Table of Contents

Advertisement

Quick Links

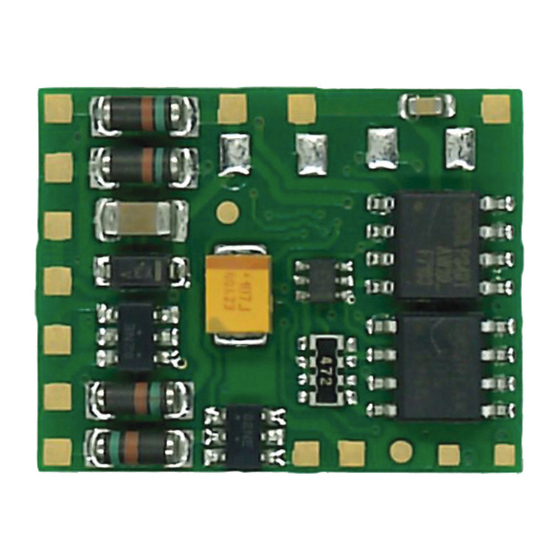

LD-G-42.2 | LD-W-42.2

MM

DCC

LD-G-42.2 without

connecting wires

Item no. 41-04480

LD-W-42.2 without

connecting wires

Item no. 41-05480

Locomotive decoders

DCC-A

LD-G-42.2 with

connecting wires

Item no. 41-04481

LD-W-42.2 with

connecting wires

Item no. 41-05481

tams elektronik

Manual

LD-G-42.2 with

NEM 652 interface

Item no. 41-04482

n n n

Advertisement

Table of Contents

Summary of Contents for tams elektronik LD-G-42.2

- Page 1 Locomotive decoders LD-G-42.2 | LD-W-42.2 Manual DCC-A LD-G-42.2 without LD-G-42.2 with LD-G-42.2 with connecting wires connecting wires NEM 652 interface Item no. 41-04480 Item no. 41-04481 Item no. 41-04482 LD-W-42.2 without LD-W-42.2 with connecting wires connecting wires Item no. 41-05480 Item no.

- Page 2 © Tams Elektronik GmbH All rights reserved, in particular the right of reproduction, distribution and translation. Copies, reproductions and alterations in any form require the written permission of Tams Elektronik GmbH. We reserve the right to make technical changes. Printing the manual The formatting is optimised for double-sided printing.

-

Page 3: Table Of Contents

3.4. Connector pin assignment LD-G-42.2..............25 3.5. Connector pin assignment LD-W-42.2..............26 3.6. Using decoders with interface connectors.............27 3.7. Use of the LD-G-42.2 in locomotives with AC motor..........27 3.8. Mounting decoders without interface..............28 3.8.1. Connecting the decoder to the motor............28 3.8.2. Connecting accessories to the outputs............29 3.9. - Page 4 4. Programming......................35 4.1. Programming with DCC central units..............35 4.2. Programming with Motorola central units.............36 5. Configuration variables and registers................37 5.1. Overview configuration variables LD-G-42.2 and LD-W-42.2........37 5.2. Basic settings.....................39 5.3. Setting the address.....................40 5.4. Setting the motor control..................41 5.5. Function mapping....................44 5.6.

-

Page 5: Getting Started

Versions Connecting wires / Interface (item number) 41-04480 LD-G-42.2 without cables / interface 41-04481 LD-G-42.2 with connecting cables (cable length: 100 mm) 41-04482 LD-G-42.2 with 8-pole plug according to NEM 652 41-05480 LD-W-42.2 without cables / interface 41-05481 LD-W-42.2 with connecting cables (cable length: 100 mm) 1.2. - Page 6 Connection of a LD-G-42.2 to an AC motor If you want to connect a LD-G-42.2 decoder (for DC motors) to an AC motor, you will need: a load control adapter LRA (item no. 70-02105 or 70-02106) or ...

-

Page 7: Intended Use

LD-G-42.2 | LD-W-42.2 1.3. Intended use The locomotive decoders LD-G-42.2 and LD-W-42.2 are designed to be operated according to the instructions in this manual in model building, especially in digital model railroad layouts. Any other use is inappropriate and invalidates any guarantees. -

Page 8: The Locomotive Decoders Ld-G-42.2 And Ld-W-42.2

the use of a digital control unit that supports SDF the installation of vehicle decoders that support SDF setting the speed step mode 28 / 128 on the decoder. 8 | The locomotive decoders LD-G-42.2 and LD-W-42.2... -

Page 9: Analogue Mode

LD-G-42.2 | LD-W-42.2 2.2. Analogue mode The locomotive decoders LD-G-42.2 and LD-W-42.2 can also be used in analogue model railway layouts run with an AC or DC speed control. The decoders automatically detect whether an AC or DC speed control is used to power the layout. -

Page 10: Overload Protection

2.3. Overload protection The locomotive decoders LD-G-42.2 and LD-W-42.2 have an overload protection which protects it from damage in case of exceeding the permissible total current or a short circuit at the motor output (the maximum form of an overload). If an overload is detected, the motor is switched off and lights that are switched with F0f or F0r flash. -

Page 11: Motor Control

60 Hz Load control The LD-G-42.2 has a load control. The load control influences the motor voltage to keep the locomotive with a set speed level at constant velocity, independent of additional loads (e.g. running up a gradient, coupled carriages). - Page 12 On delivery, the function F3 is assigned to the special function "SG". In the shunting gear mode, the velocity of all speed levels is reduced to approx. 50 % compared to the set velocity. 12 | The locomotive decoders LD-G-42.2 and LD-W-42.2...

- Page 13 CV and on the speed level when the braking process is triggered. An exact stop at stopping points is not possible. For the decoders LD-G-42.2 and LD-W-42.2 a constant braking distance can be defined, which the locomotive should cover when changing from any speed level to speed level 0. The braking distance corresponds to the distance that the locomotive covers with the set brake delay at the highest possible speed level until it comes to a stop.

-

Page 14: Automated Processes

/ a function key. 2.5.1. ABC braking procedure With the appropriate CV setting,the LD-G-42.2 and LD-W-42.2 locomotive decoders detect when entering an ABC braking section that an asymmetrical track voltage is present and then automatically reduce the driving speed with the set brake delay or braking distance. They can... -

Page 15: Braking At Dc Voltage

2.5.2. Braking at DC voltage The locomotive decoders LD-G-42.2 and LD-W-42.2 react to the application of a pure DC voltage (e.g. Märklin** braking section) with the corresponding CV setting and then automatically reduces the driving speed with the set brake delay or the set braking distance. -

Page 16: Automatic Uncoupling ("Uncoupling Waltz")

"STOP/START with a function". When the assigned function is switched on, the locomotive stops with the set braking delay; when it is switched off, it continues with the set acceleration delay. On delivery, no function is assigned to the special function "STOP". 16 | The locomotive decoders LD-G-42.2 and LD-W-42.2... -

Page 17: Outputs And Interfaces

Assignment separately for each output. Setting the flashing CV 101...102 frequency together for two outputs. By assigning the flashing function to two outputs and the function "Inverted switching" to one of the two outputs, an alternating flashing is generated. The locomotive decoders LD-G-42.2 and LD-W-42.2 | 17... - Page 18 Assignment separately for each output. Setting the voltage together for all outputs to which the function is assigned. Application example: automatic switching on and off of the driver's cab lighting at a certain voltage. 18 | The locomotive decoders LD-G-42.2 and LD-W-42.2...

-

Page 19: Triggering The Actions

Outputs F0f, F0r, AUX1, AUX2 on/off Uninterruptible power supply (UPS) on/off Stop/start (STOP) with a function active/inactive F0 to F28 F0 to F4 Shunting gear (SG) active/inactive Acceleration and brake delay (ABD) active/inactive The locomotive decoders LD-G-42.2 and LD-W-42.2 | 19... -

Page 20: Feedback With Railcom

2.8. Feedback with RailCom RailCom transmitter The locomotive decoders LD-G-42.2 and LD-W-42.2 are RailCom transmitters and fulfil the requirements of the RailCommunity standard RCN-217 "RailCom DCC feedback protocol" for mobile decoders (vehicle decoders). Sending RailCom messages is possible in layouts with a DCC signal on the rails only. It is not possible to use the RailCom-function in a pure Motorola environment. - Page 21 Method by which the decoder was registered with the control unit Functions and Specific icons can be assigned to the functions, function icons from which it is clear what they switch (e.g. front lighting, interior lighting, shunting gear). The locomotive decoders LD-G-42.2 and LD-W-42.2 | 21...

-

Page 22: Connections

LD-G-42.2 | LD-W-42.2 tams elektronik 3. Connections 3.1. Safety instructions Caution: Integrated circuits (ICs) are inserted on the decoder. They are sensitive to static electricity. Do not touch components without first discharging yourself. Touching a radiator or other grounded metal part will discharge you. -

Page 23: Safe And Correct Soldering

LD-G-42.2 | LD-W-42.2 Thermal danger A hot soldering iron or liquid solder accidentally touching your skin can cause skin burns. As a precaution: use a heat-resistant mat during soldering, always put the hot soldering iron in the soldering iron stand, ... -

Page 24: Avoiding Irreparable Damage To The Decoder

LD-G-42.2 | LD-W-42.2 tams elektronik After soldering, check (preferably with a magnifying glass) whether connections or tracks have been bridged with solder by mistake. This can lead to malfunction or destruction of components or, in the worst case, the complete circuit. You can re-liquefy excess solder with the clean hot soldering tip. -

Page 25: Connector Pin Assignment Ld-G-42.2

LD-G-42.2 | LD-W-42.2 3.4. Connector pin assignment LD-G-42.2 LD-G-42.2 Colour of Connection wire (for use of settings in state of delivery) Left track black Left current collector (or vehicle ground) Negative pole (-) of buffer capacitor / Earth connection IN... -

Page 26: Connector Pin Assignment Ld-W-42.2

LD-G-42.2 | LD-W-42.2 tams elektronik 3.5. Connector pin assignment LD-W-42.2 LD-W-42.2 Colour of Connection wire (for use of settings in state of delivery) Left track brown Left current collector (or vehicle ground) Negative pole (-) of buffer capacitor / Earth connection IN... -

Page 27: Using Decoders With Interface Connectors

(for motor connection 1) is located. 3.7. Use of the LD-G-42.2 in locomotives with AC motor The LD-G-42.2 has been designed to control direct current (DC) motors, for that reason it cannot be connected directly to alternating current (AC) motors. You can control AC motors with the LD-G-42.2 and benefit of the load control when... -

Page 28: Mounting Decoders Without Interface

LD-G-42.2 | LD-W-42.2 tams elektronik 3.8. Mounting decoders without interface Locate the position for the decoder after opening the locomotive housing. Disconnect the motor from the rail current collectors or the change-over switch from the motor and rails if you have a locomotive with electronic change-over switch. The change-over switch is no longer necessary, you can remove it. -

Page 29: Connecting Accessories To The Outputs

LD-G-42.2 | LD-W-42.2 3.8.2. Connecting accessories to the outputs Caution: The maximum current of the accessory must not exceed the maximum current of the output to which you connect it. The output may otherwise be irreparably damaged! Disconnect any existing diodes in the leads to the lamps, otherwise the lamps might not light. -

Page 30: Connecting Leds To The Function Outputs

LD-G-42.2 | LD-W-42.2 tams elektronik 3.9. Connecting LEDs to the function outputs The decoder´s function outputs switch respective to the decoder ground. For that reason you must connect the cathodes (-) of the LEDs to the function outputs and the anodes (+) to the decoder´s common return conductor for all function outputs (RC). - Page 31 LD-G-42.2 | LD-W-42.2 Parallel connection of LEDs Alternatively, you can connect several LEDs in parallel, each via a series resistor of its own. The current consumption is max. 20 mA for all LEDs, depending on the series resistor´s value.

-

Page 32: Connecting Inductive Loads

LD-G-42.2 | LD-W-42.2 tams elektronik 3.10. Connecting inductive loads When connecting inductive loads (e.g. TELEX couplings, relays or other accessories with coils), you should switch a free-wheeling diode (e.g. 1N400x) in parallel, in order to avoid damage at the output. Check to connect the anode of the diode to the function output. -

Page 33: Connecting The Switching Input

LD-G-42.2 | LD-W-42.2 3.11. Connecting the switching input The switching input switches against decoder ground and can therefore be connected to all (external) circuits that can be used to establish a ground connection. It is possible, for example, to connect reed contacts or Hall sensors which establish the ground connection as soon as they enter the magnetic field of a permanent magnet. -

Page 34: Connecting A Buffer Capacitor/Buffer Circuit

LD-G-42.2 | LD-W-42.2 tams elektronik 3.12. Connecting a buffer capacitor/buffer circuit In sections with bad contact to the rails (e.g. when running over turnouts) or with a (e.g. construction-related) bad current consumption of the locomotive, the power supply of the decoder can be interrupted briefly. -

Page 35: Completion

CV variables (Direct Programming) or the main track programming (PoM). Register programming is not supported by the LD-G-42.2 and the LD-W-42.2. You cannot program the decoders with DCC control units that only allow register programming. -

Page 36: Programming With Motorola Central Units

LD-G-42.2 | LD-W-42.2 tams elektronik 4.2. Programming with Motorola central units In Motorola format the settings are saved in registers. The registers have the same numbers as the configuration variables (CVs) for the DCC format. Please note: If you use a central unit for both DCC and Motorola format it is recommended to program the decoder in the DCC format. -

Page 37: Configuration Variables And Registers

Please note: With variables destined to set several parameters, the input value has to be calculated by adding the numerical values assigned to the desired parameters. 5.1. Overview configuration variables LD-G-42.2 and LD-W-42.2 Name Section of the manual Basic address 5.3. - Page 38 LD-G-42.2 | LD-W-42.2 tams elektronik Name Section of the manual Braking behaviour with DC voltage 5.9. Settings for driving operation RailCom channels 5.8. RailCom and DCC-A settings Configuration data 1 5.2. Basic settings 31 und 32 Index for higher CV-Pages 5.5.

-

Page 39: Basic Settings

LD-G-42.2 | LD-W-42.2 Name Section of the manual 123...127 Reserved for registration via DCC-A Values must not be changed! Values must not be changed! 257...485 Assignment of outputs and special 5.5. Function mapping functions to the functions 5.2. Basic settings... -

Page 40: Setting The Address

LD-G-42.2 | LD-W-42.2 tams elektronik Name Input values Remarks and tips (Default) Configuration 0, 4, 8, 12, 16 Reaction to ABC braking method: … 60 data 2 ABC braking method active ABC braking method inactive Inverted ABC detection Constant braking distance inactive... -

Page 41: Setting The Motor Control

5.4. Setting the motor control Optimisation of the driving characteristics By adjusting the load control (LD-G-42.2) and the motor characteristics curve (LD-G-42.2 and LD-W-42.2) the decoders are adapted to the individual characteristics of the locomotive motor. Please note: The installation of a decoder generally increases the effects of vehicle defects on driving characteristics. - Page 42 LD-G-42.2 | LD-W-42.2 tams elektronik Proceed as follows to set the load control parameters: If the locomotive is shuttering: Increase the value for CV 115 (KD) in steps of 2. If this does not lead to an improvement of the driving characteristics, set the value of CV 115 back to factory setting (default value).

- Page 43 LD-G-42.2 | LD-W-42.2 Setting the motor characteristic curve (continuation) Name Input values Remarks and tips (Default) Alternative 0 … 255 = Speed table for alternative speed characteristic curve characteristic. (only for mode 28 A specific motor voltage is assigned to speed steps) each of the 28 speed steps.

-

Page 44: Function Mapping

According to RCN-227, eight configuration variables (CVs) are assigned to each function (F0 to F28): four each for forward ("f") and reverse ("r"). Six of these are used for the LD-G-42.2 and LD-W-42.2 locomotive decoders (3 for forward and 3 for reverse): ... - Page 45 LD-G-42.2 | LD-W-42.2 off/on with Outputs Special functions function in use F0, F1, F2, Values …, F28, --- (on) (on) (on) (off) 0, 1, 2, Input 0, 1, 2, 3, 4,…, 255 0, 1, 2, 3, 4,…, 15 ...

- Page 46 LD-G-42.2 | LD-W-42.2 tams elektronik off/on with Outputs Special functions function in use F0, F1, F2, Values …, F28, --- (on) (on) (on) (off) 0, 1, 2, Input 0, 1, 2, 3, 4,…, 255 0, 1, 2, 3, 4,…, 15 ...

- Page 47 LD-G-42.2 | LD-W-42.2 off/on with Outputs Special functions function in use F0, F1, F2, Values …, F28, --- (on) (on) (on) (off) 0, 1, 2, Input 0, 1, 2, 3, 4,…, 255 0, 1, 2, 3, 4,…, 15 ...

- Page 48 LD-G-42.2 | LD-W-42.2 tams elektronik Example: Programming for shunting operation Hint: The connection of the return conductor is not shown. Outputs off/on with function AUX1 AUX2 … F28 --- Values … 28 255 CV-No. Set value CV-No. Set value name...

- Page 49 LD-G-42.2 | LD-W-42.2 Example: Programming for rear end signal "off" with coupled carriages Hint: The connection of the return conductor is not shown. Outputs off/on with function AUX1 AUX2 … F28 --- Values … 28 255 CV-No. Set value CV-No.

-

Page 50: Effects Of The Outputs

LD-G-42.2 | LD-W-42.2 tams elektronik 5.6. Effects of the outputs Dimming of the outputs Output Input values Remarks and tips (Default) = Reduction of the voltage applied to the 1...64 (64) output 1...64 (64) 1 = lowest voltage AUX1 1...64 (64) - Page 51 LD-G-42.2 | LD-W-42.2 Dimming up and down the outputs Name Input values Remarks and tips (Default) Time for dimming 1...255 (10) = Time until the maximum voltage is up and down reached or the voltage is reduced to "0".

- Page 52 LD-G-42.2 | LD-W-42.2 tams elektronik Kick time and automatic uncoupling ("uncoupling waltz") Name Input values Remarks and tips (Default) 0 ... 255 (32) Kicking time 0 = shortest kick time ("moment- 255 = longest kick time function") (= 25.5 seconds) Setting common for Increasing the input value by "1"...

-

Page 53: Settings For The Switching Inputs

LD-G-42.2 | LD-W-42.2 5.7. Settings for the switching inputs Name Input values Remarks and tips (Default) Assignment of the 1 … 255 (0) functions to the switching inputs F0 … F7 Assignment of the 1 … 255 (0) -

Page 54: Railcom And Dcc-A Settings

LD-G-42.2 | LD-W-42.2 tams elektronik 5.8. RailCom and DCC-A settings Name Input values Remarks and tips (Default) Dynamic 0,1 (0) RailCom Reception statistics: information The decoder keeps statistics on all DCC packets and reports the number of faulty packets / total number of packets in %. -

Page 55: Settings For Driving Operation

LD-G-42.2 | LD-W-42.2 5.9. Settings for driving operation Setting the Packet Time Out Name Input values Remarks and tips (Default) Packet Time Out 2 … 255 (16) Time period between the failure of the digital signal and the change to the alternative operation (analogue operation). - Page 56 LD-G-42.2 | LD-W-42.2 tams elektronik Braking behaviour with DC voltage Name Input values Remarks and tips (Default) Braking behaviour 0, 16, 32, 48 (48) No braking with d.c. voltage with DC voltage Braking with negative d.c. voltage Braking with positive d.c. voltage Tip: It is standard to switch over into analogue mode when applying a d.c.

-

Page 57: Settings For Analogue Mode

LD-G-42.2 | LD-W-42.2 5.10. Settings for analogue mode Name Input values Remarks and tips (Default) Functions 0 … 255 (0) F1 on active in F2 on analogue F3 on mode (F1 to F8) F4 on F5 on F6 on... -

Page 58: Auxiliary Functions

LD-G-42.2 | LD-W-42.2 tams elektronik 5.12. Auxiliary functions Name Input values Remarks and tips (Default) Reset 0 ... 255 Any input value restores the settings in state of delivery. Decoder lock 0 ... 255 (3) Changing the CV values of the decoder is only possible if the values in CV 15 and 16 0 ... -

Page 59: Checklist For Troubleshooting And Error Correction

LD-G-42.2 | LD-W-42.2 6. Checklist for troubleshooting and error correction Warning: ! ! ! If you notice a strong heat development or if the decoder starts to smoke, disconnect the connection to the supply voltage immediately. Fire hazard! Possible causes: ... -

Page 60: Problems With The Feedback Of The Decoder

LD-G-42.2 only: The load control is switched off. à Check the settings in CV 116. LD-G-42.2 only: The load control is poorly set. In this case the locomotive jerks or rocks when driving. à Set the default values again and follow the instructions in section 5.3 when setting the load control parameters again. -

Page 61: Problems When Switching Functions

LD-G-42.2 | LD-W-42.2 6.4. Problems when switching functions An additional device / lighting does not react to switching commands. Possible cause: The assignment of the functions to the output to which the device / lighting is connected is different than intended. -

Page 62: Technical Hotline

LD-G-42.2 | LD-W-42.2 tams elektronik 6.7. Technical Hotline If you have any questions about the use of the decoder, our technical hotline will help you (telephone number and e-mail address on the last page). 6.8. Repairs You can send us a decoder for inspection / repair (address on the last page). Please do not send us your return freight collect. -

Page 63: Technical Data

LD-G-42.2 | LD-W-42.2 7. Technical data Digital protocols Data formats Motorola II DCC (according to NMRA and RCN-standard) Formats for the automatic DCC-A according to RCN-218 (can be switched off) registration of vehicle decoders Feedback format RailCom according to RCN-211 (can be switched off) - Page 64 LD-G-42.2 | LD-W-42.2 tams elektronik Protection Protection class IP 00 Meaning: No protection against solid foreign bodies. No protection against water. Overload Automatic switch-off when the permissible total current is exceeded or a short circuit at the motor output ("short-circuit shutdown")

-

Page 65: Warranty, Eu Conformity & Weee

LD-G-42.2 | LD-W-42.2 8. Warranty, EU conformity & WEEE 8.1. Guarantee bond For this product we issue voluntarily a guarantee of 2 years from the date of purchase by the first customer, but in maximum 3 years after the end of series production. The first customer is the consumer first purchasing the product from us, a dealer or another natural or juristic person reselling or mounting the product on the basis of self-employment. -

Page 66: Eu Declaration Of Conformity

LD-G-42.2 | LD-W-42.2 tams elektronik 8.2. EU Declaration of Conformity This product fulfils the requirements of the following EU directives and therefore bears the CE marking. 2001/95/EU Product Safety Directive 2015/863/EU on the restriction of the use of certain hazardous substances in electrical and electronic equipment (RoHS) 2014/30/EU on electromagnetic compatibility (EMC Directive). - Page 67 LD-G-42.2 | LD-W-42.2...

- Page 68 Further Information and Tips: http://www.tams-online.de Warranty and Service: tams elektronik GmbH Fuhrberger Str. 4 30625 Hannover / GERMANY Phone: +49 (0)511 / 55 60 60 Fax: +49 (0)511 / 55 61 61 Email: support@tams-online.de...

Need help?

Do you have a question about the LD-G-42.2 and is the answer not in the manual?

Questions and answers