ER-6B LINE LOAD Noise Filter for the Brake Power Supply Use the following noise filter for the brake power supply. Rated Rated Model Leakage current Manufacturer current voltage Okaya Electric SUP-EK5-ER-6 250 V 1.0 mA (at 250 Vrms, 60 Hz)

- Page 205 Use one of the following filters to prevent switching noise of PWM of the Servo Drive and to prevent noise emitted from the internal clock circuit. Model Manufacturer Application 3G3AX-ZCL1 OMRON For Drive output and power cable 3G3AX-ZCL2 OMRON For Drive output and power cable ESD-R-47B...

- Page 206 4-3 Wiring Conforming to EMC Directives Impedance Characteristics 3G3AX-ZCL1 3G3AX-ZCL2 1000 1000 10000 Frequency (kHz) Frequency (kHz) ESD-R-47B ZCAT3035-1330 1000 10000 1000 1000 1000 Frequency (MHz) Frequency (MHz) 4-33 OMNUC G5-Series AC Servo Drives Users Manual (Built-in MECHATROLINK-II communications type) WWW.BSNEW.IR...

- Page 207 J7L-09-22200 11 A 200 VAC J7L-12-22200 13 A 200 VAC J7L-18-22200 18 A 200 VAC J7L-32-22200 26 A 200 VAC OMRON J7L-40-22200 35 A 200 VAC J7L-50-22200 50 A 200 VAC J7L-65-22200 65 A 200 VAC J7L-75-22200 75 A 200 VAC...

- Page 208 4-3 Wiring Conforming to EMC Directives Improving Encoder Cable Noise Resistance Take the following steps during wiring and installation to improve the encoder's noise resistance. Always use the specified encoder cables. If cables are joined midway, be sure to use connectors. And do not remove more than 50 mm of the cable insulation.

- Page 209 4-3 Wiring Conforming to EMC Directives Improving Control I/O Signal Noise Resistance Positioning can be affected and I/O signal errors can occur if control I/O is influenced by noise. Use completely separate power supplies for the control power supply (especially 24 VDC) and the external operation power supply.

- Page 210 Components require that manufacturers take appropriate remedies to suppress harmonic current emissions onto power supply lines. Select the proper Reactor model according to the Servo Drive to be used. Reactor Drive model Rated Model Inductance current R88D-KNA5L-ML2 3G3AX-DL2002 1.6 A 21.4 mH R88D-KN01H-ML2 R88D-KN01L-ML2 3G3AX-DL2004 3.2 A 10.7 mH...

- Page 211 Manufacturer Model Comment current 3G3AX-NF001 3G3AX-NF002 12 A 3G3AX-NF003 25 A OMRON For inverter output 3G3AX-NF004 50 A 3G3AX-NF005 75 A 3G3AX-NF006 100 A Note 1. Motor output lines cannot use the same noise filters for power supplies. Note 2. General noise filters are made for power supply frequencies of 50/60 Hz. If these noise filters are connected to the PWM output of the Servo Drive, a very large (about 100 times larger) leakage current may flow through the noise filter's capacitor and the Servo Drive could be damaged.

- Page 212 4-3 Wiring Conforming to EMC Directives 3G3AX-NF003/-NF004/-NF005/-NF006 6−O 2−N 4−φ6.5 Dimensions (mm) Model 3G3AX-NF003 − − 3G3AX-NF004 3G3AX-NF005 3G3AX-NF006 4-39 OMNUC G5-Series AC Servo Drives Users Manual (Built-in MECHATROLINK-II communications type) WWW.BSNEW.IR...

-

Page 213: Regenerative Energy Absorption

4-4 Regenerative Energy Absorption 4-4 Regenerative Energy Absorption The Servo Drives have internal regeneration process circuitry, which absorbs the regenerative energy produced during motor deceleration and prevents the DC voltage from increasing. An overvoltage error occurs, however, if the amount of regenerative energy from the motor is too large. - Page 214 4-4 Regenerative Energy Absorption Vertical Axis Downward movement Motor operation Upward movement −N Motor output torque In the output torque graph, acceleration in the forward direction (rising) is shown as positive, and acceleration in the reverse direction (falling) is shown as negative. The regenerative energy values in each region can be derived from the following equations.

-

Page 215: Servo Drive Regeneration Absorption Capacity

Lengthen the operation cycle, i.e., the cycle time. (Average regenerative power decreases.) Internal regeneration Allowable resistor Regenerative energy minimum Servo Drive model absorbable by built-in Average amount of regeneration capacitor (J) regenerative energy resistance (Ω) absorbable (W) R88D-KNA5L-ML2 − R88D-KN01L-ML2 − R88D-KN02L-ML2 − R88D-KN04L-ML2 R88D-KN01H-ML2 − R88D-KN02H-ML2 − R88D-KN04H-ML2 − R88D-KN08H-ML2... -

Page 216: Regenerative Energy Absorption With An External Regeneration Resistor

4-4 Regenerative Energy Absorption Regenerative Energy Absorption with an External Regeneration Resistor If the regenerative energy exceeds the regeneration absorption capacity of the drive, connect an External Regeneration Resistor. Connect the External Regeneration Resistor between B1 and B2 terminals on the drive. Double-check the terminal names when connecting the resistor because the drive may be damaged if connected to the wrong terminals. -

Page 217: Connecting An External Regeneration Resistor

4-4 Regenerative Energy Absorption Connecting an External Regeneration Resistor R88D-KNA5L-ML2/-KN01L-ML2/-KN02L-ML2/-KN01H-ML2/-KN02H-ML2/-KN04H-ML2 Normally B2 and B3 are open. If an External Regeneration Resistor is necessary, connect the External Regeneration Resistor between B1 and B2 as shown in the diagram below. Servo Drive Thermal switch output θ... - Page 218 4-4 Regenerative Energy Absorption Combining External Regeneration Resistors Regeneration absorption 20 W 40 W 70 W 140 W capacity R88A-RR08050S R88A-RR08050S R88A-RR22047S R88A-RR22047S Model R88A-RR080100S R88A-RR080100S Resistance 50 Ω/100 Ω 25 Ω/50 Ω 47 Ω 94 Ω value Connection method Regeneration 140 W 280 W...

- Page 219 BASIC CONTROL Mode This chapter explains an outline of operations available in various CONTROL modes and explains the contents of setting. 5-1 Position Control............5-1 5-2 Speed Control ...............5-4 5-3 Torque Control..............5-6 5-4 Full Closing Control .............5-9 OMNUC G5-Series AC Servo Drives Users Manual (Built-in MECHATROLINK-II communications type) WWW.BSNEW.IR...

-

Page 220: Position Control

5-1 Position Control 5-1 Position Control The CJ1W- and CS1W-NCx71 Position Control Units for MECHATROLINK-II issue the position control commands. The Servo Drive uses the commands and rotates the motor in the values obtained by multiplying the command by the Electronic Gear Ratio (determined by the settings in Pn009 or Pn010) Servo Drive Host Controller... -

Page 221: Related Functions

5-1 Position Control Related Functions Parameter Parameter name Explanation Reference number Position Command Filter Set the time constant of the first-order lag filter for the Pn222 P.8-24 Time Constant position command. Positioning Completion Set the threshold of position error for output of the positioning Pn431 P.8-36 Range 1... -

Page 222: Parameter Block Diagram For Position Control Mode

5-1 Position Control Parameter Block Diagram for POSITION CONTROL mode OMNUC G5-Series AC Servo Drives Users Manual (Built-in MECHATROLINK-II communications type) WWW.BSNEW.IR... -

Page 223: Speed Control

5-2 Speed Control 5-2 Speed Control The CJ1W- and CS1W-NCx71 Position Control Units for MECHATROLINK-II issue the speed control commands. The Servo Drive uses the commands and rotates the motor in the commanded speed output. The present value to be fed back from the Servo Drive to the Controller is the values obtained by dividing the command by the Electronic Gear Ratio (determined by the settings in Pn009 or Pn010). -

Page 224: Parameter Block Diagram For Speed Control Mode

5-2 Speed Control Parameter Block Diagram for SPEED CONTROL mode OMNUC G5-Series AC Servo Drives Users Manual (Built-in MECHATROLINK-II communications type) WWW.BSNEW.IR... -

Page 225: Torque Control