Enerpac SFP Series Operation And Maintenance Manual

Split flow hydraulic pump

Hide thumbs

Also See for SFP Series:

- Operating manual (43 pages) ,

- Operating manual (6 pages) ,

- Instruction sheet (12 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Enerpac SFP Series

- Page 1 Operation and Maintenance Manual Enerpac SFP-Series Split Flow Hydraulic Pump Document Number: L4447 Document Revision: D Document Revision Date: 14-JUL-2023 Document Language: ENGLISH EN To reduce the risk of injury, user must read and understand this document before use.

- Page 3 Enerpac for quality tools, services and solutions. For additional information, visit www.enerpac.com. WARRANTY Refer to the Enerpac Global Warranty document for terms and conditions of the product warranty. Such warranty information can be found at www.enerpac.com. AVAILABLE LANGUAGES L4447 is available in the following languages, visit www.enerpac.com...

-

Page 4: Table Of Contents

Contents 1. SAFETY .....................................3 SAFETY PRECAUTIONS ............................3 2. COMPLIANCE STATEMENT ............................5 EU DECLARATION OF CONFORMITY ........................5 UL CERTIFICATION ...............................5 3. INTRODUCTION ................................5 OVERVIEW ................................5 APPLICATION ................................5 DELIVERY INSTRUCTIONS ............................5 4. TRANSPORT..................................5 5. FEATURES & COMPONENTS............................6 HYDRAULIC POWER UNIT ............................6 HYDRAULIC MANIFOLD............................7 STARTER ..................................8 ELECTRIC PANEL ..............................9 PENDANT CONTROL ..............................9... -

Page 5: Safety

Enerpac cannot be responsible for any damage or injury Failure to observe and comply with the following from unsafe use, lack of maintenance, or incorrect precautions could result in death or serious personal operation. - Page 6 Use of incorrect power source will damage the motor. • Immediately replace worn or damaged parts. Use only genuine Enerpac parts from approved • Do not use electric pumps in an explosive distributors or service centers. Standard grade atmosphere. Adhere to all local and national parts will break causing personal injury and electrical codes.

-

Page 7: Compliance Statement

If damage is found the carrier should be notified at once. Shipping damage 2.1 EU Declaration of Conformity is not covered by the Enerpac warranty. The carrier is responsible for all repair and replacement costs resulting from damage in shipment. -

Page 8: Features & Components

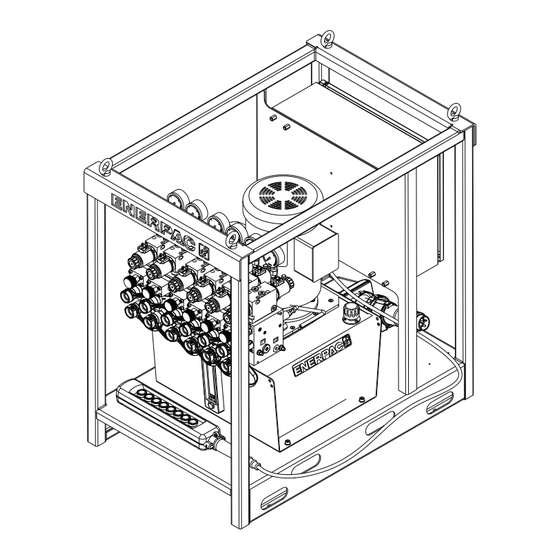

5. Features & Components 5.1 Hydraulic Power Unit 5.1.1 Split Flow Pump 10 Liters 1. Female coupler 4. Gasket asm reservoir/ motor Z 7. Pump set 2. Frame 5. Reservoir cover plate 8. Filling plug 3. Reservoir kit 6. Motor 9. -

Page 9: Hydraulic Manifold

5.1.3 Split Flow Pump 150 Liters 1. Electric cabinet (electric valves) 4. Breather filter 8. Coupling Starter (manual valves) 5. Visual level 9. Electric motor 2. Frame 6. Pump 10. Assembly manifold 4P 3. Clogging filter indicator, return filter 7. Housing 11. -

Page 10: Starter

5.2.2 Solenoid Valves 1. Gauge 5. Threaded bar 9. Needle valve 2. Nut 6. Bonded seal 10. Solenoid distribution valve 3. Washer 7. Plug 11. Flow control valve 4. Hydraulic manifold 8. Relief valve 12. Female copupler Side view Front view Figure 6: Hydraulic manifold with solenoid valves 5.3 Starter 1. -

Page 11: Electric Panel

5.4 Electric Panel 1. Main switch 4. Reset push-button 7. Pendant control plug 2. Power on led. 5. Start/Stop motor push-button 8. Communication plug 3. System alarm light 6. Decompress push-button 9. Power supply plug 40H3 40H12 41S5 40S6 100S11 Figure 8: Electric panel 5.5 Pendant Control 1. -

Page 12: Hydraulic Scheme

5.6 Hydraulic Scheme 5.6.1 SFP with 2 outlets 1. Hydraulic oil 6. Pump set 11. Compensated flow control valve 2. Reservoir 7. Assembly manifold 12. Gauge 3. Visual oil level 8. Relief valve 13. Needle valve 4. Plug 9. Manual/solenoid distribution valve 14. - Page 13 5.6.2 SFP with 4 outlets 1. Hydraulic oil 7. Pump 12. Compensated flow control valve 2. Reservoir 8. Assembly manifold 13. Gauge 3. Visual oil level 9. Relief valve 14. Needle valve 4. Plug 10. Manual/solenoid distribution valve 15. Hydraulic coupler 5.

- Page 14 5.6.3 SFP with 6 outlets 1. Hydraulic oil 7. Pump set 11. Plug for double acting cylinders 2. Reservoir 8. Assembly manifold (4 outputs and 2 12. Compensated flow control valve outputs) 3. Visual oil level 13. Gauge 9. Relief valve 4.

- Page 15 5.6.4 SFP with 8 outlets 1. Hydraulic oil 7. Pump 12. Compensated flow control valve 2. Reservoir 8. Assembly manifold (4 outputs and 4 13. Gauge outputs) 3. Visual oil level 14. Needle valve 9. Relief valve 4. Plug 15. Hydraulic coupler 10.

-

Page 16: Technical Product Data

6. Technical Product 6.2 Dimensional Table Model Dimension Data 1,016 10 l SFP202 6.1 Dimensional Callout Art 25.2 38.18 1.18 1,016 SFP213 40 l SFP404 SFP604 25.2 38.18 1.18 SFP228 1,356 53.39 SFP242 SFP409 7.56 SFP414 25.2 SFP421 38.18 150 l 1.18 1,356 53.39... -

Page 17: Initial Setup

Pendant control plug: The operator must connect warnings, before starting to operate high force tool the pendant control to this connector to work with equipment. In case of doubt, contact Enerpac. solenoid valves. Communication plug: This connector allows 7.2 Electric Connections communication with the controller in synchronized applications (refer to instruction sheet L4476). -

Page 18: Hydraulic Oil Requirements

7.5 Hydraulic Oil Requirements Models with solenoid valves are operated from a remote Use of Enerpac HF Series ISO 32 hydraulic oil is pendant control (Figure 9) connected to the electric recommended. Enerpac HF oil is available at your local cabinet with a 5 m. -

Page 19: Relieving Hydraulic Pressure

Always be sure cylinder is fully retracted before adding fluid to the reservoir. 9.2 Change Oil and Clean Reservoir Enerpac HF oil is a crisp blue color. Frequently check oil condition for contamination by comparing pump oil to new Enerpac oil. Replace oil and return filter cartridge when return filter is clogged. -

Page 20: Bleeding The Pump

9.5 Changing Pump’s Configuration sight gauge, but letting some visible part without oil. from Double Acting Cylinder to Sim- Leave the pump two hours quiet to purge the air. ple Acting Cylinder Close the pump’s purge plug. Under customer request, pump can be supplied to work 9.3 Bleeding the Pump with simple acting cylinders. -

Page 21: Alarm Guide

Check that all couplers are fully tightened. Air trapped in system. Remove air. Cylinder plunger binding. Check for damage to cylinder. Have cylinder serviced by an authorized Enerpac service center. Cylinder advances, but Leaking oil connection. Check that all connections are tightened. -

Page 22: Parts List

Parts List Product Date Code Beginning With: B 11.1 SFP 10 Liters Upper view Front view Figure 19: SFP 10 Liters Powerpack Components 11.1.1 SFP 10 Liters Table of Parts Repair Parts List - Figure 19 Part number Item Description Qty. -

Page 23: Sfp 40 Liters

11.2 SFP 40 Liters Front view Upper view Figure 20: SFP 40 Liters Powerpack Components 11.2.1 SFP 40 Liters Table of Parts Repair Parts List - Figure 20 Part number Item Description Qty. SFP213M SFP404M SFP604M SFP213S SFP404S SFP604S Electric starter DB06960380 DB06960380 DB06960380... -

Page 24: Sfp 150 Liters

11.3 SFP 150 Liters Front view Upper view Figure 21: SFP 150 Liters Powerpack Components 11.3.1 SFP 150 Liters Table of Parts Repair Parts List - Figure 21 Part number Item Description Qty. SFP228M SFP242M SFP409M SFP414M SFP228S SFP242S SFP409S SFP414S Electric starter DB06960380... -

Page 25: Hydraulic Manifold Manual Valves

Repair Parts List - Figure 21 Part number Part number Item Description Qty. Qty. SFP421M SFP613S SFP813S SFP421S Electric starter DB06960380 Electric cabinet SFP frame 150 l DB0106201 DB0107201 DB0107201 Return filter housing DB4603118 DB4603118 DB4603118 Return filter element DB4604175 DB4604175 DB4604175 clogging filter indicator... - Page 26 11.4.1 Hydraulic Manifold Manual Valves Table of Parts Repair Parts List - Figure 22 Part number Part number Part number Item Description Qty. Qty. Qty. SFP202M SFP213M SFP404M Gauge G2536L G2536L G2536L Nut M8 DIN934 CAL 8 Washer M8 DIN125 CAL 8 Hydraulic manifold DB5104840 DB5128840...

-

Page 27: Hydraulic Manifold Solenoid Valves

11.5 Hydraulic Manifold Solenoid Valves Side view Front view Figure 23: SFP Hydraulic Manifold with Solenoid Valves 11.5.1 Hydraulic Manifold Solenoid Valves Table of Parts Repair Parts List - Figure 23 Part number Part number Part number Item Description Qty. Qty. - Page 28 Repair Parts List - Figure 23 Part number Part number Part number Part number Item Description Qty. Qty. SFP228S SFP242S SFP409S SFP414S Gauge G2536L G2536L G2536L G2536L Nut M8 DIN934 CAL 8 Washer M8 DIN125 CAL 8 Hydraulic manifold DB5128840 DB5129840 DB5129840 DB5129840...

- Page 29 NOTES ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________...

- Page 30 NOTES ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________...

- Page 31 NOTES ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________...

- Page 32 © 2023 Enerpac Tool Group, All Rights Reserved. www.enerpac.com...

Need help?

Do you have a question about the SFP Series and is the answer not in the manual?

Questions and answers