Advertisement

INSTALLATION INSTRUCTIONS

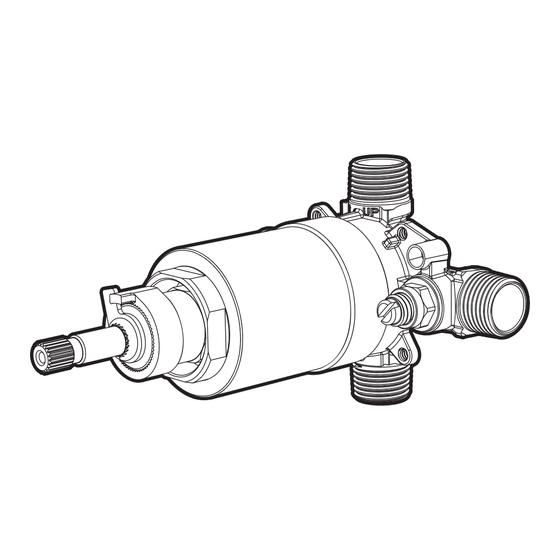

CPV-TP2

Thermostatic / Balance Pressure

Shower Valve

CPV-TP2-DV

Thermostatic / Balance Pressure

Shower Valve

with Integral Diverter

92-CPV-TP2-01

NEED HELP?

For additional assistance or service please contact:

ROUGH IN VERTICAL REFERENCE

TUB/SHOWER

78"

(1981mm)

21"

(533mm)

4"

(102mm)

TO TOP OF

TUB LEDGE

TOOLS & SUPPLIES NEEDED

Pencil

Measuring

Level

Tape

Drill

Phillips

Mounting

Drive Bit

Hardware

(not included)

Flat Tip

Phillips

Slip Joint

Screwdriver

Screwdriver

Wrench

Wrench

Socket

9/16"

Tubing

Wrench

(14mm)

Cutter

Deep Well Socket

Thread Seal

Eye Protection

Tape

www.speakman.com

800-537-2107

SHOWER ONLY

78"

(1981mm)

48"

(1219mm)

IMPORTANT

SAFETY TIPS:

Be sure to read and understand all instructions

before beginning installation.

Inspect all connections after installation.

Cover the drain to avoid loss of parts.

Be sure to wear proper eye protection.

Do NOT over tighten any connections or damage

may occur.

Shut OFF water supplies before beginning

installation.

Observe all local plumbing and building codes.

Pipe

VALVE SPECIFICATIONS:

This Valve has an operating range of 20-80 psi.

This Valve is engineered to be used in conjunction

with a Shower Head rated at 1.35 gpm (5.1 L/min)

or higher flow rate.

Maximum water pressure: 125 psi static.

Solder Kit

Minimum water pressure: 20 psi flowing.

Minimum Cold Supply Temperature: 40°F.

Maximum Hot Supply Temperature: 160°F.

Minimum Hot Supply Temperature: 5°F above set

point.

Determine the mounting depth of the Valve referencing the diagrams below. The Protective Cover on the

Valve has reference markings showing where the Valve should align with the Finished Wall Surface. The

distance from the Finished Wall Surface to the centerline of the Valve Inlets/Outlets MUST fall between

2-1/2" Minimum and 3-1/2" Maximum.

FINISHED

WALL

SURFACE

Risk of personal injury. Do NOT use the Valve

without properly adjusting the Temperature Limit

Stop (TLS) as outlined in this installation

manual.

Ensure proper structure is in place to support

the Valve and plumbing during use.

MAINTENANCE

Your new product is designed for years of

trouble-free performance.

This type of valve must be cleaned and

maintained on a regular basis. Periodic

maintenance should be performed at least

every 12 months or after any changes have

been made to the building's plumbing system.

Valves that are installed outdoors should be

winterized by removing all of the internal parts

and removing any standing water from the

valve. Quarterly the maximum hot temperature

setting (TLS) should be checked and adjusted

accordingly.

FINISH MAINTENANCE:

Keep the surface finish looking new by cleaning

it periodically with a soft cloth. Avoid abrasive

cleaners, steel wool, and harsh chemicals as

these will dull the finish and void your warranty.

ROUGH IN DEPTH REFERENCE

THE MINIMUM ALLOWED

ALIGNS WITH THE

FINISHED WALL AT

THE MAXIMUM ALLOWED

ROUGH IN DEPTH

2-½"

64mm

MINIMUM

FINISHED

WALL

SURFACE

CAUTION

ALIGNS WITH THE

FINISHED WALL AT

ROUGH IN DEPTH

3-½"

89mm

MAXIMUM

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Speakman CPV-TP2

- Page 1 INSTALLATION INSTRUCTIONS TOOLS & SUPPLIES NEEDED IMPORTANT CAUTION CPV-TP2 Pencil Measuring Level SAFETY TIPS: Risk of personal injury. Do NOT use the Valve Tape Be sure to read and understand all instructions Thermostatic / Balance Pressure without properly adjusting the Temperature Limit before beginning installation.

- Page 2 SITE PREPARATION PREPARE VALVE FOR MOUNTING Referencing the rough in guides, install a 1” x 4” Cross Brace between the Vertical Studs at the Remove O-Ring and Protective Cover from Valve. Set aside for future use. proper height and depth outlined. Use a Level to ensure the front surface of the Cross Brace is perfectly vertical.

- Page 3 PLUMB SHOWER HEAD OUTLET PLUMB TUB/ACCESSORY OUTLET Make plumbing connections to the Shower Head Outlet of the Valve. Shower Head Outlet Make plumbing connections to the Tub/Accessory Outlet of the Valve. Tub/Accessory Outlet Connection is 1/2” NPT Male (1/2” Copper Sweat). See “Rough In Vertical Reference” for the Connection is 1/2”...

-

Page 4: Back To Back Installation

BACK TO BACK INSTALLATION FLUSH SYSTEM / CHECK FOR LEAKS Your Shower Valve has the ability to be mounted back-to-back with another Valve in a shared Temporarily place the Spindle Adapter (A) on to the Valve Spindle. Rotate the Valve Spindle space. -

Page 5: Product Warranty

Consumer/Residential: Limited Lifetime Warranty Commercial Use: 5 Year Limited Warranty Speakman warrants to its purchasers only (“Buyer”) that goods are sold free from defects in materials and workmanship and conform to Speakman’s specifications at the time of manufacturing, provided the goods are properly installed and maintained. -

Page 6: Repair Parts

VALVE REPAIR CARTRIDGE RPG49-118834 WITH LOWER SEALS AND VALVE BODY O-RING VALVE BODY O-RING RPG05-119153 REPLACEMENT BONNET CPV-TP2 ROUGH-IN DIAGRAM COMPLIANCE ASME A112.18.1 / CSA B125.1 ASSE 1016 / ASME A112.1016 / CSA B125.16 1" 25mm HOLE FOR SHOWER ARM CONNECTIONS 6'-6"... - Page 7 CPV-TP2-DV ROUGH-IN DIAGRAM COMPLIANCE ASME A112.18.1 / CSA B125.1 ASSE 1016 / ASME A112.1016 / CSA B125.16 1" 25mm HOLE FOR SHOWER ARM CONNECTIONS 6'-6" [2 METERS] TO FLOOR HOT / COLD Inlets: 1/2” NPT Male 5-1/2" (140MM) DIA. 1/2" NPT MALE HOLE FOR 1/2"...

Need help?

Do you have a question about the CPV-TP2 and is the answer not in the manual?

Questions and answers