Table of Contents

Advertisement

Quick Links

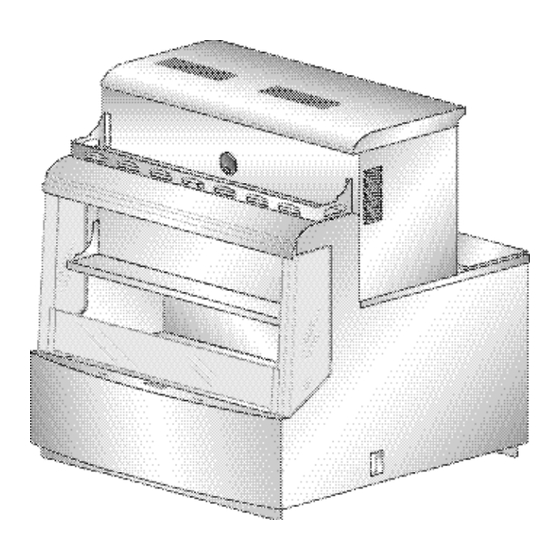

SUBWAY

RFM-51

Please read this manual completely before attempting

This document is prepared for trained Duke service technicians. It is not to be used by anyone not

properly qualified to perform these procedures.

This Service Manual is not all encompassing. If you have not been trained on servicing this product,

be sure to read the manual completely before attempting servicing. Be sure all necessary tools, test

equipment, and skills are available. Those procedures for which you do not have the proper skills

and test equipment must be performed only by a qualified Duke trained service technician.

This manual is Copyright © 2013 Duke Manufacturing Co. All rights reserved.

Reproduction without written permission is prohibited. Duke is a registered

to install, operate or service this equipment

trademark of the Duke Manufacturing Co.

Duke Manufacturing Co.

2305 N. Broadway

St. Louis, MO 63102

Phone: 314-231-1130

Toll Free: 1-800-735-3853

Fax: 314-231-5074

www.dukemfg.com

Service Manual

P/N 229885A

Advertisement

Table of Contents

Summary of Contents for Duke SUBWAY RFM-51

- Page 1 Please read this manual completely before attempting to install, operate or service this equipment This document is prepared for trained Duke service technicians. It is not to be used by anyone not properly qualified to perform these procedures. This Service Manual is not all encompassing. If you have not been trained on servicing this product, be sure to read the manual completely before attempting servicing.

- Page 2 Service Manual for RFM-51 IMPORTANT WARNING AND SAFETY INFORMATION THIS MANUAL HAS BEEN PREPARED FOR PERSONNEL QUALIFIED TO INSTALL ELECTRICAL EQUIPMENT, WHO SHOULD PERFORM THE INITIAL FIELD STARTUP AND ADJUSTMENTS OF THE EQUIPMENT COVERED BY THIS MANUAL. READ THIS MANUAL THOROUGHLY BEFORE OPERATING, INSTALLING OR PERFORMING MAINTENANCE ON THE EQUIPMENT.

-

Page 3: Table Of Contents

Service Manual for RFM-51 TABLE OF CONTENTS GENERAL ........................4 ELECTRICAL DATA ......................4 INSTALLATION .........................5 Location ........................5 Leveling ........................5 Electrical Connection ....................5 PARTS REPLACEMENT ....................7 Digital Thermostat.......................7 Compartment Air Temperature Probe ................7 Temperature Probe – Evaporator Coil ................8 Expansion Valve ......................8 Capacitor ........................10 Evaporator ........................10 Evaporator Fan Motor .................... -

Page 4: General

Service Manual for RFM-51 GENERAL ELECTRICAL DATA This unit was shipped from the factory assembled and receptacle, wired circuit, and protection must meet requires only the necessary electrical connections. the required local codes for proper operation. There There are four separate circuits. The terminal block are 2 receptacles mounted on top. -

Page 5: Installation

ELECTRICAL CONNECTION temperature. For optimal performance and lowest There are 4 separate circuits. The unit must be energy usage Duke Manufacturing recommends the grounded. The receptacle, wired circuit and protection RFM be located a minimum horizontal distance of 10 must meet all required local codes for proper operation. - Page 6 Service Manual for RFM-51 REFER TO THE AMPERAGE IMPORTANT: For US and Canada - L1 to Neutral must DATA LIST IN THE SPECIFICATIONS OR THE be 120 volts AC. For 230V international applications: SERIAL TAG DATA AND YOUR LOCAL CODE This is a Class A appliance and is not intended for use OR THE NATIONAL ELECTRICAL CODE TO BE on public electrical mains.

-

Page 7: Parts Replacement

Service Manual for RFM-51 PARTS REPLACEMENT DIGITAL THERMOSTAT COMPARTMENT AIR TEMPERATURE PROBE THE POWER MUST BE TURNED THE POWER MUST BE TURNED OFF AND DISCONNECTED AT ALL TIMES DURING OFF AND DISCONNECTED AT ALL TIMES DURING MAINTENANCE OR REPAIR FUNCTIONS. MAINTENANCE OR REPAIR FUNCTIONS. -

Page 8: Temperature Probe - Evaporator Coil

NOTE: Using a Refrigeration-Charging Unit, evacuate 7. Locate and disconnect sensor wires from plug on refrigerant from the system according to Duke back of temperature controller. Manufacturing Service Bulletin Number 26. Refrigerant must be recovered in accordance with Federal, State and Local regulations. - Page 9 13. Re-insulate the Evaporator Inlets, Suction Line and Accumulator. 14. Evacuate the system to 500 microns or below. 15. Charge system according to Duke Manufacturing Service Bulletin Number 26. NOTE: Service Bulletin Number 26 can be found in the SERVICE INFORMATION section of this manual.

-

Page 10: Capacitor

5. To properly recover refrigerant, install a Line Tap Assembly. Valve only on High Process side tube. NOTE: Using a Refrigeration-Charging Unit, evacuate refrigerant from the system according to Duke Manufacturing Service Bulletin Number 26. Refrigerant must be recovered in accordance with Federal, State and Local regulations. -

Page 11: Evaporator Fan Motor

THE POWER MUST BE TURNED 3. Using a Refrigeration-Charging Unit, evacuate OFF AND DISCONNECTED AT ALL TIMES DURING refrigerant from the system according to Duke MAINTENANCE OR REPAIR FUNCTIONS. Manufacturing Service Bulletin Number 26. 1. Disconnect the unit from its power source. -

Page 12: Evaporator Anti-Sweat Heater (Upper)

12. Using tags, connect the wiring at the Junction Box. 13. Connect unit to power source and test unit. 14. Charge system according to Duke Manufacturing Service Bulletin Number 26. NOTE: Service Bulletin Number 26 can be found in 5. Remove element/pan from unit. -

Page 13: Led Lights

7. Install replacement Hot Gas Loop and braze connections. 8. Connect unit to power source and test unit. 9. Charge system according to Duke Manufacturing Service Bulletin Number 26. NOTE: Service Bulletin Number 26 can be found in the SERVICE INFORMATION section of this manual. -

Page 14: Service Information

Refrigerant Type: See refrigerant charges page 9. low side of process hoses as close to factory crimps as possible. Charging Procedure 2. Use temporary valves to perform repair. Duke Manufacturing will not reimburse the cost of NOTE: Prior to refrigeration system service, special permanently installed valves. -

Page 15: Rfm Refrigeration System Joint Mapping Diagram

Service Manual for RFM-51 RFM REFRIGERATION SYSTEM JOINT MAPPING DIAGRAM In the event a leak is found in production, use the following list to document the joint repaired. 1 – Outlet from compressor toward condenser. 4 – Inlet to condenser – A 5 –... -

Page 16: Service Bulletin Number 26 - November 12, 2003

NEVER USE OXYGEN OR condensables from the system. To evacuate a system ACETYLENE IN PLACE OF REFRIGERANT properly, Duke Manufacturing recommends a triple AND DRY NITROGEN FOR LEAK TESTING. A evacuation procedure outlined below. Failure to follow VIOLENT EXPLOSION MAY RESULT, CAUSING this process could cause poor performance of the PERSONAL INJURY OR DEATH. -

Page 17: Maintenance

Service Manual for RFM-51 MAINTENANCE STAINLESS STEEL CARE CLEANING THE CONDENSER COIL THE POWER MUST BE TURNED Cleaning OFF AND DISCONNECTED AT ALL TIMES DURING Stainless steel contains 70-80% iron, which will rust MAINTENANCE OR REPAIR FUNCTIONS. if not properly maintained. It also contains 12-30% chromium, which forms an invisible passive, protective Failure to maintain a clean condenser coil can cause film that shields against corrosion. If the film remains... -

Page 18: Troubleshooting

1. Charge the unit using the instructions in the RECHARGING THE REFRIGERATION SYSTEM NOTE: Waiting two minutes allows pressure to build section of this manual, and DUKE SERVICE up on the low side (suction side) of the unit. BULLETIN 26 (see page 16). -

Page 19: Wiring Diagrams

Service Manual for RFM-51 WIRING DIAGRAMS WIRING SCHEMATIC 120V MODELS 229797... -

Page 20: Wiring Schematic 230V Models

Service Manual for RFM-51 WIRING SCHEMATIC 230V MODELS 229799... - Page 21 Service Manual for RFM-51 NOTES...

- Page 22 Service Manual for RFM-51 NOTES...

-

Page 23: Customer Assistance

DATE OF PURCHASE ____________________________________________________________________ DEALER____________________________________ TELEPHONE _______________________________ SERVICER __________________________________ TELEPHONE _______________________________ NORTH AMERICA & LATIN AMERICA UK, IRELAND, NORDIC COUNTRIES Duke Manufacturing Company Duke Manufacturing UK Ltd. 2305 N. Broadway Unit 10, Greendale Business Park St. Louis, MO 63102 Woodbury Salterton Phone: 314-231-1130... - Page 24 2305 N. Broadway St. Louis, MO 63102 Phone: 314-231-1130 Toll Free: 800-735-3853 Fax: 314-231-5074 www.dukemfg.com Duke EMEA - Europe, Middle East, Africa, Russia Duke Manufacturing CR, s.r.o. Zdebradska 92 Jazlovice, Ricany Building number DC 4 on the ProLogis Park Prague D1 West...

Need help?

Do you have a question about the SUBWAY RFM-51 and is the answer not in the manual?

Questions and answers