Advertisement

Quick Links

Advertisement

Summary of Contents for Bucktool SCM8103

- Page 1 GET IT DONE ! 10 VARIABLE SPEED " SHARPENER Contact Us: email: service@bucktool.com https://www.bucktool.com IMPORTANT: INSTRUCTION For your own safety, read and follow all of the Safety Guidelines and Operating Instructions before operating MANUAL this product.

-

Page 2: Table Of Contents

SCM8103 TABLE OF CONTENTS Specifications Safety guidelines Package contents Key parts diagram Operating instructions Maintenance Exploded view Parts list Troubleshooting Warranty SPECIFICATIONS Motor VAC, 60Hz , S1 1.0A, S2 30min 1.2A Wet Wheel size 10" x 2" x 1/2" Stropping wheel size 8"... - Page 3 SCM8103 GENERAL SAFETY GUIDELINES BEFORE USING THIS POWER TOOL Always wear eye protection and respirator. s and eye s properly sted and t tened. ted. Stand to t side o start . Switc it on and let t operate a...

- Page 4 SCM8103 ADDITIONAL SPECIFIC SAFETY RULES 1. DO NOT operate this machine until it is completely assembled and inst alled according to the instructions. A machine incorrectly assembled can cause serious injury. 2. OBTAIN ADVICE from your supervisor, instructor, or another qualified person if you are not thoroughly familiar with the operation of this machine.

- Page 5 SCM8103 16. NEVER START THE MACHINE with the workpiece against the grinding wheel. The workpiece can be drawn into the wheel, causing damage to the machine and/or serious injury. 17. CLEAN THE MACHINE thoroughly when processing different types of workpieces (wood, steel, or aluminium). Combining wood and metal dust can create an explosion or fire hazard.

-

Page 6: Specifications

SCM8103 IMPORTANT INFORMATION-Electrical A separate electrical circuit should be used for your machines. This circuit should not be less than #12 wire and should be protected with a 20-A time-lag fuse. If an extension cord is used, use only 3-wire extension cords which have 3-pronged grounding type plugs and matching receptacle which will accept the machine’s plug. - Page 7 SCM8103 The plug must be plugged into a matching outlet that is properly installed and grounded in accordance with all local codes and ordinances. Do not modify the plug provided–if it will not fit the outlet, have the proper outlet installed by a qualified electrician.

-

Page 8: Package Contents

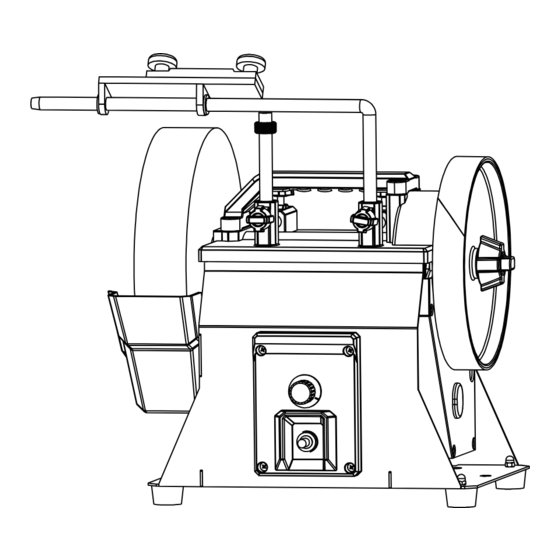

SCM8103 Package contents No. Description Qty. Sharpener (not shown) Universal support Grinding jig Wet Grinding wheel Water reservoir Cord & plug Angle guide Honing compound Wheel dressing stone Wrench Short knife jig Lock knob... - Page 9 SCM8103 Description Horizontal mounts with knobs Universal support Leather stropping wheel Vertical mounts with knobs Power switch Water reservoir Grinding wheel Variable speed knob...

- Page 10 SCM8103 Mount The Wet Stone The sharpener is shipped with the Wet Stone (1) off of the machine. Make sure that the machine is not plugged in before assembling the stone onto the sharpener. Remove the nut (3) and outer flange(2)from the main shaft, slide the wet stone onto the shaft, then reinstall the flange (2) and nut (3) to secure the stone in place.

- Page 11 SCM8103 Mount The Universal Support 1. Select the suitable position for mounting the Universal support. Orient the work support so that the support arm is extended over the wheel you’ll be working with. 2. Loosen the mounting locking knobs and slide the work support into the mounting bushings.

- Page 12 SCM8103 GRINDING JIP The grinding jig provided with the wet sharpener is used for securing a variety is used for securing a variety of tools, and can be positioned to grind with and against the wheel rotation. To mount the grinding jig:...

- Page 13 SCM8103 Here are some tips for using the sharpener water reservoir: the water level before every use and be sure the wheel is wet before Leavin the n wheel tored in water will cause dama e to the wheel and create otential hazards because the wheel will become unbalanced...

- Page 14 SCM8103 Wheel Dressing n on the ty e of n you do, the n wheel may require dressin A variety of dressin tools are available (not included) and can be used to restore the tabrasive quality of the wheel surface and brin the wheel ed e back to...

-

Page 15: Maintenance

SCM8103 MAINTENANCE ROUTINE INSPECTION Before each use, inspect the general condition of the tool. If any of these following conditions exist, do not use until parts are replaced or the Sharpener is properly repaired. Check for: • Loose hardware, • Misalignment or binding of moving parts, •... - Page 16 SCM8103 REPLACING THE STROPPING WHEEL Inspect the leather stropping wheel for any damage or wear before each use. If the leather stropping wheel becomes damaged or worn, replace it as follows. 1. Unscrew the locking knob (3). 2. Remove the outer flange (2) and stropping wheel (1) from the spindle.

- Page 17 SCM8103...

- Page 18 SCM8103 Item Description Item Description Base assy Bearing plate Bearing housing Bearing shaft Washer D10 Bearing block Ball bearing 6200-2RS Wave washer D35 Philips screw M5x35 Main shaft Nut M5 ball bearing 6003-2RZ Nut M4 V-belt pulley Tension spring Flat key 5×5×25...

-

Page 19: Troubleshooting

SCM8103 TROUBLE SHOOTING SYMPTOM PROBABLE CAUSE CORRECTIVE ACTION Check power source for proper Low voltage. voltage. Inspect all connections on motor Open circuit in motor Motor will not start. for loose or open connections. or loose connections. (Send for Servicing.) Blown fuse or breaker. -

Page 20: Warranty

GET IT DONE ! TWO-YEAR LIMITED WARRANTY Having Problems ? Give us a chance to help you before returning this product Email : service@bucktool.com https://www.bucktool.com https://www.bucktool.com...

Need help?

Do you have a question about the SCM8103 and is the answer not in the manual?

Questions and answers