Bartec APEXmpc 07-37A2-2211/M5 Operating Instructions Manual

Manual ex p control unit

Hide thumbs

Also See for APEXmpc 07-37A2-2211/M5:

- Operating instruction and safety manual (98 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Bartec APEXmpc 07-37A2-2211/M5

- Page 1 Manual Ex p Control Unit APEX SILAS...

- Page 2 Operating instructions – Motor Purge Controller Ex p control unit APEX Type: 07-37A2-2211/*M5* – Safety manual – ATEX / IECEx Zone 1 / 21 Ex p control unit SILAS Type: A7-37S2-2111/*M5* ATEX / IECEx Zone 2 / 22 Document: 01-37A2-7D0003 Revision: A-03-2024 / 413876 01-37A2-7D0003 / REV-A-03-2024 / 413876 Subject to technical changes...

-

Page 4: Table Of Contents

BARTEC Operating instructions – Ex p control unit mpc Table of contents Table of contents .......................... 3 General information ........................7 Manufacturer ..........................7 Purpose of these operating instructions ..................7 Languages ............................ 7 Technical changes ........................8 Additional documents ........................8 Conformity to standards and directives .................. - Page 5 BARTEC Operating instructions – Ex p control unit mpc System structure .........................19 General ............................19 Ex p control unit mpc, Standard ....................20 4.2.1 Ex e protective enclosure ......................21 4.2.2 Ex p functional unit ........................21 4.2.3 Ex digital valve ..........................21 4.2.4 Ex p pressure measuring card ......................21 4.2.5...

- Page 6 BARTEC Operating instructions – Ex p control unit mpc Electrical connections ........................33 Wiring instructions ........................33 EMC-compliant connection ......................34 7.2.1 Back-up fuse ..........................35 7.2.2 Inductive loads ..........................35 Electrical wiring ...........................37 7.3.1 Terminal block overview .......................37 7.3.2 Wiring diagram ..........................38 7.3.3 Ex e connection terminals ......................38 7.3.4...

- Page 7 BARTEC Operating instructions – Ex p control unit mpc Maintenance and care ........................68 11.1 Visual inspection .........................68 11.2 Cleaning ............................68 11.3 Regular maintenance ........................68 11.4 Repairs ............................69 11.5 Malfunction and troubleshooting ....................69 11.6 Fault table ...........................69 11.7 Error messages ..........................70 11.7.1 Positive messages ........................70...

-

Page 8: General Information

These operating instructions are an integral part of the scope of delivery, even if they can be ordered and delivered separately for logistical reasons. - If you require any further information, please request it from your local or responsible BARTEC subsidiary. Please read the operating instructions and, in particular, the safety instructions carefully before using the device. -

Page 9: Technical Changes

BARTEC Operating instructions – Ex p control unit mpc Technical changes BARTEC reserves the right to change the contents of this document without prior notice. No guarantee is given for the correctness of the information. In case of doubt, the German safety instructions apply, as translation and printing errors cannot be ruled out. -

Page 10: Markings On The Device

BARTEC Operating instructions – Ex p control unit mpc 1.7.2 Markings on the device CE marking with certifying body in accordance with the currently valid directive. 0044 This applies to Ex p control units of the APEX , Typ 07-37A2-2211/*M5* version. -

Page 11: Safety

BARTEC Operating instructions – Ex p control unit mpc Safety Handling the product The product which is described in these operating instructions has left the factory in a safe and tested condition. In order to maintain this condition and to achieve faultless and safe operation of this product, it may only be used in the manner described by the manufacturer. -

Page 12: Warranty

BARTEC Operating instructions – Ex p control unit mpc Warranty WARNING No modifications or conversions may be made without the written approval of the manufacturer. Explosion protection is no longer guaranteed if non-specified components are used. In the case of externally supplied parts, there is no guarantee that they have been designed and manufactured to withstand the stresses and to meet the safety requirements. -

Page 13: Operator's Obligations

BARTEC Operating instructions – Ex p control unit mpc Operator’s obligations The operator is obligated to ensure that only persons work with the Ex p control unit APEX SILAS who: - are familiar with the basic regulations on safety and accident prevention and have been instructed in the use of the Ex p control unit APEX and SILAS;... -

Page 14: Safety Instructions

BARTEC Operating instructions – Ex p control unit mpc Safety instructions 2.6.1 General safety instructions - General statutory regulations or guidelines on occupational safety, accident prevention regulations and environmental protection laws must be observed, e.g. Ordinance on Industrial Safety and Health (BetrSichV) or the nationally applicable ordinances. -

Page 15: Avoiding Any Material Damage

BARTEC Operating instructions – Ex p control unit mpc Avoiding any material damage 2.7.1 Short circuit due to incorrect connection Incorrect connection of the power supply will destroy the electronics and invalidate the warranty. 2.7.2 EMC-compliant connection In order to ensure the safe operation of the Ex p control unit, it is important that the wiring is EMC- compliant. -

Page 16: Sil Qualification / Safety According To Iec 61508

BARTEC Operating instructions – Ex p control unit mpc SIL qualification / safety according to IEC 61508 Note The SIL qualification is only valid for the type 07-37A2-***1/**** (APEX) version. Important notes and information on safety-related handling of the product. -

Page 17: Safety Parameters

BARTEC Operating instructions – Ex p control unit mpc 2.8.3 Safety parameters The following safety parameters are without optional sensors. The optional sensors must be taken into account when determining the overall failure rate! - The safety parameters can be found in the documentation for the used optional sensors. -

Page 18: Product Description

BARTEC Operating instructions – Ex p control unit mpc Product description General The type of protection Ex p, called “pressurised enclosure”, is based on the measure that explosive gases present in a closed volume are flushed out and then an overpressure is generated and maintained compared to the surrounding atmosphere. -

Page 19: Pressure Monitor, Type 17-51P3-3*03

BARTEC Operating instructions – Ex p control unit mpc 3.2.3 Pressure monitor, Type 17-51P3-3*03 The mpv pressure monitor has two functions within the Ex p control unit. Firstly, it serves as an overpressure valve which opens if the internal pressure is too high and reduces the overpressure. -

Page 20: System Structure

BARTEC Operating instructions – Ex p control unit mpc System structure General Pos. Designation Remarks Pressure reducing station Max. set pressure 3.5 bar Digital purge gas valve Opening during the purge phase Limitation of purge flow during the purge Purge flow regulation... -

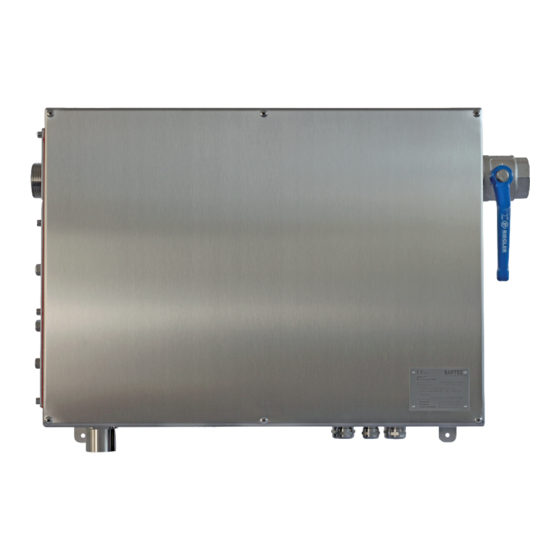

Page 21: Ex P Control Unit Mpc, Standard

BARTEC Operating instructions – Ex p control unit mpc Ex p control unit mpc, Standard The system structure of the Ex p control units APEX SILAS is shown below. The protective enclosure is designed in accordance with the Ex e type of protection and can be mounted on the outside of the pressurised enclosure / motor. -

Page 22: Ex E Protective Enclosure

BARTEC Operating instructions – Ex p control unit mpc Pos. Designation Remarks Purge flow regulation Limitation of the purging flow Purge gas supply Supplying the Ex p system with purge air Cable inlets Introduction of electrical cables Purge gas supply Ex p Purge gas supply to the Ex p equipment A –... -

Page 23: Ex Proportional Valve

BARTEC Operating instructions – Ex p control unit mpc 4.2.5 Ex proportional valve The proportional valve is used in order to maintain the pressure of the protected Ex p equipment during the operating phase. This means that as soon as the Ex p equipment has been purged, it closes and the proportional valve supplies as much air as is required in order to maintain the internal pressure of the Ex p equipment at po (internal pressure during operation). -

Page 24: Purging Gas Supply Ex P" Connection

BARTEC Operating instructions – Ex p control unit mpc 4.2.10 “Purging gas supply Ex p” connection The “Ex p purging gas supply” connection is connected to the protected Ex p operating equipment at the point where the purging air shall be introduced. For this purpose, a threaded connection G1 ½"... -

Page 25: Pressure Monitor Mpv

BARTEC Operating instructions – Ex p control unit mpc Pressure monitor mpv The system structure of the mpv pressure monitor for the mpc Ex p control unit is shown below. The protective enclosure is mounted outside the pressurised enclosure / motor. -

Page 26: Pressure Monitor Mpv

BARTEC Operating instructions – Ex p control unit mpc 4.3.1 Pressure monitor mpv The mpv pressure monitor associated with the system is used in order to record the purging pressure and outlet of the purging gas during the purging phase. -

Page 27: Transport And Storage

BARTEC Operating instructions – Ex p control unit mpc Transport and storage Scope of delivery Note Any missing parts or any damage must be reported immediately in writing to the carrier, the insurance company or BARTEC GmbH. Check the completeness of the scope of delivery against the delivery note... -

Page 28: Installation

BARTEC Operating instructions – Ex p control unit mpc Installation DANGER Unsuitable positioning of the Ex p control unit on the pressurised enclosure. This will result in improper purging of the pressurised equipment. Gas bubbles may form inside the pressurised enclosure and lead to an explosion when the internals are activated. -

Page 29: Mounting The Mpc

BARTEC Operating instructions – Ex p control unit mpc Mounting the MPC Two mounting rails are mounted on the rear of the Ex e protective enclosure of the Ex p control unit mpc. These rails can be used in order to suspend and screw the Ex p control unit to the fastening screws which are provided on the Ex p equipment. -

Page 30: Mounting The Pressure Monitor

BARTEC Operating instructions – Ex p control unit mpc Mounting the pressure monitor A flange connection is integrated on the bottom side of the MPV enclosure, which serves as a mounting for the MPV. The purge air is fed through this flange during purge and is guided via an integrated orifice, which is required in order to record the differential pressure. -

Page 31: Pneumatic Connections

BARTEC Operating instructions – Ex p control unit mpc Pneumatic connections Note We recommend only seamless soft annealed stainless steel pipes made of material 1.4571 in accordance with DIN 2391, Part 1 or DIN 2462, tolerance class D4 / T3. -

Page 32: Pressure Measurement Connections On The Mpc

BARTEC Operating instructions – Ex p control unit mpc 6.4.4 Pressure measurement connections on the mpc The pressure measurement connections “I-Internal Pressure” and “L-Outlet Pressure” are each designed with a 10 mm pipe connection. “I-Internal Pressure”: This must be piped to the reference measuring point on the pressurised equipment. -

Page 33: Mounting Pipes To The Cutting Ring Fitting

BARTEC Operating instructions – Ex p control unit mpc 6.4.7 Mounting pipes to the cutting ring fitting The following procedure is recommended in order to ensure a clean and tight connection of pipes to the cutting ring fittings. Designation Union nut... -

Page 34: Electrical Connections

BARTEC Operating instructions – Ex p control unit mpc Electrical connections DANGER Death or serious injury from working on live parts! Danger to life due to electric current. - Observe the 5 safety rules for working on electrical systems: Disconnect; secure against being switched on again;... -

Page 35: Emc-Compliant Connection

Directive must be ensured by the manufacturer (EMC-compliant design of a system) and the user (interference-free design of a complete system). BARTEC Ex p control units can only operate safely and trouble-free with EMC-compliant wiring. This chapter shall support you in the EMC-compliant design of your system. -

Page 36: Back-Up Fuse

BARTEC Operating instructions – Ex p control unit mpc Shielding In order to ensure interference-free operation of a system, cables with the largest possible surface area (not cross-section) are important. High-frequency currents do not flow through the entire cable cross-section, but predominantly on the outer skin of a conductor. - Page 37 BARTEC Operating instructions – Ex p control unit mpc Protective circuits protect the Ex p control unit from premature failure due to the overvoltage which occurs when the current flowing through an inductive load is interrupted. In addition, protective circuits limit the electrical interference which occurs when switching inductive loads.

-

Page 38: Electrical Wiring

BARTEC Operating instructions – Ex p control unit mpc Electrical wiring WARNING Explosion protection is not guaranteed if intrinsically safe (Ex i) signals are connected to relay outputs! Relay outputs are not suitable for intrinsically safe (Ex i) signals. - Use suitable isolating relays between relay outputs and Ex i signals! -

Page 39: Wiring Diagram

BARTEC Operating instructions – Ex p control unit mpc 7.3.2 Wiring diagram 7.3.3 Ex e connection terminals 7.3.3.1 Terminal row “X3” The supply voltage is connected to terminal row X3. Ferrite sleeve assembly! Please see Section “EMC-compliant connection” Termina... - Page 40 BARTEC Operating instructions – Ex p control unit mpc 7.3.3.2 Terminal row “X5” A potential-free changeover contact K3 and K4 is available on the Ex p control unit for signalling and processing signals. The associated switching function can be set in the Ex p control unit via the WEB interface and is freely programmable.

- Page 41 BARTEC Operating instructions – Ex p control unit mpc 7.3.3.4 Terminal row “X12” Potential-free signal K2 can be categorised as a pure enable according to SIL when used. A potential-free signal (4x NO) is available on the Ex p control unit. This signal can either be used as an enable, which is also safety-related, or it can be used as a potential-free signal.

- Page 42 BARTEC Operating instructions – Ex p control unit mpc 7.3.3.6 Terminal row “X7” ATTENTION Material damage due to incorrect back-up fuse! Valve or Ex p control unit may become damaged. - Only operate the digital outlet valve with a 1.0 A back-up fuse and the proportional outlet valve with a 1.6 A back-up fuse.

-

Page 43: Ex I Connection Terminals

BARTEC Operating instructions – Ex p control unit mpc 7.3.4 Ex i connection terminals 7.3.4.1 Terminal row “X9” DANGER Death or serious injury due to commissioning with bypass key switch in potentially explosive atmosphere! Risk of explosion. - The commissioning with a bypass key switch must be authorised by the plant manager or his representative. - Page 44 BARTEC Operating instructions – Ex p control unit mpc Terminal Connection Bypass IN Bypass OUT Temperature sensor 1 IN Temperature sensor 1 OUT Temperature sensor 1 MESS 7.3.4.2 Terminal row “X14” Note The main switch IN // main switch OUT contact is fitted with a jumper as standard. This jumper has the effect of automatically enabling the system after the purge process.

- Page 45 BARTEC Operating instructions – Ex p control unit mpc In order to change settings and setpoints on the device, the programming release must be connected and activated. This should only be connected during the deliberate changing of parameters. After changing or adjusting parameters, a subsequent function test has to be carried out.

- Page 46 BARTEC Operating instructions – Ex p control unit mpc 7.3.4.5 Terminal row “X15” Caution when connecting external sensors to the Ex p control unit! When connecting external sensors to the Ex p control unit, attention must be paid to functional safety! - The external sensors must fulfil the requirements of SIL 2.

-

Page 47: Operation

BARTEC Operating instructions – Ex p control unit mpc Operation The following chapters describe the operation of the Ex p control unit for the end user. Configuration and setting instructions are described in a separate operating manual. The complete solution is self-starting once the purging gas supply and supply voltage have been connected. - Page 48 BARTEC Operating instructions – Ex p control unit mpc - Using the “Configure...” button. Open the settings for the network adapter and select the “Advanced” tab. - Click on the “Speed & Duplex” function in the “Property” field on the left.

-

Page 49: Operating The Web Operating System

BARTEC Operating instructions – Ex p control unit mpc Operating the WEB operating system The WEB operating system (WEB-OS) is operated by using the input devices on the PC. Logging into the WEB operating system Two levels are available for logging into the WEB interface... -

Page 50: Menu Structure Of The Web Operating System

BARTEC Operating instructions – Ex p control unit mpc Menu structure of the WEB operating system The WEB operating system integrated in the Ex p control unit has the following menu structure. Ex p parameter Purging parameter Purging modes Pressure... -

Page 51: Led Displays On The Ex P Functional Unit

BARTEC Operating instructions – Ex p control unit mpc LED displays on the Ex p functional unit Colour Function Minimum pressure Green Lights up when the minimum pressure is exceeded Pre-alarm Yellow Lights up when the pressure falls below the set value... -

Page 52: Purge Parameter / Purging Parameters

BARTEC Operating instructions – Ex p control unit mpc 8.8.1 Purge parameter / Purging parameters The purging parameters are summarised in the “Ex p parameters / Purging parameters” menu. This includes the purging modes, pressure parameters, characteristic curve and enclosure parameters submenus. - Page 53 BARTEC Operating instructions – Ex p control unit mpc 8.8.1.2 Pressure parameters The system pressures of the Ex p operating equipment are defined in the “Pressure parameters” submenu. Value Description Operating pressure. Regulating pressure value during the operating phase Minimum pressure. Switch-off value, if undershot, the release is cancelled.

-

Page 54: Info

BARTEC Operating instructions – Ex p control unit mpc 8.8.1.4 Enclosure parameters DANGER Incorrect parameterisation of the parameters in the Ex p control unit! The purging process takes place with a too low flow of purging gas and there is a risk of residual explosive gases inside the Ex p equipment. -

Page 55: File

BARTEC Operating instructions – Ex p control unit mpc 8.8.2.3 Messages In the “Info / Messages”, the current system status is displayed as a plain text message. Green messages = Positive Yellow messages = Warning Red messages = Error messages 8.8.3 File... -

Page 56: Settings / Extended

BARTEC Operating instructions – Ex p control unit mpc 8.8.4 Settings / Extended 8.8.4.1 Temperature sensors Up to three connected PT100/1000 sensors can be configured in the “T. sensors” menu item. Various functions can be executed in the control unit sequence for the recorded temperature. - Page 57 BARTEC Operating instructions – Ex p control unit mpc Procedure - Connect the computer to the Ex p control unit / control unit - Activate the programming switch - Log into the WEB interface with the user level - Call up the “Advanced / Sensors” menu - Activate the corresponding button for the required temperature sensor, e.g.

- Page 58 BARTEC Operating instructions – Ex p control unit mpc 8.8.4.2 Valves Note The valve settings are preconfigured by BARTEC and must not be changed. Any changes may result in malfunctions. The purging gas valve connected to the Ex p control unit can be set in the “Valves”...

- Page 59 BARTEC Operating instructions – Ex p control unit mpc Procedure - Connect the computer to the Ex p control unit - Activate the programming switch - Log into the WEB interface with the user level - Call up the “Advanced / Relay” menu - Activate the specific message(s) in the “of the respective relay”...

- Page 60 BARTEC Operating instructions – Ex p control unit mpc 8.8.4.7 Password A new password can be stored for the guest and user in the “Password” menu item. The password should consist of a four-digit numerical sequence. 8.8.4.8 Network All network-specific settings are made in the “Network”...

-

Page 61: System Status

BARTEC Operating instructions – Ex p control unit mpc System status By connecting the laptop to the Ex p control unit, initial information about the system status can be called up on the start screen. Procedure - Log in to the WEB interface by opening the browser and entering the IP address 192.168.11.101 The start screen provides an initial overview of the status of the Ex p system. - Page 62 BARTEC Operating instructions – Ex p control unit mpc The username/password must be entered. Username: “operator” Password: “operator” Response from the Ex p control unit KEY/ID Parameter Unit _0x0401 Operating pressure po (setpoint) _0x0101 Operating pressure po (actual value) _0x0402...

-

Page 63: Commissioning

BARTEC Operating instructions – Ex p control unit mpc Commissioning DANGER Risk of explosion if parameters are incorrect! Incorrect parameters and settings cancel the explosion protection. Check the settings and parameters by using the “four eyes principle”. Note It must be ensured that the electrical wiring is as described in the relevant operating instructions and that the purging gas supply is connected. - Page 64 BARTEC Operating instructions – Ex p control unit mpc Procedure - Connect the PC to the Ex p control unit, activate the programming switch - Log into the WEB-OS with the user level - Call up the “Purging parameters / Pressure parameters” menu - Enter and confirm the “po - operating overpressure”...

- Page 65 BARTEC Operating instructions – Ex p control unit mpc Calculating the purging time Note Subtract 0.5 mbar from the measured p3 value. In order to ensure that fluctuating purging gas supplies do not cause problems for the operator during the purging cycle, we recommend calculating and setting the p3 value as follows: 0.5 mbar from the actual measured value.

-

Page 66: Function Test Of The Ex P

BARTEC Operating instructions – Ex p control unit mpc 9.2.2 Function test of the Ex p Note Safe operation with pressure fluctuations For safe operation (pressure fluctuations), the inlet pressure of the pressure reducer must be increased by 0.5 bar. -

Page 67: Operation

BARTEC Operating instructions – Ex p control unit mpc Operation 10.1 Safety during the operation DANGER Death or serious injury due to damaged explosion protection measures! Risk of explosion. - Take the Ex p control unit out of operation and secure it against being switched on again until it has been repaired. -

Page 68: Purging Phase

BARTEC Operating instructions – Ex p control unit mpc 10.2.3 Purging phase The pressurised enclosure is purged with the purging gas in order to remove any explosive gas/air mixture which is present in it or to dilute it to a non-hazardous concentration before the possible ignition sources in the pressurised enclosure are switched on. -

Page 69: Maintenance And Care

In the event of any anomalies, the operator should consider the possibility of a timely and proper cleaning by BARTEC GmbH as opposed to a spontaneous failure of the control unit. In addition, the function of the entire system should be checked. The correct sequence of the purge phase and operating phase should be checked. -

Page 70: Repairs

BARTEC Operating instructions – Ex p control unit mpc 11.4 Repairs Any repairs to the control unit and accessories may only be carried out by BARTEC GmbH. 11.5 Malfunction and troubleshooting ATTENTION A change in the operating behaviour may be a sign of existing damage. -

Page 71: Error Messages

BARTEC Operating instructions – Ex p control unit mpc The leakage air compensation Adjust the pre-pressure Overpressure is not is too low maintained internally Check air leakage increase No purging air Activate the purging air The Ex p control unit does... -

Page 72: Warning Messages

BARTEC Operating instructions – Ex p control unit mpc 11.7.2 Warning messages Status Code Plain text 00000005 Bypass active The bypass is activated on the control unit. 00000006 Door contact / main switch open The main switch or bridge HS_IN / HS_OUT is not closed. -

Page 73: Alarm Messages

BARTEC Operating instructions – Ex p control unit mpc 11.7.3 Alarm messages Status Code Plain text 0000000D Ex p inactive The protected equipment is deactivated. 0000000E Device fault 1 HW test error (processors) 0000000F Device fault 2 HW test error (barriers) -

Page 74: Technical Data

BARTEC Operating instructions – Ex p control unit mpc Technical data 12.1 Ex px control unit APEX Certifications ATEX, IECEx, EAC, CCC Areas of use Zone 1, Zone 21 ATEX Certification BVS 19 ATEX E 015 X Marking II 2(1)G Ex eb mb ib [ib pxb] [ia Ga] IIC T4 Gb II 2(1)D Ex tb [ib pxb] [ia Da] IIIC T130 °C Db... -

Page 75: Ex P Specific Data

BARTEC Operating instructions – Ex p control unit mpc 12.3 Ex p specific data Pressure measuring range 0 to 25 mbar Tolerance range ± 0.5 mbar over the entire measuring range Purging time 10 seconds to 120 minutes (adjustable) Purging gas valve... -

Page 76: Purging Gas

BARTEC Operating instructions – Ex p control unit mpc 12.6 Purging gas Residual dust < 40 µm Residual water Dew point +3 °C Residual oil content 1 mg/m³ Temperature Maximum + 40 °C 12.7 Mechanical data Protection class IP 64 pursuant to EN IEC 60079-0... -

Page 77: Ordering Information

BARTEC Operating instructions – Ex p control unit mpc Ordering information 13.1 Ex p control unit Designation Order number Zone 1 APEXmpc, DC version, Ta -25°C… +50 °C 07-37A2-2211/1M50 APEXmpc, AC version, Ta -25°C… +50 °C 07-37A2-2211/2M50 APEXmpc, DC version, Ta -50°C… +50 °C, heating AC 230 V 07-37A2-2211/1M51 APEXmpc, AC version, Ta -50°C…... -

Page 78: Appendix

BARTEC Operating instructions – Ex p control unit mpc Appendix 14.1 Dimensions of the Ex p control unit 01-37A2-7D0003 / REV-A-03-2024 / 413876 77 / 80 Subject to technical changes... -

Page 79: Dimensions Of The Fastening

BARTEC Operating instructions – Ex p control unit mpc 14.1.1 Dimensions of the fastening Subject to technical changes 78 / 80 01-37A2-7D0003 / REV-A-03-2024 / 413876... -

Page 80: Block Diagram

BARTEC Operating instructions – Ex p control unit mpc 14.2 Block diagram 14.3 Dimensions of the pressure monitor 01-37A2-7D0003 / REV-A-03-2024 / 413876 79 / 80 Subject to technical changes... -

Page 81: Dimensions Of The Flange

BARTEC Operating instructions – Ex p control unit mpc 14.3.1 Dimensions of the flange mpv 2 mpv 3 Subject to technical changes 80 / 80 01-37A2-7D0003 / REV-A-03-2024 / 413876... -

Page 82: Purging Gas Diagram

BARTEC Operating instructions – Ex p control unit mpc 14.4 Purging gas diagram 14.4.1 Pressure monitor mpv 2 Q [m³/h] 14.4.2 Pressure monitor mpv 3 Q [m³/h] 01-37A2-7D0003 / REV-A-03-2024 / 413876 81 / 80 Subject to technical changes... -

Page 83: Process Control

BARTEC Operating instructions – Ex p control unit mpc 14.5 Process control Subject to technical changes 82 / 80 01-37A2-7D0003 / REV-A-03-2024 / 413876... -

Page 84: Declaration Of Conformity

BARTEC Operating instructions – Ex p control unit mpc Declaration of Conformity 15.1 Declaration of Conformity Ex px control unit APEX 01-37A2-7D0003 / REV-A-03-2024 / 413876 83 / 80 Subject to technical changes... -

Page 85: Declaration Of Conformity Ex Pz Control Unit Silas

BARTEC Operating instructions – Ex p control unit mpc 15.2 Declaration of Conformity Ex pz control unit SILAS Subject to technical changes 84 / 80 01-37A2-7D0003 / REV-A-03-2024 / 413876... - Page 86 BARTEC BARTEC GmbH Max-Eyth-Str. 16 97980 Bad Mergentheim Germany Tel: +49 7931 597 0 Mail: info@bartec.com bartec.com...

Need help?

Do you have a question about the APEXmpc 07-37A2-2211/M5 and is the answer not in the manual?

Questions and answers