Summary of Contents for DST RL-60

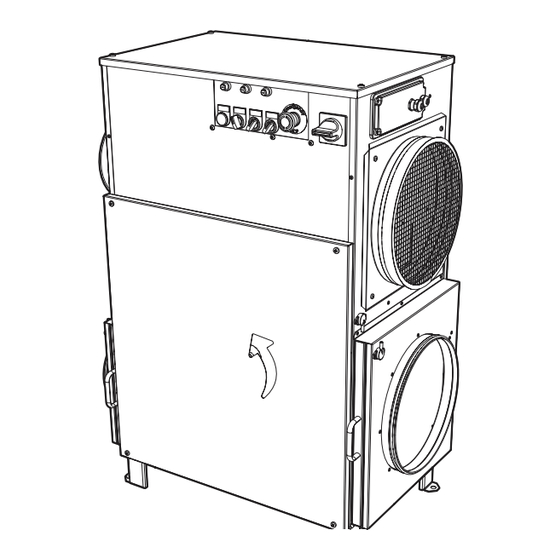

- Page 1 World leaders in dehumidification. USER’S MANUAL Document version: EN.052 24.01 Product: RL-60/60L Desiccant dehumidifier Product supplied may differ from that illustrated...

- Page 2 Empty page Seibu Giken DST RL-60, 60L EN.052 24.01...

-

Page 3: Table Of Contents

6.3 Stop ................15 6.4 Reset buttons & switches ...........15 7. Functions ............16 7.1 Dehumidification function ...........16 7.1.1 Automatic or Manual ........16 7.1.2 Ventilation modes ..........16 7.1.3 Humidistat connection ........17 7.1.4 0-10VDC connection ........17 RL-60, 60L EN.052 24.01 Seibu Giken DST... - Page 4 Empty page Seibu Giken DST RL-60, 60L EN.052 24.01...

- Page 5 FIGURE 20: C4 PLC with 5.7" color touchscreen ..........19 FIGURE 21: Troubleshooting table and solution ..........20 FIGURE 22: General troubleshooting table and solution ........20 FIGURE 23: Capacity troubleshooting and solution table........21 FIGURE 24: Service chart .................22 RL-60, 60L EN.052 24.01 Seibu Giken DST...

- Page 6 Empty page Seibu Giken DST RL-60, 60L EN.052 24.01...

-

Page 7: Safety

This equipment is specifically designed for atmospheric air drying. It is unsuitable for any other use. For further advice please contact a DST representative. 1.6 SAFETY ADVICE REGARDING TRANSPORTATION Unless specifically stated in this manual, the following applications are prohibited: •... -

Page 8: Electrical Installation

When the unit is no longer in use, dismantle the unit and recycle the components and retightened if necessary: according to local regulations. Contact a DST representative if you have any questions. •... -

Page 9: Introduction

In the appendix, a component list details spare parts with articlenumbers as well as the electrical diagram number for the electrical box. If there is a special unit with custom- installed components that list will include a list of installed options. RL-60, 60L EN.052 24.01 Seibu Giken DST... -

Page 10: Product Description

3.2 APPLICATIONS DST desiccant-type dehumidifiers are normally used where dry air is essential to the various manufacturing processes used in chemical, pharmaceutical, food or confectionery industries, or where a dry environment is required for the storing and handling of moisture-sensitive products and raw materials. -

Page 11: Installation

Position the machine with adequate working space around the unit to allow inspection and service. Size of unit and the position of the access panels/doors vary depending on the model. To avoid incorrect positioning, see the dimensional drawing in the appendix for service space and foot bolt-hole dimensions. RL-60, 60L EN.052 24.01 Seibu Giken DST... -

Page 12: General Duct Work Installation

4.2 GENERAL DUCT WORK INSTALLATION The guidelines are to assist the installers and operators to adjust the duct/dehumidifier installation. Consult a DST representative or local mechanical installation company for more information. • Avoid recirculation from the separate airflows, direct entering and exiting airflow away from each other. -

Page 13: Earth Leakage Circuit Breaker

Each indicator, standard or optional, are marked on the electrical diagram to indicate whether it is a normally closed or a normally opened circuit. * Standard indicator may differ depending on model and configuration. See electrical diagram for more information. RL-60, 60L EN.052 24.01 Seibu Giken DST... -

Page 14: Operation Check & Adjustment

7. If connected, check remote control operation. 8. If connected, check remote alarm function (see 5 above). 9. If connected, check humidistat/electronic humidity controller function. Seibu Giken DST RL-60, 60L EN.052 24.01... -

Page 15: Operating

Reset is only required when a operation is halted by hardware failure or triggered a safety mechanism. See troubleshooting for more information. See the electrical diagram for correct layout and information of the reset devices. RL-60, 60L EN.052 24.01 Seibu Giken DST... -

Page 16: Functions

Note: AUTO ECO VENT is an option but it is included for DC/DR-50 and RL-60/61/71 when Energy saving 2 or 3 is selected. * Option - Contact a DST representative for more on information on which unit can be fitted with AUTO-ECO VENT. -

Page 17: Humidistat Connection

EH3 T2/others 0...10VDC 0...100% * N/A for R-51/60/61, RL-60/61/71. See “8.6 Energy saving” for more feature description. 7.2 REMOTE CONTROL SWITCH Connections for a external power switch is available as standard. The remote power switch allows the user to shut down or turn on the unit from another location. -

Page 18: Option & Accessory

Add-on component to allow sub options to be installed and to improve process airflow. Available sub-options for filter box: • 19 mm insulation • Filter guard • F7 Filter FIGURE 17: Filter box - Add-on module Seibu Giken DST RL-60, 60L EN.052 24.01... -

Page 19: Energy Saving

Using a humidity controller EH3 T2 + PLC C2 or an external control signal (BMS + PLC C2), the drying capacity is finely adjusted to accurately maintain the required setpoint (humidity or dew point). Contact a DST representative to view the energi saving option for each specific unit as options across the products range may vary. 8.7 HUMIDITY CONTROLLER Control the dehumidification process using the advanced electronic humidity controller EH3 T2 or the simpler electronic humidistat EH4. -

Page 20: Troubleshooting

Check remote control is set to ‘On/Run’ position and if the cable is undamaged. not appear to be operating. operation. Confirm electric supply and check local isolator is on. FIGURE 22: General troubleshooting table and solution Seibu Giken DST RL-60, 60L EN.052 24.01... -

Page 21: Capacity Troubleshooting

Measured airflows are lower than arrow on fan motor casing. The incoming specified. Change over two of the three incoming phase supply wires. Re-check fan rotation. phase supply is incorrect. FIGURE 23: Capacity troubleshooting and solution table RL-60, 60L EN.052 24.01 Seibu Giken DST... -

Page 22: Maintenance

Inspect rotor motor - replace if necessary Inspect radial & peripheral seals - replace if worn or damaged Check operation of geared drive motor, drive pully, belt/chain, rotor - adjust as neccessary Inspect rotor for contamination or damage - clean/repair (contact DST) Inspect condenser* Inspect evaporator*... -

Page 23: Technical Data

The content of in this document may be subject to change without prior notice. For questions and comments regarding the content in this document, please send it to Number of electric heater steps Seibu Giken DST AB, ATT: Documentation, Avestagatan 33, 163 53 SPÅNGA, 1/2 - 3 1/2 - 4,5 Heating power in steps [kW] SWEDEN. - Page 24 Component list RL-60 Description Type, Drwg No etc Qty. Art No Notes Rotor unit Rotor DMR-550H05 108676 Rotor mantle seal DX1175-13mm 0,15m 102851 Rotormotor 109059 80.547.0 6 rpm 230V 50Hz 0,033A 7,2kW Beltpulley 30 5M 09 axel 8 100642 Belt...

- Page 25 Compounds-EN v1.1 RevE...

- Page 26 Panel mounted PLC C4 (option) Designed by Date Title/Description 2013-10-31 Dimension drawing Approved by Date RL-60R/LR 2023-06-28 Status Tolerance Drawing no Seibu Giken DST AB Approved DST05145 +46 8 445 77 20 Scale Format Rev Part Weight (Kg) www.dst-sg.com 68.000 1:10...

- Page 27 CE &UKCA As of 2022, the latest declaration of confomity for fully assembled machinery and declaration of incorporation of partly assembled machinery for CE and UKCA are available for downloads. If unable to scan the QR-code, visit DST website at:...

- Page 28 Seibu Giken DST AB Avestagatan 33 | 163 53 Spånga, Sweden Phone: +46 8 445 77 20 | Fax: +46 8 445 77 39 info@dst-sg.com | www.dst-sg.com CERTIFIED ISO 9001 Quality management systems Seibu Giken DST is certified according to ISO 9001...

Need help?

Do you have a question about the RL-60 and is the answer not in the manual?

Questions and answers