Subscribe to Our Youtube Channel

Summary of Contents for Gema MagicCompact BA04-XL

- Page 1 Rev. 00 1024 624 Operating instructions and Spare parts list Powder coating booth MagicCompact BA04-XL Translation of the original operating instructions...

- Page 2 To the best of our knowledge and belief, the information contained in this publication was correct and valid on the date of publication. Gema Switzerland GmbH makes no representations or warranties with respect to the contents or use of this publication, and reserves the right to revise this publication and make changes to its content without prior notice.

-

Page 3: Table Of Contents

Overall view....................20 Booth – superstructure ..................20 Booth – basement ....................21 Floor blow-off system ................22 Powder suction ..................23 Exhaust air system with After Filter ............... 24 Fire protection ....................... 24 Table of contents • 3 MagicCompact BA04-XL... - Page 4 Hazard notes ................... 44 Putting out of service ................44 Cleaning....................44 Packing ....................44 Identification .................... 44 Maintenance during storage ................. 45 Maintenance schedule ................45 Maintenance works .................. 45 Return to service ....................45 4 • Table of contents MagicCompact BA04-XL...

- Page 5 Disposal regulations ................. 47 Materials ....................47 Spare parts list Ordering spare parts ..................... 49 MagicCompact BA04-XL – spare parts list ............50 Floor blow-off system – Pneumatics ..............51 Pressure regulator ....................52 Sensor/Actor Box ....................53 Gun blow off equipment ..................54 Door drive unit .......................

-

Page 7: About These Instructions

General information This operating manual contains all the important information which you require for the working with the MagicCompact BA04-XL. It will safely guide you through the start-up process and give you references and tips for the optimal use when working with your powder coating system. -

Page 8: Structure Of Safety Notes

Presentation of the contents Figure references in the text Figure references are used as cross references in the descriptive text. Example: "The high voltage (H) created in the gun cascade is guided through the center electrode." 8 • About these instructions MagicCompact BA04-XL... -

Page 9: Safety

If this product is to be used for other purposes or other substances outside of our guidelines then Gema Switzerland GmbH should be consulted. -

Page 10: Product Specific Security Regulations

For this reason, the operating manual must always be available at the plant. Should difficulties arise, however, your Gema service center is always ready to assist. 10 • Safety... -

Page 11: Inspection

Start-up ✓ ✓ Fault localization and remedy during commissioning ✓ ✓ Operation ✓ ✓ ✓ Scheduled maintenance ✓ ✓ ✓ Fault localization and remedy during operation and maintenance ✓ ✓ Disposal ✓..Permissible --.. Prohibited Legend: Safety • 11 MagicCompact BA04-XL... -

Page 12: Emergency Action

Switch off the installation. unusual noises, unusual – Disconnect the mains plug. generation of heat – Contact the Technical Service Department of Gema. – Fire in the electrical Disconnect the mains plug. system – Extinguish the fire with an appropriate fire extinguisher. -

Page 13: Residual Risks

► Blow off the powder from the booth floor before entering. WARNING Risk of collapse/falling through! Walking on the booth roof can result in serious falls with serious injury or death. ► Never step on the booth roof! Safety • 13 MagicCompact BA04-XL... - Page 14 Rev. 00 11/23 14 • Safety MagicCompact BA04-XL...

-

Page 15: Transport • 15

Requirements on personnel carrying out the work Use only technical personnel who are trained in operating the respective equipment (e.g. a crane). If there are any uncertainties, please contact Gema Switzerland GmbH. Packing material Not necessary for the internal transport. For external transport: see chapter "Decommissioning / Storage"... -

Page 16: Transport

The result is a material failure and unwanted deformation. ► Avoid heat accumulations and storage in sunlight. ► The plastic booth must not be transported at temperatures above +60 °C. 16 • Transport MagicCompact BA04-XL... -

Page 17: Product Description

For a better understanding of the interrelationships in powder coating, it is recommended that the operating instructions for all other components be read as well, so as to be familiar with their functions too. Product description • 17 MagicCompact BA04-XL... -

Page 18: Reasonably Foreseeable Misuse

Input pressure too low – Coating of non grounded objects – Use in connection with unauthorized coating equipment or components Technical Data Electrical data MagicCompact BA04-XL Connected load* 3 x 400 V Frequency* 50/60 Hz Protection type IP54 Approvals II 3 D... -

Page 19: Dimensions

Rev. 00 11/23 Dimensions MagicCompact BA04-XL min. 2.5 m - max. 6.5 m Booth length (Iin the nterior) Booth width 2.2 / 2.4 / 2.6 / 2.8 / 3.0 m Booth basement height min. 0.71 m - max. 1 m Weight –... -

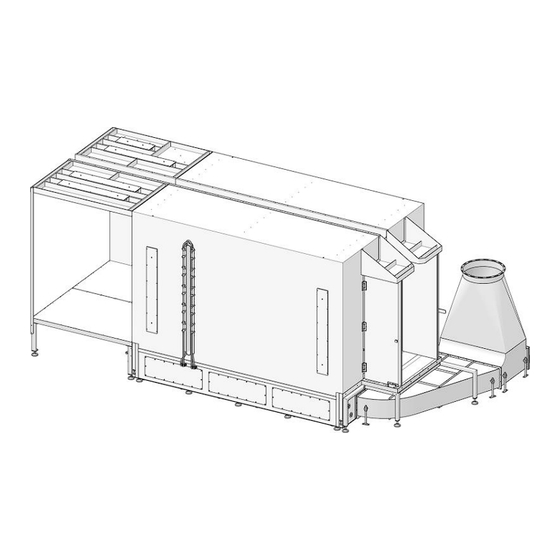

Page 20: Design And Function

The basic version of this booth has no hand coating openings. The booth can be equipped either on one or both sides with manual coating equipment, as precoating or touch-up station alternatively. 20 • Product description MagicCompact BA04-XL... -

Page 21: Booth - Basement

Rev. 00 11/23 Booth – basement The booth basement consists of reinforced plastic material. The booth basement contains the floor blow-off unit and the powder suction (suction duct). Fig. 3: Basement Floor blow-off system Suction duct Product description • 21 MagicCompact BA04-XL... -

Page 22: Floor Blow-Off System

The valves for the control of the floor blow-off segments are located in the booth basement. The compressed air input pressure for the floor blow-off system must amount to 4.0 bar. – The pressure regulator for the floor blow-off system can be set to max. 2 bar. 22 • Product description MagicCompact BA04-XL... -

Page 23: Powder Suction

The ducts are autocleaning and can be blown out with compressed air. The collected powder is delivered to the cyclone separator. Deposited overspray powder on the walls must sometimes be cleaned manually. Product description • 23 MagicCompact BA04-XL... -

Page 24: Exhaust Air System With After Filter

During the automatic gun cleaning, the work piece entrance or exit door is closed, thereby an increased air inlet speed results at the remaining openings at the booth. This ensures a dust-free environment around the booth during the color change procedure. 24 • Product description MagicCompact BA04-XL... -

Page 25: Automatic Booth Cleaning

The powder hose connection makes possible a perfect fixing of the powder hose by the clamping device. This is a prerequisite for the automatic rinsing of the powder transport equipment (further information about automatic guns, see in the corresponding user manual). Product description • 25 MagicCompact BA04-XL... -

Page 26: Guns Exterior Cleaning

The booth control takes place by the corresponding control unit with operating interface. The gun control units are fitted into one or two control cabinets. The switching on and off of the guns takes place by the gap detection unit in the automatic mode. 26 • Product description MagicCompact BA04-XL... -

Page 27: Operational Procedure

Automatic powder guns The powder is fluidized in the OptiCenter (7). The injectors/application pumps convey the powder through the hoses to the guns (8). The guns spray the powder/air mixture onto the workpieces to be coated. Product description • 27 MagicCompact BA04-XL... - Page 28 (5). The after filter separates the powder into a waste container (6) which is positioned directly under the filter elements and is very easy to empty. The cleaned air then exits the filter and is fed directly back into the workshop environment. 28 • Product description MagicCompact BA04-XL...

-

Page 29: Assembly / Connection

Cable connections / junctions The connecting cables between control unit and guns must be laid out in such a way that they cannot be damaged during operation. Observe the safety regulations! Assembly / Connection • 29 MagicCompact BA04-XL... -

Page 30: Grounding The Booth

► Check grounding regularly. Appropriate connection points are provided on the booth superstructure and the booth basement, on the cyclone separator, on the duct and on the filter housing for equipotential bonding. 30 • Assembly / Connection MagicCompact BA04-XL... -

Page 31: Start-Up

Is the transport hose connected correctly on the exhaust side? − Are the settings for the powder transport connection unit correct? The plant may be put into operation only after all these points are checked and any faults are corrected! Start-up • 31 MagicCompact BA04-XL... - Page 32 Rev. 00 11/23 32 • Start-up MagicCompact BA04-XL...

-

Page 33: Operation

Turn the key switch, the control unit is activated, the operating unit is activated and the key switch returns to its starting position. Start the system, the main menu appears on the operating unit Activate the OptiCenter (see therefore the corresponding user manual) Operation • 33 MagicCompact BA04-XL... -

Page 34: Switching Off The Booth

Switching over the booth control to cleaning operation – Move the guns to the cleaning position Prepare the OptiCenter for cleaning – Remove the powder container from the OptiCenter (the recovery hose remains on the powder container) 34 • Operation MagicCompact BA04-XL... - Page 35 They do not replace by any means the enclosed manuals of the components, and presuppose that you read and understand the corresponding chapters in the operating manual as well as the safety regulations. Operation • 35 MagicCompact BA04-XL...

- Page 36 Rev. 00 11/23 36 • Operation MagicCompact BA04-XL...

-

Page 37: Maintenance / Repairs

The following activities on the switching unit should be carried out regularly: – Remove powder deposits and caked powder – Check the gaskets and if necessary, replace them For further information, see the corresponding operating manual! Maintenance / Repairs • 37 MagicCompact BA04-XL... - Page 38 Rev. 00 11/23 38 • Maintenance / Repairs MagicCompact BA04-XL...

-

Page 39: Fault Clearance

Only use original spare parts. Pressurized pneumatics system The pressurized pneumatics system may trigger dangerous situations. Disconnect the compressed air supply before working on the pneumatics system. Depressurize the pneumatics system. Secure the compressed air supply against reactivation. Fault clearance • 39 MagicCompact BA04-XL... -

Page 40: General

(see wiring diagram), see also the "Troubleshooting" section in the After Filter operating manual. – In the case of repeated alarm, contact your Gema service center – Pressure increase is Pressure increase on the filter Switch off the gun control units,... - Page 41 Insufficient pretension force of Check and adjust correctly the fasteners – Sieve clogged up Check the powder for dampness – Check if too much powder has passed through the cyclone, e.g. when cleaning the booth Fault clearance • 41 MagicCompact BA04-XL...

- Page 42 Rev. 00 11/23 Fault Cause Corrective action Automatic floor blow-off Pressure reducing valve Check the compressed air supply system not OK defective or adjusted incorrectly Solenoid valve defective (coil, Replace or check cable) or missing signal 42 • Fault clearance MagicCompact BA04-XL...

-

Page 43: Decommissioning / Storage

Use only technical personnel who are trained in operating the respective equipment (e.g. a crane). If there are any uncertainties, please contact Gema Switzerland GmbH. Storage conditions Storage duration If the physical conditions are maintained, the unit can be stored indefinitely. -

Page 44: Hazard Notes

Identification Apply the label “Protect from dampness and moisture” on the product and the packaging. 44 • Decommissioning / Storage MagicCompact BA04-XL... -

Page 45: Maintenance During Storage

► Avoid stress in the plastic material. ► Allow all plastic components such as panels etc. to "acclimatize" at a room temperature of at least 15 °C for at least 24 hours. Decommissioning / Storage • 45 MagicCompact BA04-XL... - Page 46 Rev. 00 11/23 46 • Decommissioning / Storage MagicCompact BA04-XL...

-

Page 47: Disposal

Requirements on personnel carrying out the work The disposal of the product is to be carried out by the owner or operator. When disposing of components that are not manufactured by Gema, the instructions in the respective manufacturer’s documentation must be observed. - Page 48 Rev. 00 11/23 48 • Disposal MagicCompact BA04-XL...

-

Page 49: Spare Parts List

When using the spare parts from other manufacturers the explosion protection is no longer guaranteed. If any damage is caused by this use all warrantee claims become invalid! ► Only original Gema spare parts should be used! Spare parts list • 49 MagicCompact BA04-XL... -

Page 50: Magiccompact Ba04-Xl - Spare Parts List

Rev. 00 11/23 MagicCompact BA04-XL – spare parts list Floor blow-off system – Pneumatics (see separate spare parts list) Gun blow off equipment (see separate spare parts list) Sensor/Actor-Box (see separate spare parts list) Pressure regulator (see separate spare parts list) Door drive unit (see separate spare parts list) Lamp –... -

Page 51: Floor Blow-Off System - Pneumatics

Double nipple – 1/2"-1/2", divisible 243 582 Elbow joint – 1/2"-1/2" 223 166 Hose – Ø 12/10 mm (not shown) 100 382* * Please indicate length Fig. 11: Floor blow-off system – Pneumatics Spare parts list • 51 MagicCompact BA04-XL... -

Page 52: Pressure Regulator

Pressure gauge – 0-10 bar, 1/8" 243 620 Adapter nipple – 1/8"-1/4" 265 454 Double nipple – 1"-1", divisible 1005 563 Pressure regulator – 0-4 bar, 1” (floor blow-off system) 1008 184 Fig. 12: Pressure regulator 52 • Spare parts list MagicCompact BA04-XL... -

Page 53: Sensor/Actor Box

Rev. 00 11/23 Sensor/Actor Box Sensor-/Actor Box – M12 8P 1008 242 Y-distributor – threefold, M12 1008 246 Plug screw – M12 1006 905 Sensor/actuator cable – 30 m 1008 243 Fig. 13: Sensor/Actor Box Spare parts list • 53 MagicCompact BA04-XL... -

Page 54: Gun Blow Off Equipment

Valve cable – 3 pins, M12, for pos. 12 1008 244 Grounding cable – complete 1006 077 Compressed air hose – Ø 33/25 mm 1018 622* Hose clamp – Ø 25–35 mm 226 335 * Please indicate length 54 • Spare parts list MagicCompact BA04-XL... - Page 55 Rev. 00 11/23 Gun blow off equipment Fig. 14: Gun blow off equipment Spare parts list • 55 MagicCompact BA04-XL...

-

Page 56: Door Drive Unit

Throttle check valve 1013 837 Silencer 1014 078 Inline regulator – 6 bar 263 320 Door monitoring and door locking Proximity switch 259 802 Magnetic closure 257 826 Door locks 1018 309 Hook 1020 956 56 • Spare parts list MagicCompact BA04-XL... - Page 57 Rev. 00 11/23 Door drive unit Fig. 15: Door drive unit Fig. 16: Door monitoring and door locking Spare parts list • 57 MagicCompact BA04-XL...

-

Page 58: Lamps

Type 600, 230 V, 22 W, length 582 mm 1014 537 Adhesive seal strip – 19x4 mm 1014 137* Screw – M6x20 mm 244 414 Membrane grommet 1003 577 Cable – 3x1 mm² 1013 099* * Please indicate length Fig. 17: 58 • Spare parts list MagicCompact BA04-XL... -

Page 59: Switching Unit (Exhaust Air)

Ø 500 mm 1016 744 Ø 550 mm 1016 745 Ø 600 mm 1016 746 Ø 650 mm 1016 747 Ø 700 mm 1016 748 Ø 800 mm 1018 319 Fig. 18: Switching unit, double Spare parts list • 59 MagicCompact BA04-XL... -

Page 60: Booth Accessories

1016 732 400F type 1016 733 Cleaning granules – 4 kg (not shown) 269 115 Polishing agent – 500 ml (not shown) 262 641 Tangit PVC Cleaner – 1000 ml (not shown) 800 196 60 • Spare parts list MagicCompact BA04-XL... - Page 61 Rev. 00 11/23 Booth accessories Fig. 19: Booth accessories Spare parts list • 61 MagicCompact BA04-XL...

-

Page 63: Index

Spare parts list ..........49 Figure references in the text ......8 Start-up ............31 Storage ............43 Storage conditions ........... 43 Grounding Potential equalization ........30 Technical Data ..........18 Transport ............15 Intended use ............ 17 Index • 63 MagicCompact BA04-XL... - Page 64 Rev. 00...

Need help?

Do you have a question about the MagicCompact BA04-XL and is the answer not in the manual?

Questions and answers