Graco 237286 Instructions-Parts List Manual

Hide thumbs

Also See for 237286:

- Instructions-parts list manual (34 pages) ,

- Instructions-parts list manual (28 pages)

Advertisement

Quick Links

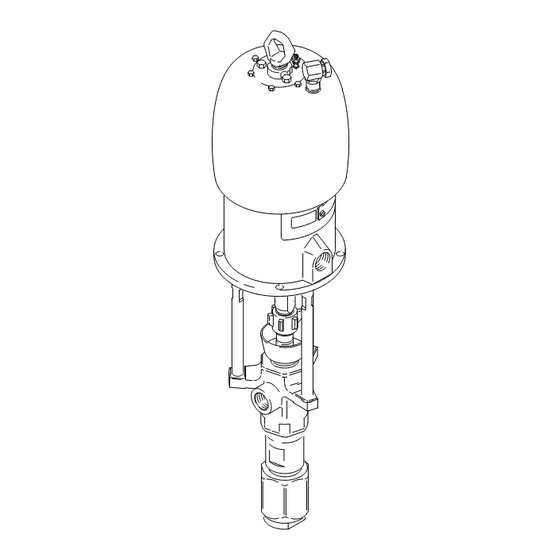

Instructions – Parts List

Parts

STAINLESS STEEL

Dura–Flo 900t Pumps

With Severe–Duty Rod and Cylinder

U.S. Patent No. 5,456,583

Foreign Patents Pending

Read warnings and instructions.

See page 2 for model numbers and maximum

working pressures.

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440-1441

Copyright 2002, Graco Inc. is registered to I.S. EN ISO 9001

Model 237286

Model 237287

04143B

308354F

04275B

Advertisement

Subscribe to Our Youtube Channel

Summary of Contents for Graco 237286

- Page 1 Foreign Patents Pending Read warnings and instructions. See page 2 for model numbers and maximum working pressures. Model 237286 Model 237287 04275B 04143B GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440-1441 Copyright 2002, Graco Inc. is registered to I.S. EN ISO 9001...

- Page 2 List of Models Pump Part No. Maximum Fluid Maximum Air and Series Pump Model Ratio Working Pressure Input Pressure 237286, Reduced Icing Quiet Kingt 56:1 38.6 MPa, 386 bar 0.7 MPa, 7 bar Series B (5600 psi) (100 psi) 237287,...

- Page 3 D This equipment is for professional use only. D Read all instruction manuals, tags, and labels before operating the equipment. D Use the equipment only for its intended purpose. If you are not sure, contact your Graco distributor. D Do not alter or modify this equipment.

- Page 4 WARNING INJECTION HAZARD Spray from the gun, leaks or ruptured components can inject fluid into your body and cause extremely serious injury, including the need for amputation. Fluid splashed in the eyes or on the skin can also cause serious injury. D Fluid injected into the skin might look like just a cut, but it is a serious injury.

- Page 5 WARNING FIRE AND EXPLOSION HAZARD Improper grounding, poor ventilation, open flames or sparks can cause a hazardous condition and re- sult in a fire or explosion and serious injury. D Ground the equipment and the object being sprayed. Refer to Grounding on page 6. D If there is any static sparking or you feel an electric shock while using this equipment, stop spray- ing immediately.

- Page 6 NOTE: Reference numbers and letters in parentheses in the text refer to the callouts in the figures and the parts drawing. NOTE: Always use Genuine Graco Parts and Acces- sories, available from your Graco distributor. Refer to Product Data Sheet, Form No. 305715 (Senator 0864 Pumps), Form No.

- Page 7 Installation System Accessories (continued) A pump runaway valve (C) senses when the pump is running too fast and automatically shuts off the air to the motor. A pump which runs too fast WARNING can be seriously damaged. An air manifold (G) has a 3/4 npsm(f) swivel air A bleed-type master air valve (E) and a fluid drain inlet.

- Page 8 Installation TYPICAL INSTALLATION Pump Electrically Conductive Air Supply Hose Fluid Whip Hose Wall Bracket Air Line Filter Gun Swivel Pump Runaway Valve Bleed-Type Master Air Valve Airless Spray Gun Air Line Lubricator (for accessories) Suction Kit Bleed-Type Master Air Valve Fluid Filter Ground Wire and Clamp (required, for pump)

- Page 9 Operation/Maintenance Pressure Relief Procedure Packing Nut/Wet-Cup Before starting, fill the packing nut (2) 1/3 full with Graco Throat Seal Liquid (TSL) or compatible solvent. WARNING See Fig. 4. INJECTION HAZARD The system pressure must be manually WARNING relieved to prevent the system from starting or spraying accidentally.

- Page 10 Operation/Maintenance Flush the Pump Before First Use NOTE: When changing fluid containers with the hose and gun already primed, open the drain valve (M) to The pump is tested with lightweight oil, which is left in help prime the pump and vent air before it enters the to protect the pump parts.

- Page 11 Operation/Maintenance Shutdown and Care of the Pump Flush with a fluid that is compatible with the fluid you are pumping and with the wetted parts in your system. Check with your fluid manufacturer or supplier for rec- WARNING ommended flushing fluids and flushing frequency. Al- ways flush the pump before fluid dries on the displace- To reduce the risk of serious injury whenever you ment rod.

- Page 12 Turn on the air just enough to start the pump. If the pump starts when the air is turned on, the obstruction is in the fluid hose or gun. NOTE: If you experience air motor icing, contact your Graco distributor. 308354...

- Page 13 5. Reconnect all hoses. Reconnect the ground wire if CAUTION it was disconnected. Fill the packing nut (2) 1/3 full of Graco Throat Seal Liquid or compatible solvent. Be sure to use at least two people when lifting, mov- ing, or disconnecting the pump. This pump is too 6.

- Page 14 Service Model 237287 Shown Torque to 136–149 N.m (100–110 ft-lb) Torque to 196–210 N.m (145–155 ft-lb) Torque to 81–89 N.m (60–66 ft-lb) 04142B Fig. 5 308354...

- Page 15 Service DISPLACEMENT PUMP SERVICE If the assembly separates at joint B: Disassembly a. Unscrew the cylinder (9) and valve housing (18) from the outlet housing (7). Gently pull the When disassembling the pump, lay out all the removed cylinder and valve housing straight out of the parts in sequence, to ease reassembly.

- Page 16 Service Torque to 325–353 N.m (240–260 ft-lb). Lubricate. Torque to 190–217 N.m (140–160 ft-lb). 03794B Fig. 6 Torque to 271–298 N.m (200–220 ft-lb). 03793A Fig. 7 308354...

- Page 17 Service Reassembly 6. Lubricate the piston packings. Slide the displace- ment rod (1) and piston assembly down into the cylinder (9). The cylinder is symmetrical, so either 1. If it was necessary to remove the piston ball hous- end may face up. Use a rubber mallet to drive the ing (10) from the displacement rod (1), clean the rod into the cylinder, until the piston seat housing threads of the rod and the ball housing.

- Page 18 Service Torque to 136–149 N.m (100–110 ft-lb). Torque to 325–353 N.m (240–260 ft-lb). Torque to 271–298 N.m (200–220 ft-lb). Lubricate. Lips face up. Lips face down. See Throat Packing Detail at left. See Piston Packing Detail at left. Torque to 190–217 N.m (140–160 ft-lb). Throat Packing Stack Detail (Displacement Pump 236470 Shown;...

- Page 19 Parts Part No. 237286 Pump, Series B Ref. Part No. Description Qty. 56:1 Ratio, with Reduced Icing 245112 AIR MOTOR, King, reduced icing Quiet King Air Motor For Model 237286 See 309348 for parts Part No. 245172 Pump, Series A...

- Page 20 Parts Part No. 237287 Pump, Series A Ref. Part No. Description Qty. 28:1 Ratio, with Bulldog Air Motor 208356 AIR MOTOR, Bulldog See 307049 for parts 102Y 176529 LABEL, warning 105{ 190000 ROD, tie; 224 mm (8.82”) shoulder to shoulder; carbon steel 106{ 186925 NUT, coupling...

- Page 21 Parts Part No. 237280 Pump, Series A Ref. Part No. Description Qty. 17:1 Ratio, with Senator Air Motor 217540 AIR MOTOR, Senator See 307592 for parts 102Y 176529 LABEL, warning 105{ 190000 ROD, tie; 224 mm (8.82”) shoulder to shoulder; carbon steel 106{ 186925 NUT, coupling...

- Page 22 Parts NOTE: The parts listed on this page are common to all dis- Part placement pumps covered in this manual. Refer to page 23 Description for the different packing configurations available. 189316 ROD, displacement; stainless steel 236582 PACKING NUT; stainless steel * These parts are included in Repair Kit 237172, which may 237182 HOUSING, outlet;...

- Page 23 Packing Kits Leather Packing Kit 237172, for Standard Displacement Pump 236470, Series A Part THROAT PACKINGS: PISTON PACKINGS: LIPS FACE DOWN LIPS FACE UP Description 184304 V-PACKING, throat; leather 184174 GLAND, throat, female; stainless steel 1 PTFE 109304 V-PACKING, throat; 184224 GLAND, throat, male;...

- Page 24 Technical Data (Model 237286 Reduced Icing Quiet King Pump, Model 245173 Quiet King Pump, and Model 245172 King Pump) WARNING Be sure that all fluids and solvents used are chemically compatible with the Wetted Parts listed below. Always read the manufacturer’s literature before us- ing fluid or solvent in this pump.

- Page 25 Technical Data (Model 237287 Bulldog Pump) WARNING Be sure that all fluids and solvents used are chemically compatible with the Wetted Parts listed below. Always read the manufacturer’s literature before us- ing fluid or solvent in this pump. Ratio ............... 28:1 Maximum fluid working pressure .

- Page 26 Technical Data (Model 237280 Senator Pump) WARNING Be sure that all fluids and solvents used are chemically compatible with the Wetted Parts listed below. Always read the manufacturer’s literature before us- ing fluid or solvent in this pump. Ratio ............... 17:1 Maximum fluid working pressure .

- Page 27 548 mm 257 mm 2 in. npt(f) 1 in. npt(f) 3/4 npsm(f) (44.80 in.) (23.23 in.) (21.57 in.) (10.12 in.) 237286 1180 mm 590 mm 590 mm 257 mm 2 in. npt(f) 1 in. npt(f) 3/4 npsm(f) (46.44 in.) (23.23 in.) (23.21 in.)

- Page 28 Graco distributor to the original purchaser for use. With the exception of any special, extended, or limited warranty published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by Graco to be defective.

Need help?

Do you have a question about the 237286 and is the answer not in the manual?

Questions and answers