Table of Contents

Advertisement

Quick Links

READ ALL INSTRUCTIONS BEFORE

USING THIS PUMP. FAILURE TO READ

AND FOLLOW THE INSTRUCTIONS IN

THIS USER MANUAL COULD CAUSE

DEATH OR SERIOUS INJURY.

Table of Contents

GENERAL INFORMATION ..................................... 1, 2

WARNINGS ............................................................ 3

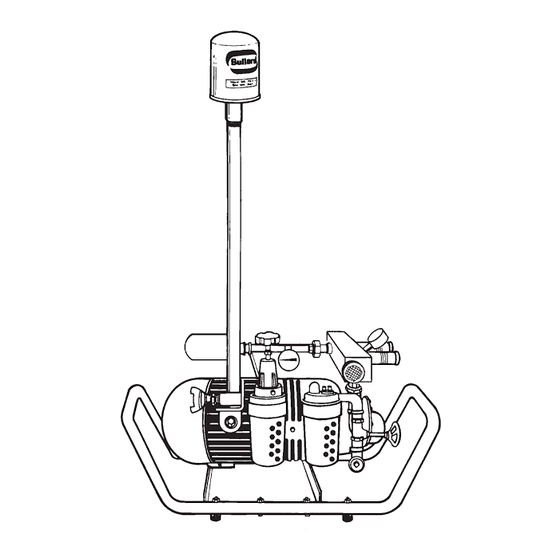

PUMP COMPONENTS ........................................... 4

BREATHING AIR REQUIREMENTS ........................ 4

Assembling the Free-Air Pump .................... 4

How Air Motor Works ................................... 4

How Motor Drives Pump .............................. 4

How Pump Supplies Air ................................. 4, 5

Installation ..................................................... 5

OPERATING THE FREE-AIR PUMP ........................ 5, 6

Maintaining the Air Motor ........................... 6

Maintaining the Pump .................................. 6

Ensuring Pump Performance ....................... 6

TROUBLESHOOTING GUIDE ................................. 6, 7

REPLACEMENT PARTS ........................................... 7

PUMP WARRANTY ................................................ 7

AIR FILTER REPLACEMENT SCHEDULE ................ 7, 8

AUTHORIZATION FOR RETURNED GOODS ......... 8

General Information

Bullard Free-Air Pumps MUST be located in a clean air envi-

ronment where at least Grade D breathable air is assured at

all times. Bullard Free-Air Pumps transfer ambient air from a

clean air location, where at least Grade D breathable air can be

assured at all times, to workers wearing Type C or CE continu-

ous flow supplied-air respirator hoods or tight fitting half or full

face masks. Only NIOSH approved respirators should be used

with this pump.

The ambient air is filtered through a medium efficiency Inlet Air

Filter and a Carbofine Outlet Filter before entering the respira-

tor's air supply hose.

Bullard Free-Air Pumps are oil-less and have rotary carbon

vanes. They produce no carbon monoxide, oil vapors, oil mist

or moisture. They do not require expensive carbon monoxide

monitors, high temperature alarms or other standard supplied

air pressure monitoring equipment. No calibration is required.

www.bullard.com

ADP20 Free-Air® Pump

NOTE

Industrial High Pressure Compressed Air (psig) determines

horsepower of air motor which directly affects output

air pressure and output air volume that comes from the

Free Air Pump Compressor that is sent to the Respirator

System.

User Manual

Advertisement

Table of Contents

Summary of Contents for Bullard Free-Air ADP20

-

Page 1: Table Of Contents

AUTHORIZATION FOR RETURNED GOODS ..8 General Information Bullard Free-Air Pumps MUST be located in a clean air envi- ronment where at least Grade D breathable air is assured at all times. Bullard Free-Air Pumps transfer ambient air from a... - Page 2 (6) cfm is required for each hood-style respirator. These air flow ratings are the NIOSH Required Minimums per OSHA Standard 42 CFR Part 84, Subpart J, Table 8, Type C or CE Respirator System. *** Quality Check at Factory occurs on every pump, built by Bullard, to assure air flow and pressure parameters are reliable and consistent.

-

Page 3: Warnings

THREATENING DELAYED LUNG DISEASE INCLUDING BUT NOT LIMITED TO SILICOSIS, PNEUMOCONIOSIS, OR ASBESTOSIS. 5.DO NOT MODIFY OR ALTER THIS PUMP IN ANY MANNER. USE ONLY APPROVED BULLARD FREE-AIR PUMP COMPONENTS AND REPLACEMENT PARTS ON THE PUMP. FAILURE TO USE APPROVED BULLARD COMPONENTS AND REPLACEMENT PARTS VOIDS ALL BULLARD WARRANTIES AND COULD CAUSE DEATH OR SERIOUS INJURY OR LIFE-THREATENING DELAYED LUNG DISEASE INCLUDING BUT NOT LIMITED TO SILICOSIS, PNEUMOCONIOSIS, OR ASBESTOSIS. -

Page 4: Pump Components

If the inlet air filter cannot be placed at a source containing clean, at least Grade D breathable air, install Bullard’s 50 foot Inlet Extension Hose Kit (Part No. V50IN) to the pump’s inlet port. See the directions shipped with the Extension Hose Kit for assembly instructions. -

Page 5: Installation

If the inlet filter cannot be placed at a source containing clean, from compressor to pump; 1” or 3/4” internal diameter is best. A at least Grade D breathable air, install Bullard’s 50 foot Inlet larger diameter compressed air hose may be required depend- Extension Hose Kit (Part No. -

Page 6: Maintaining The Free-Air Pump

To check the filter - while running the pump, momentarily remove the FILTER (1) from - Reset pressure relief adjustment valve the INLET PIPE (2). If the motor speeds up or the outlet pressure shown on GAUGE (5) increases, the filter needs replacement. www.bullard.com... -

Page 7: Replacement Parts

- Flush pump with GAST AH255D SAFETY SOLVENT In no event shall Bullard be responsible for damages for loss of use or other indirect, incidental, consequential or special costs, expens- RESPIRATOR AIR TEMPERATURE TOO HIGH (ABOVE AMBIENT) es or damages incurred by the purchaser, notwithstanding that - Air supply hoses coiled too tightly. -

Page 8: Authorization For Returned Goods

To return goods to Bullard for repair, or replacement, whether under the terms of Bullard’s warranty provisions or for paid repairs, you 3. Prior to packing the product for return shipment to Bullard, be MUST: certain that it has been fully decontaminated and cleaned of any hazardous materials which may have settled on the prod- 1.

Need help?

Do you have a question about the Free-Air ADP20 and is the answer not in the manual?

Questions and answers